Flexible low-smoke halogen-free flame-retardant wire and cable material and preparation method thereof

A wire and cable material, flame-retardant technology, applied in the field of polymer materials, can solve the problems of strong graininess, rough cable surface, poor mechanical properties, etc., and achieve the effect of simple production process, good wear resistance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

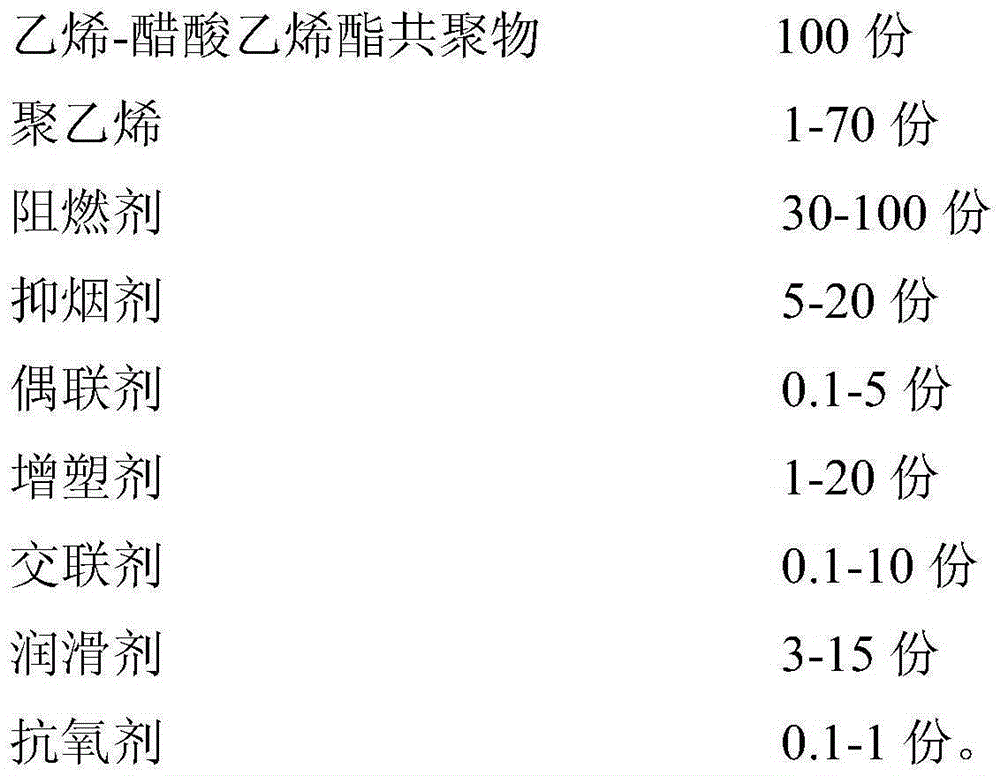

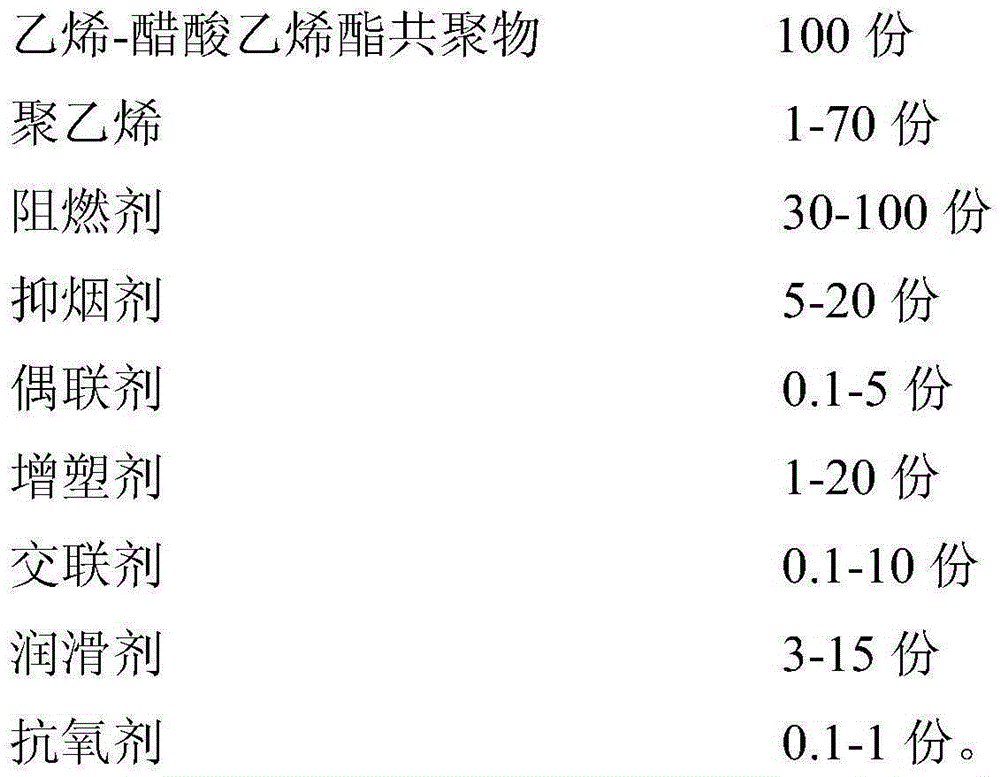

Method used

Image

Examples

Embodiment 1

[0032] Weigh 100 parts by weight of ethylene-vinyl acetate copolymer (VA content 18%), 20 parts by weight of low-density polyethylene, 50 parts by weight of intumescent flame retardant (ExolitIFR-10), 8 parts by weight of ferrocene, KH5701. 5 parts by weight, 15 parts by weight of tricresyl phosphate, 5 parts by weight of zinc stearate, 10 parts by weight of silicone masterbatch, 5 parts by weight of dicumyl peroxide, N,N'-m-phenylene bismaleyl 3 parts by weight of imine, 10101 parts by weight of antioxidant. Put the above-mentioned raw materials into a high-speed mixer, mix for 8 minutes to obtain a uniformly mixed powder, then put the powder into an internal mixer, and banbury for 10 minutes at 160°C to obtain a dough-like mixture; mix the dough-like mixture Put it into a single-screw extruder with a rotation speed of 50r / min to extrude and granulate. The temperatures of the first, second, and third stages of the single-screw extruder are respectively set to 180°C, 180°C, an...

Embodiment 2

