Single-axis two-way loading and split Hopkinson pressure bar and pull bar device and experimental method

A Hopkinson pressure bar, uniaxial bidirectional technology, applied in the direction of measuring devices, analytical materials, instruments, etc., to achieve the effect of symmetrical loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

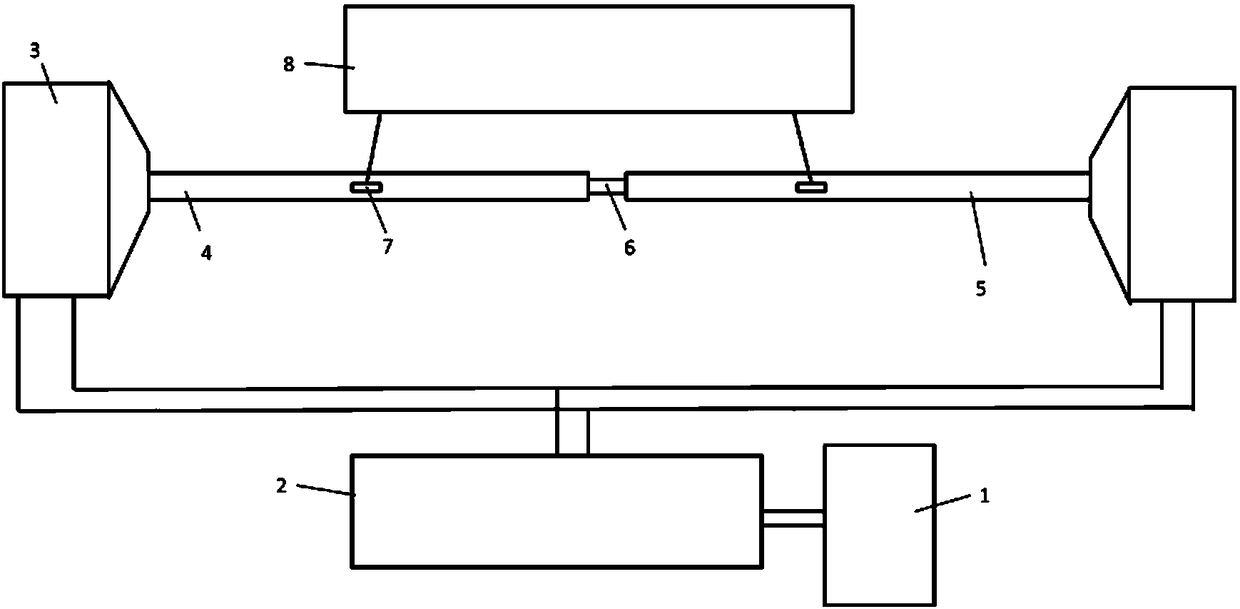

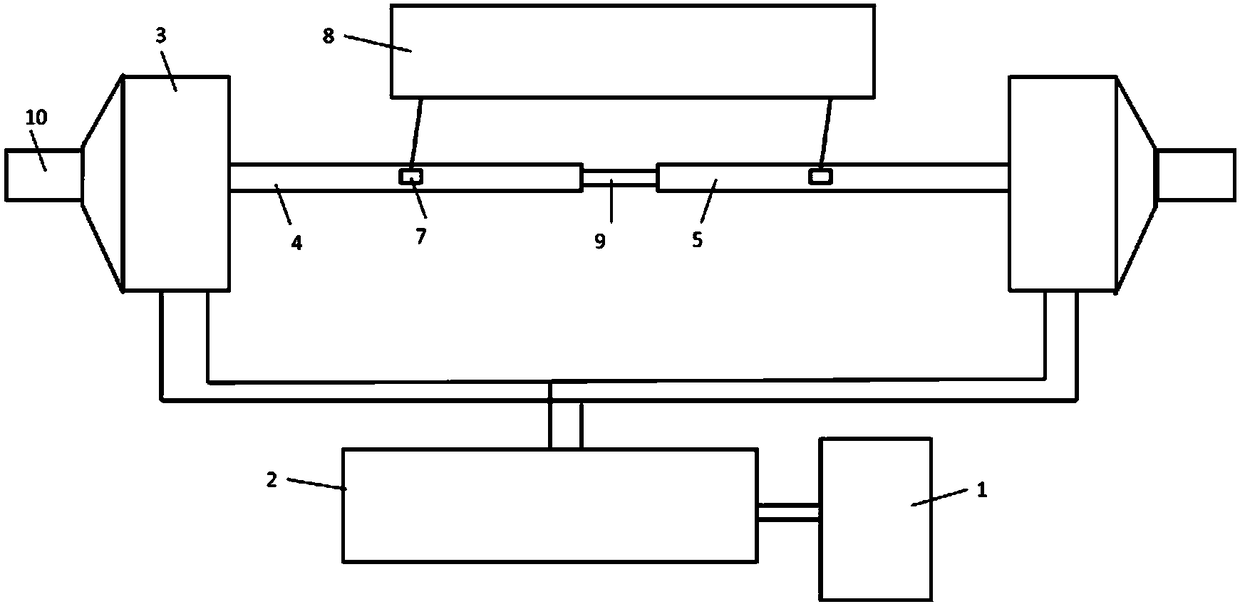

[0061] This embodiment is a uniaxial bidirectional loading separated Hopkinson compression rod and tension rod device and experimental method.

[0062] The device of the present invention includes a loading device and two incident rods, which are respectively the incident rod a (first incident rod) 4 and the incident rod b (second incident rod) 5 .

[0063] The loading device adopts the loading device proposed in the Chinese invention patent No. ZL 201510956545.4, including a power supply 1 , a capacitor charger 2 and a loading gun 3 . The capacitor charger 2 adopts the power supply part of the existing electromagnetic riveting equipment. After connecting two loading guns 3 with identical parameters in parallel, they are connected to the capacitor charger 2 . The power supply 1 adopts 220V three-phase alternating current.

[0064]In this embodiment, the capacitor charger 2 adopts the power supply part of the electromagnetic riveting equipment published in the Chinese patent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com