Method of Supporting a Subterranean Conduit

a technology of subterranean conduits and conduits, which is applied in the direction of fluid removal, wellbore/well accessories, sealing/packing, etc., can solve the problems of affecting the productivity and equipment of wells, and affecting the operation of wells. , to achieve the effect of small resistance to point loading and easy collaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

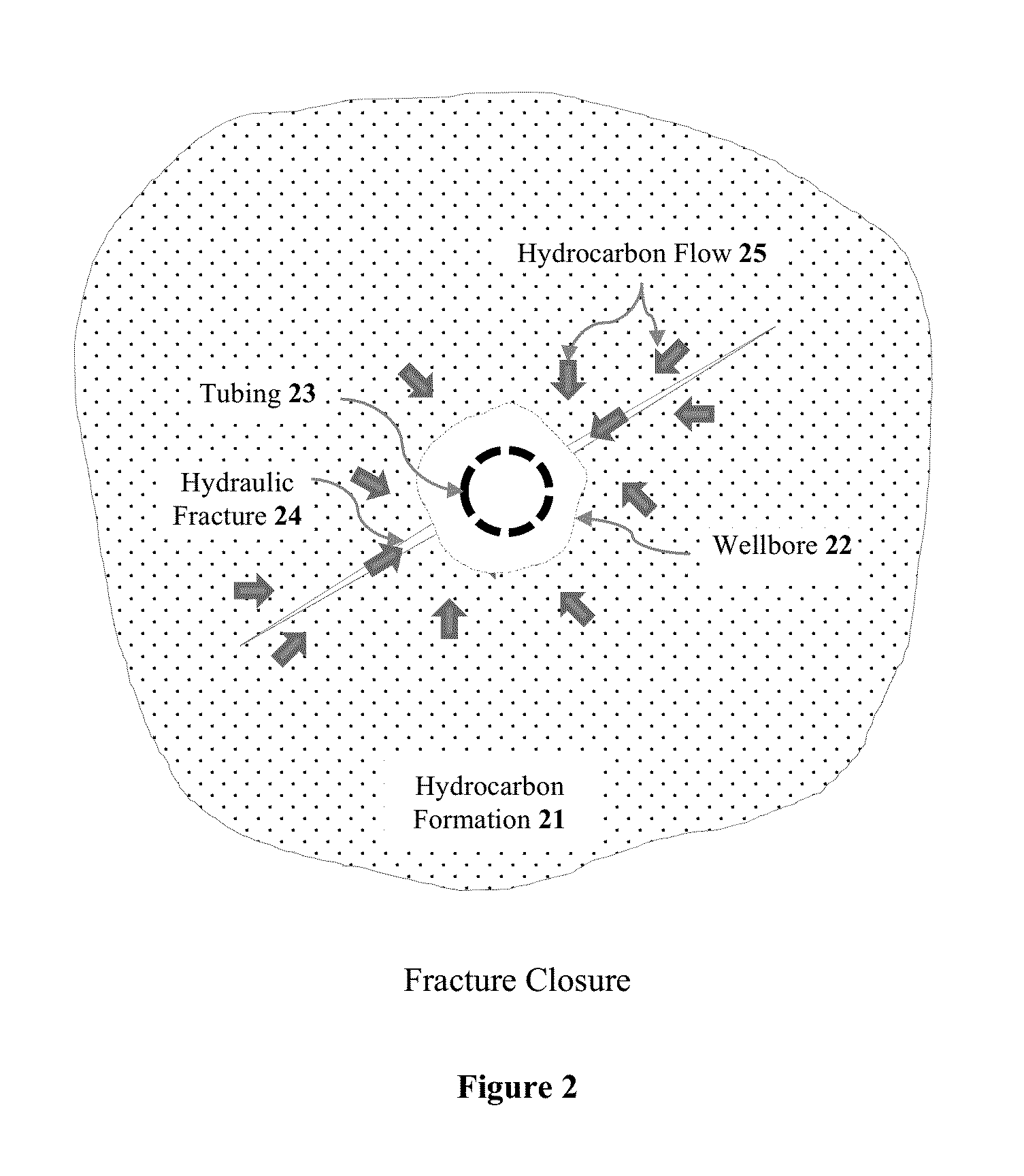

[0047]FIG. 3 demonstrates a bead packing column 32 of loose beads and the packing has a column height 34. When a vertical stress Sv 31 is applied downward at the top of the column, the bead packing tends to bulge radially or demonstrate radial expansion tendency 33. If the bead column is radially confined such as in a conduit and the bulging is not allowed, a radial force or stress Sr 35 then is generated. This radial stress is acting on the wall of the conduit. This means the vertical stress 31 has been converted into a stress in the radial direction. This is a basic property of materials. The magnitude of the stress converted can be related by the Poisson's ratio of the packing. Stress is just force on a unit area. If v is the Poisson's ratio, Sv is the vertical stress, then the radial stress Sr=[v / (1−v)]Sv. With different bead like materials, the packing may behave slightly different in term of the Poisson's ratio, v. It is preferred that the bead like materials are less compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com