Novel SHPB (split Hopkinson pressure bar) explosive power source device

A power source and a new type of technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of strong impact strength, low safety factor, and high safety factor, and achieve precise impact energy control, high impact speed, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

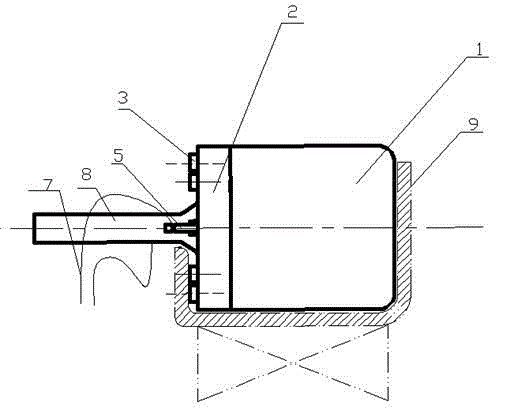

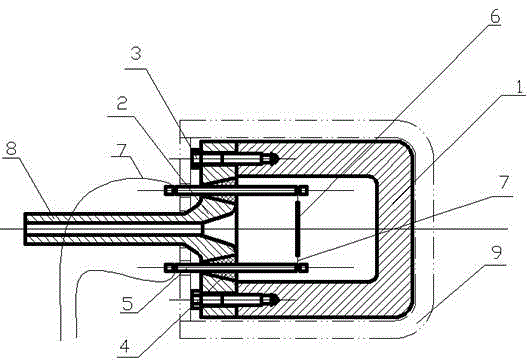

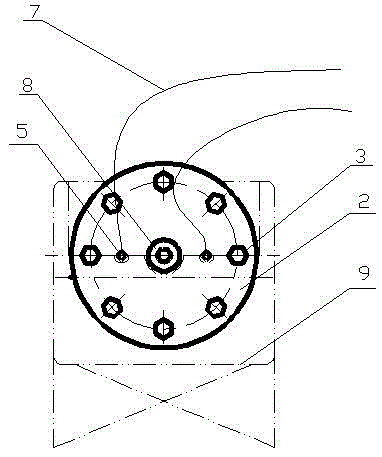

[0018] Attached Figure 1-4 This is a specific embodiment of the present invention. The SHPB new type explosive power source device of the invention includes a cylinder block 1, a cylinder cap 2, two conductive rods 5, and a wire 7. It is characterized in that the cylinder cap 2 is fixed on the cylinder block 1 by bolts 3, and the cylinder cap 2 There is a bullet launching rod 8 in the center. The bullet launching rod 8 and the cylinder cap 2 are designed as one piece. The cylinder cap 2 has two tapered through holes on both sides of the bullet launching rod 8 symmetrically, and there are rubber plugs in the through holes. 4. The conductive rod 5 is inserted into the rubber plug 4, and the two conductive rods 5 are respectively connected to the wire 7 at one end located outside the cylinder 1, and the wire 7 is connected to an external AC current source, and the end located inside the cylinder 1 passes through the wire 7 is connected to an explosive fuse 6, the large port of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com