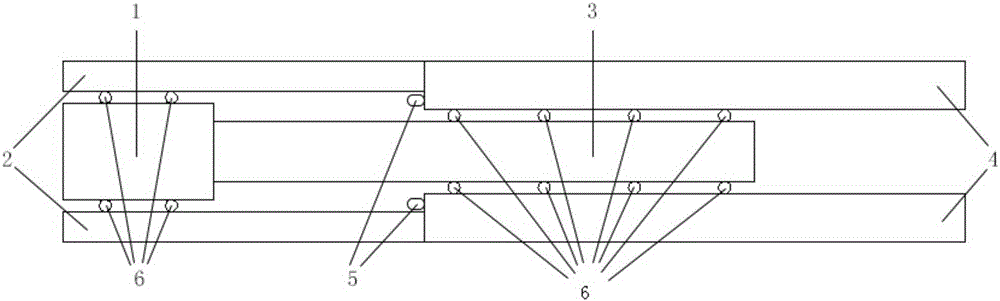

Double-cartridge electromagnetic drive device used for split Hopkinson pressure bar

A Hopkinson pressure rod, electromagnetic drive technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of complex non-electromagnetic material bullets, reduce difficulty and complexity, and avoid the effect of introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the embodiment, the main bullet has a diameter of 16mm and a length of 25mm, and the auxiliary bullet has a diameter of 10mm and a length of 90mm. The rear movement also pushes the auxiliary bullet to move backward, during which the two bullets are not separated. When the main bullet moves to the middle of the main rail, due to the reverse electromagnetic force, the main bullet will decelerate, while the auxiliary bullet will continue to move backward at the original speed because it is not affected by the electromagnetic force, and the two bullets will be separated from then on. In the end, the main bullet was blocked by the buffer device, and the secondary bullet was successfully fired.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com