Tool Wear Detector

A tool wear and detector technology, applied in the field of mechanical processing, can solve the problems of difficult position and angle of the tool to be tested, low data accuracy, etc., and achieve the effects of intuitive display, accurate collection, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

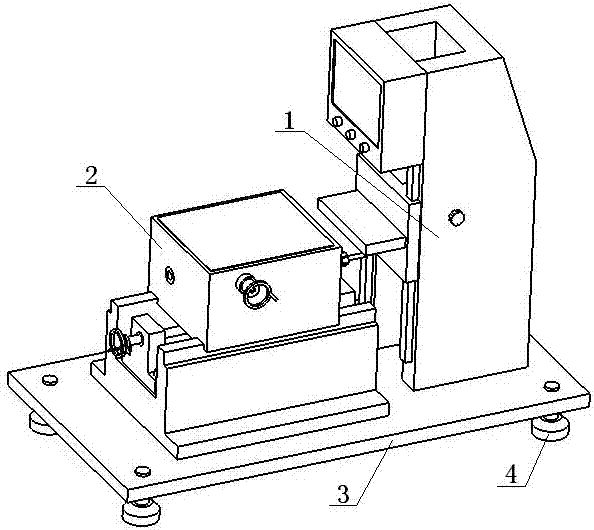

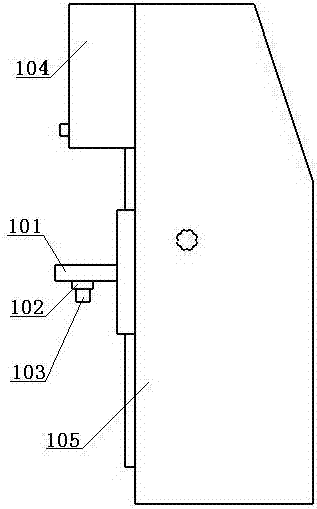

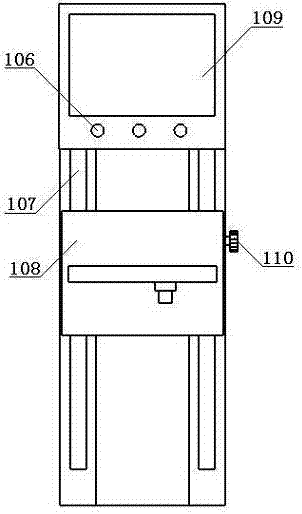

[0017] The lens height adjustment device 1 and the tool axial and rotation adjustment device 2 are fixedly connected with the support platform 3 respectively, and the platform adjustment screw 4 is screwed with the four corners of the bottom surface of the support platform 3; the lens 103 is installed under the lens support plate 101, and the lens is finely adjusted The knob 102 is installed on the outer edge of the lens 103, the guide rail one 107 is installed on the front portion of the casing 105, and the display system 104 is installed on the upper end of the front surface of the casing 105. The display system 104 has a display adjustment knob 106 and a liquid crystal screen 109, and the slide block 108 and Guide rail one 107 is slidingly connected, the rack support plate 112 is fixedly connected to the inside of the slider 108, the rack 113 is installed on the rack support plate 112, the two ends of the shaft of the worm 114 are respectively connected to the two side plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com