Synchronous measurement method of split Hopkinson pressure bar experiment based on digital images

A technology of Hopkinson compression bar and digital image, which is applied in the direction of measuring device, analyzing materials, and testing material strength by using one-time impact force, which can solve the problems of waveform synchronization, stress-strain data error, and inability to truly realize the test piece. Problems such as strain synchronization measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

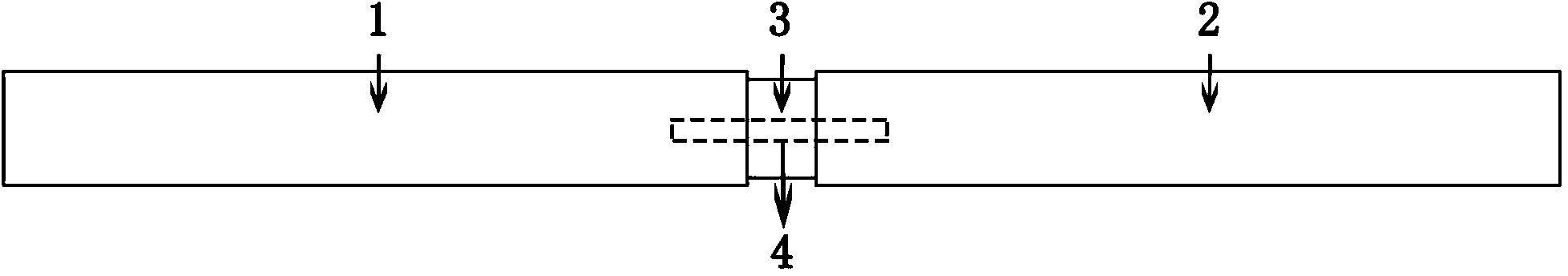

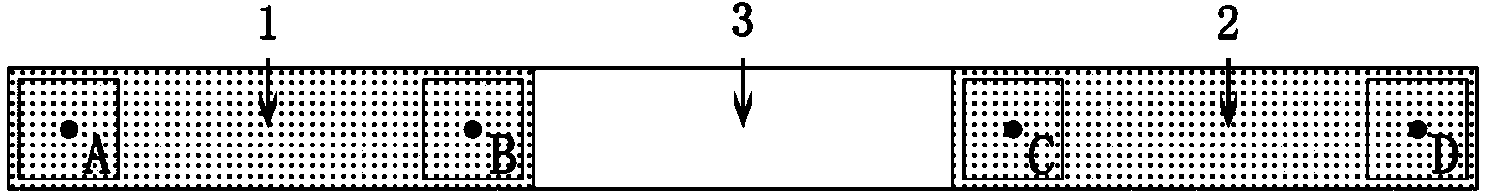

[0024] In this embodiment, the length of the incident rod 1 is 320cm, the length of the transmission rod 2 is 200cm, the cross-section of the incident rod and the transmission rod is circular, and its diameter is 74mm, all of which are steel rods. The high-speed camera adopts the Phantomv1610 system and is tested Part 3 is a cylindrical steel fiber reinforced concrete with a diameter of 70.2 mm and a height of 31.6 mm, which has withstood multiple impacts. figure 1 The 4 in represents the shooting area of the high-speed camera.

[0025] A digital image-based method for simultaneous measurement of split Hopkinson compression bar experiments, including

[0026] Such as figure 1 As shown, before the experiment, a marking area is made on the outer surface of the incident rod 1 in contact with the test piece 3, and on the outer surface of the transmission rod 2 in contact with the test piece 3. The marking area is composed of speckles, and the speckle The particle size is deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com