Test piece dynamic lateral strain measurement device and method based on SHPB test system

A lateral strain and test system technology, which is applied in the field of dynamic lateral strain measurement devices for specimens based on the SHPB test system, can solve problems affecting the integrity of experimental data, uneven lateral strains of specimens, inaccurate lateral strains, etc. problem, to achieve the effect of not easy to paste, easy to operate, and easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

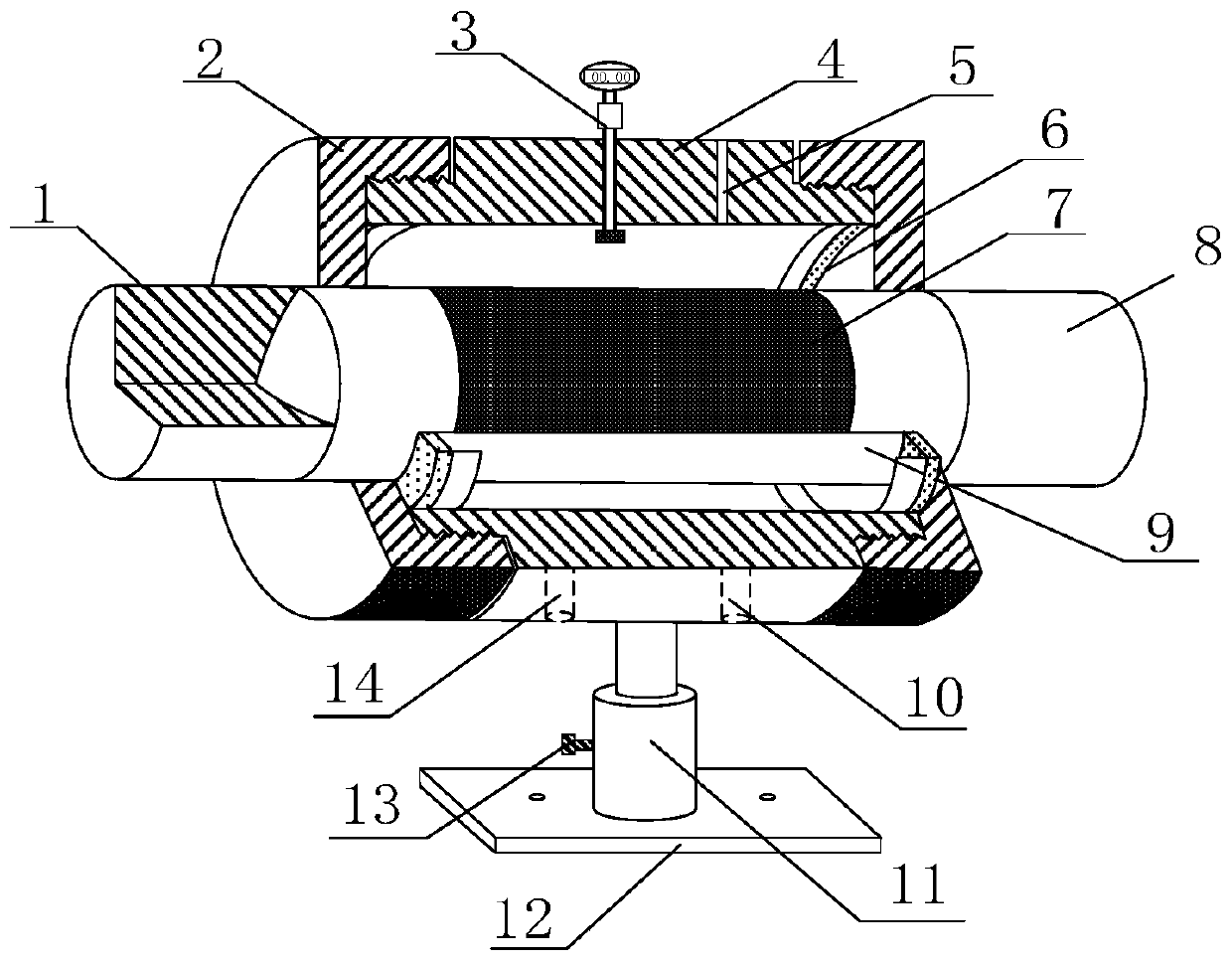

