Uniaxial tension compression system

A test system, uniaxial tension and compression technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as imperfect rock mechanics models and failure criteria, inability to fully meet engineering needs, complex structures and environments, etc. , to avoid the stress concentration effect of the fixture, occupy a small space, and guarantee the stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

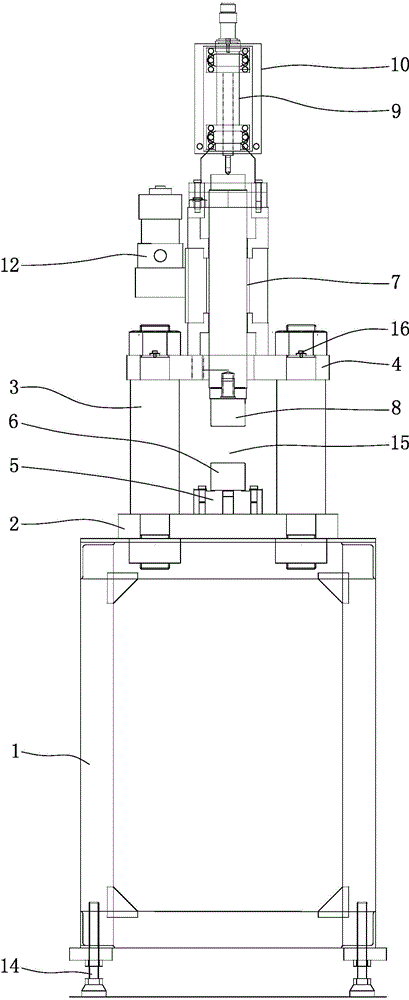

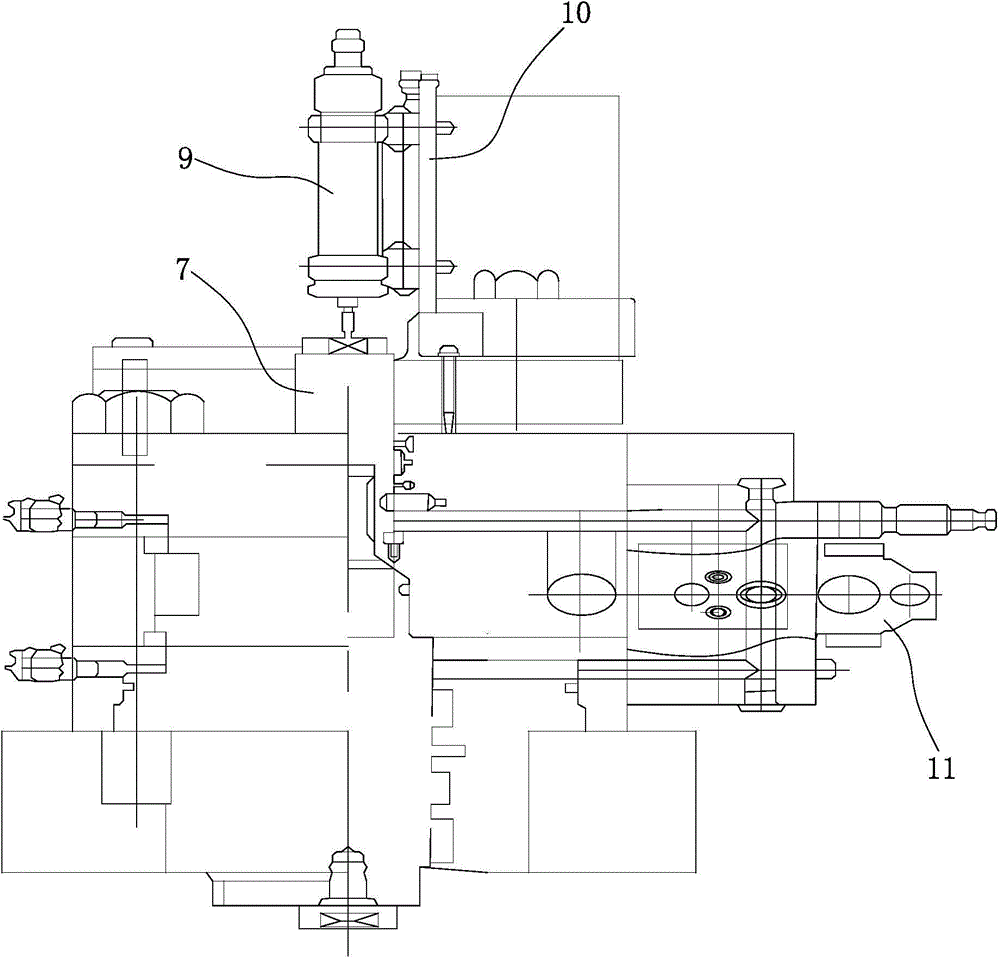

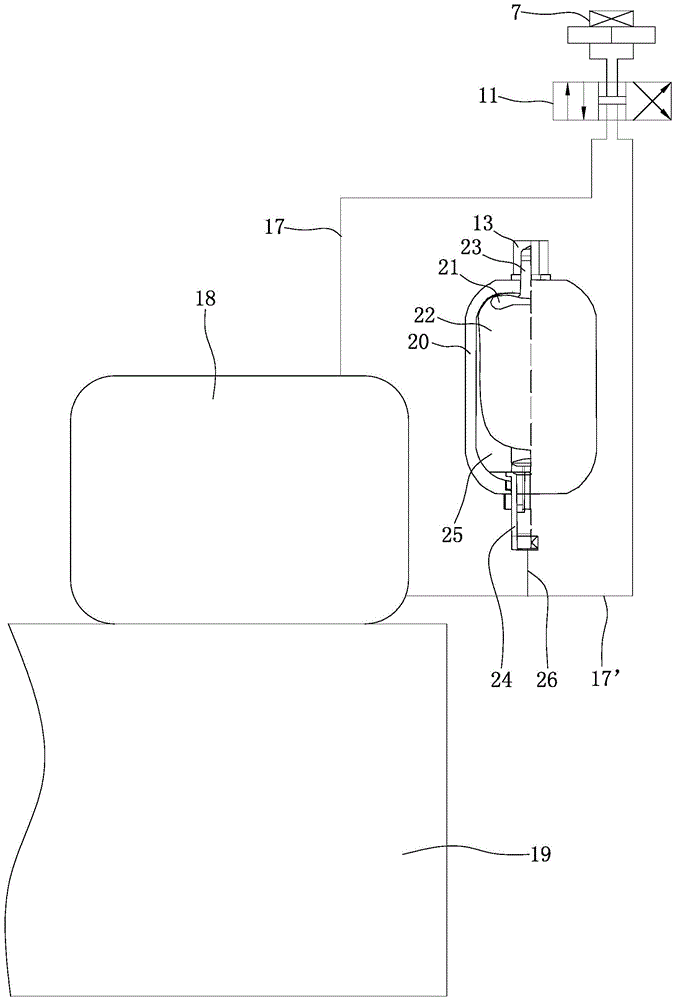

[0046] Such as figure 1 As shown, the fixed frame 1 is a frame structure, and the four corners of the bottom of the fixed frame 1 are equipped with anchor bolts 14 . A lower positioning plate 2 is arranged on the top of the fixing frame 1, and the lower positioning plate 2 is preferably rectangular and located on a horizontal plane. Directly above the lower positioning plate 2 is provided with an upper positioning plate 4, and the upper positioning plate 4 is also preferably rectangular. The reaction force column 3 is connected, and the reaction force column 3 is perpendicular to the upper positioning plate 4, and the upper and lower ends of the reaction force column 3 are locked with the corresponding positioning plate by nuts. Two suspension rings 16 are installed side by side on the top surface of upper positioning plate 4, and are connected with the hoo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com