Spatial flexible filter supporting mechanism and method for mounting filter

A flexible support and filter technology, which is applied in the aerospace field, can solve the problems of poor filter surface deformation, filter breakage, and high processing precision of the mirror holder, and achieve good elasticity, high strength and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

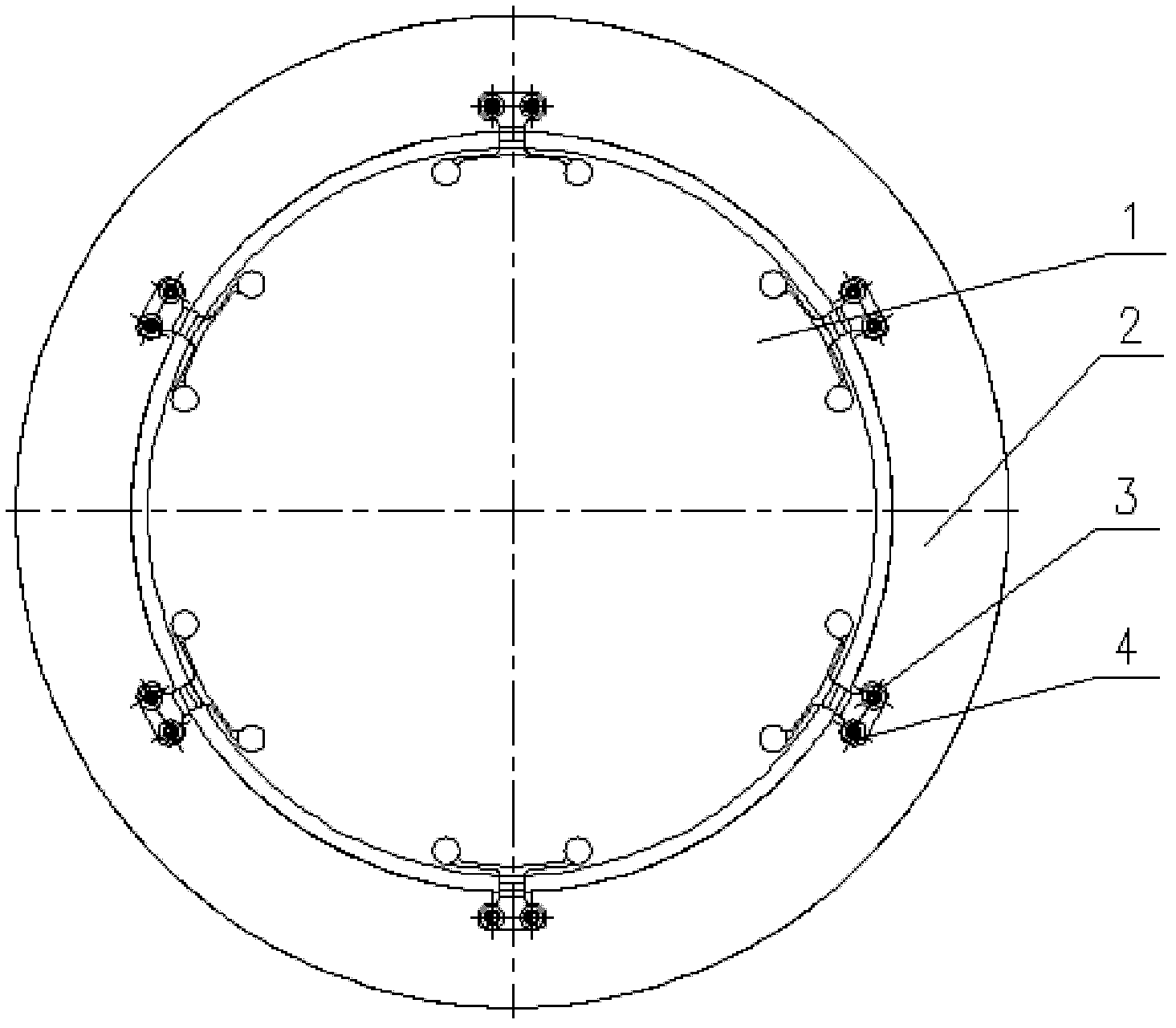

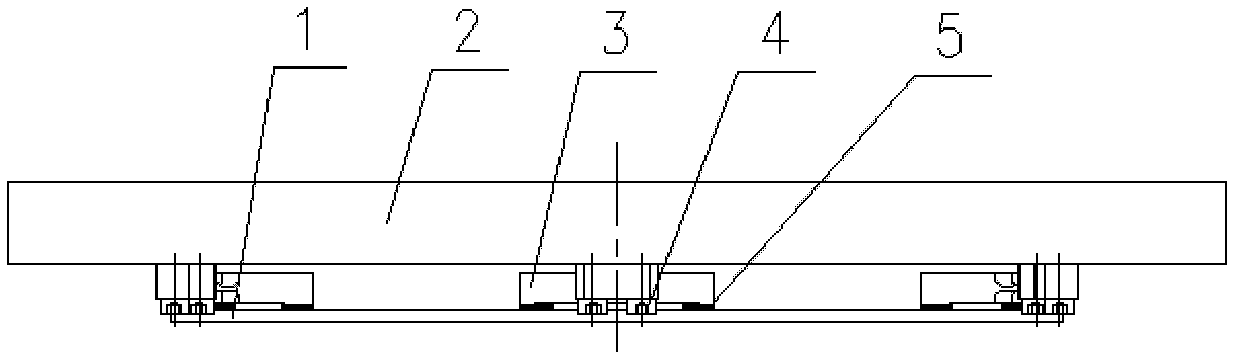

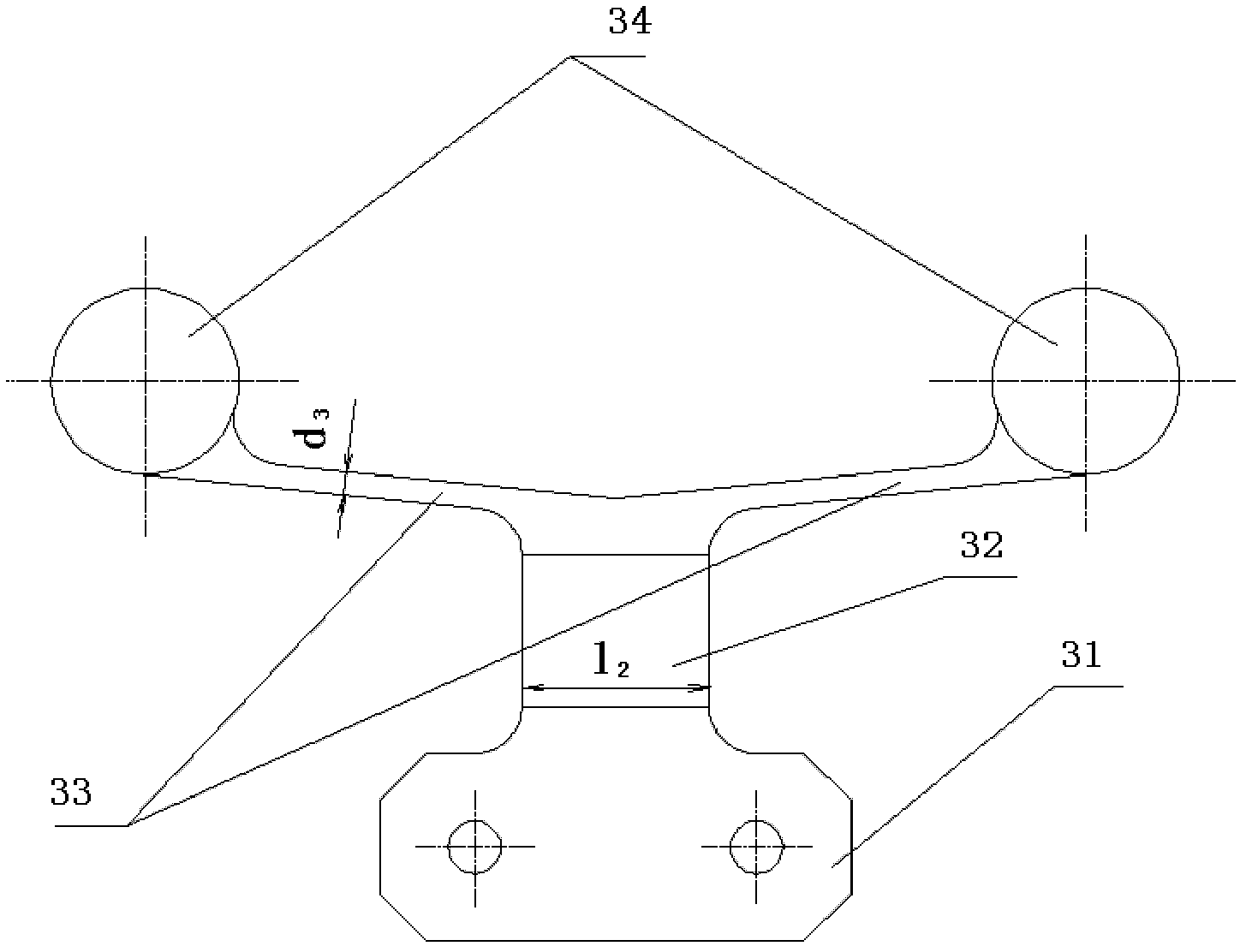

[0017] Such as figure 1 , figure 2 As shown, the space filter flexible support mechanism of the present invention includes a mirror base 2 and six flexible support members 3 . Such as image 3 , Figure 4 As shown, the flexible support 3 is composed of a fixed end 31 , an axial stress unloading portion 32 , a radial stress unloading portion 33 and an adhesive boss 34 . The fixed end 31 is connected to the mirror base 2 through two screws 4, the axial stress unloading portion 32 is located between the fixed end 31 and the radial stress unloading portion 33, and the thickness d of the axial stress unloading portion 32 is 2 less than its width l 2 The two ends of the radial stress unloading portion 33 each have a viscose boss 34, and the thickness d of the radial stress unloading portion 33 3 less than its width l 2 ; The portion near the edge of the filter 1 is bonded with the adhesive boss 34 through the adhesive 5 .

[0018] The screw 4 is an inner hexagonal screw; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com