Patents

Literature

55results about How to "Short working distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

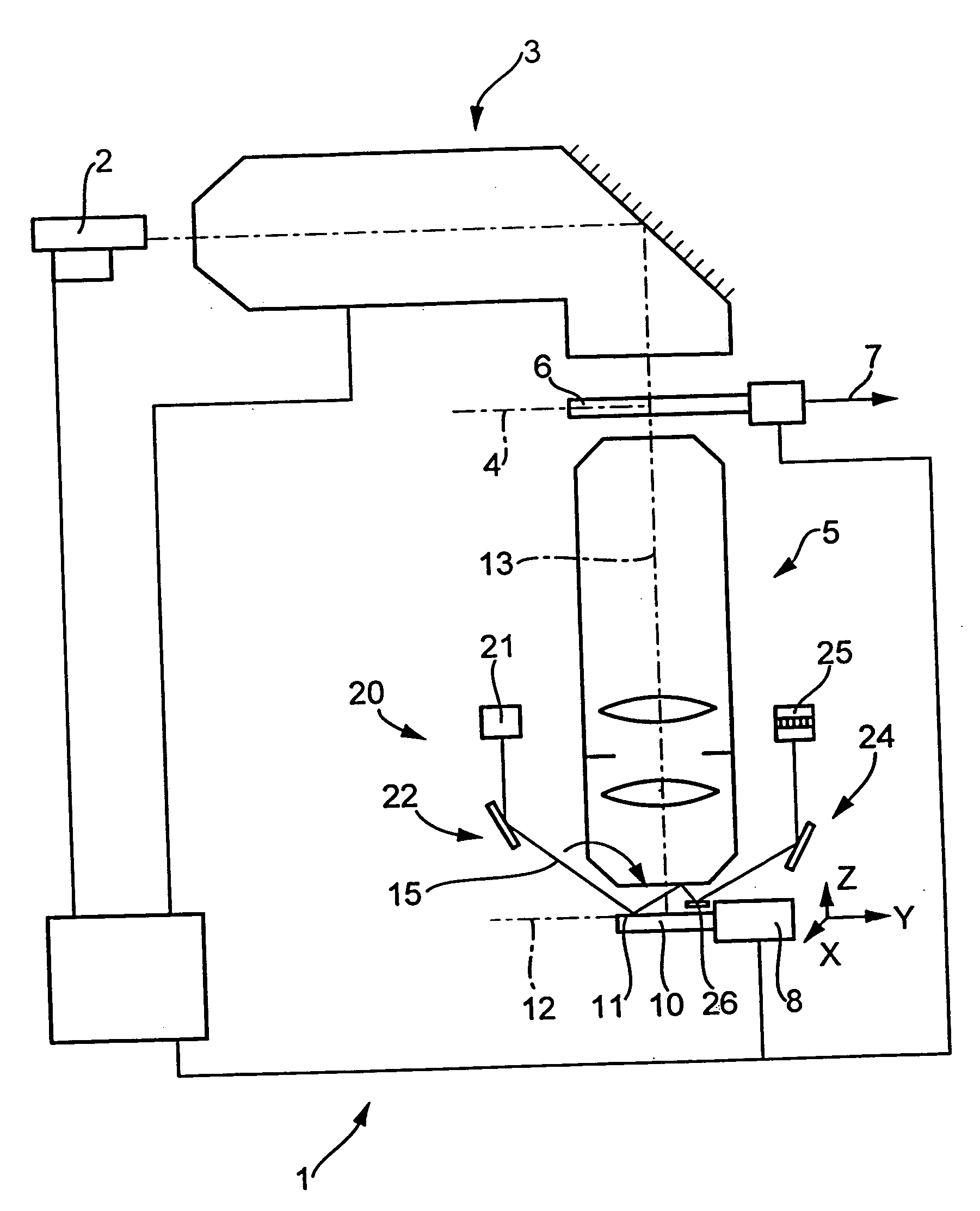

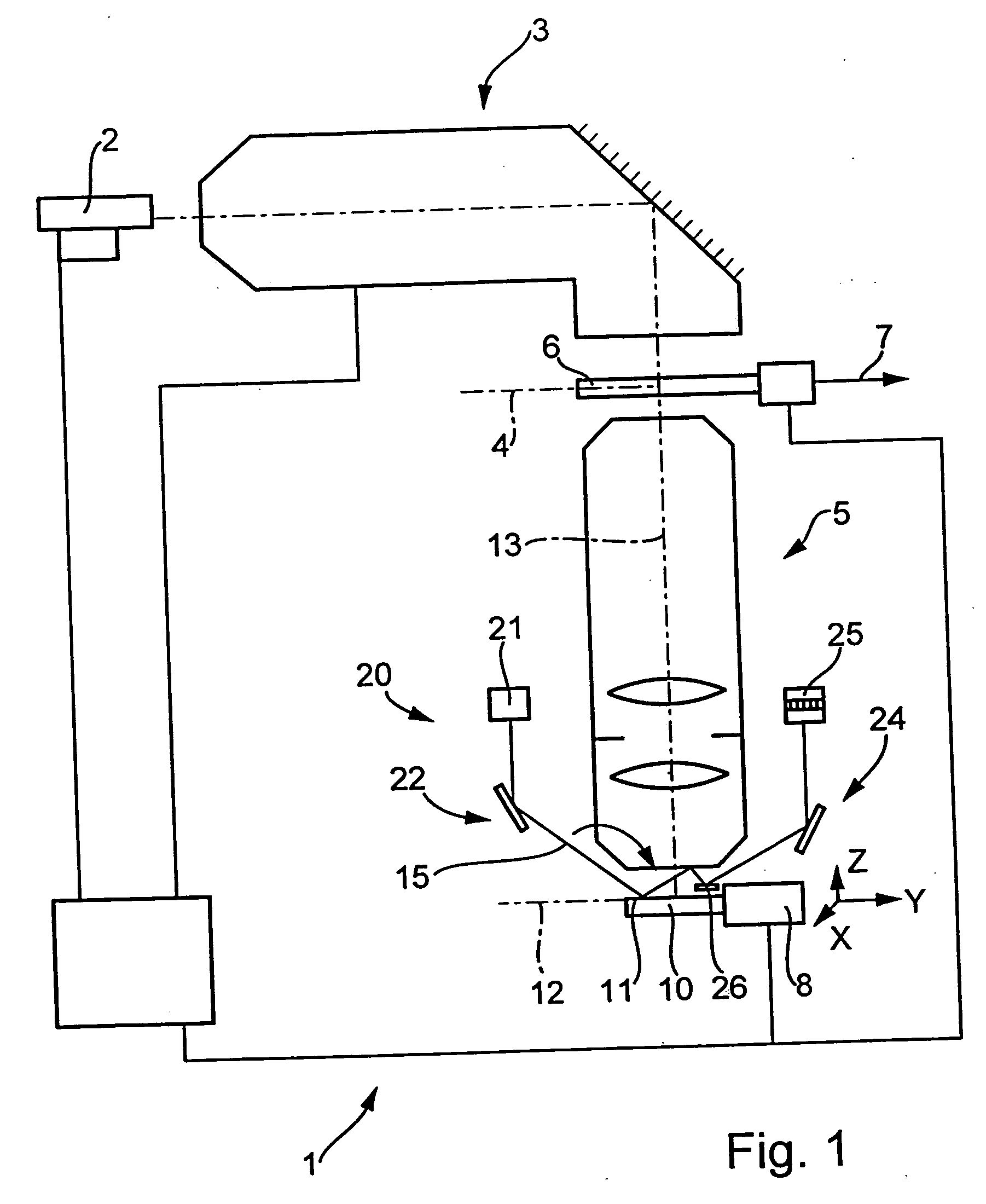

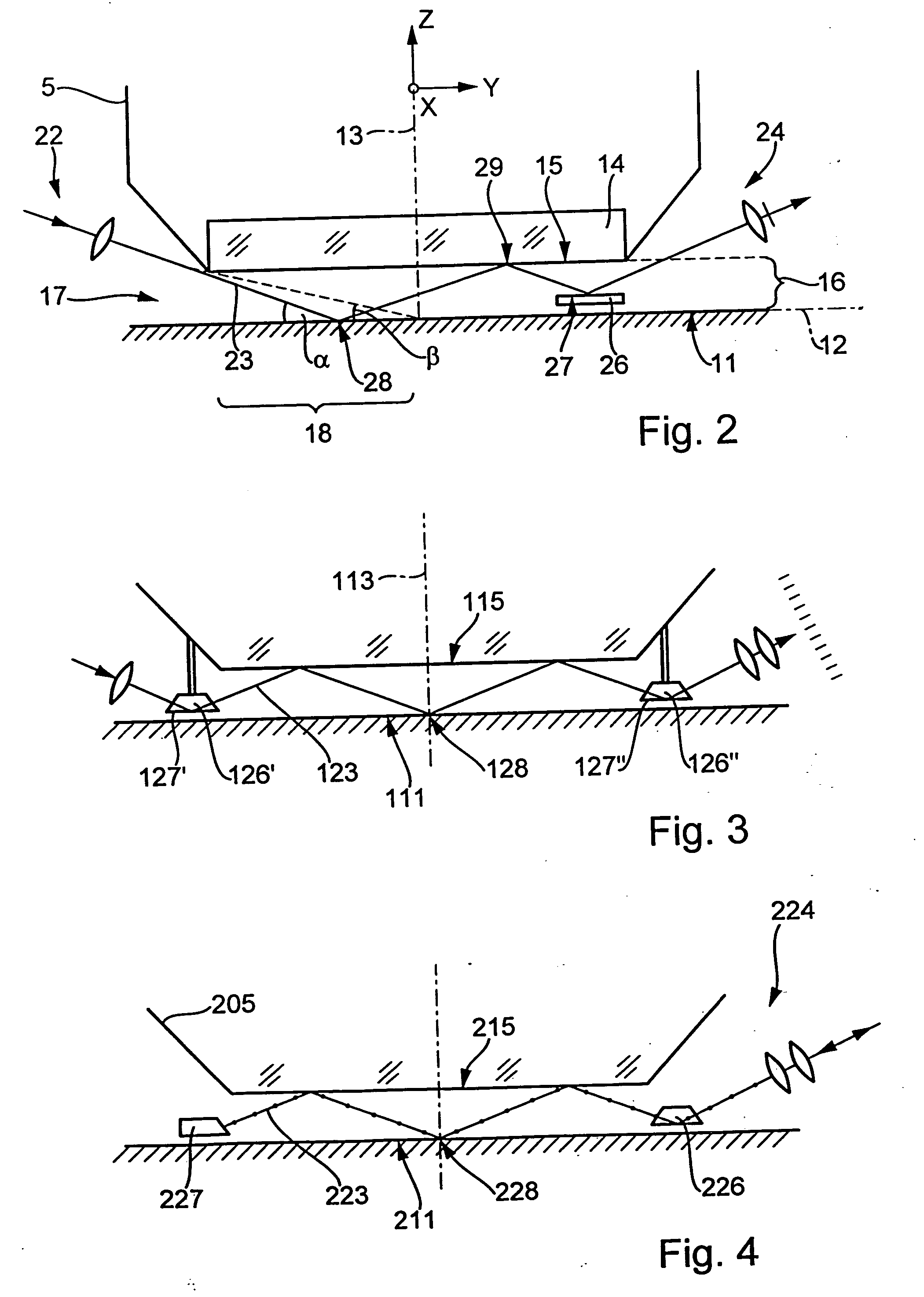

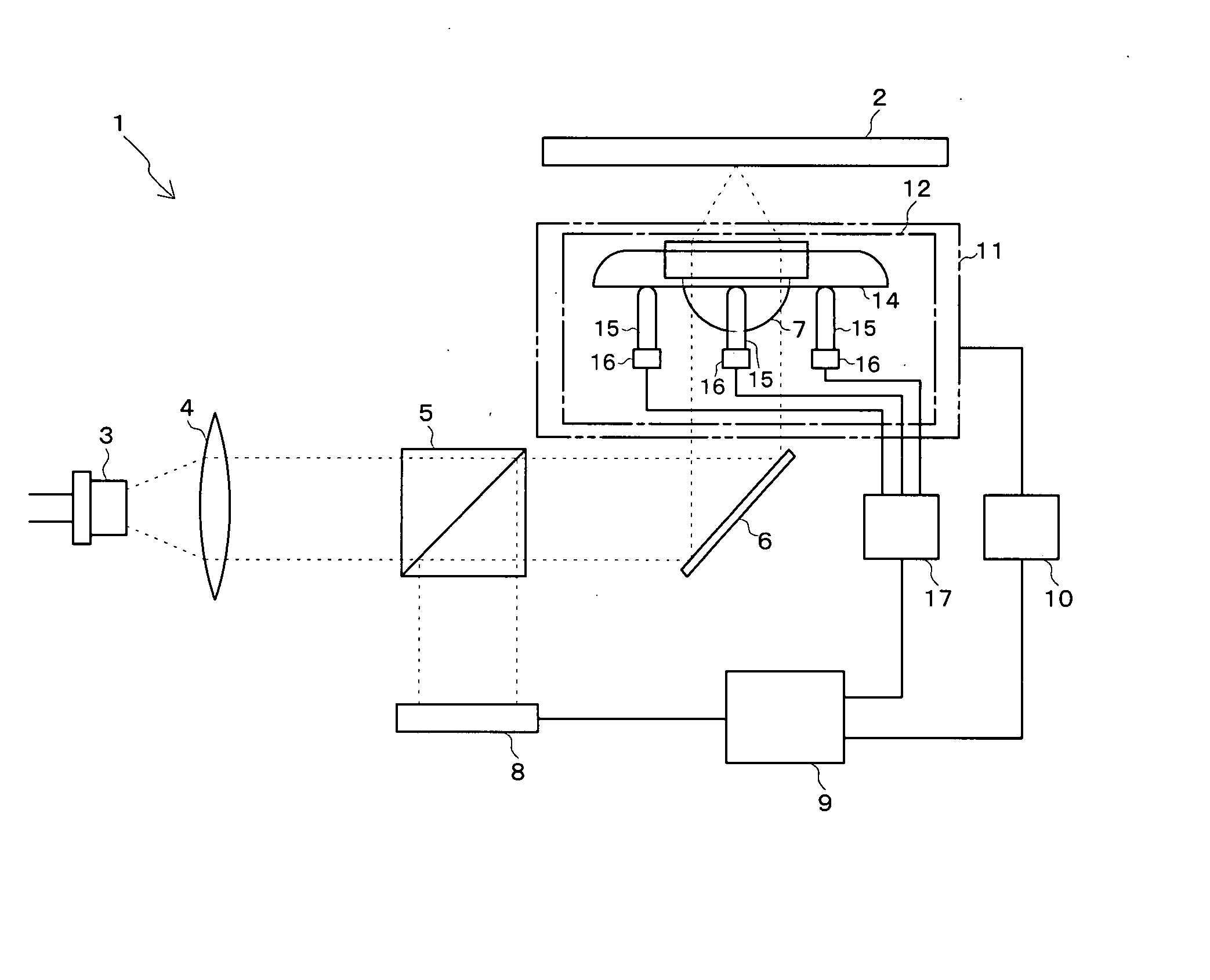

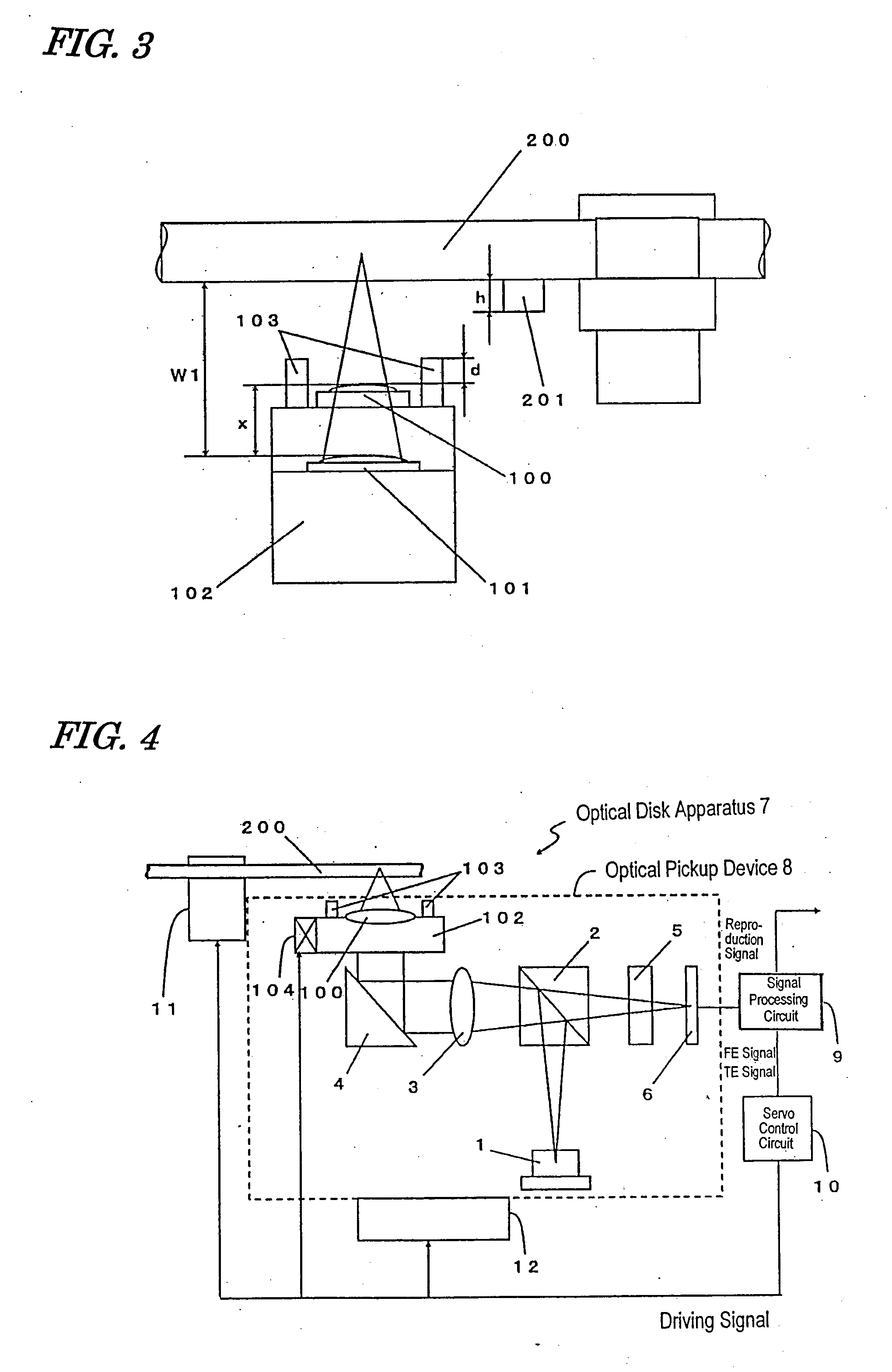

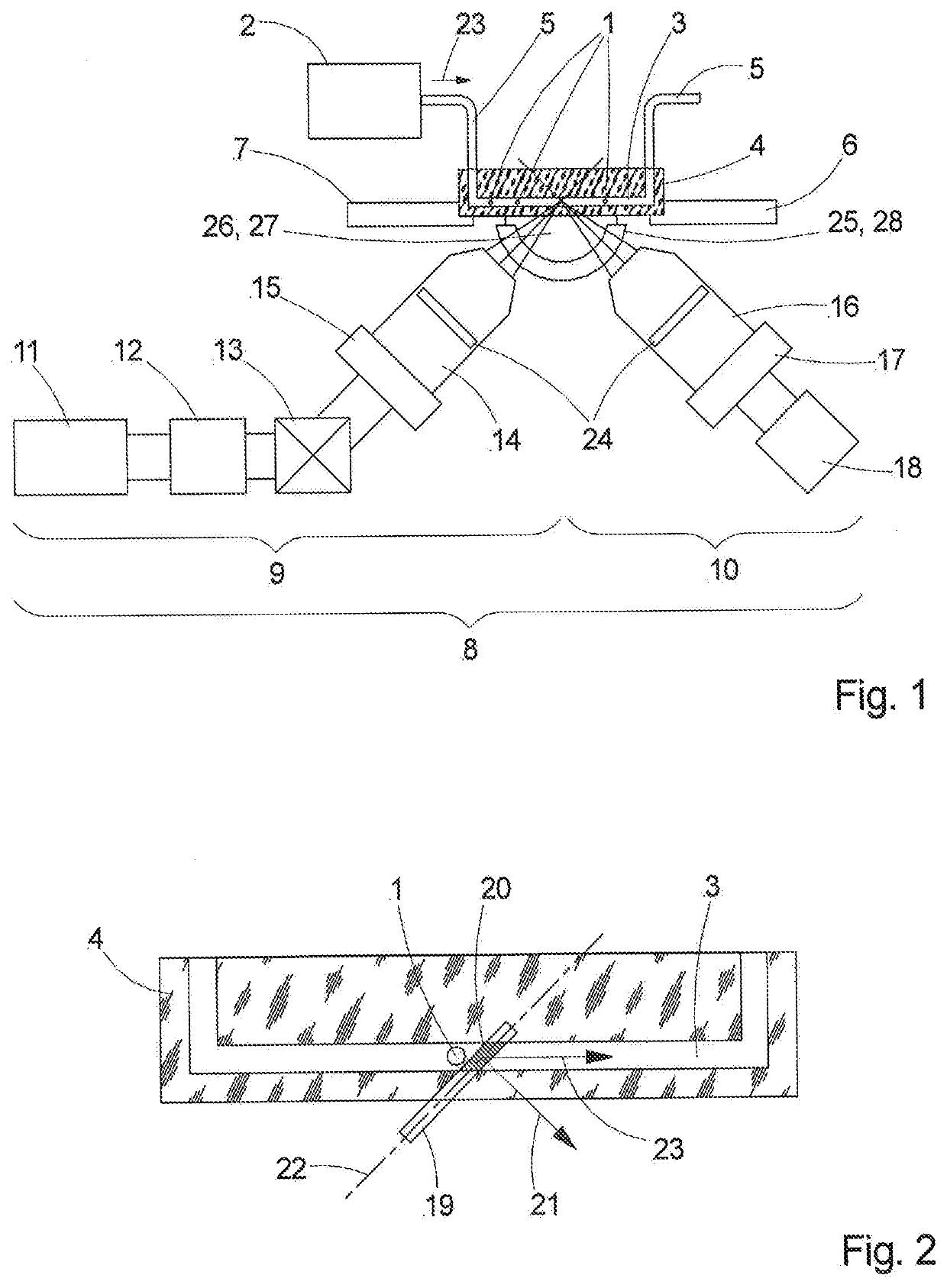

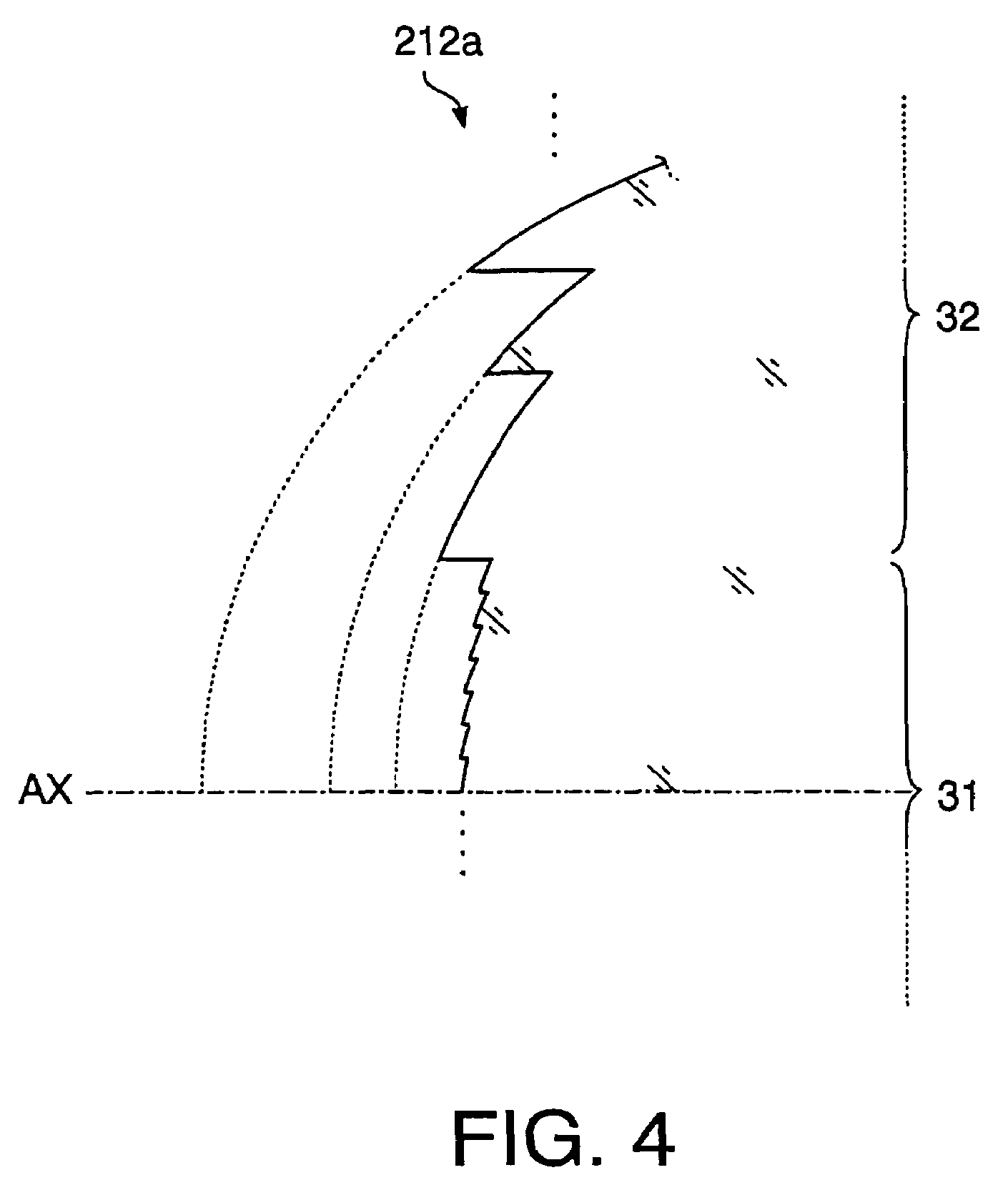

Method for optically detecting deviations of an image plane of an imaging system from the surface of a substrate

InactiveUS20050178944A1High image-side numerical apertureShort working distanceSemiconductor/solid-state device manufacturingMaterial analysis by optical meansLight beamProjection lens

A microlithographic projection illumination system has a focus-detection system for optically detecting deviations of the image plane of a projection lens from the upper surface of a substrate arranged in the vicinity of its image plane. The focus-detection system has a system for coupling in at least one measuring beam that is obliquely incident on, and to be reflected at, the substrate surface into an intermediate zone between the final optical surface of the imaging system and the substrate surface and a system for coupling out the measuring beam and detecting it following its reflection at the substrate surface. The system for coupling the measuring beam in and the system for coupling it out are configured such that the measuring beam is reflected at least once at the substrate surface and at least once at a reflecting surface of the imaging system that reflects the light employed for measurement purposes before the measuring beam enters the system for coupling it out, which allows employing the image side of the imaging system as part of the focus-detection system. The focus-detection system also operates reliably when used on ultrahigh-aperture lenses that have correspondingly short working distances.

