Experimental device for automatically loading impacts on SHPB (Split Hopkinson Pressure Bar) at high temperature

A technology of loading experiment and experimental device, which is applied in the direction of using one-time impact force to test the strength of materials and the preparation of test samples, etc. It can solve the problems of uneven heating of test pieces, inaccurate experimental process, and low heating efficiency, so as to ensure stability Safety and safety, accurate experimental process, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

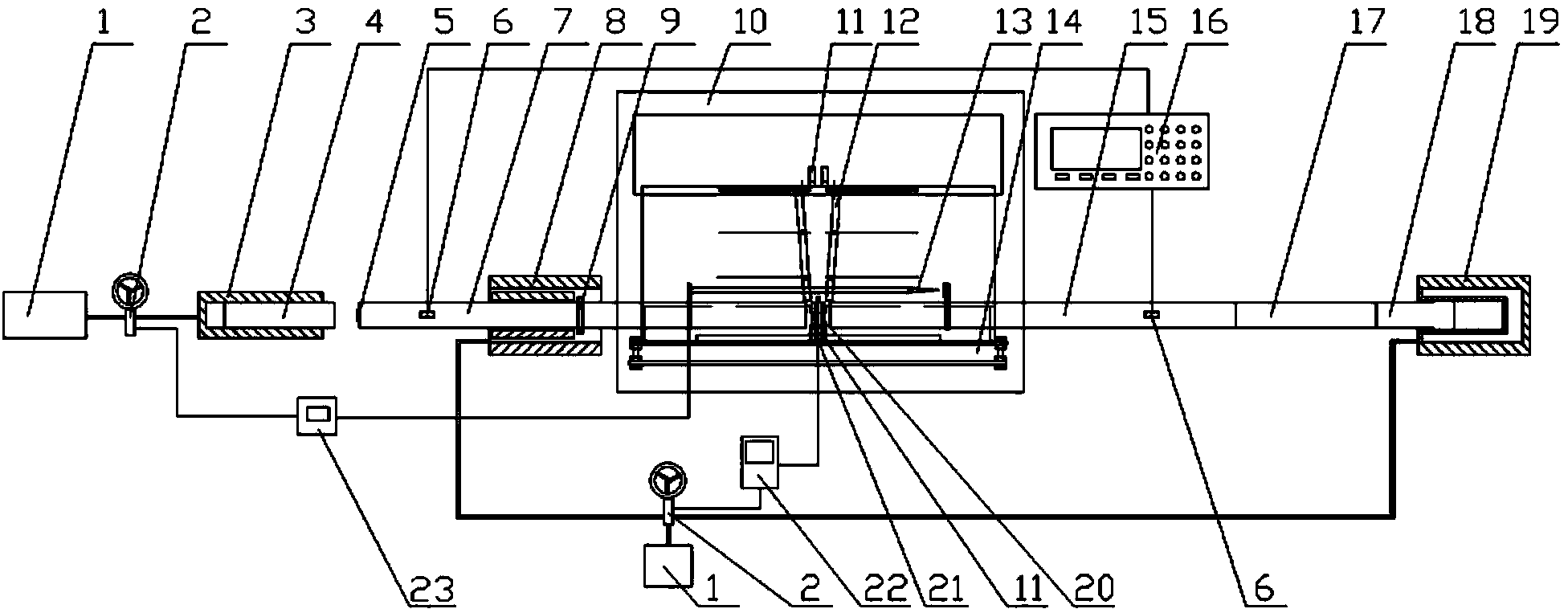

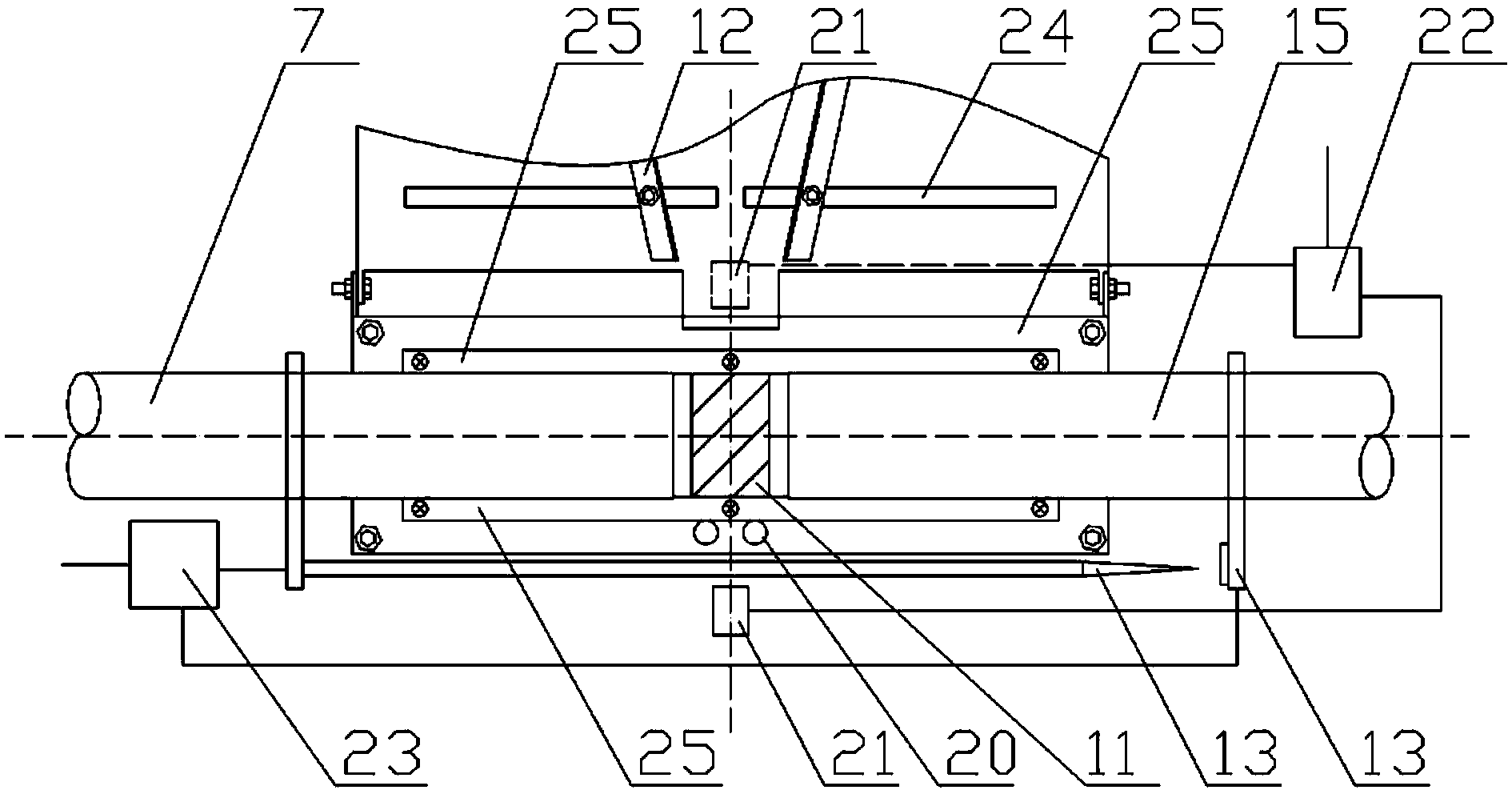

[0022] Such as figure 1 As shown, the SHPB automatic rod impact loading experimental device under high temperature conditions of the present invention includes a high-pressure gas tank 1, an incident rod 7, a transmission rod 15, a base 14 and a test piece for placing the incident rod 7, the transmission rod 15 and the test piece Heating device 10, said test piece heating device 10 is separated from base 14, and between heating device 10 and base 14, there is a test piece guide rail 12 with adjustable width for guiding the test piece from heating device to base 14, on base 14 The other side of the test piece opposite to the test piece guide rail 12 is provided with a test piece stop rod 20 to limit the position of the test piece, and the base 14 is three-dimensionally adjustable.

[0023] The test piece heating device is set separately from the base, so that the test piece can be heated evenly, and at the same time, the test piece guide rail is used to ensure that the test pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com