Preparation method of functionalized polyester fiber

A polyester fiber and functionalization technology, applied in the field of preparation of functionalized polyester fiber, can solve the problems of narrow applicability and complex processing technology, and achieve the effects of high universality, improvement of agglomeration phenomenon, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of PBT-coated carbon nanotube powder

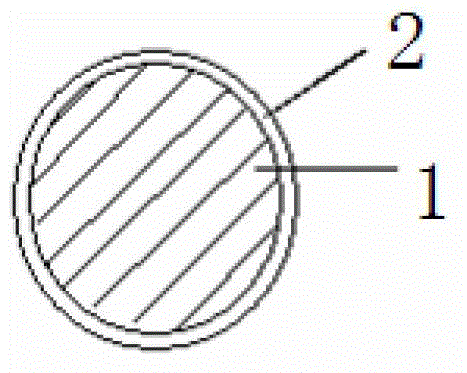

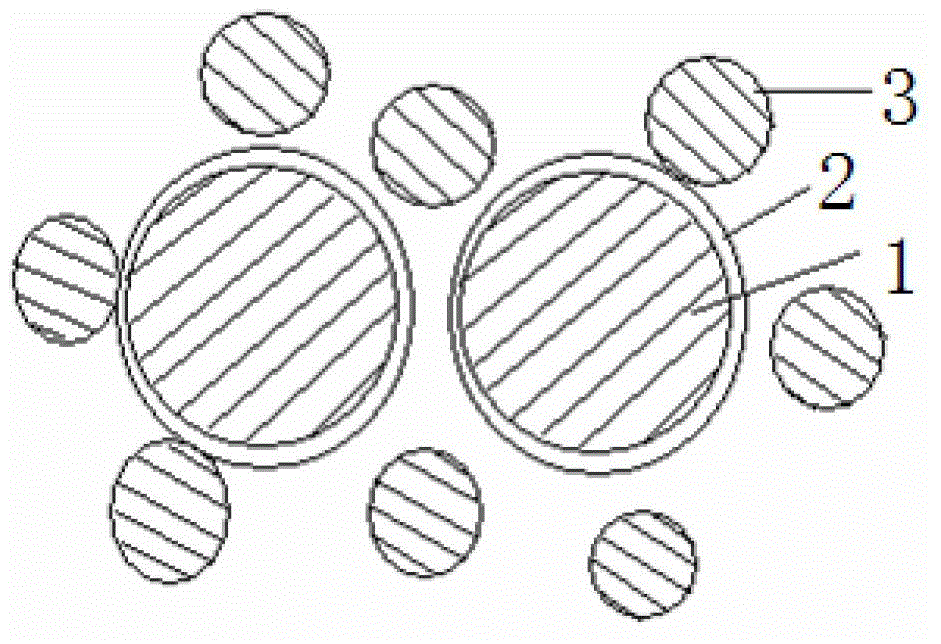

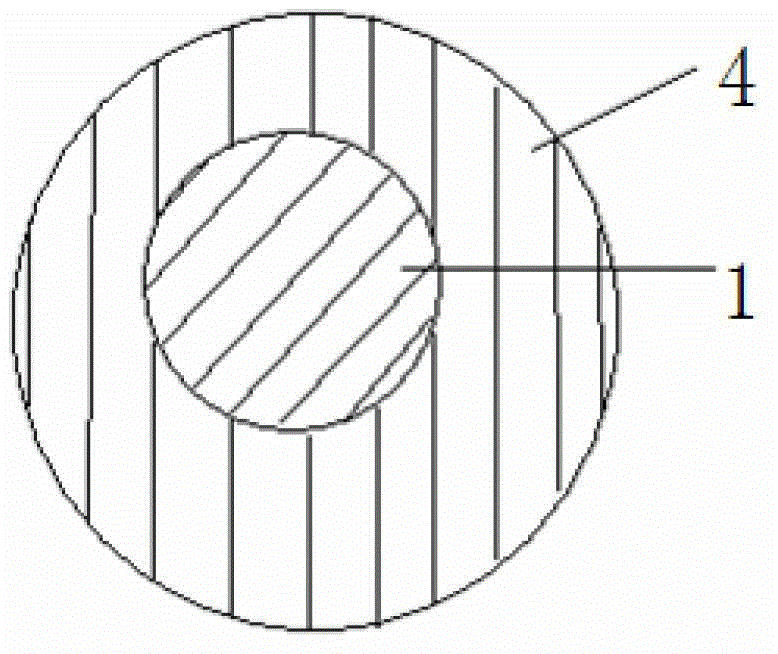

[0047] 1) Carry a layer of CBT catalyst on the surface of carbon nanotube powder: dissolve the catalyst ethyl titanate in ethanol to form a solution with a mass concentration of 25%; add carbon nanotube powder to the above solution in, and stirred; the particle diameter of the carbon nanotube powder is 20nm, and the mass ratio of the carbon nanotube powder to the ethyl titanate in the solution is 15:1; standing for stratification, obtaining the lower layer of precipitation , further remove the ethanol solvent at 90°C to obtain the loaded carbon nanotube powder loaded with ethyl titanate, figure 1 It is a schematic diagram of a loaded functional powder with a CBT catalyst on its surface, that is, a schematic diagram of a loaded carbon nanotube powder with ethyl titanate loaded on its surface. The functional powder shown in Figure 1 is a carbon nanotube powder , 2 means that the titanium catalyst is ethyl titanate, c...

Embodiment 2

[0055] (1) Preparation of PBT-coated nano-titanium dioxide powder

[0056] 1) Carry a layer of CBT catalyst on the surface of nano-titanium dioxide powder: dissolve the catalyst isopropyl titanate in ethanol to form a solution with a mass concentration of 35%; add nano-titanium dioxide powder to the above solution , and stirred; the particle size of the nano-titanium dioxide powder is 40nm, and the mass ratio of the nano-titanium dioxide powder to the isopropyl titanate in the solution is 25:1; standing for stratification, obtaining the lower layer of precipitation, and The ethanol solvent is further removed at 100°C to obtain nano-sized titanium dioxide powder loaded with isopropyl titanate. figure 1 It is a schematic diagram of a loaded functional powder loaded with a CBT catalyst on the surface, that is, a schematic diagram of a loaded nano-titanium dioxide powder loaded with isopropyl titanate on the surface. The functional powder shown in Figure 1 is a nano-titanium dioxi...

Embodiment 3

[0074] (1) Preparation of PBT-coated tourmaline powder

[0075]1) Carry a layer of CBT catalyst on the surface of the tourmaline powder: dissolve the catalyst 2-ethylhexyl titanate in ethanol to form a solution with a mass concentration of 30%; add the tourmaline powder to in the above solution, and stirred; the particle diameter of the tourmaline powder is 60nm, and the mass ratio of the tourmaline powder to the 2-ethylhexyl titanate in the solution is 20:1; , to obtain the lower precipitate, and further remove the ethanol solvent at 95°C to obtain the loaded tourmaline powder loaded with 2-ethylhexyl titanate, figure 1 It is a schematic diagram of a loaded functional powder with a CBT catalyst loaded on its surface, that is, a schematic diagram of a loaded tourmaline powder with 2-ethylhexyl titanate loaded on its surface. The functional powder shown in Figure 1 is tourmaline Powder, the titanium catalyst represented by 2 is 2-ethylhexyl titanate. After the tourmaline powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com