Gradienter for split-Hopkinson-pressure-bar splitting test piece

A Hopkinson pressure bar and test piece technology, used in instruments, scientific instruments, measuring devices, etc., can solve problems such as poor axis alignment and impact on test accuracy, to improve accuracy, prevent splashes from hurting people, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

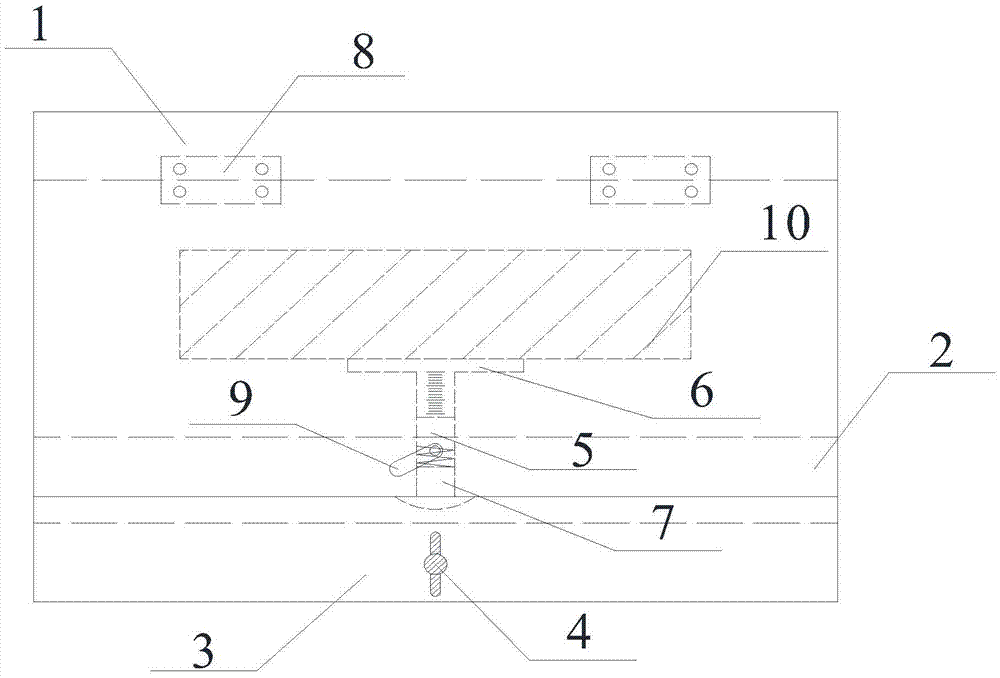

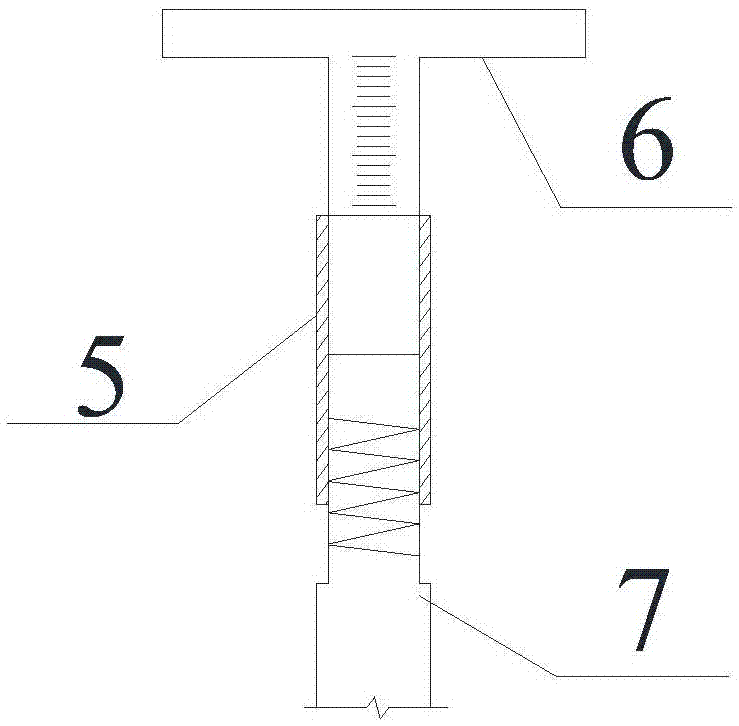

[0023] A Hopkinson compression bar splitting test specimen leveling instrument, comprising a protective cover, a support (3), a half-thread sleeve (5), a leveling tray (6), and a fixing rod (7);

[0024] The upper surface of the support (3) is an inclined surface, and there is a groove in the middle of the contact between the upper surface and the protective cover front cover (2). 3) The middle part of the upper surface is fixed with a fixed rod (7). The size of the cross-section of the fixed rod (7) is different from bottom to top. The lower part has a large cross-section and the upper part has a small cross-section. The lower part of the small section section is provided with external threads, and the small section section is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com