Metallic oxide-coated modified doped ternary anode material and preparation method thereof

A cathode material and oxide technology, applied in the field of metal oxide coating modified doped ternary cathode material and its preparation field, can solve the problems such as cycle stability to be improved, electrochemical performance deterioration, capacity retention rate decline and the like , to achieve excellent rate performance and cycle stability, improve cycle stability, and reduce the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to a second aspect of the present invention, there is provided a method for preparing the positive electrode material as described above, which specifically includes the following steps:

[0043] Step 1), the preparation of matrix

[0044] The matrix is obtained by mixing a nickel-cobalt-manganese ternary precursor, a lithium source and a strontium source, calcining at a high temperature, crushing and sieving.

[0045] In a preferred embodiment according to the present invention, the nickel-cobalt-manganese ternary precursor, the lithium source and the strontium source are respectively passed through a 100-300 mesh sieve and mixed uniformly in a molar ratio of 1:(1-1.06):(0-0.005) , calcined in an air atmosphere for 3 to 40 hours, preferably 5 to 36 hours, during which the calcining temperature was programmed to increase from 200°C to 1000°C, and the heating rate was 5°C / min, then lowered to room temperature, crushed, passed 100 to 300 Mesh sieve to obtain ...

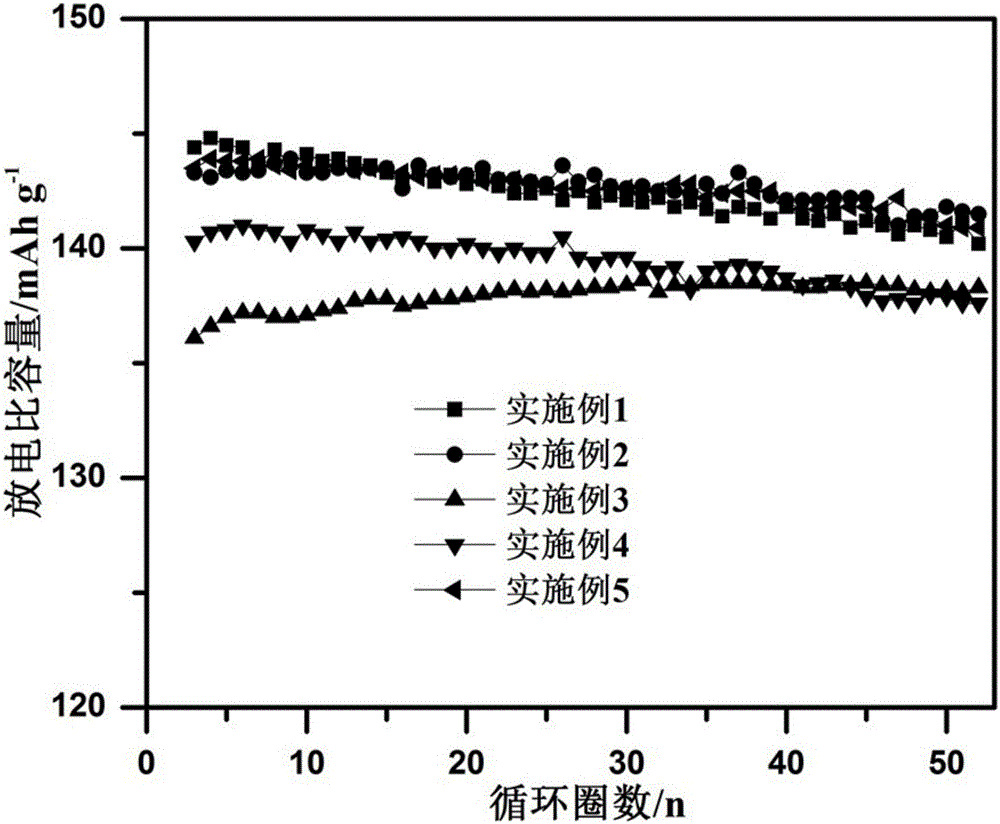

Embodiment 1

[0062] The preparation of the nickel cobalt lithium manganese oxide substrate of embodiment 1 doping Sr element

[0063] Weigh 84.4g of lithium carbonate, 200g of nickel-cobalt-manganese hydroxide, and 1.08g of strontium carbonate, and add them to a 200-mesh sieve in turn, and mix evenly after sieving;

