A large biaxial in-situ in-plane transmission fatigue testing machine

A fatigue testing machine, transmission type technology, applied in the field of fatigue testing machine, can solve the problem that the lower surface of the sample cannot be observed, achieve the effect of enriching the test plan, improving the rigidity of the whole machine, and improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

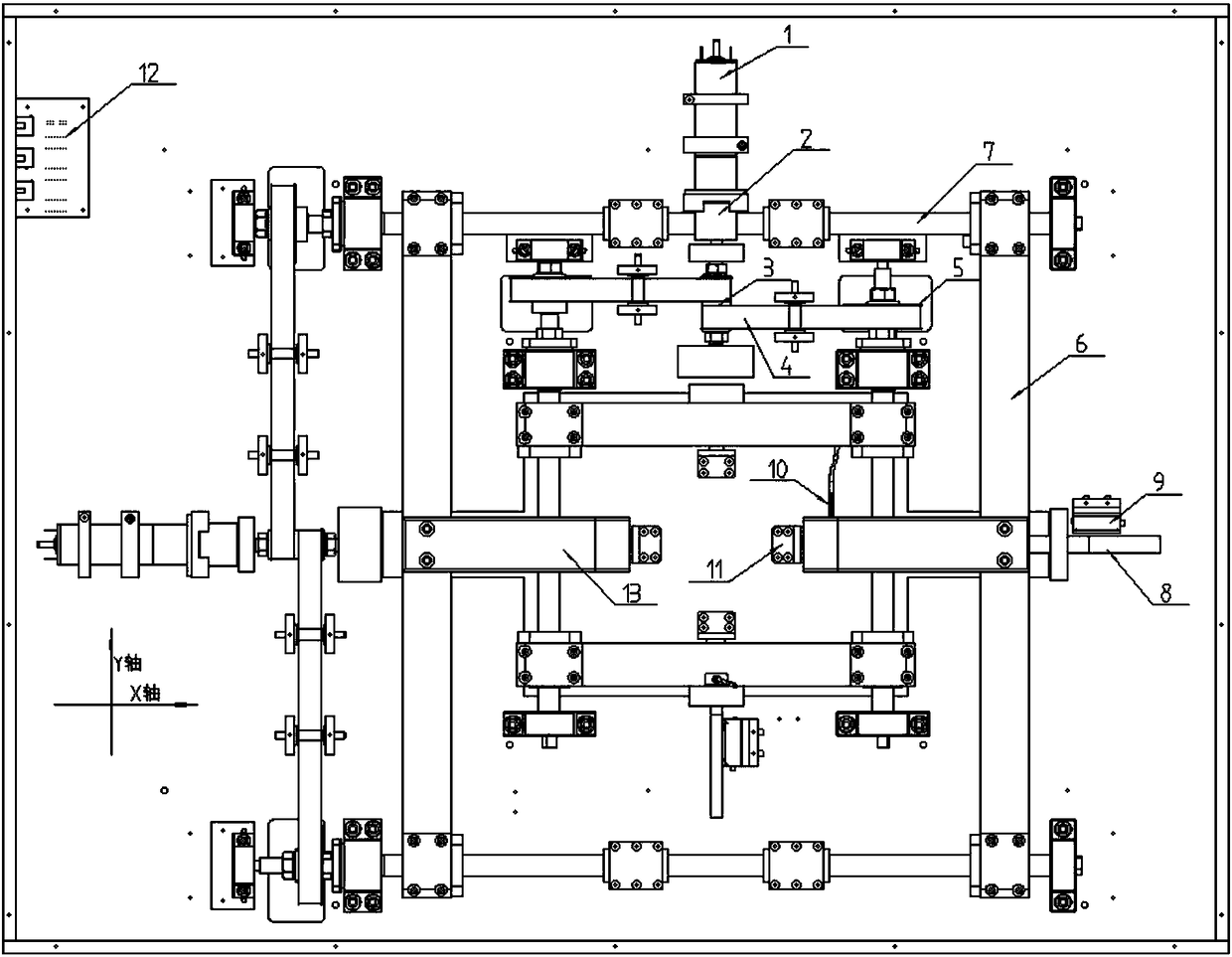

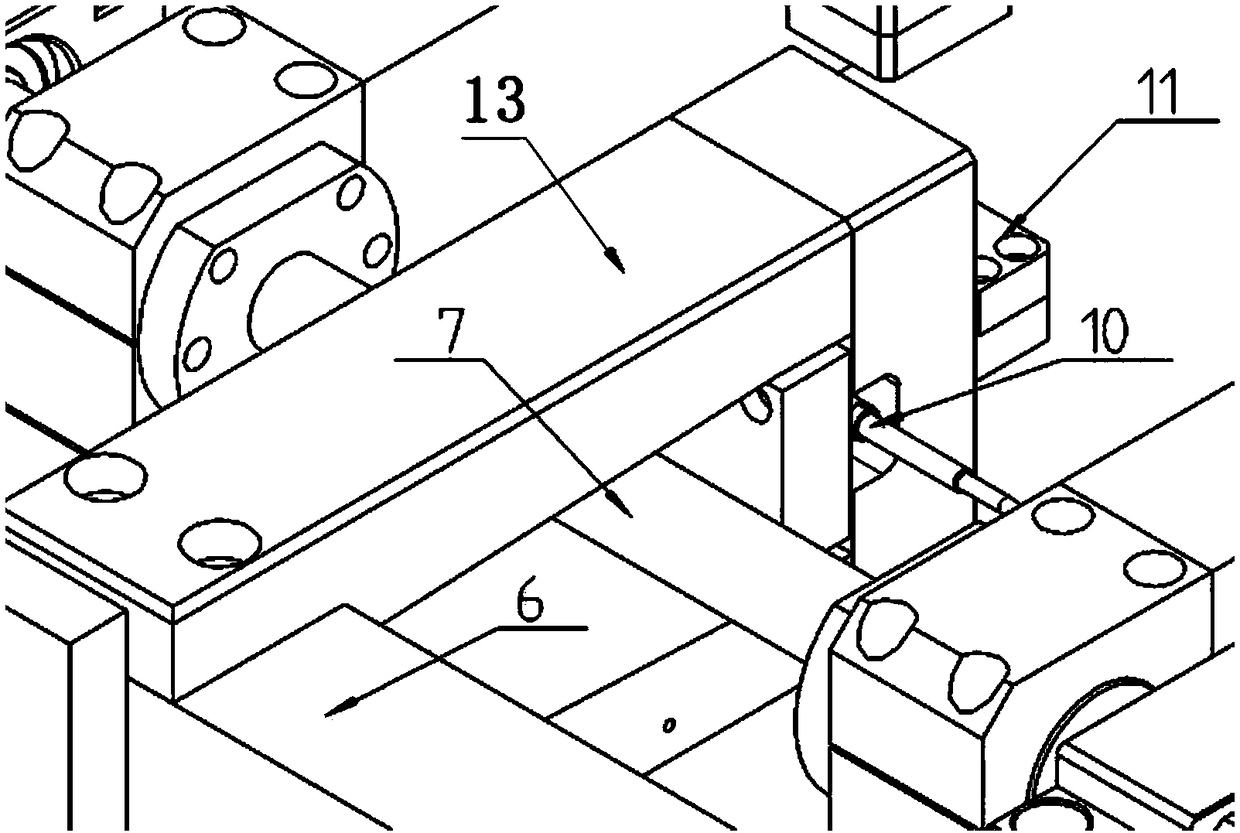

[0027] Such as figure 1 As shown, this embodiment provides a large-scale biaxial in-situ in-plane transmission fatigue testing machine, including an X-axis module and a Y-axis module. The X-axis module can be built into the Y-axis module, and the Y-axis module can also be used. The module is built into the form of the X-axis module. The X-axis module and the Y-axis module have the same structure, both of which are composed of a motor 1, a coupling 2, a first synchronous pulley 3, a synchronous belt 4, a second synchronous pulley 5, a beam 6, a left and right rotating ball screw 7, and a grating Ruler 8, grating ruler reading head 9, load sensor 10 and fixture 11.

[0028] The motor 1 is configured with a planetary gear reduction motor with low backla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com