Universal type true-triaxial static load pre-loading system for split Hopkinson pressure bar

A Hopkinson pressure bar, general-purpose technology, applied in the direction of applying stable tension/pressure to test material strength, analyze materials, measuring devices, etc., can solve the problem of difficult to achieve good simulation of underground engineering rocks, variable size true triaxial The static load preloading system has not yet appeared and other problems, achieving the effect of simple structure, convenient installation and operation, and high overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

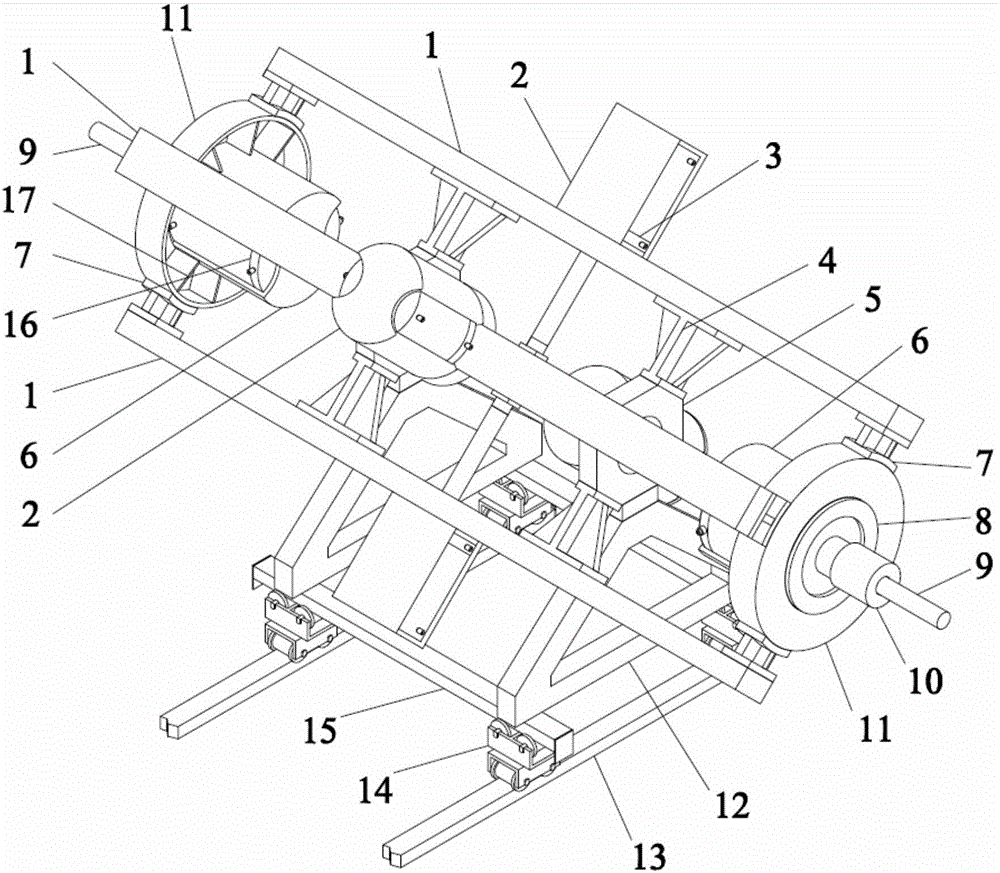

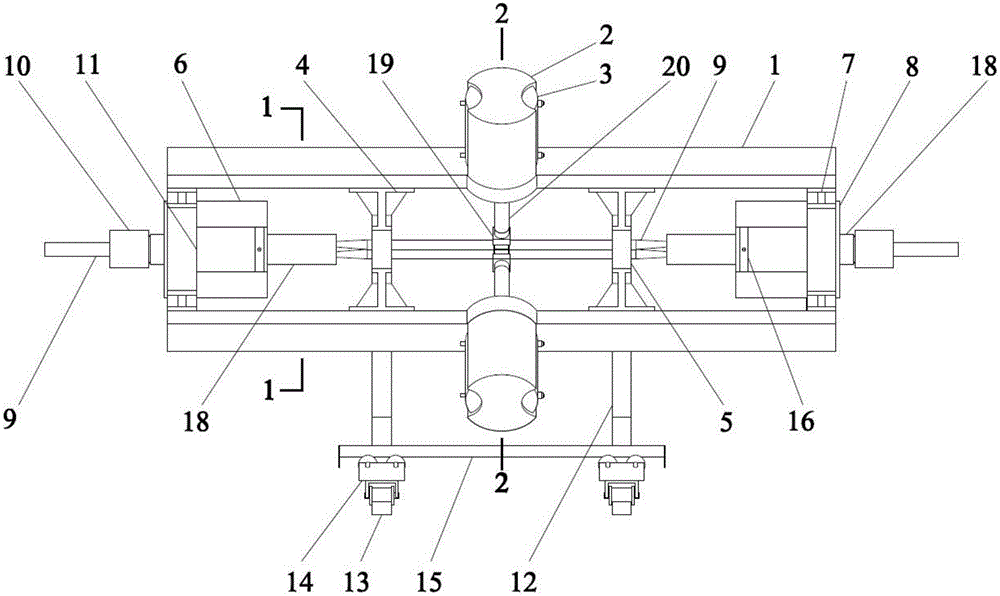

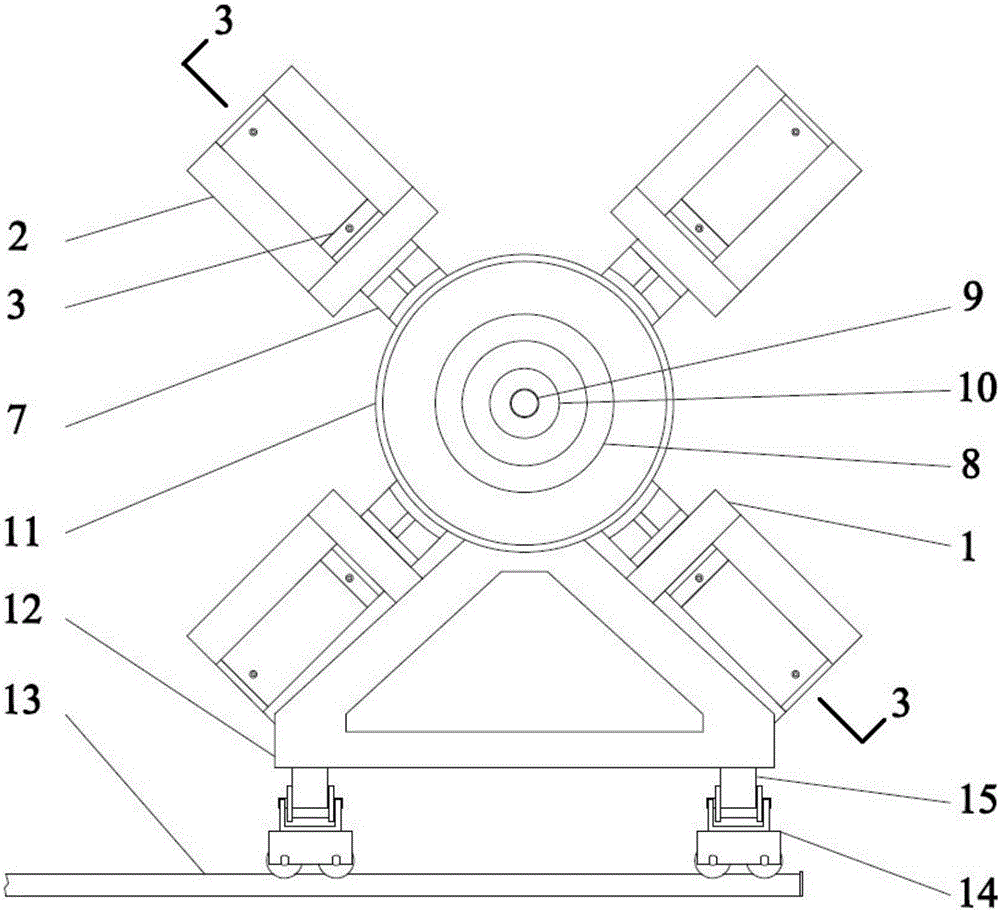

[0043] This embodiment is a general-purpose true three-axis static load preloading system suitable for separate Hopkinson compression bars. It can be used in conjunction with the SHPB device to achieve true three-axis dynamic and static combined loading, and it can be used alone to achieve true three-axis loading. . The diameter range of the waveguide rod of the SHPB device is: 50mm~110mm. The size range of the experimental sample 21 may be: length and width 40mm-100mm, height 20mm-300mm. The piston stroke of axial jack and radial jack is designed to be 300mm, the maximum axial load level is 3000KN, and the maximum radial load level is 1500KN. Through servo control and displacement acquisition, the true three-axis loading with unequal stress in three directions is realized, and obtained The stress-strain curve of sample 21 during the whole loading process.

[0044] This embodiment includes a main body reaction force steel frame, an axial preload system, a radial preload syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com