Manufacture method of selective front surface field N-type solar cell

A manufacturing method and a front surface field technology, applied in the field of solar photovoltaic power generation, can solve problems such as electrode difficulties, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

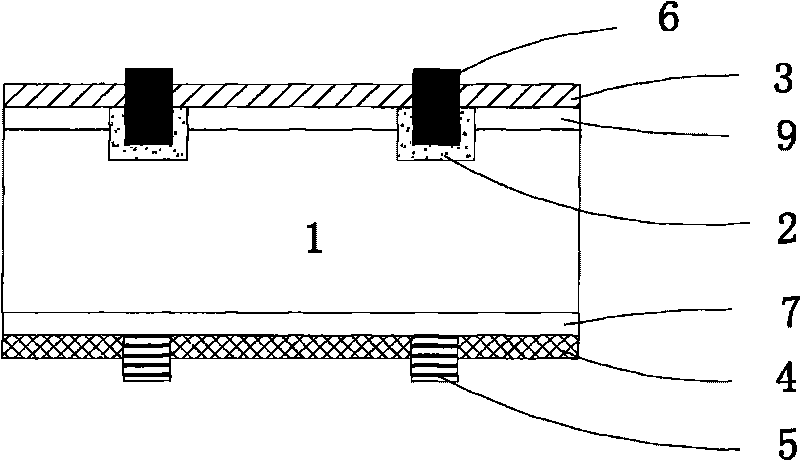

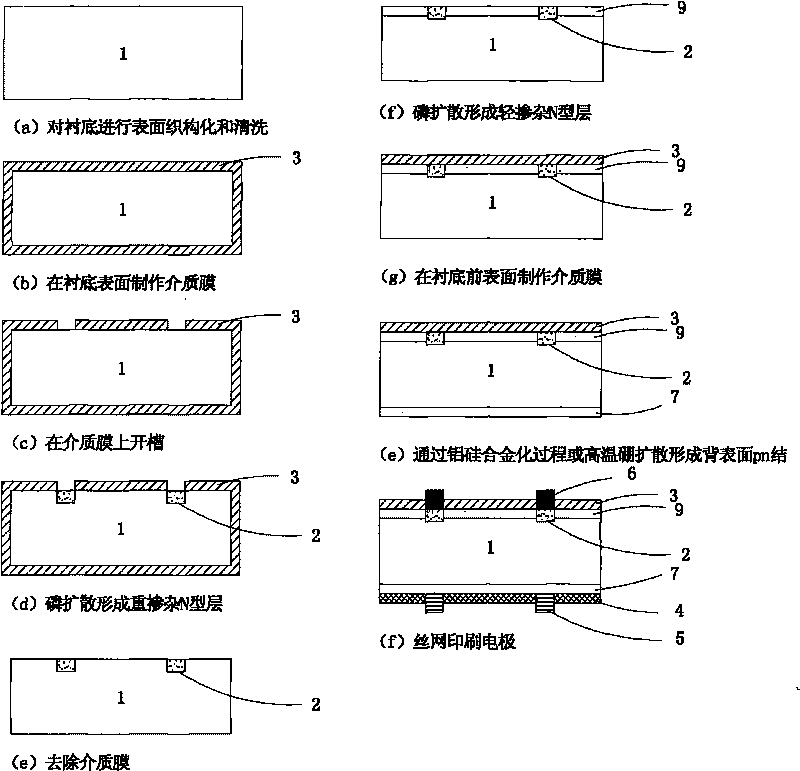

[0053] image 3 It is the first technical solution of the selective front surface field N-type solar cell manufacturing method provided by the present invention, which specifically includes the following steps:

[0054] (a) Surface texturing and chemical cleaning of N-type semiconductor substrates

[0055] For N-type monocrystalline silicon substrates, use dilute sodium hydroxide or potassium hydroxide solution to make a pyramid-shaped light trapping structure on the substrate surface; for N-type polycrystalline silicon substrates, use a mixed solution of nitric acid and hydrofluoric acid on the substrate A pit-like light-trapping structure is made on the surface. Subsequently, the substrate is cleaned with diluted hydrochloric acid and hydrofluoric acid, respectively.

[0056] (b) High-temperature phosphorous diffusion forms a lightly doped N-type layer on the front surface

[0057] Phosphorus oxychloride is used as a dopant source, and the semiconductor substrate is diffu...