Owner:CARL ZEISS SMT GMBH

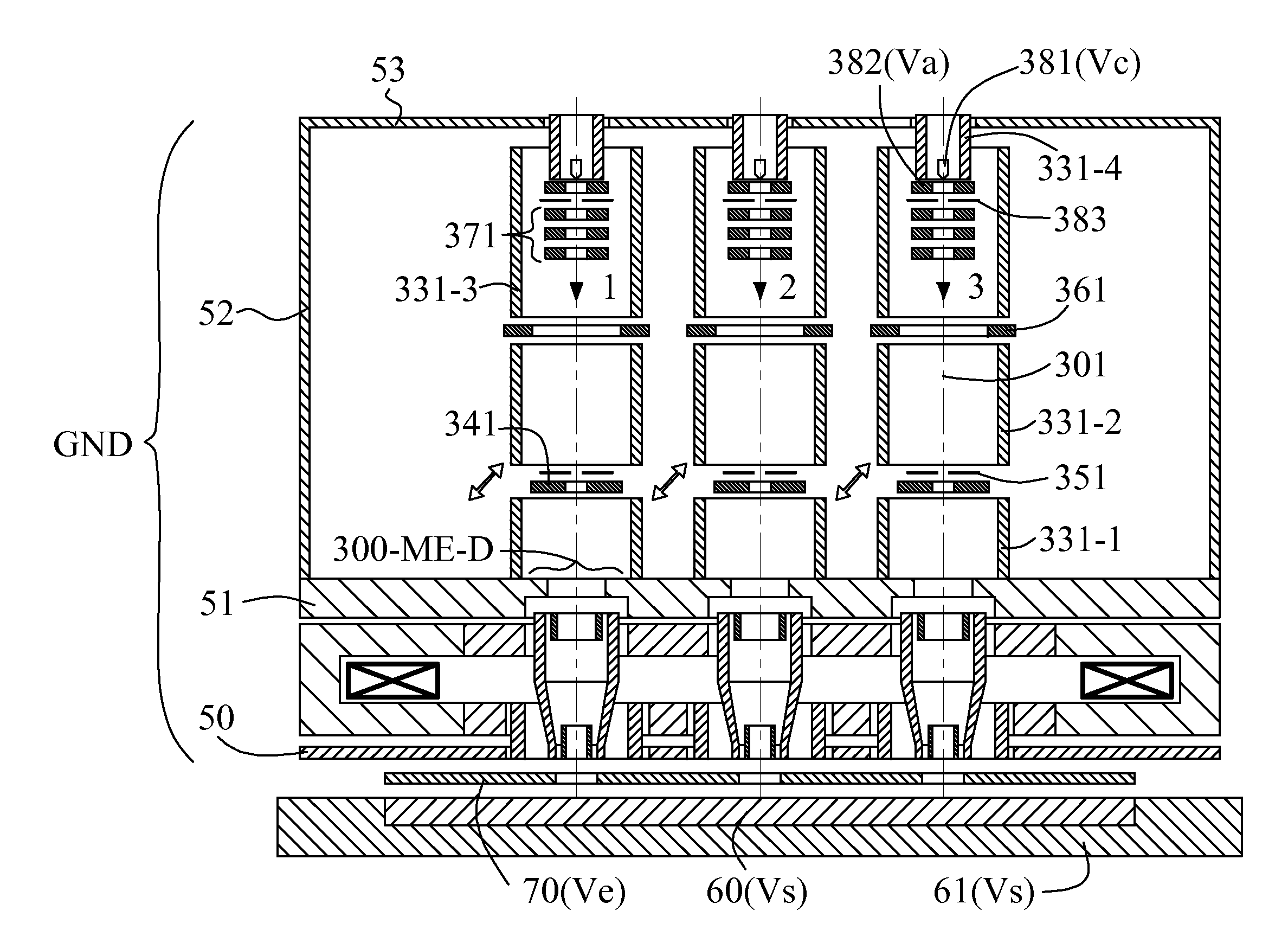

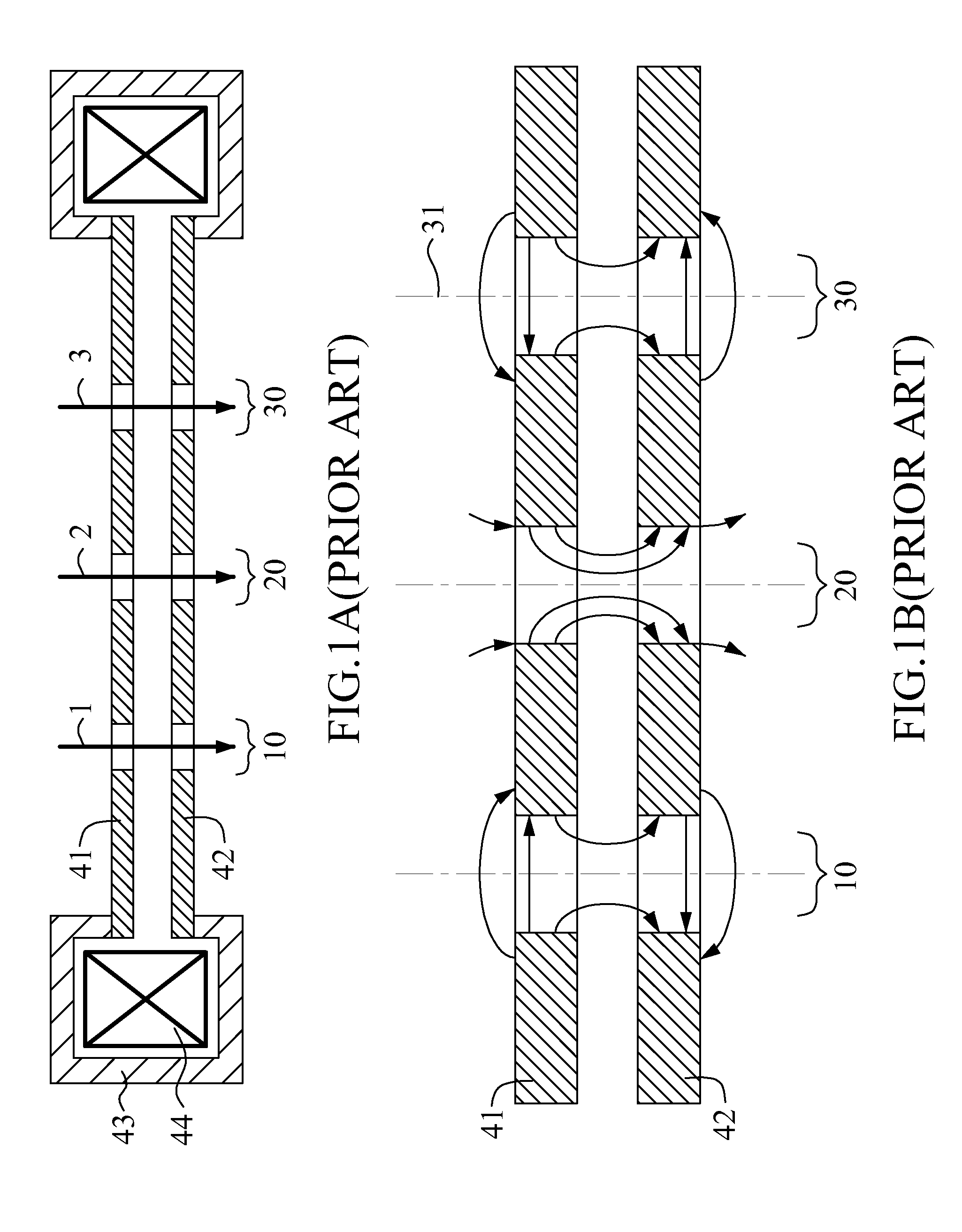

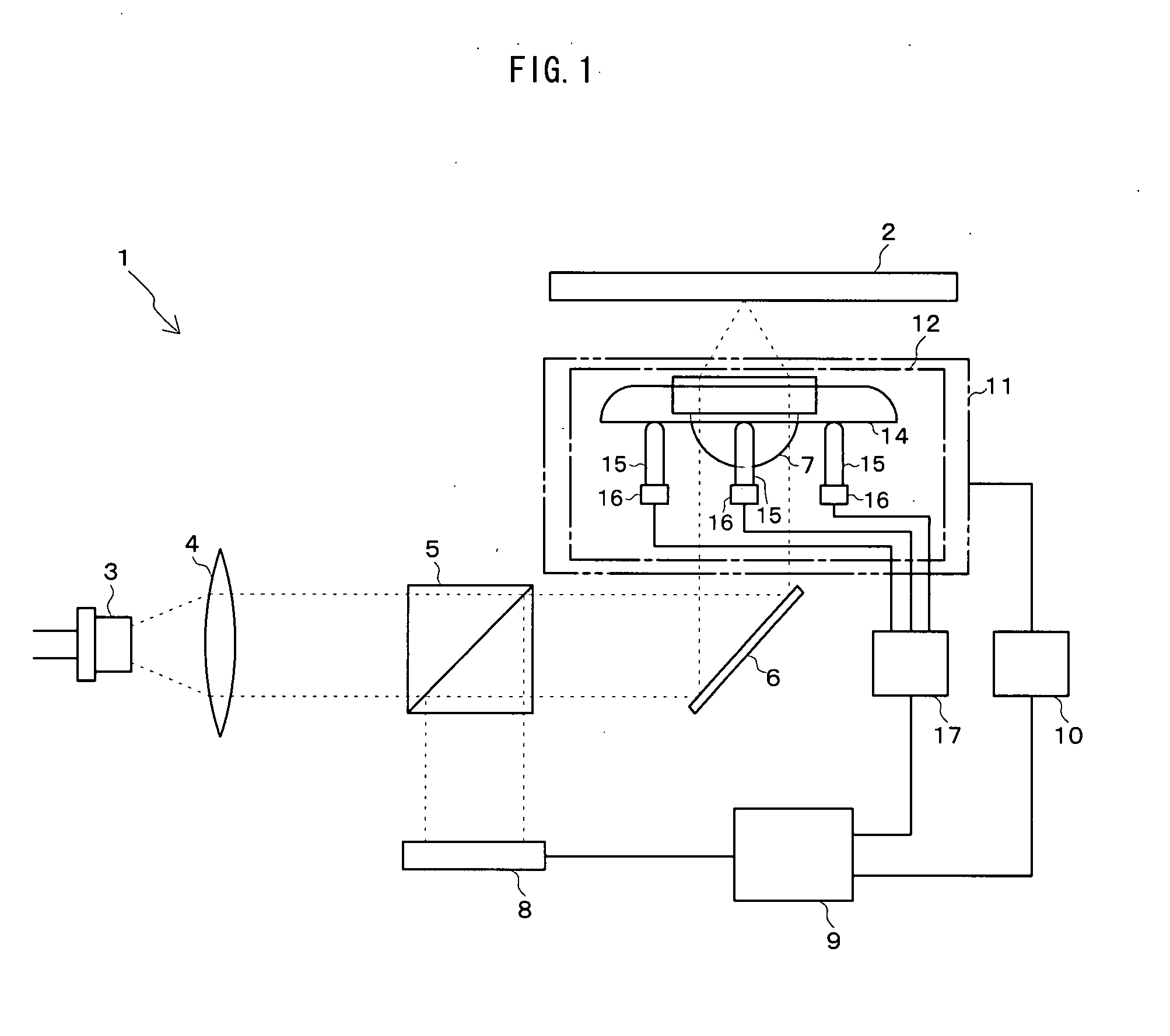

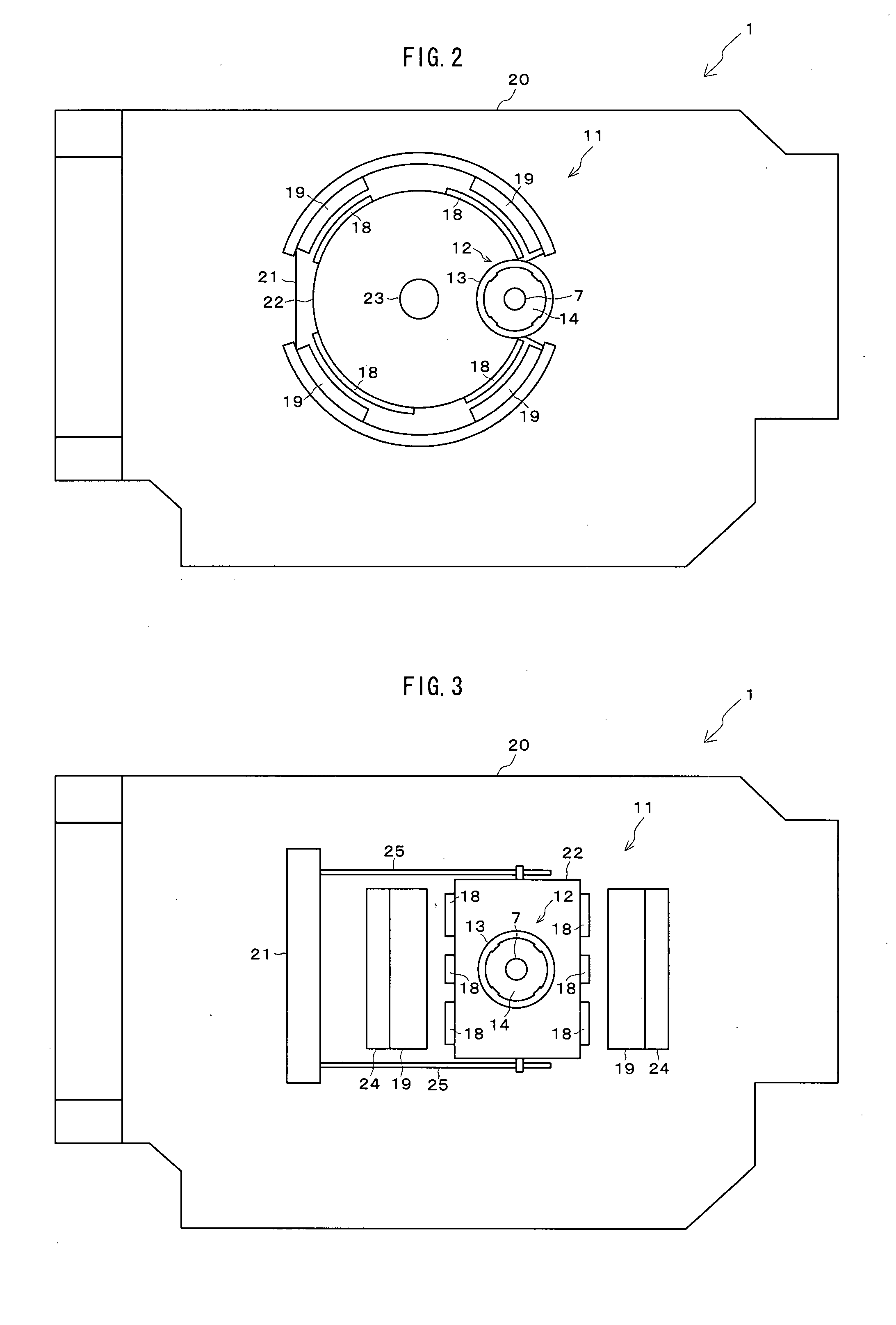

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS8294095B2Low aberration lowAvoid damageMaterial analysis using wave/particle radiationElectrode and associated part arrangementsCouplingOptical axis