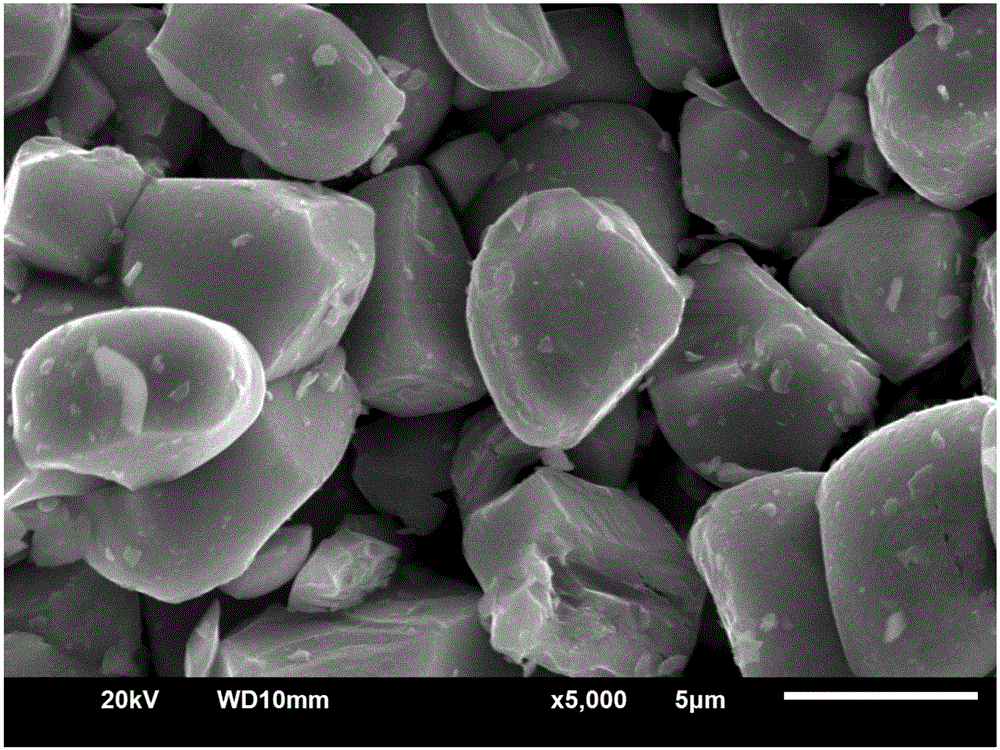

[0064] Put the sieved material into the crucible, and calcined in the muffle furnace under the air atmosphere for 36 hours, during which the calcining temperature was programmed to increase from 200°C to 1000°C, and the heating rate was 5°C / min, and then naturally dropped to room temperature , passed through a 200-mesh sieve after ball milling for 3 hours to obtain the matrix Li(Ni 0.5 mn 0.3 co 0.2 )1-x Sr x o 2 , where x=0.003.

Embodiment 20

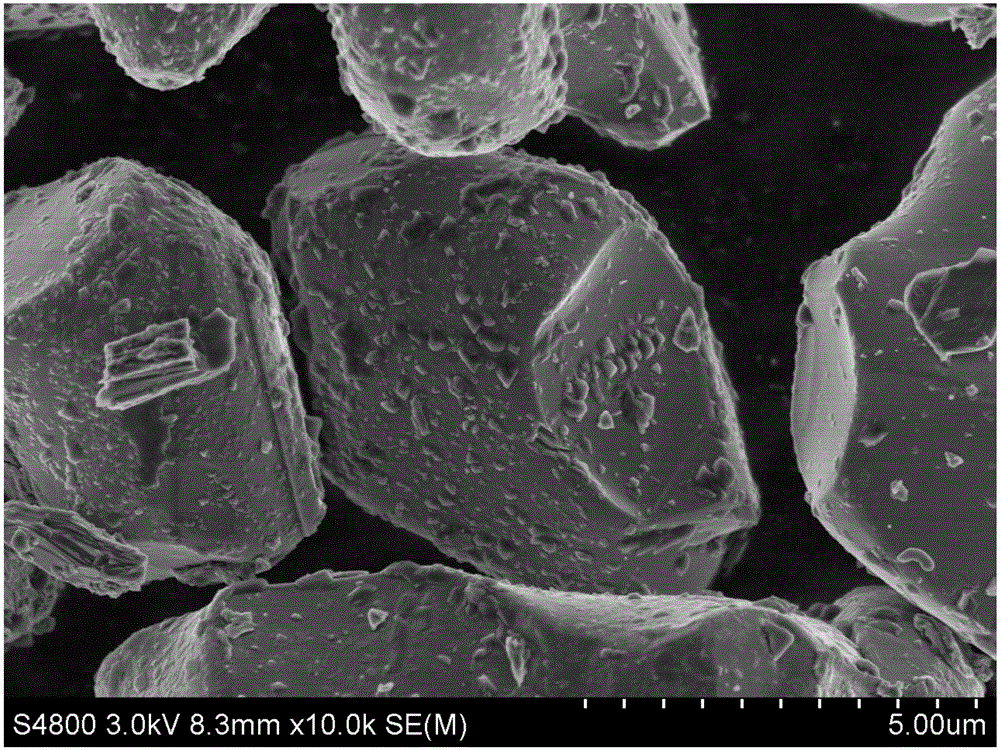

[0065] Example 20.01% Al 2 o 3 Preparation of Coated Modified Doped Ternary Cathode Material

[0066] Weigh 0.06g of lithium carbonate, add it to a beaker containing 120mL ultrapure water, stir under heating, wait until the temperature rises above 50°C, weigh 120g of the matrix prepared in step 1) and add it to the above solution, continue stirring and The solution was heated to 80°C to obtain a mixed solution A;

[0067] Weigh 0.167 g of aluminum nitrate nonahydrate and add it to a beaker with 30 mL of ultrapure water, stir to dissolve, add it to the mixed solution A at a flow rate of 10 mL / min through a constant flow pump, and heat the solution to 80°C, keep stirring for 1-2 hours;

[0068] Filter the solution after the above reaction is completed, place the filtered insoluble matter in an oven at 150°C, dry it, pass through a 300-mesh sieve, put it into a porcelain boat, and calcinate it in a muffle furnace at 550°C for 5 hours, then cool down naturally to At room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com