Internal expansion tool for mechanical processing

A technology of machining and expanding tools, which is applied in the field of machining tools, can solve the problems of high roundness and coaxiality, which cannot meet the requirements of parts processing, etc., and achieve uniform distribution of clamping force, guarantee of grinding radial stress, The effect of a large contact surface on the inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

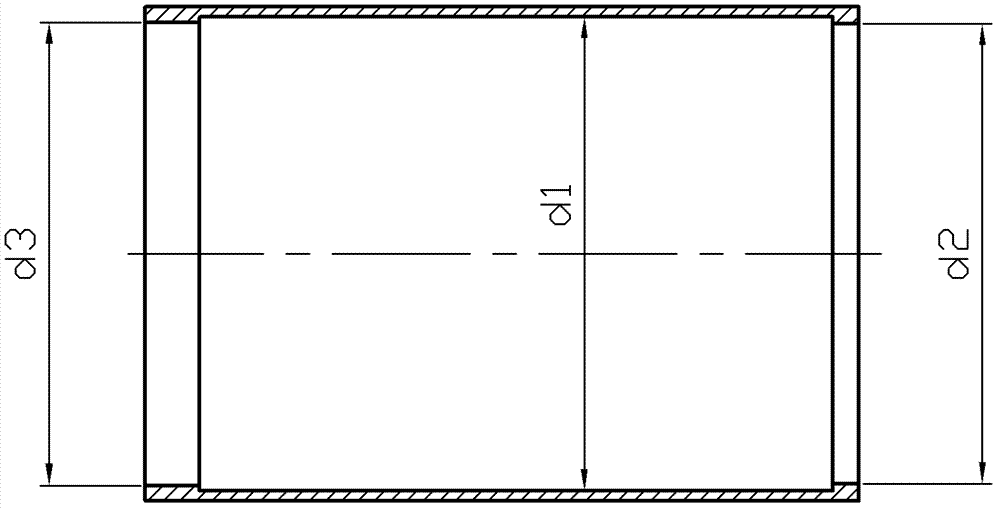

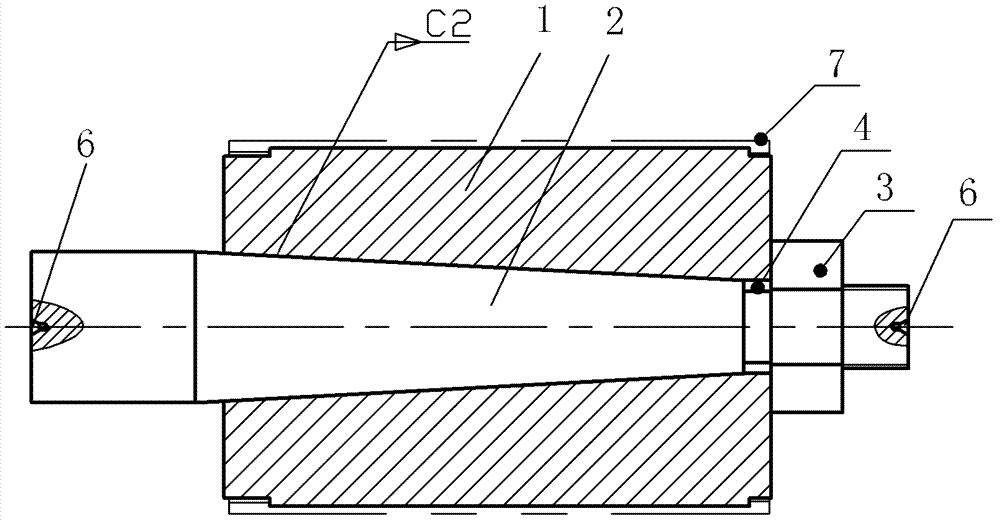

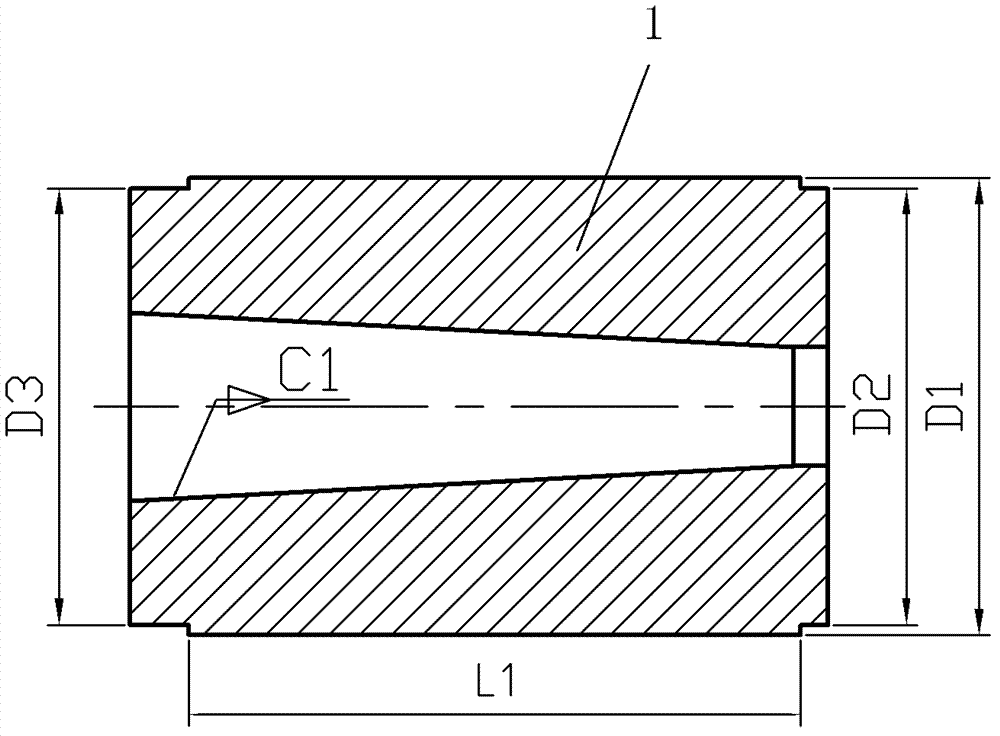

[0017] Embodiment 1: The present invention is applicable to the processing of thin-walled tubular and mouth-stepped tubular parts, including an expander main body 1, a mandrel 2, and a nut 3. The expander main body 1 is composed of at least three petals (in this example It is divided into three lobes evenly along the circumference), and after combination, it becomes a cylindrical structure in which the outer peripheral surface matches the inner peripheral surface of the part to be processed, with an inner tapered hole inside, and the tapered hole of the mandrel 2 is the same as the outer circle of the expander main body 1 The shaft is a structure matched with the inner tapered hole of the expander main body 1, the mandrel 2 is placed in the expander main body 1, the protruding end is fixed by the nut 3, and the shaft centers at both ends are mounted on the machine tool. There is a gap 5 between adjacent petals of the expander main body 1, and the gap 5 is determined by the diam...

Embodiment 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the main body of the expander in this embodiment is evenly divided into four lobes along the circumference, which can also meet the requirements for processing parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com