Owner:ASML NETHERLANDS BV

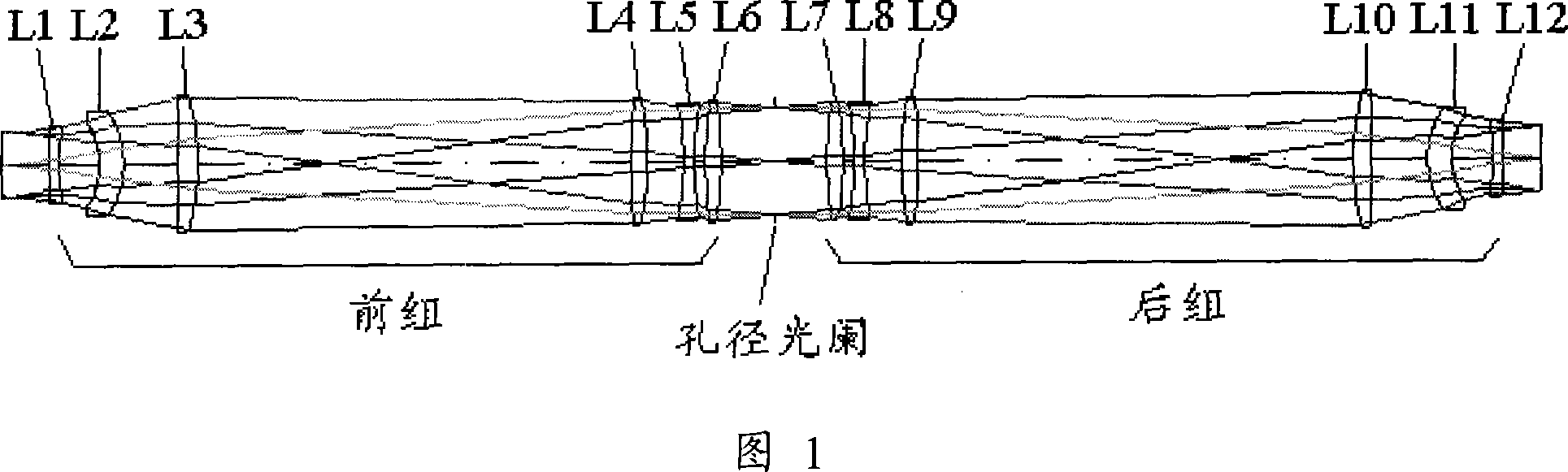

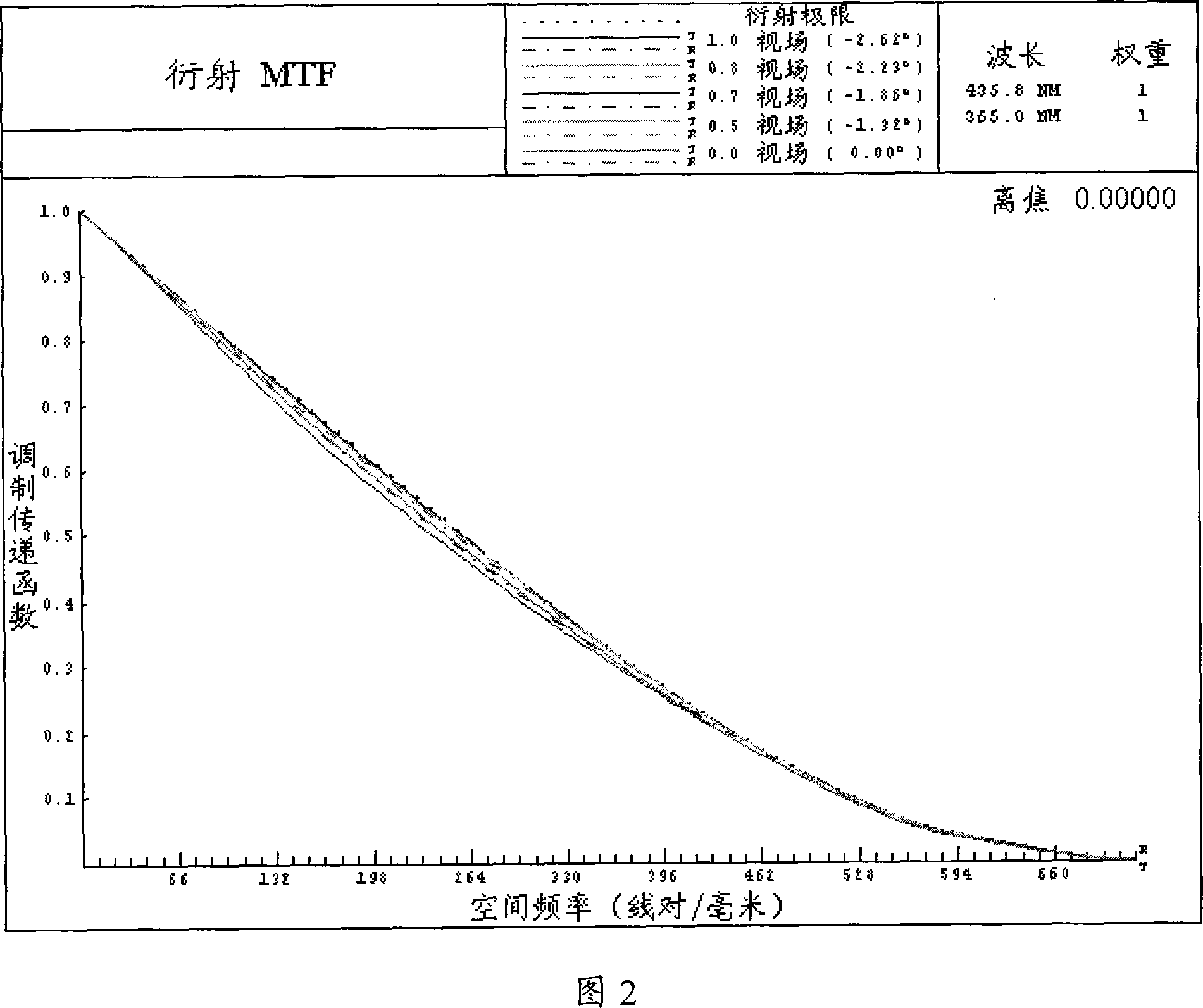

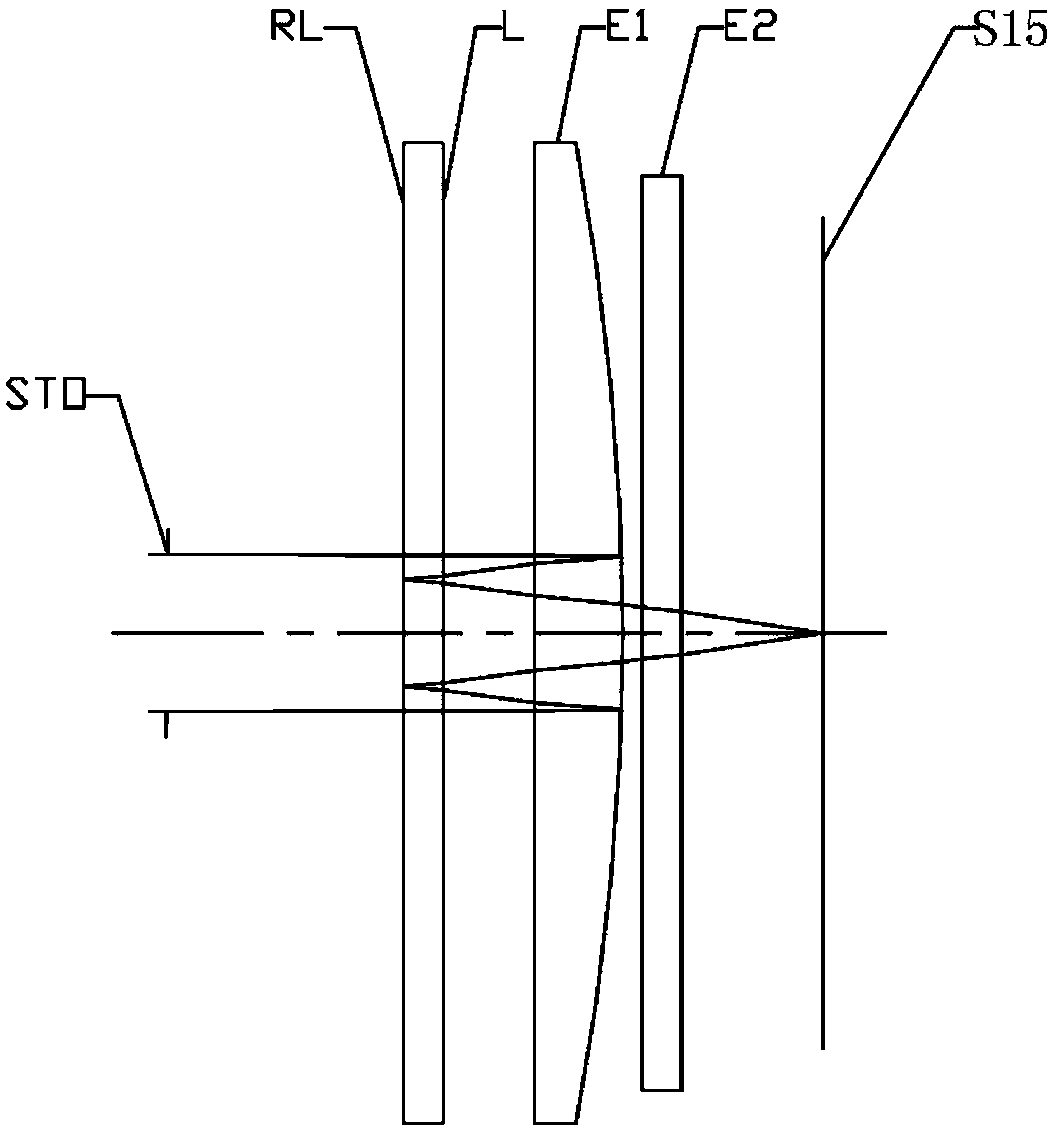

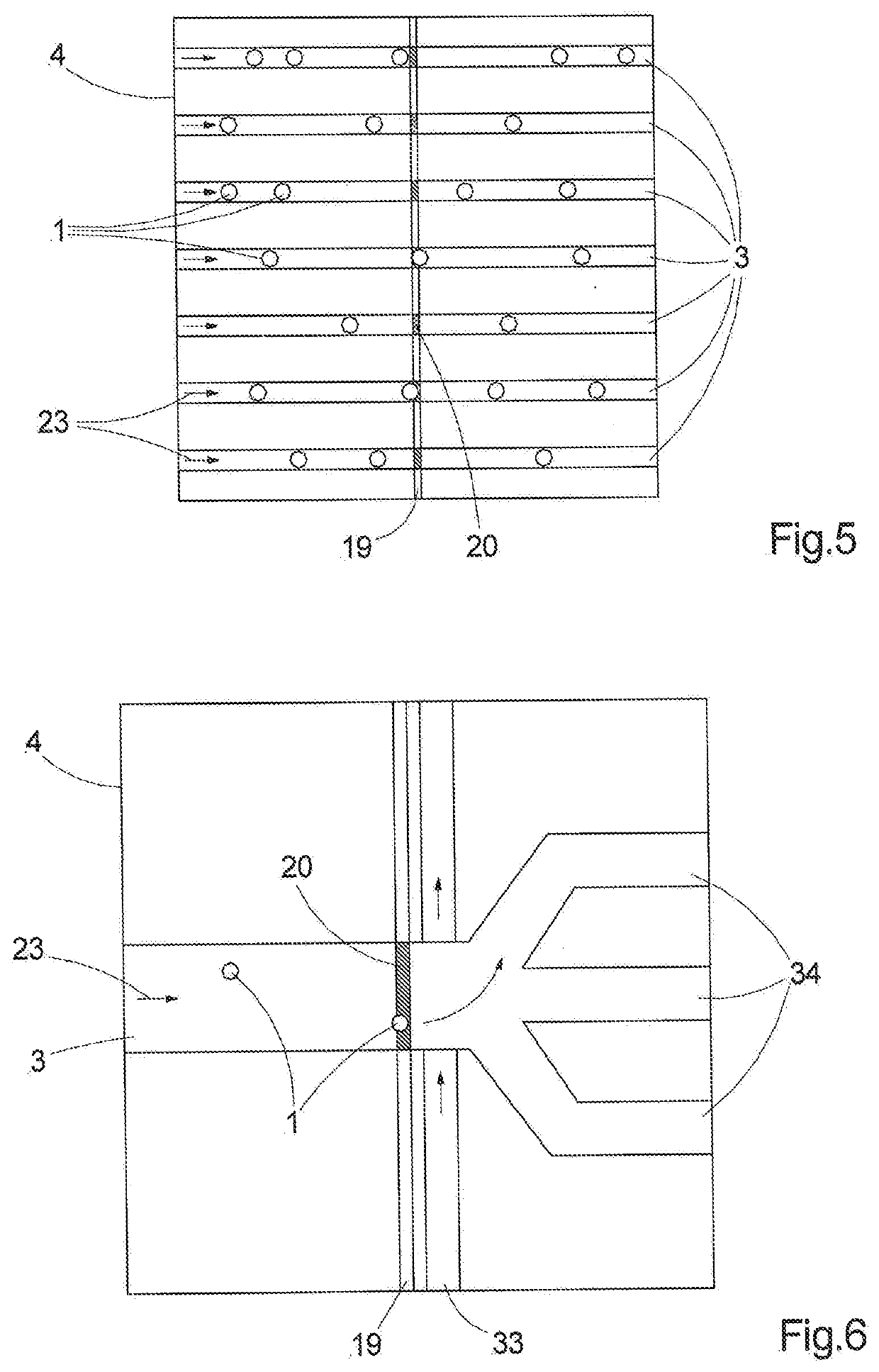

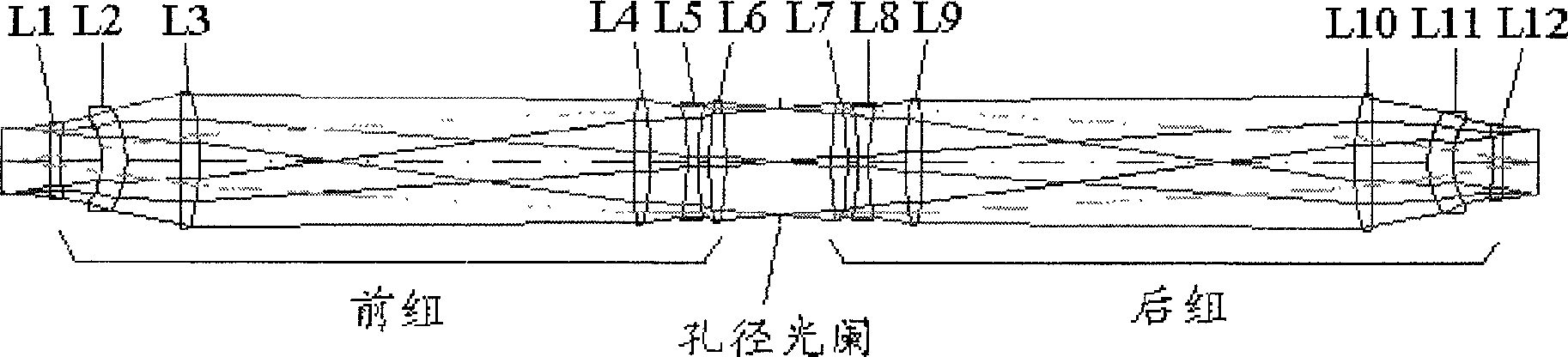

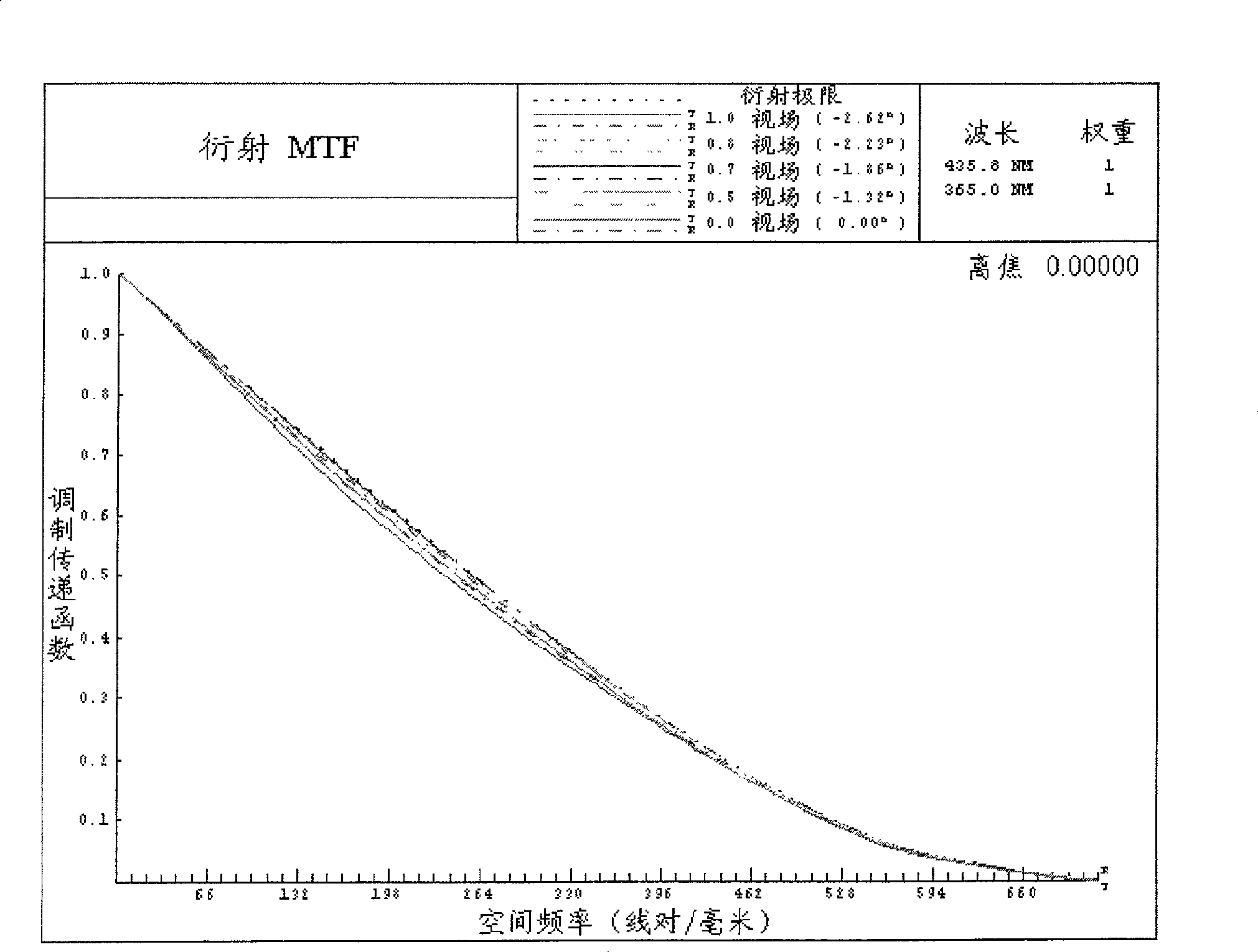

Full refraction projection optical system

ActiveCN101063743AEffective correctionImprove image qualityOptical elementsImaging qualityOptical axis

This invention provides one total reflection projection optical system for object plane to form imaging plane, wherein the said system is divided into front and back sets to form hole diaphragm as symmetric surfaces; the front set comprises first to sixth lens with one to three lens form reverse distant structure; the back set orderly comprises seven to twelve lens symmetric to six to one lens about hole radium; the said whole reflection projection optical system all surface types are of sphere or plane without non-sphere surface.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

