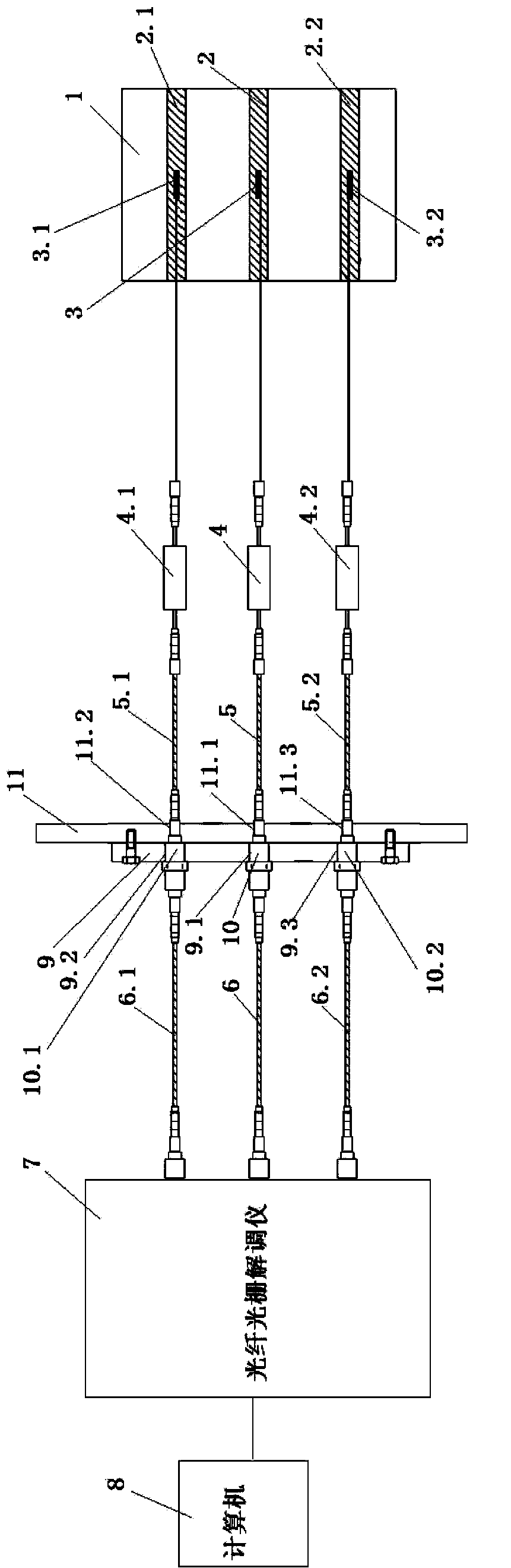

Device and method for measuring radial stress of transformer winding

A transformer winding and stress measurement technology, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problem of the difficulty of truly grasping the stress status of the transformer winding, the inability to provide support for the research and judgment of the transformer, and the complex mechanical structure of the transformer. and other problems, to achieve the effect of accurate and effective winding amplitude stress measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] When the transformer winding passes through the AC current, the transformer winding will generate amplitude stress, which will cause the transformer winding to generate amplitude strain. The purpose of measuring the transformer winding stress can be achieved by detecting the amplitude strain of the transformer winding. Specifically, a glass fiber tape is wound on the outer layer of the transformer winding, so that the strain of the transformer winding can be linearly characterized by the strain of the glass fiber tape. A fiber grating strain sensor is installed on the glass fiber strip, and the deformation of the glass fiber strip is measured by the fiber grating strain sensor, and then the signal is analyzed by the fiber grating mediator to calculate the measured strain, and finally the strain is converted into the stress of the winding. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com