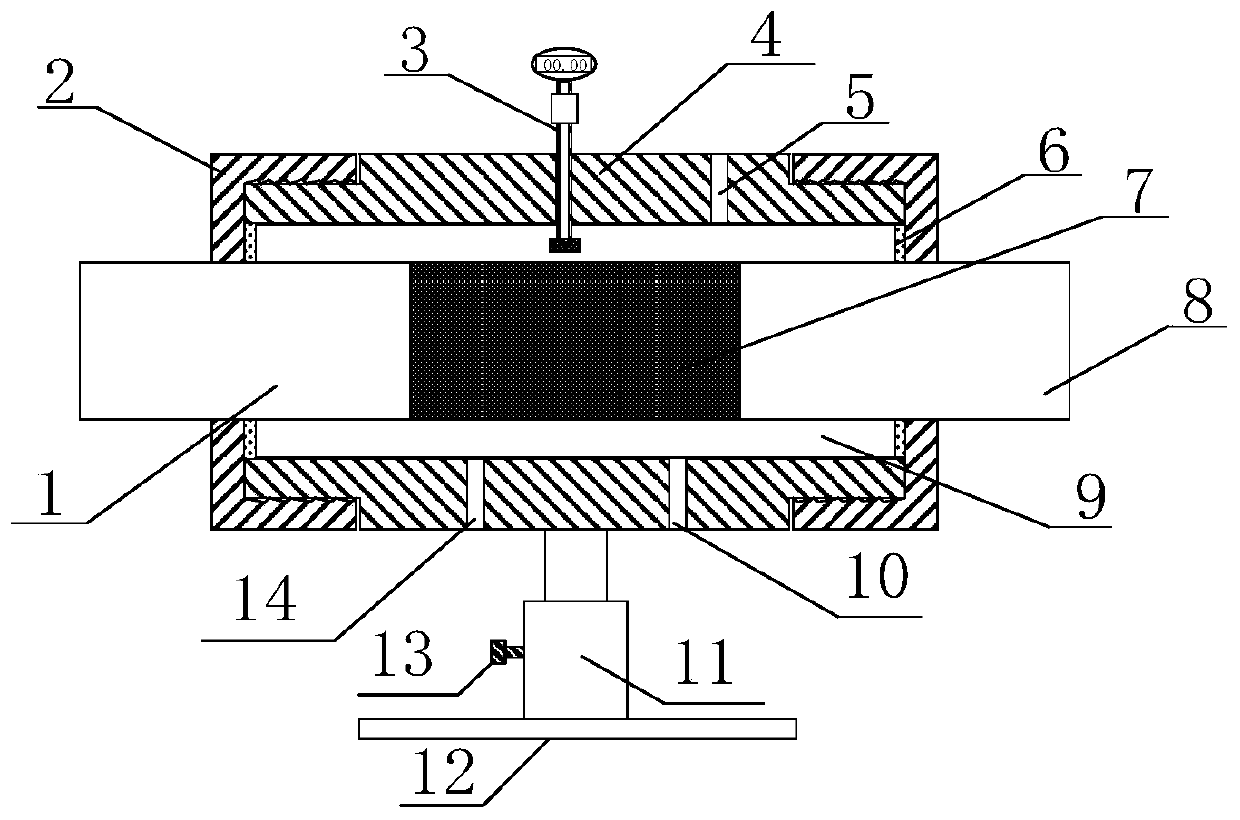

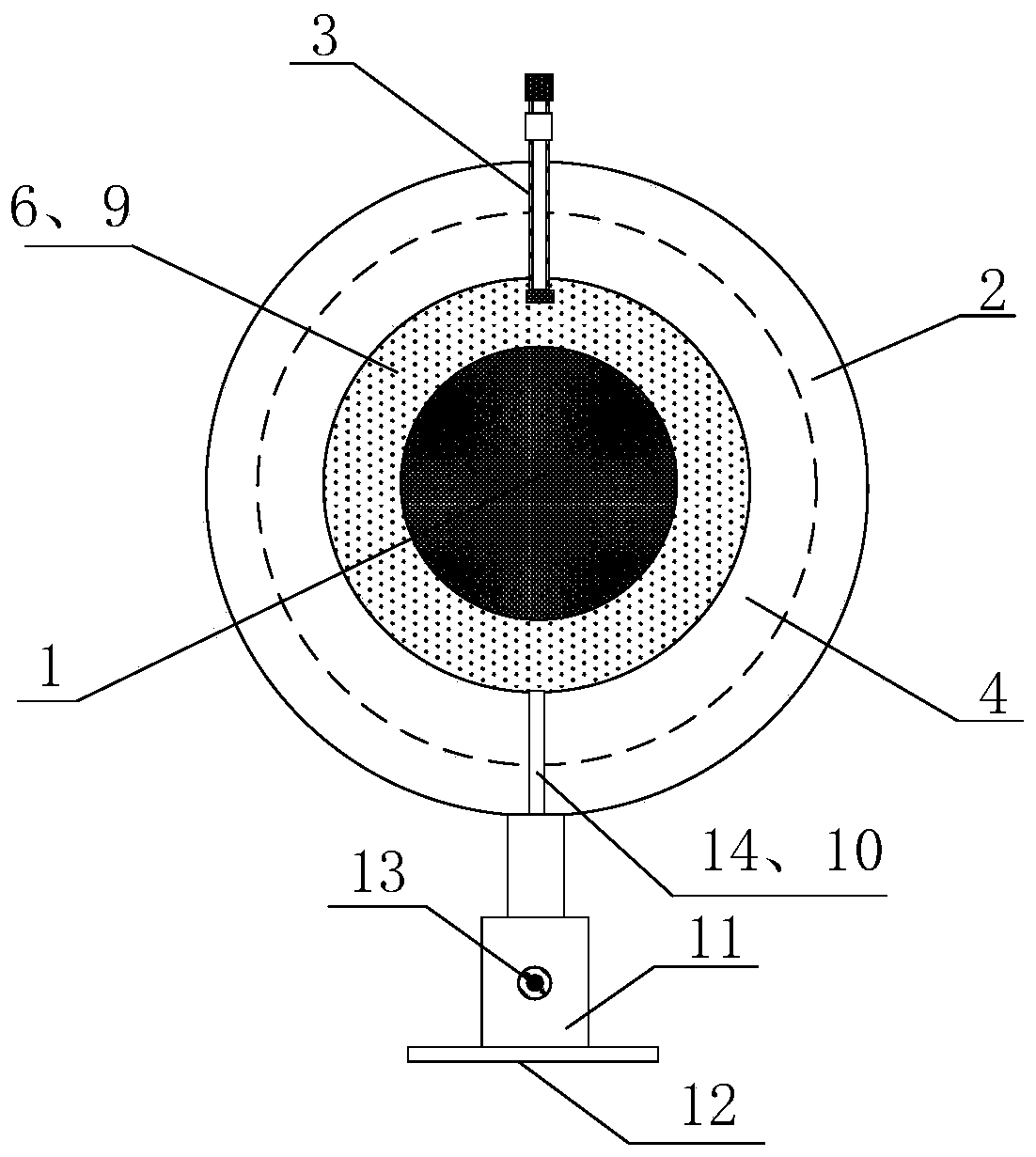

[0043] The invention relates to a test piece dynamic lateral strain measuring device and method based on a SHPB test system. The measuring device includes a fixing system, an oil pressure system and a data acquisition system. The fixing system is used to fix the whole device on the SHPB test bench and adjust the height of the device; the oil pressure system is used to apply the required confining pressure to the specimen and set the The volume change signal of the test piece is converted into the oil pressure change signal; the data acquisition system is used to capture the oil pressure change signal and obtain the time history change curve of the lateral strain. The invention applies confining pressure to the test piece by using the oil pressure system, simulates the comprehensive loading of the confining pressure of the test piece, and cooperates with the axial force caused by the separate Hopkinson pressure bar device, so as to realize the complex stress state of the test pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com