High-energy-storage flywheel rotor and manufacturing method thereof

A technology for energy storage flywheels and manufacturing methods, which is applied in the direction of flywheels, etc., can solve the problems of difficult forming of flywheels and easy layering in the radial direction, and achieve the effects of increasing energy storage density and improving stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

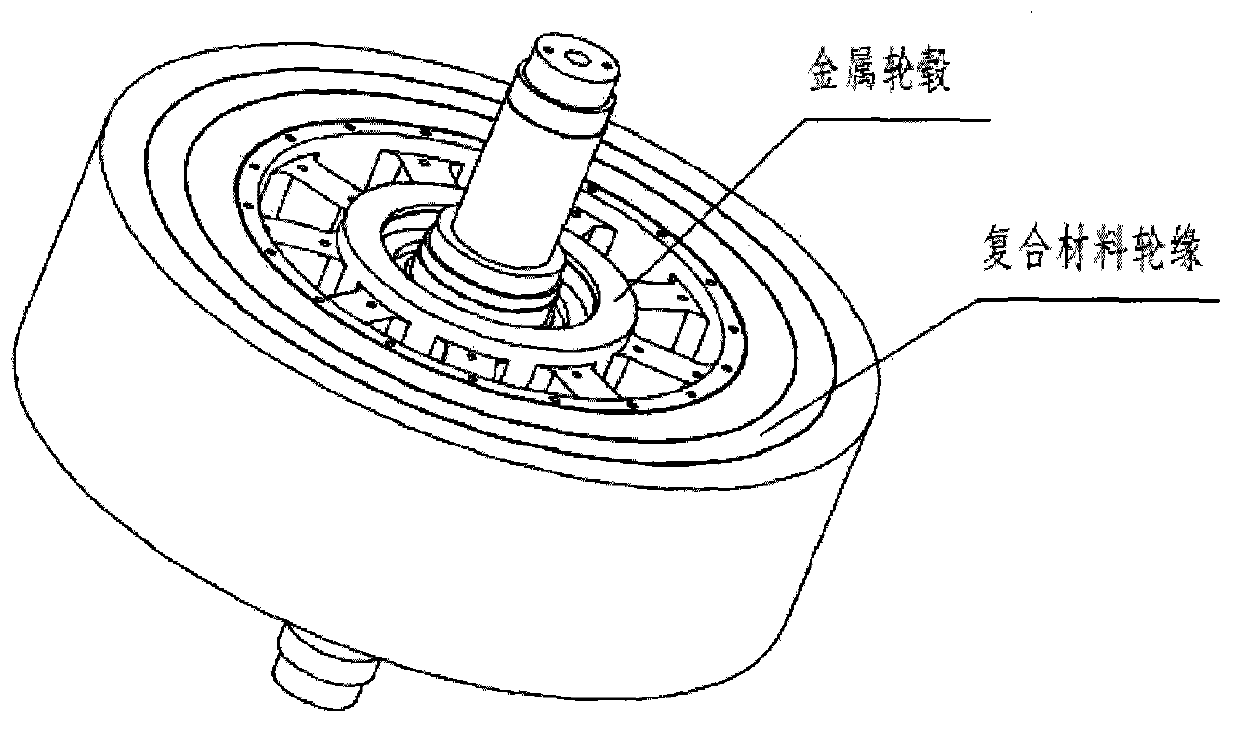

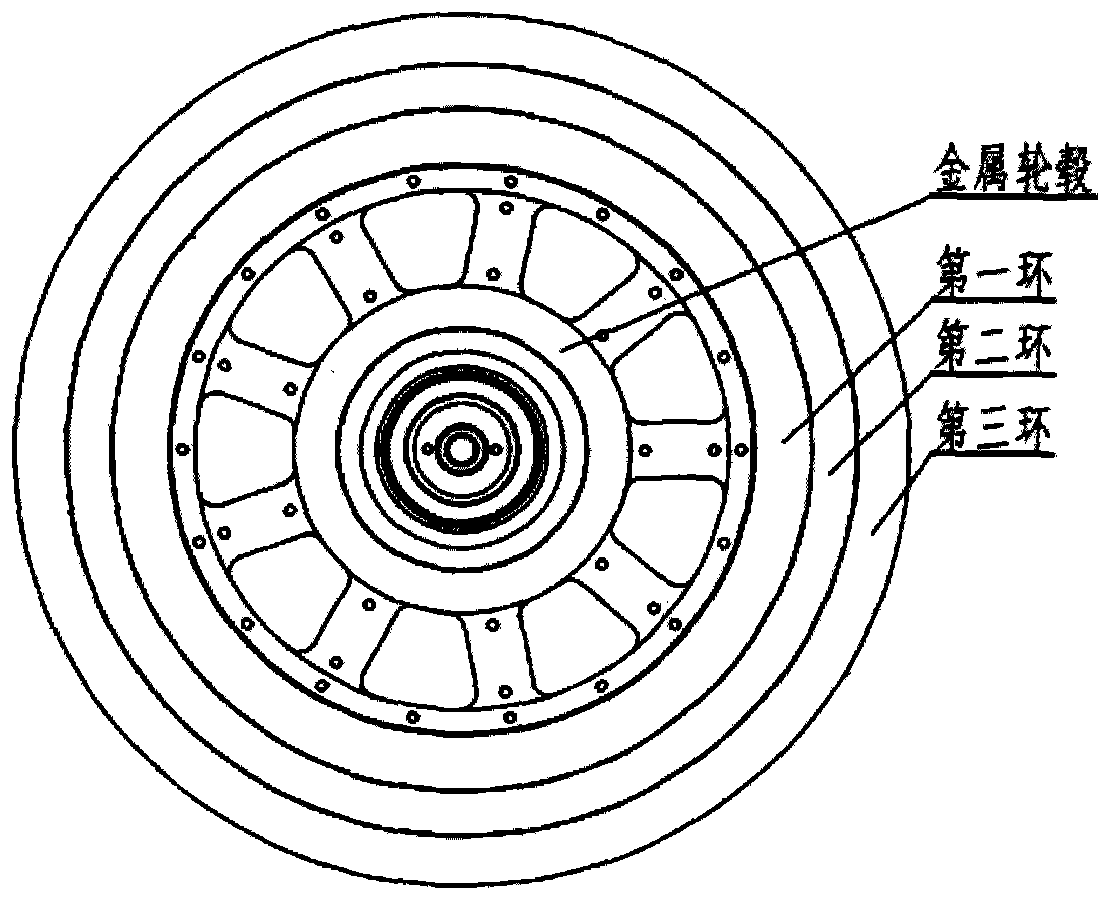

[0027] Such as Figure 1-2 As shown, a large energy storage flywheel rotor includes a metal hub and a rim, the rim is a ring structure of multi-layer carbon fiber reinforced composite material, the surface of the metal hub is wound with glass fiber reinforced composite material, and the multi-layer carbon fiber reinforced The composite ring passes sequentially over the fit-up suit and the metal hub wrapped with glass fiber reinforced composite. Among them, the outer diameter of the metal hub or the inner diameter of the rim is 516mm, the outer diameter of the composite material rim is 786mm, the height is 250mm, and the diameter of the central axis is 100mm.

