Device and method for measuring engine valve landing radial deflection

A technology of engine valves and valves, which is applied in the direction of measuring devices, electrical devices, instruments, etc., can solve problems such as the analysis and research of unfavorable valve radial offset, and achieve the effects of simple structure, improved efficiency, and convenient long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

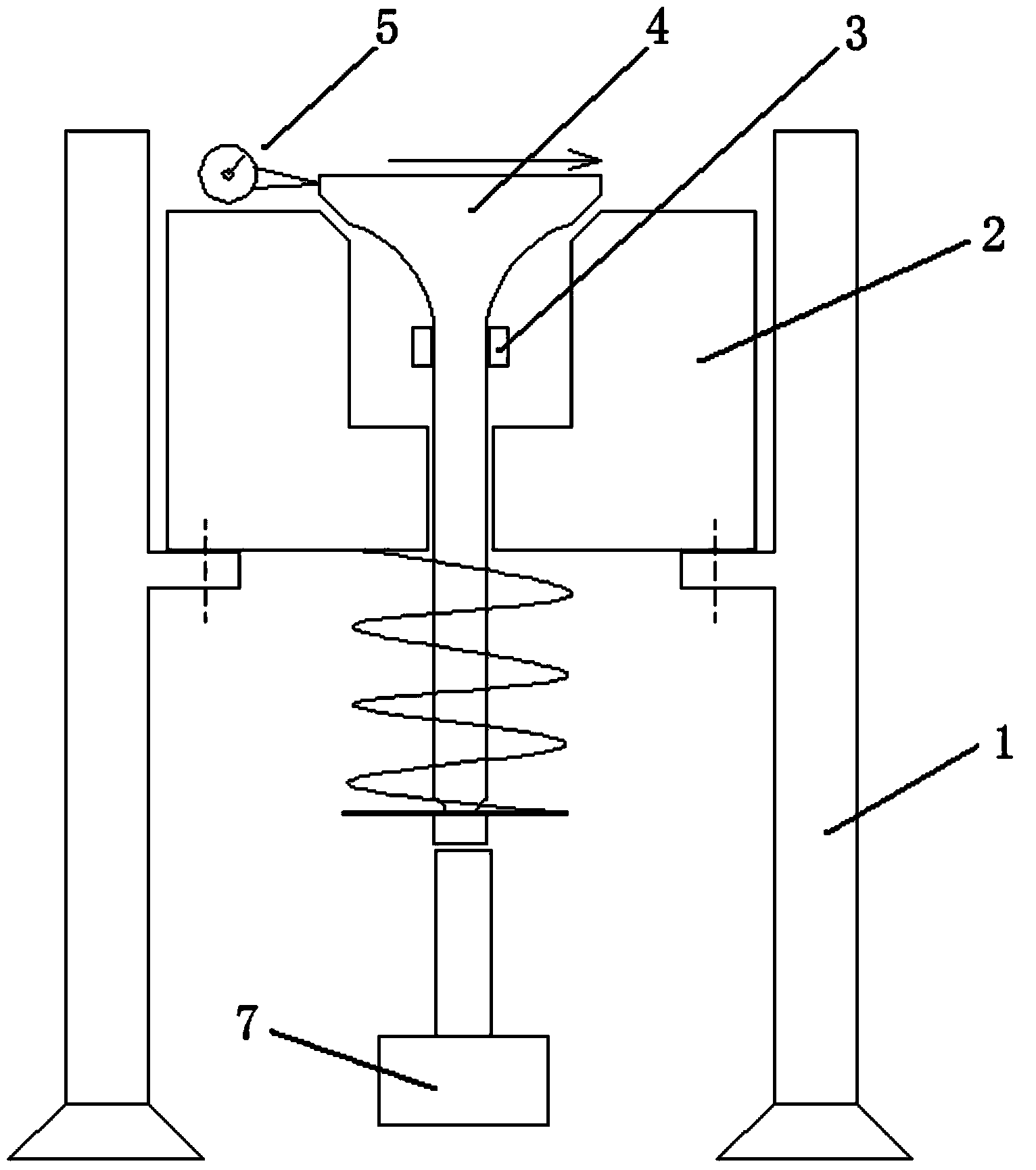

[0020] Such as figure 1 As shown, the engine valve seat radial offset calibration test bench includes: a bench 1, a cylinder head 2, a strain gauge 3, a valve 4, a dial indicator 5 and a screw lifter 7.