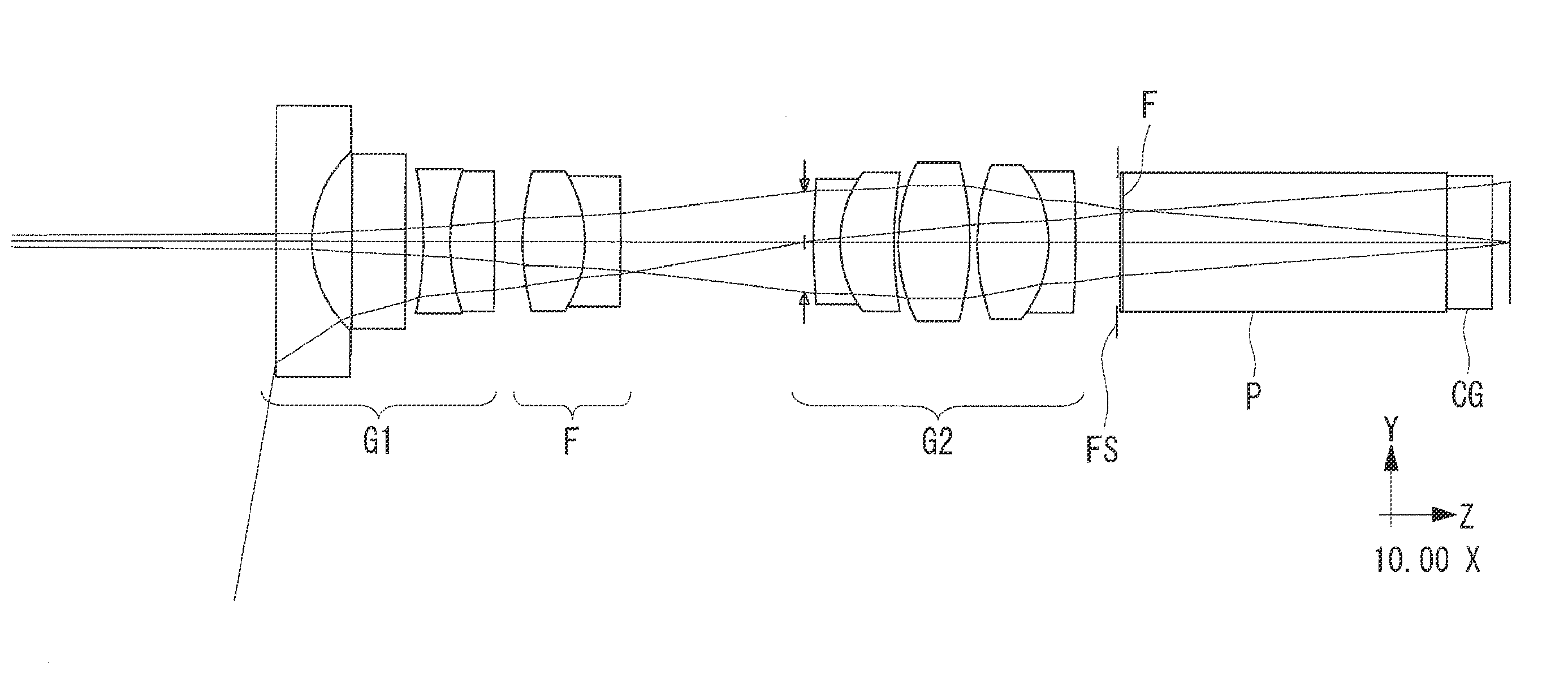

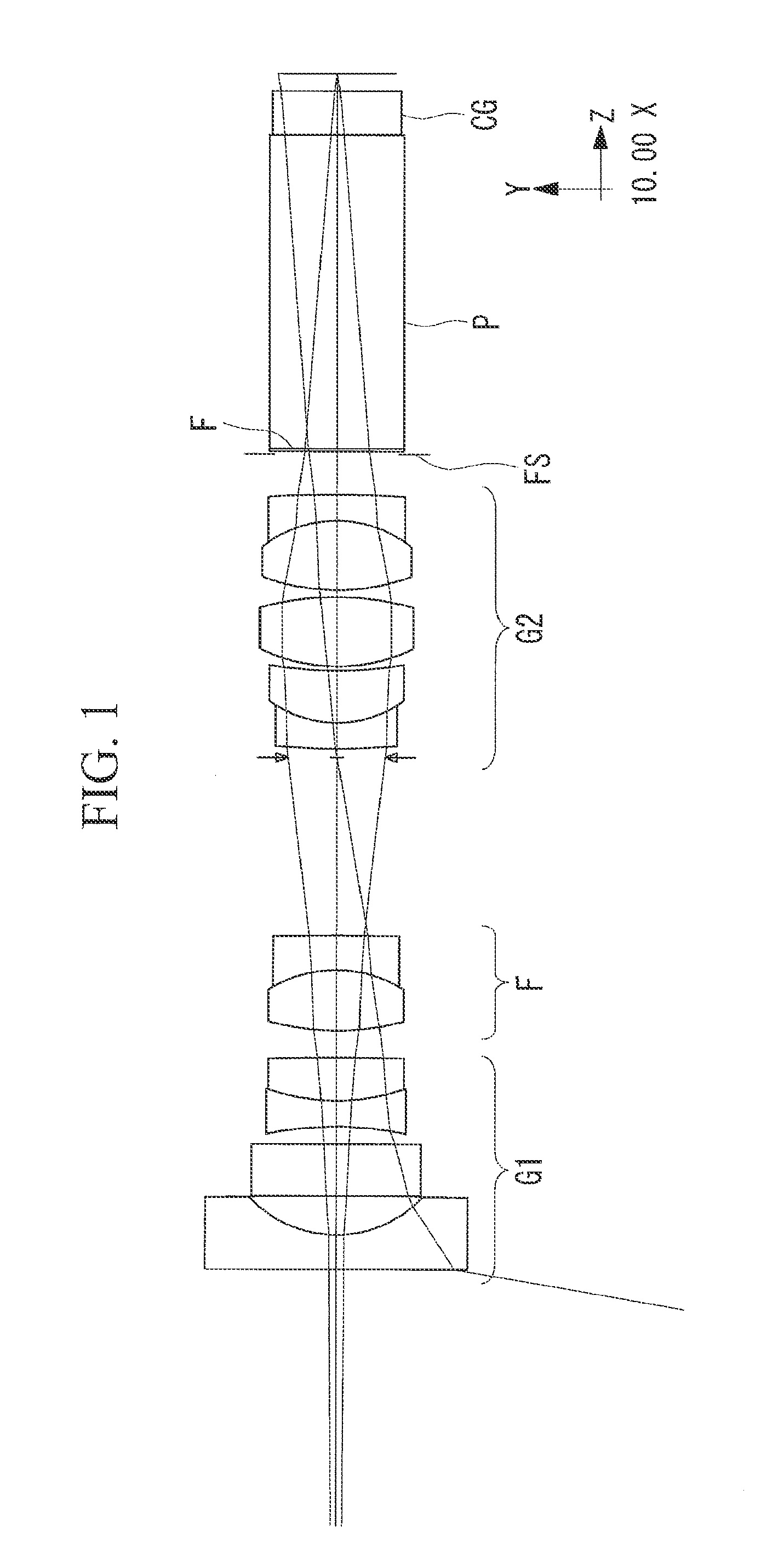

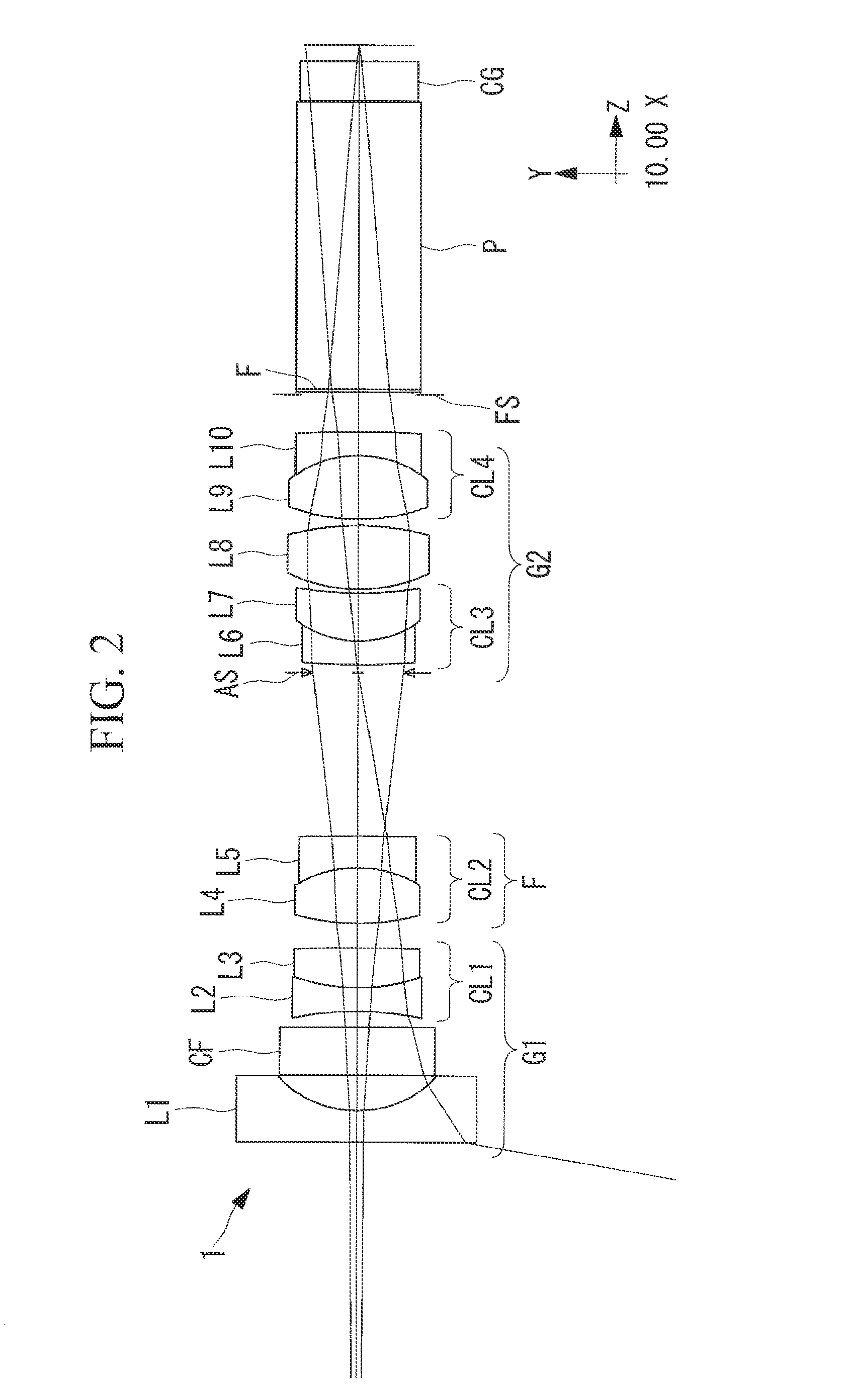

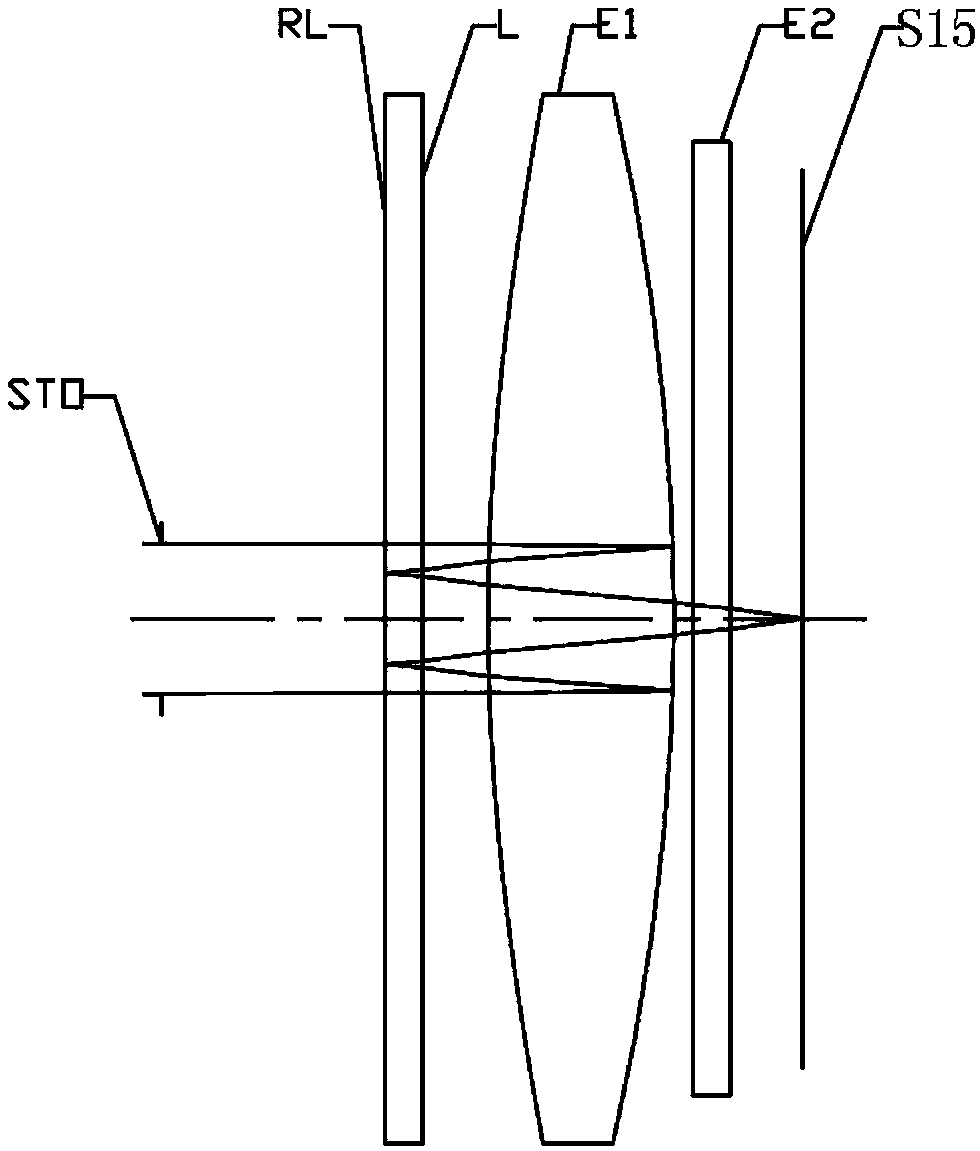

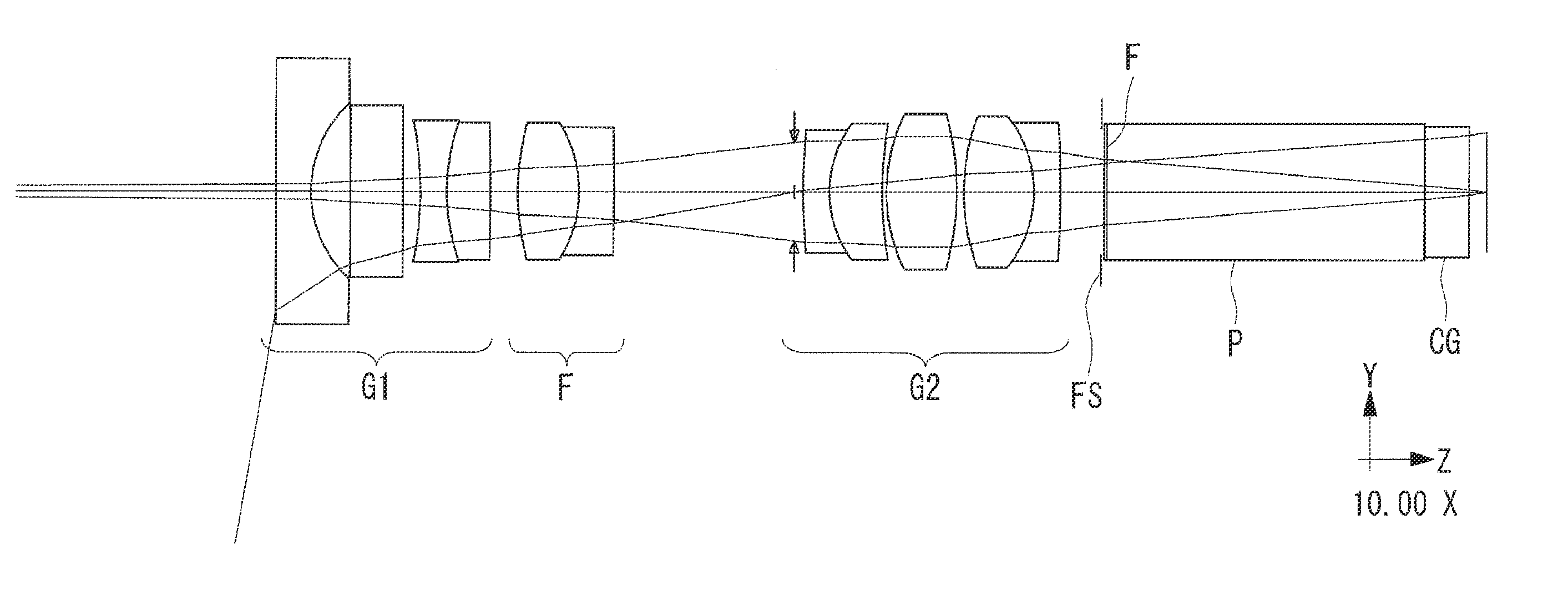

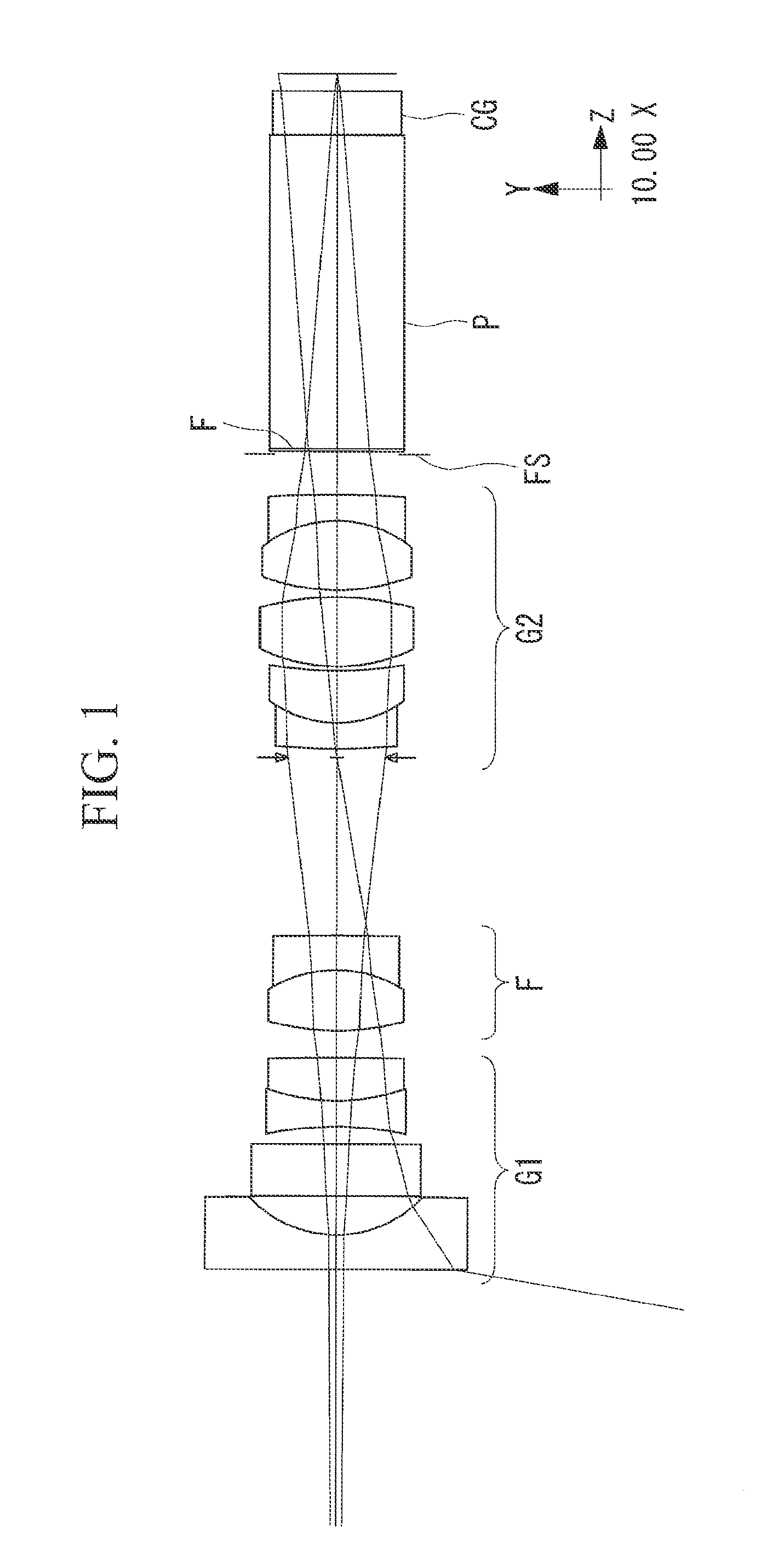

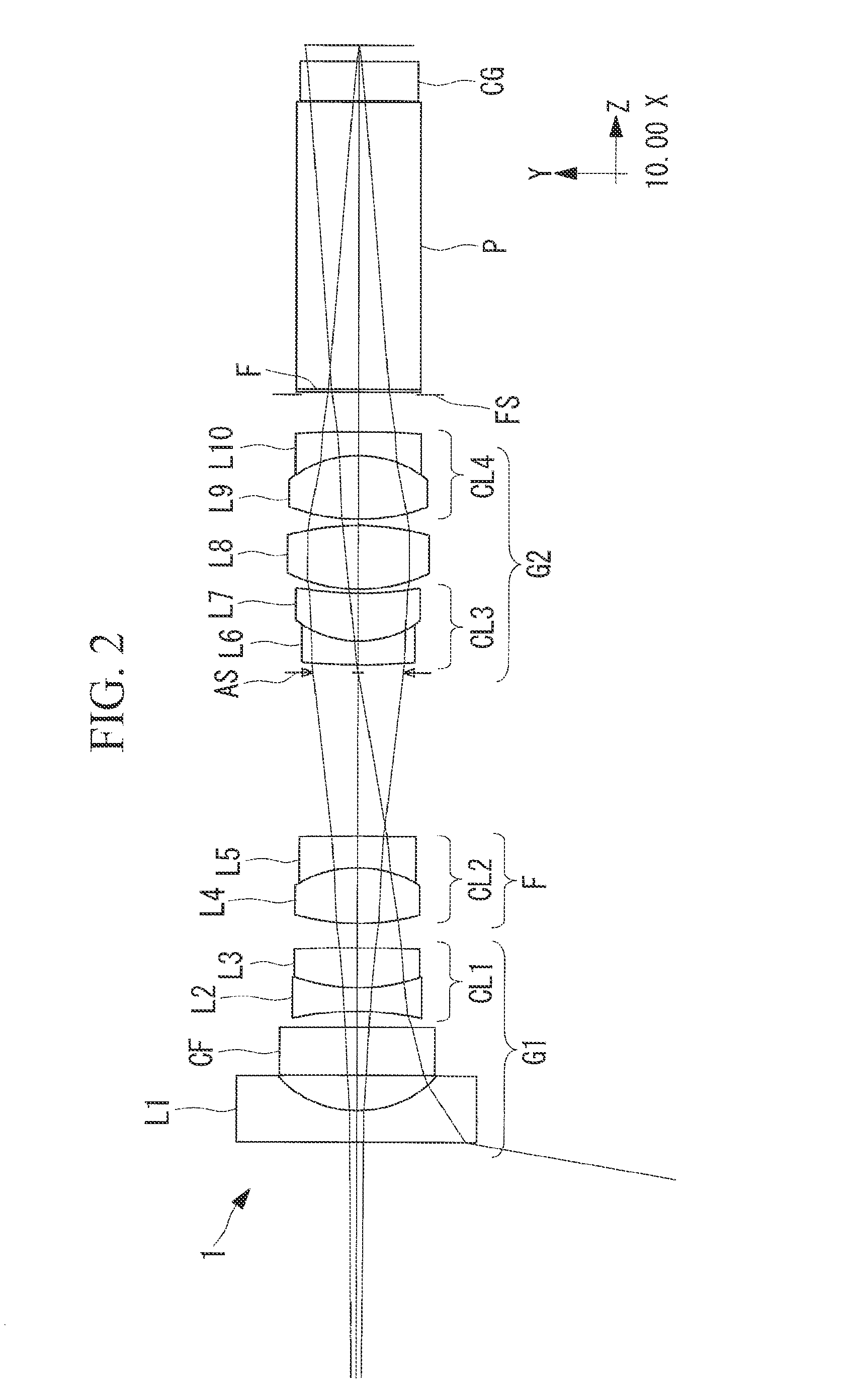

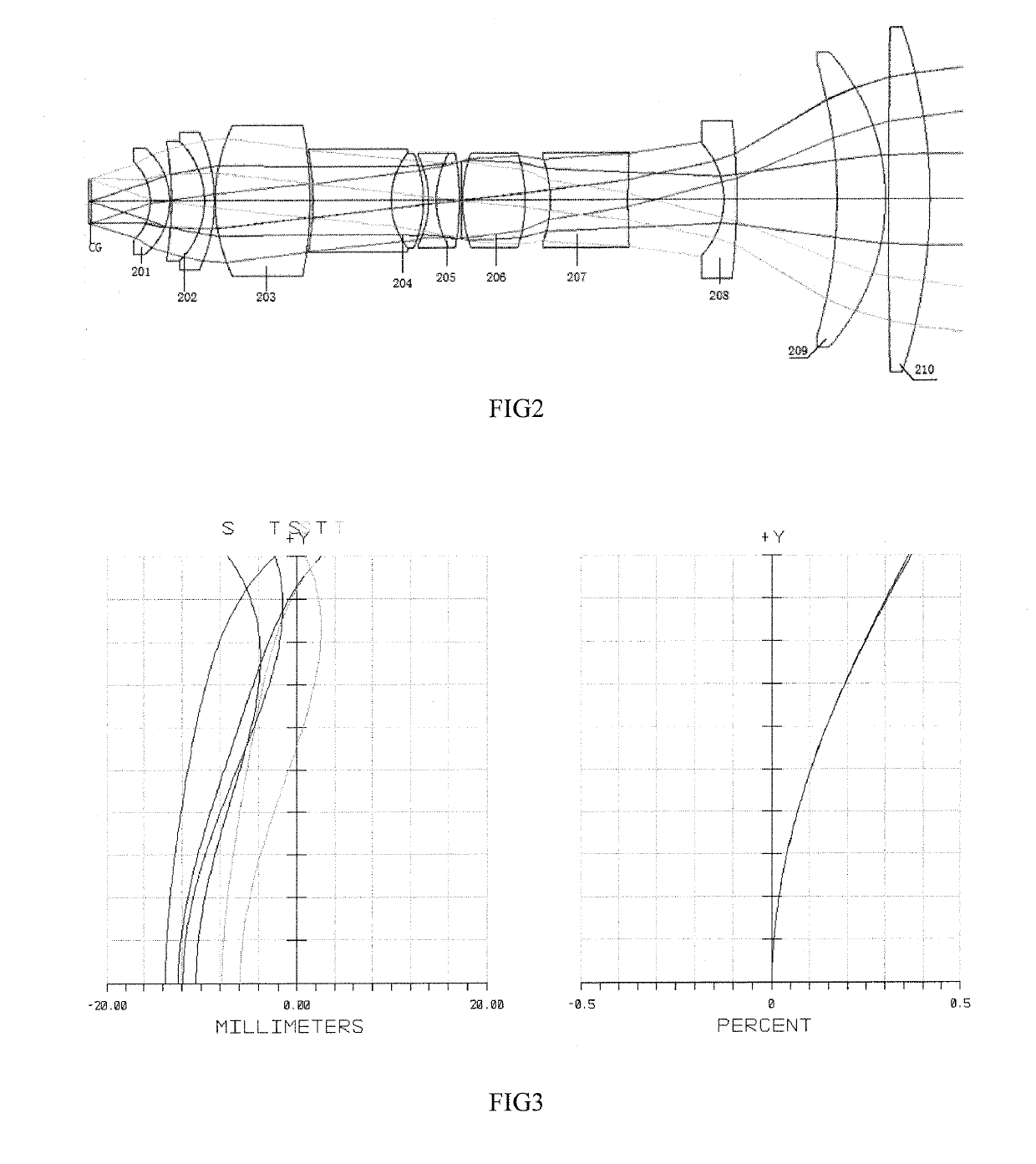

Endoscopic Objective Optical System and Imaging Apparatus

ActiveUS20150042773A1Short work distanceBack focal lengthEndoscopesColor television detailsConditional expressionEngineering

To allow placement of optical members by providing a long back focus, make aberrations less subject to manufacturing errors, and reduce variations in aberrations during focusing. An endoscopic objective optical system includes, in order from an object side, a front group with negative refractive power, a focusing lens, and a rear group with positive refractive power, wherein: the endoscopic objective optical system satisfies conditional expressions (1) to (4) below:4<FB / FL (1)FL / |Fc|<0.1 (2)−3<F—F / FL<−0.9 (3)2.5<F—R / FL<5 (4)where FB is back focus of the entire system, FL is a focal length of the entire system, fc is a focal length of the focusing lens, |fc| is an absolute value of fc, F_F is a focal length of the front group, and F_R is a focal length of the rear group.

