Test system for simulating anti-explosion characteristic of target under confining pressure condition

A technology of anti-explosion characteristics and test system, applied in the field of test system, can solve the problem of inability to realize explosion disturbance loading and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

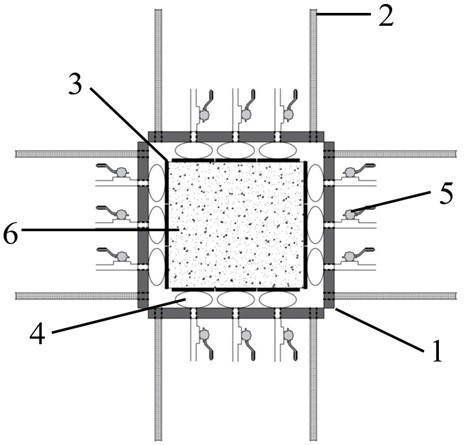

[0026] like figure 1 As shown, a test system for simulating the anti-knock characteristics of a target under confining pressure conditions of the present embodiment includes a target 6 in the shape of a cuboid, a plurality of pressure plates 3 are arranged around the target 6, and a plurality of pressure plates 3 are enclosed in a rectangular frame shape , a number of support bases 1 are arranged on the periphery of the pressure plate 3, and a number of support bases 1 are enclosed in a rectangular frame shape, and a number of flexible oil bags 4 are arranged between the support base 1 and the pressure plate 3, and each pressure plate 3 corresponds to a flexible oil bag 4, each Each flexible oil bag 4 is connected to a pressing machine through pipelines.

[0027] In this embodiment, the support base 1 is fixedly arranged on the guide rail 2 at the bottom, the two sides of the flexible oil bag 4 are in contact with the corresponding pressure plate 3 and the support base 1 respe...

Embodiment 2

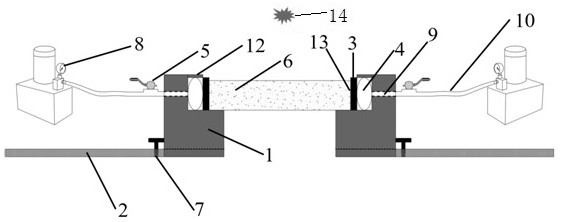

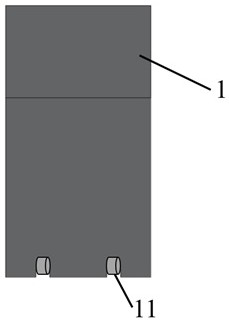

[0030] combine figure 2 As shown in the figure, the structure of the test system of this embodiment is basically the same as that of the first embodiment. Matching rollers, such as image 3 As shown, the support base 1 is slidably connected to the guide rail 2 through rollers, and the guide rail 2 is provided with several positioning holes (not shown in the figure) along the sliding direction of the support base 1. The positioning holes can be inserted into the positioning holes 7; The base 1 slides on the guide rail to control the distance between the two relative support bases 1, which can meet the placement of targets 6 of different sizes. When the support base 1 slides to a suitable position, insert the limiter into the positioning hole closest to the support base 1 The pin 7 and the limit pin 7 can abut on the side of the support base 1 away from the flexible oil bag 4 , so that the support base 1 is fixed on the guide rail 2 .

[0031] The support base 1 is provided w...

Embodiment 3

[0034] The structure of the test system of this embodiment is basically the same as that of the second embodiment, the difference is that the pressure plates 3 are only symmetrically arranged on opposite sides of the target 6 in this embodiment, which can simulate the unidirectional loading of the target 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com