[0035] Weigh 100 parts by weight of ethylene-vinyl acetate copolymer (VA content 50%), 50 parts by weight of low-density polyethylene, 70 parts by weight of intumescent flame retardant (ExolitIFR-10), 8 parts by weight of ferrocene, TC- 1144 parts by weight, 10 parts by weight of tricresyl phosphate, 5 parts by weight of trioctyl trimellitate, 5 parts by weight of zinc stearate, 10 parts by weight of silicone masterbatch, 3 parts by weight of dicumyl peroxide parts by weight, triallyl isocyanurate 5 parts by weight, antioxidant 10100.5 parts by weight. Put the above-mentioned raw materials into a high-speed mixer, mix for 8 minutes to obtain a uniformly mixed powder, then put the powder into an internal mixer, and banbury for 10 minutes at 170°C to obtain a dough-like mixture; mix the dough-like mixture Put it into a single-screw extruder with a rotation speed of 100r / min to extrude and granulate, and the temperatures of the first, second, and third stages of the single-screw ...

Embodiment 3

[0038] Weigh 100 parts by weight of ethylene-vinyl acetate copolymer (VA content 28%), 10 parts by weight of low-density polyethylene, 70 parts by weight of intumescent flame retardant (ST-EPFR-100D), and 10 parts by weight of ammonium octamolybdate , 5 parts by weight of polypropylene glycol diglycidyl ether, 10 parts by weight of tricresyl phosphate, 8 parts of trioctyl trimellitate, 5 parts by weight of zinc stearate, 10 parts by weight of silicone masterbatch, 2,5-di 5 parts by weight of methyl-2,5-bis(tert-butylperoxy)hexane, 4 parts by weight of N,N'-m-phenylene bismaleimide, and 10100.3 parts by weight of antioxidant. Put the above-mentioned raw materials into a high-speed mixer, mix for 8 minutes to obtain a uniformly mixed powder, then put the powder into an internal mixer, and banbury for 10 minutes at 160°C to obtain a dough-like mixture; mix the dough-like mixture Put it into a single-screw extruder with a rotation speed of 60r / min to extrude and granulate. The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com