Method for preparing conductive ultrahigh molecular weight polyethylene fiber

A polyethylene fiber, ultra-high molecular weight technology, applied in the polymer field, can solve the problems of inert fiber surface, difficult to coat or adsorb conductive substances, difficult to adsorb other substances, etc., to achieve simple preparation of instruments and simplified pretreatment process. , good activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

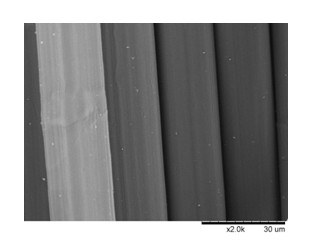

[0055] Step (1) Soak the ultra-high molecular weight polyethylene fiber in an acetone solution, ultrasonically wash it for 1 hour, rinse it with deionized water, and dry it naturally at room temperature;

[0056] Step (2) configuring an activation solution: dissolving 3,4-dihydroxyphenylalanine in a Tris-hydrochloric acid buffer solution with a pH of 7.5 to prepare an activation solution with a concentration of 0.01mol / L;

[0057] Step (3) placing the washed ultra-high molecular weight polyethylene fiber in a reaction vessel, adding an excessive amount of activation solution, and activating it under stirring, and the activation time is 24 hours;

[0058] Step (4) configuration electroless silver plating solution, concrete steps are:

[0059] ① Configure silver solution: Add silver nitrate to deionized water at a ratio of 0.1mol per liter of deionized water, and add concentrated ammonia water with a mass concentration of 26% dropwise while stirring until the precipitate is comp...

Embodiment 2

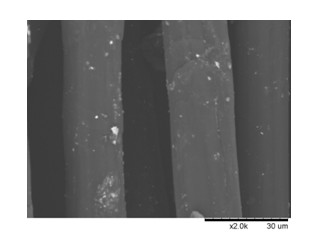

[0065] Step (1) Soak the ultra-high molecular weight polyethylene fiber in an ethanol solution, ultrasonically wash it for 2 hours, rinse it with deionized water, and dry it naturally at room temperature;

[0066] Step (2) configuring an activation solution: dissolving 3,4-dihydroxyphenethylamine in a Tris-hydrochloric acid buffer solution with a pH of 7, and configuring an activation solution with a concentration of 0.02mol / L;

[0067] Step (3) placing the washed ultra-high molecular weight polyethylene fibers in a reaction vessel, adding an excessive amount of activation solution, and activating under stirring, the activation time is 1.5 hours;

[0068] Step (4) configuration electroless silver plating solution, concrete steps are:

[0069] ① Prepare silver solution: In deionized water, add silver nitrate at a ratio of 0.2mol per liter of deionized water, and silver chloride at a ratio of 0.2mol, and add concentrated ammonia water with a mass concentration of 28% dropwise wh...

Embodiment 3

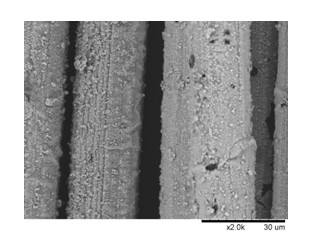

[0075] Step (1) soak the ultra-high molecular weight polyethylene fiber in a tetrahydrofuran solution, ultrasonically wash it for 5 hours, rinse it with deionized water, and dry it in vacuum at 50°C;

[0076] Step (2) configuring an activation solution: dissolving tyrosine in a Tris-hydrochloric acid buffer solution with a pH of 8.5 to configure an activation solution with a concentration of 0.005mol / L;

[0077] Step (3) placing the washed ultra-high molecular weight polyethylene fiber in a reaction vessel, adding an excessive amount of activation solution, and activating it under stirring, and the activation time is 12 hours;

[0078] Step (4) configuration electroless silver plating solution, concrete steps are:

[0079] ① Configure silver solution: Add silver perchlorate to deionized water at a ratio of 0.12mol per liter of deionized water, and add concentrated ammonia water with a mass concentration of 25% dropwise while stirring until the precipitate is completely dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com