Method for manufacturing large elastic obturating piston ring

A sealing ring and manufacturing method technology, which is applied in the field of mechanical processing technology, can solve problems such as deformation, weak structural rigidity, and no manufacturing process for large elastic sealing rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

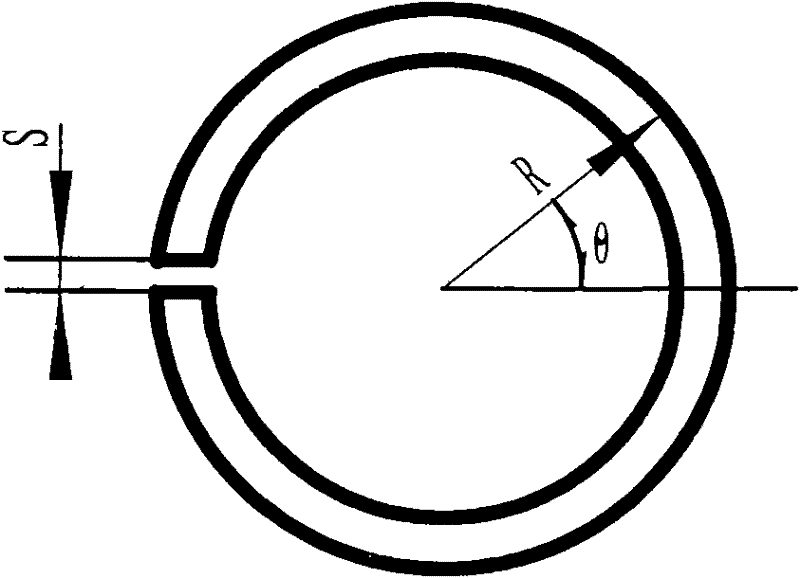

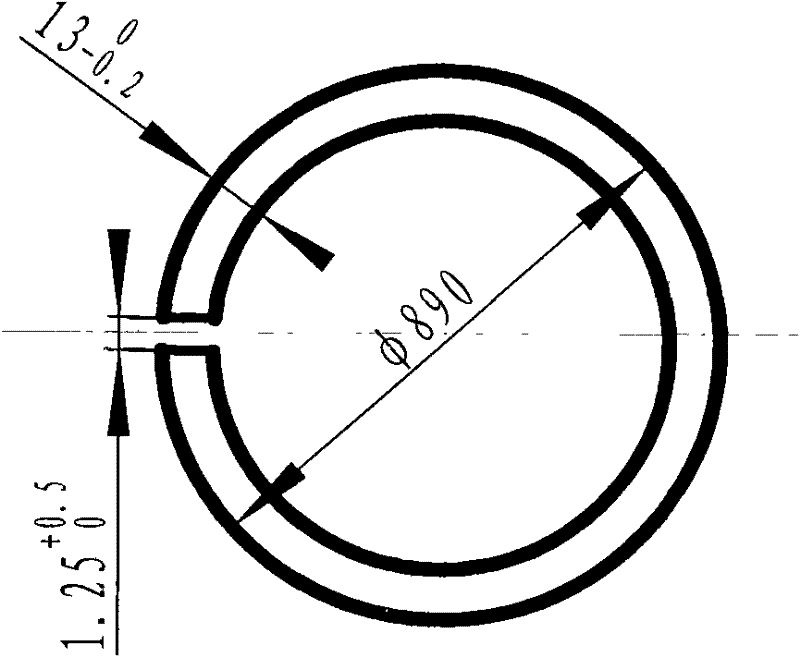

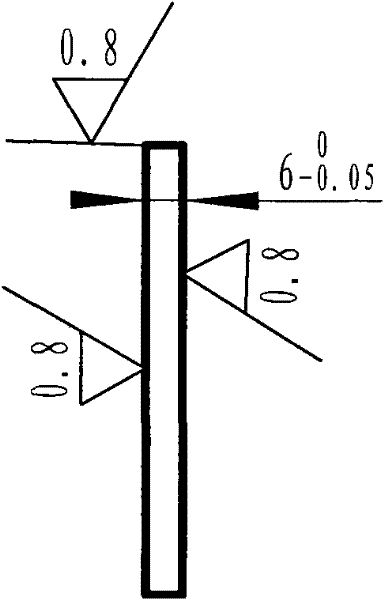

[0043] A gas turbine requires a large elastic sealing ring with a pressure-equalizing radial sealing ring structure to meet gas sealing requirements. Use the present invention to process large elastic opening annular spring ring, such as figure 2 As shown, the requirement is that the outer diameter is Φ890 in the restricted state +0.03 mm, inner diameter Φ864mm (guaranteed radial width 13 -0.2 mm), thickness 6 -0.05 mm open ring spring expansion ring, the outer circle profile is 0.02mm-0.04mm in the restricted state, and the part material is GH150.

[0044] The specific processing steps are as follows:

[0045] 1. In the free state of the part, use a lathe to turn a ring with an outer diameter of Φ920mm, an inner diameter of Φ855mm, and a thickness of 7mm. Cutting parameters: cutting speed 30m / min, feed rate 0.3mm / n, cutting depth 0.4mm.

[0046] 2. When the part is in a free state, use a drilling machine to drill 32 process pressing holes evenly distributed on the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com