Embodiment 2

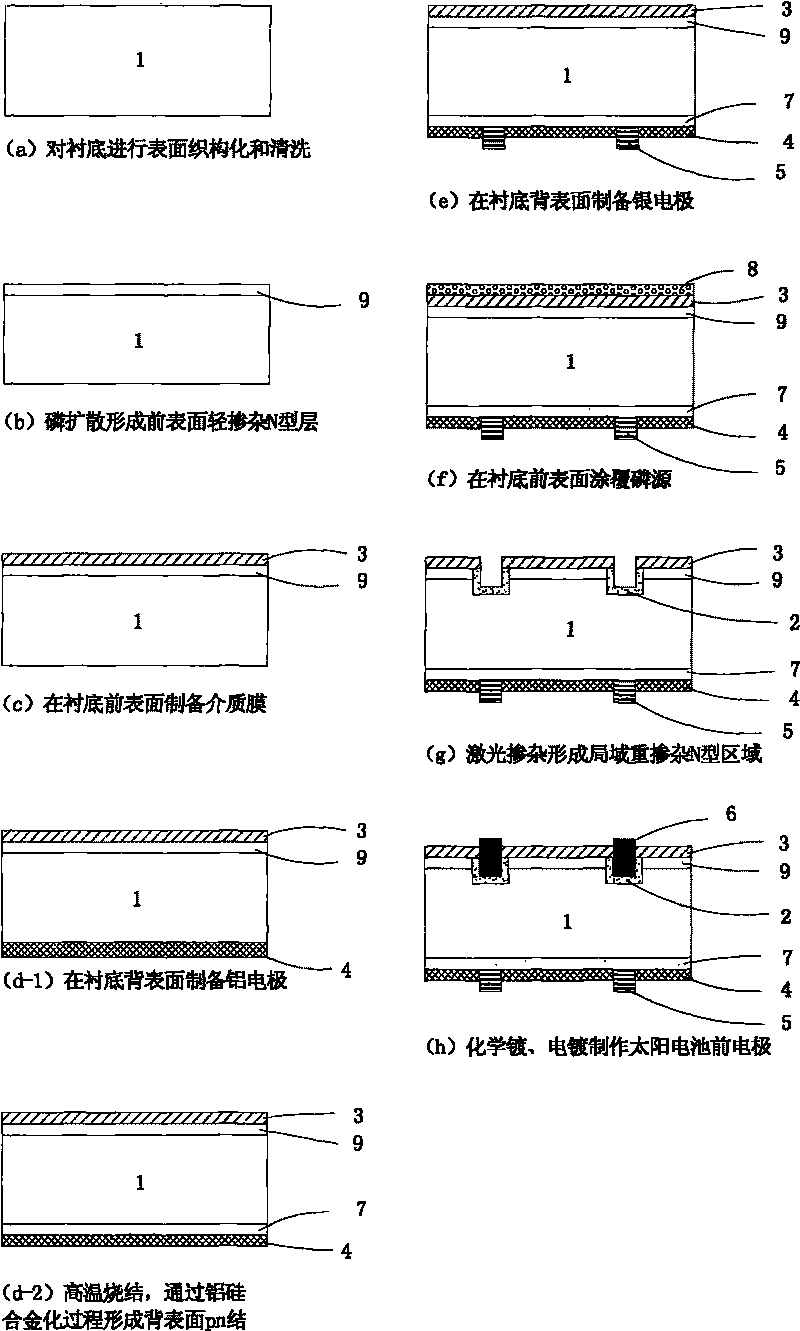

[0073] Figure 4 It is the second technical solution of the selective front surface field N-type solar cell manufacturing method provided by the present invention, which specifically includes the following steps:

[0074] (a) Texturing and chemically cleaning the surface of the N-type semiconductor substrate;

[0075] (b) High-temperature phosphorous diffusion forms a lightly doped N-type layer on the front surface;

[0076] (c) preparing a dielectric film on the front surface of the N-type semiconductor substrate;

[0077] (d) Form a p-type layer on the back surface during the high-temperature boron diffusion process, thereby obtaining a p-n junction on the back surface (using boron tribromide as a doping source, and performing p-type diffusion at a temperature of 800-1000°C);

[0078] (e) preparing silver electrodes and aluminum electrodes by screen printing on the back surface of the N-type semiconductor substrate, and performing high-temperature sintering;

[0079] (f) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com