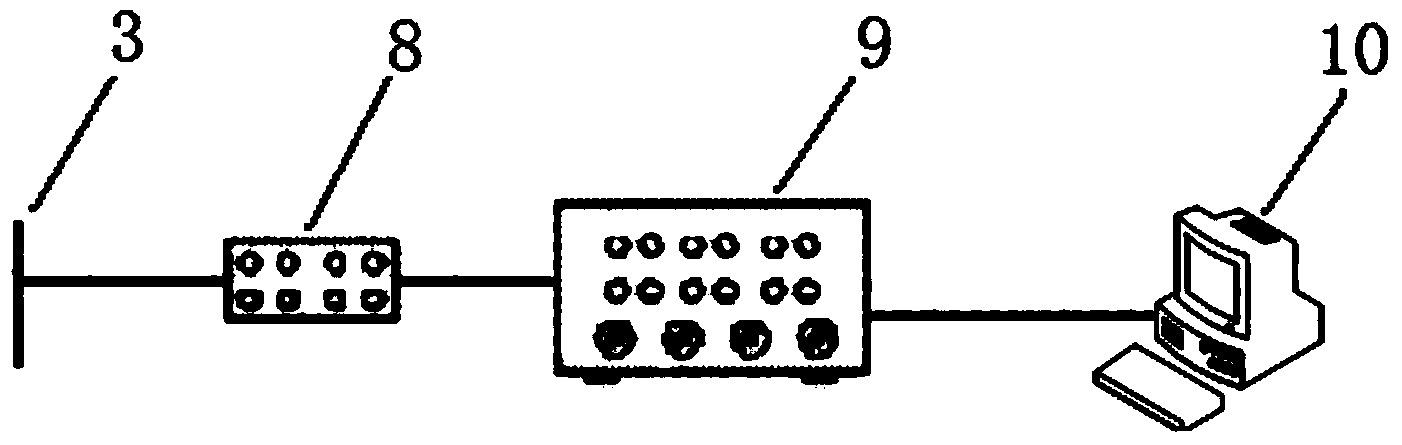

[0021] First paste the strain gauge 3 on the neck of the valve 4 to connect the bridge box 8, the strain gauge 9 and the host computer 10; assemble the valve 4 and the valve spring to the cylinder head 2; then fix the cylinder head 2 on the stand 1 , Use the lead screw lifter 7 to give it a lift against the end of the valve 4; finally put the dial indicator 5 against the side end of the valve 4.

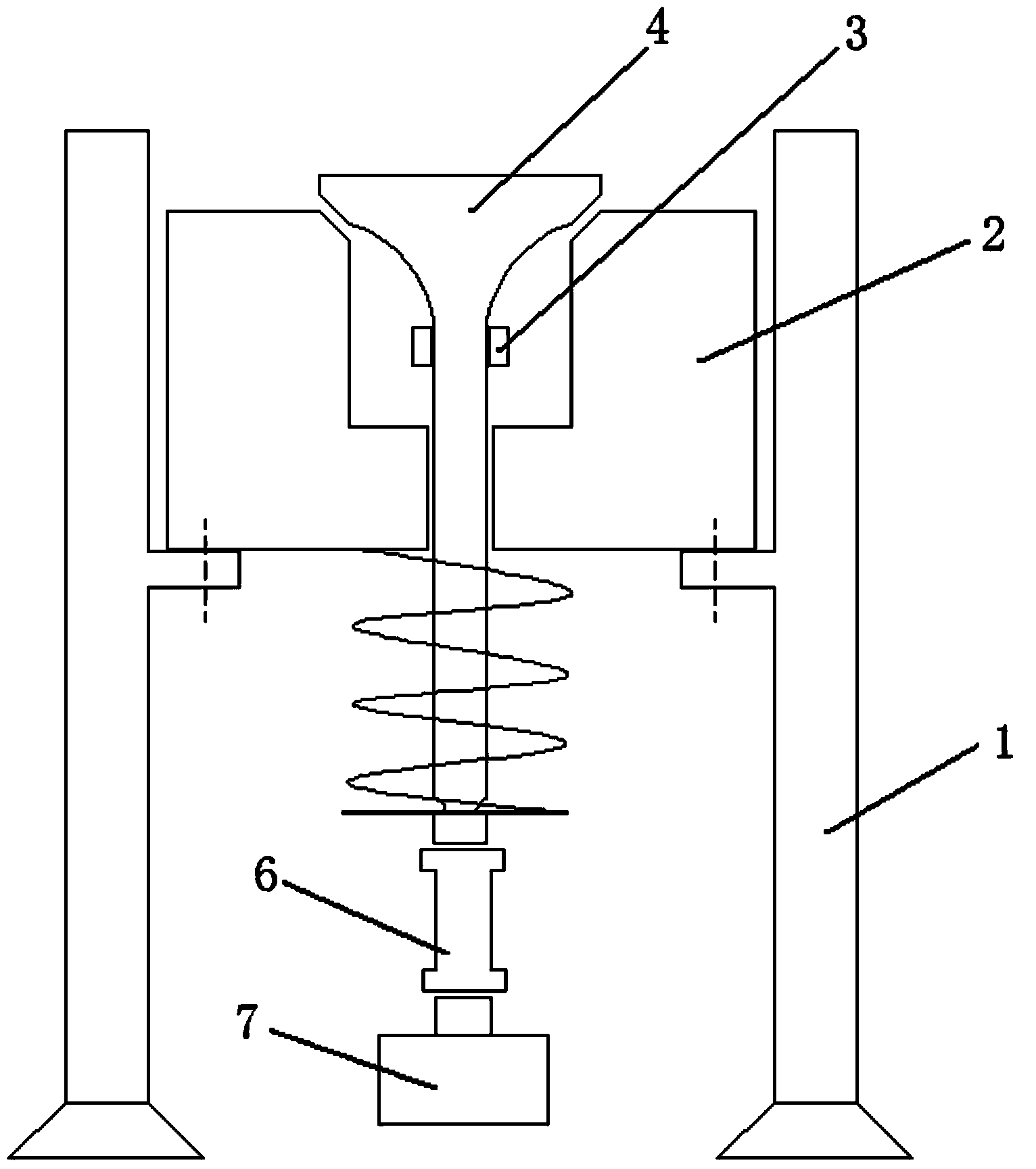

[0022] Such as figure 2 As shown in the test bench for the free seat of the engine valve, the valve 4 is first lifted up by a lift with the iron rod 6 and the lead screw lift 7, and then the iron rod is removed to allow the valve to sit freely, and the voltage change on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com