[0028] According to the ring and radial stress distribution of the rotor rim part obtained by finite element analysis, the rim part is divided into three rings, and the interference is increased between the rings, which changes the radial stress distribution of the flywheel and generates The pre-pressure is ensured, so ...

Embodiment 2

[0031] The manufacturing method of a flywheel rotor involved in the present invention, the hub and the rim are respectively formed by selecting different materials, and then assembled. The forming method of the hub and the rim is as follows:

[0032] The casting method of the hub of the energy storage flywheel comprises the following steps: making wooden molds, sand cores, casting in a closed box, cleaning the casting after being kept warm in the sand box, cutting the riser with gas, completing the casting of the hub of the energy storage flywheel, and then cooling The method of combining thermal processing, the flywheel hub is obtained after the final finishing.

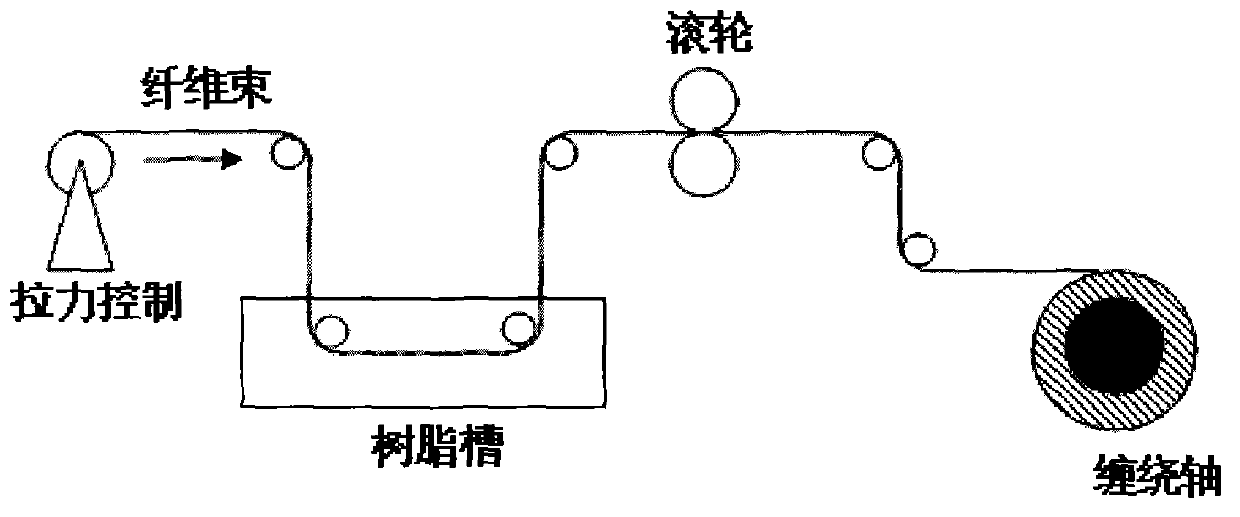

[0033] The rim of the flywheel rotor involved in the present invention consists of three rings of fiber-reinforced composite material, and the forming process of a single ring of fiber-reinforced composite material is as follows:

[0034] The whole process adopts the wet winding process, and the schematic diagram of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com