Owner:OLYMPUS CORP

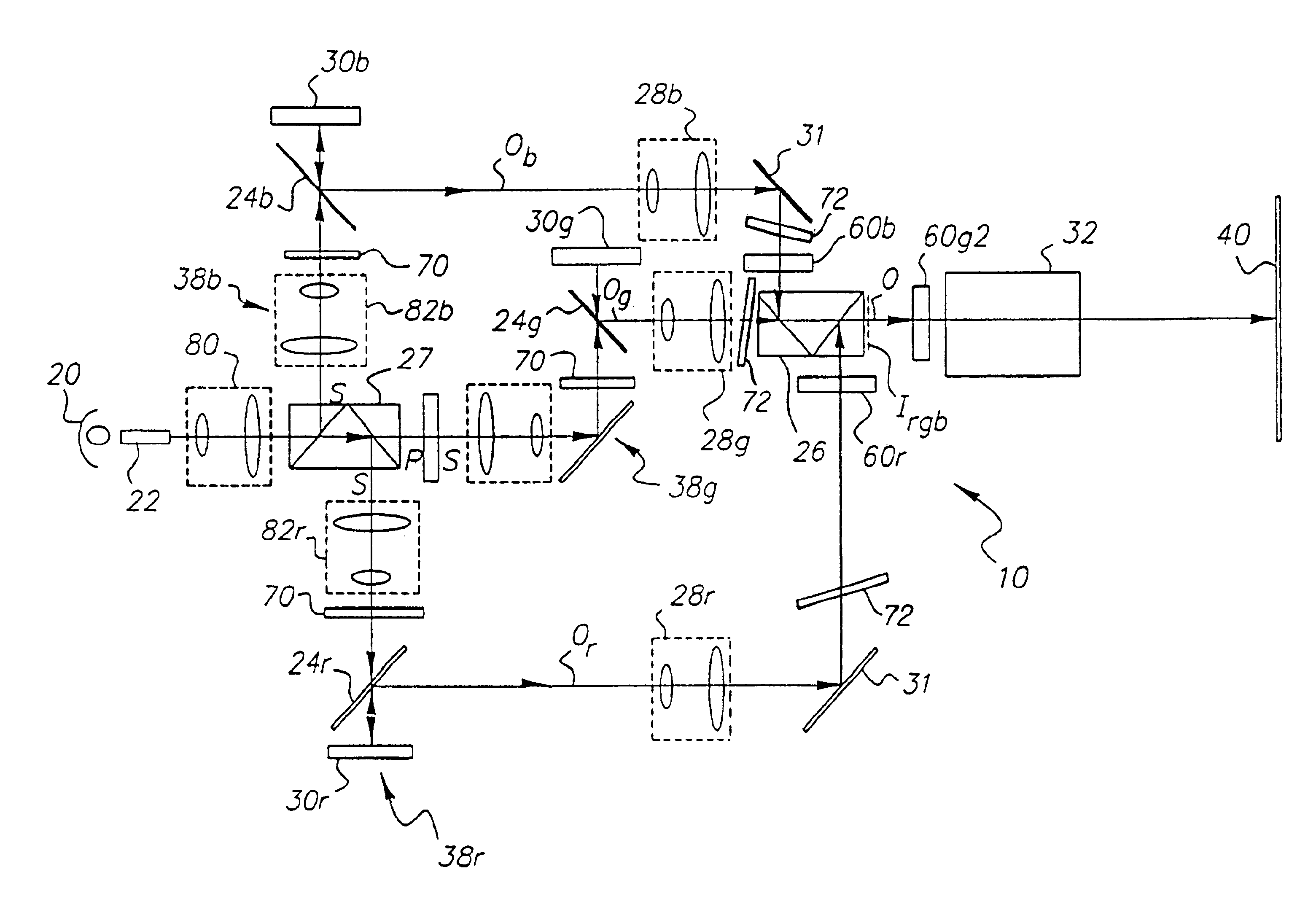

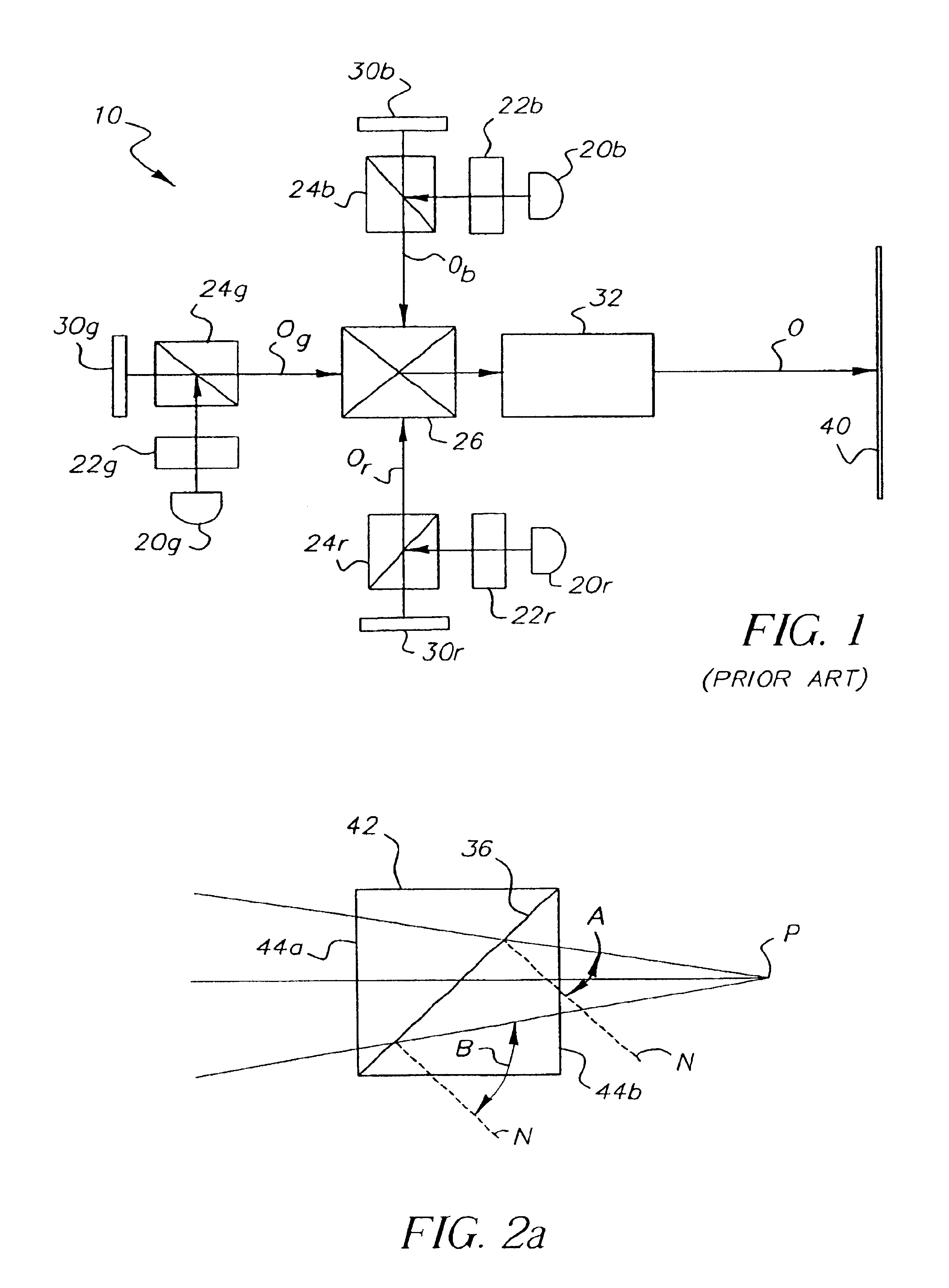

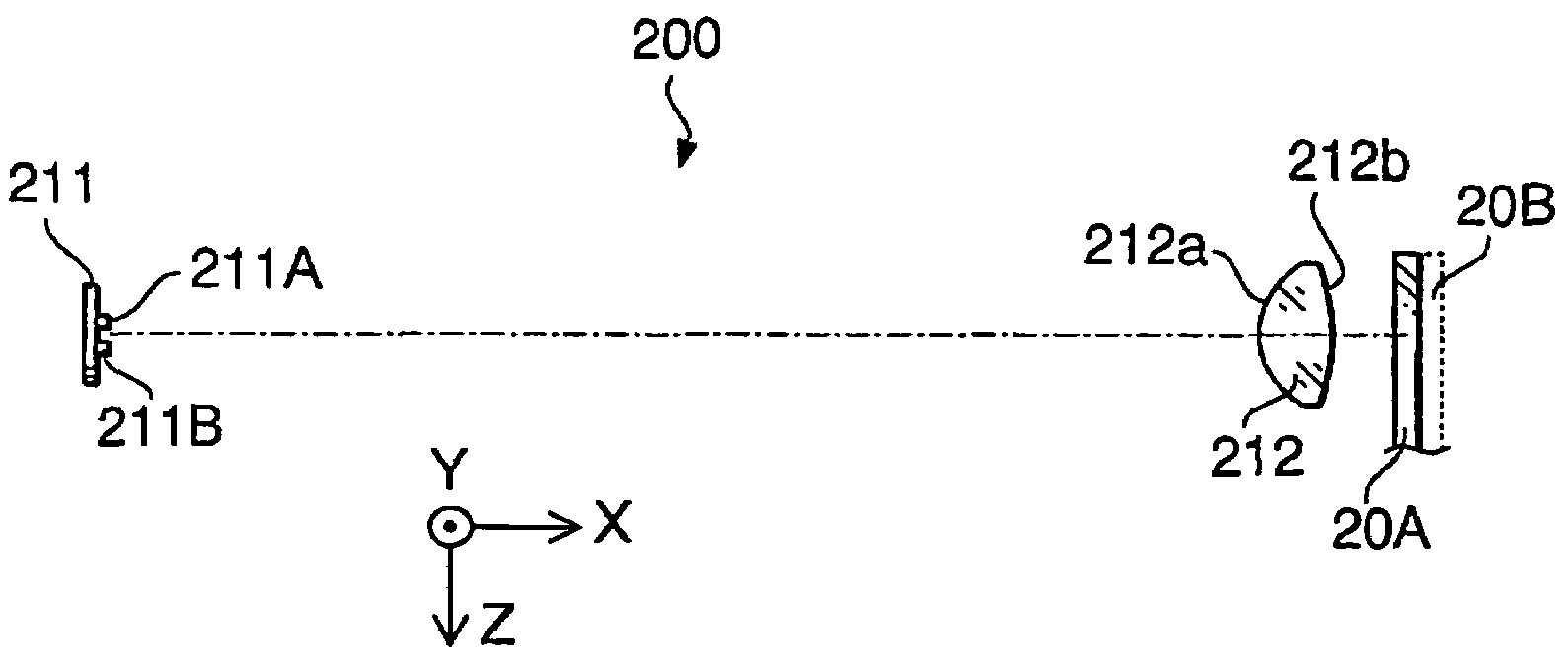

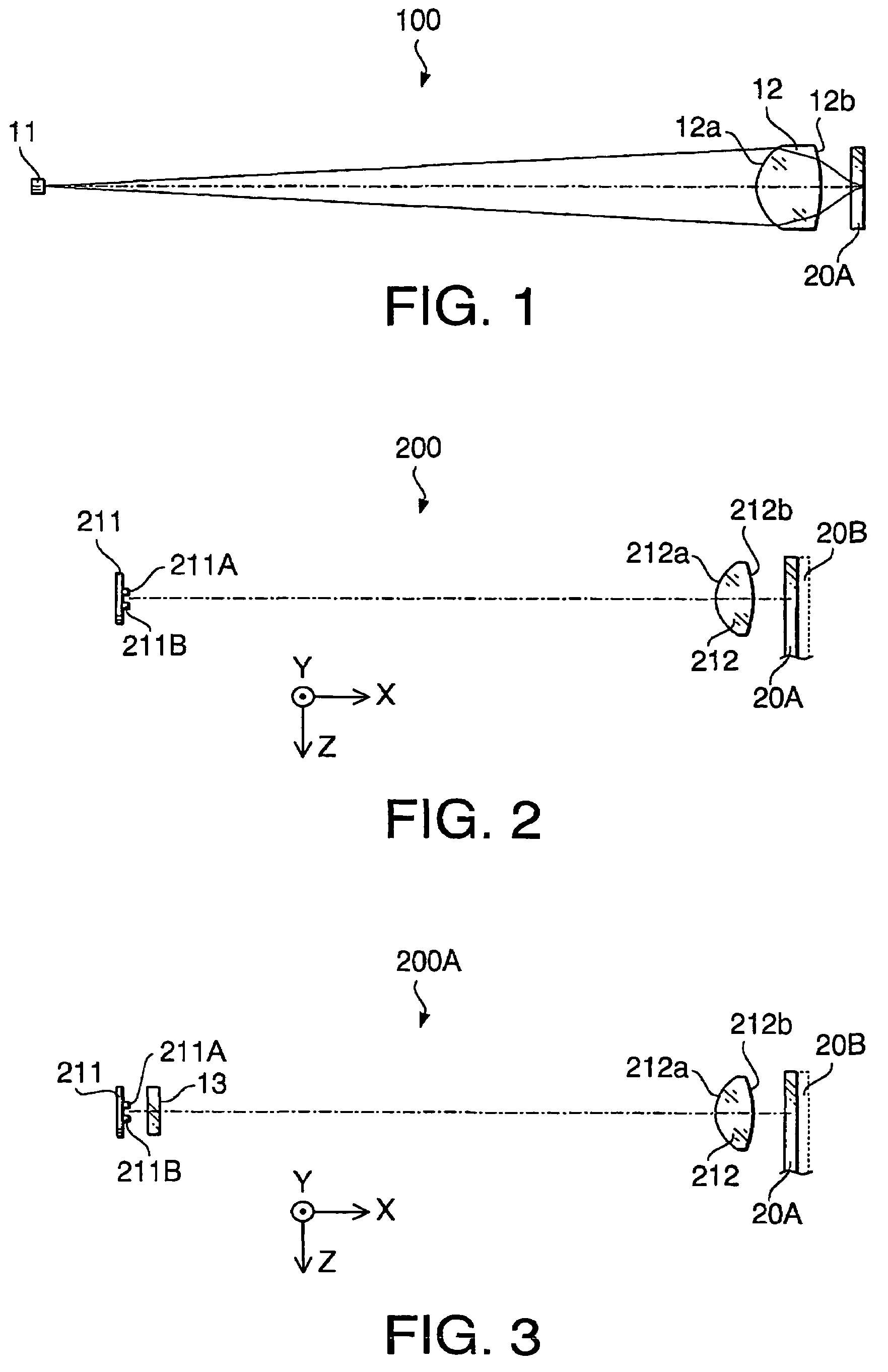

Projection apparatus using telecentric optics

InactiveUS6877859B2Less expensiveEasy to changeTelevision system detailsProjectorsSpatial light modulatorOptical axis

A digital projection apparatus (10) for projection of a multicolor image. A light source (20) provides visible light and a dichroic separator (27) splits the visible light into color light beams. Illumination optics directs each of the color light beams into a corresponding light modulation assembly (38). A magnifying relay lens (28) for each color light beam focuses and relays the modulated light to form a magnified real image of the reflective spatial light modulator (30). A dichroic combiner (26) forms a multicolor image by overlapping the magnified real images corresponding to each of the color light beams on a common optical axis. A projection lens projects the multicolor image toward a display surface. The polarization analyzers (72) are tilted relative to a local optical axis and are located in proximity to at least one of the magnified real images of the color light beams.

Owner:EASTMAN KODAK CO

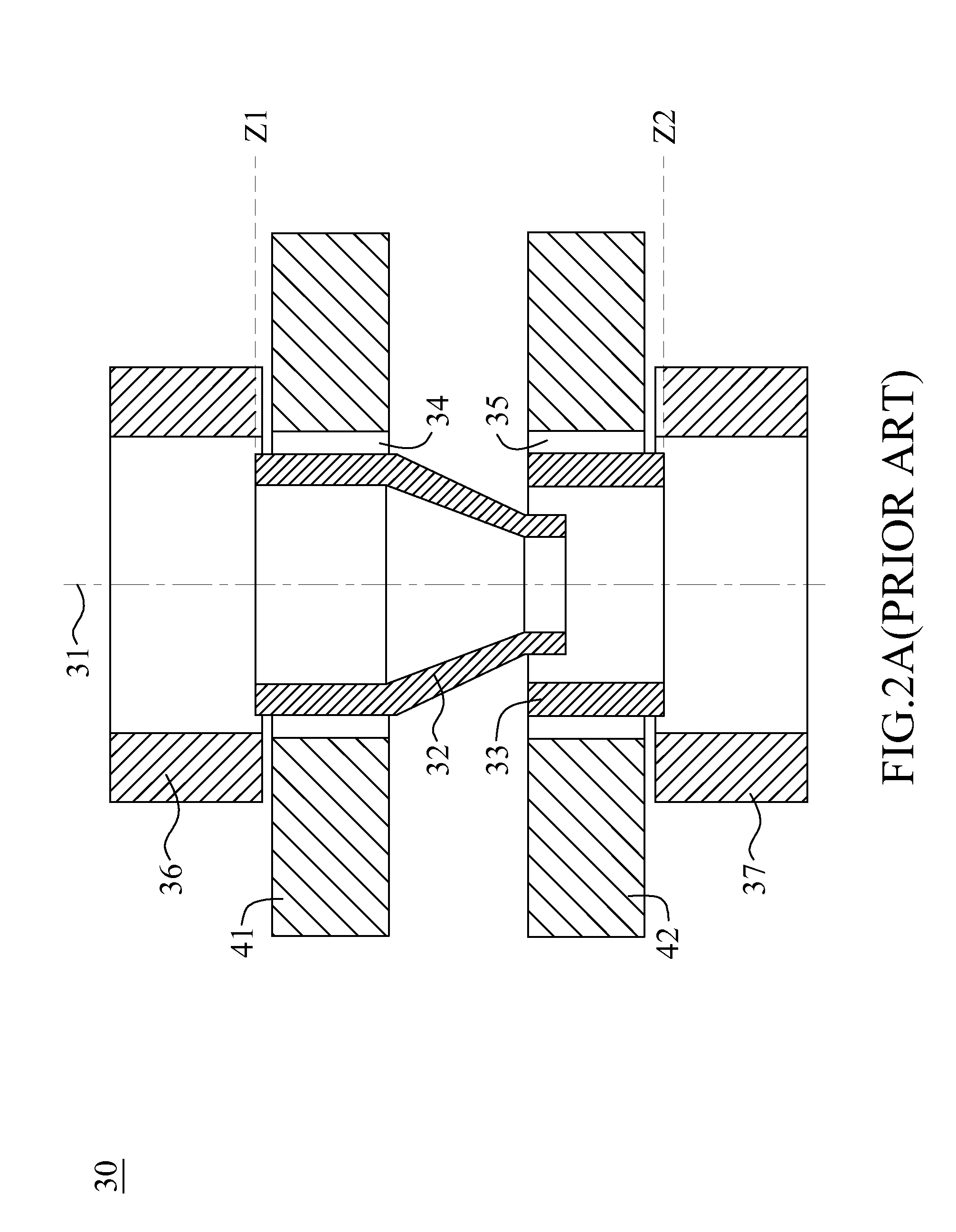

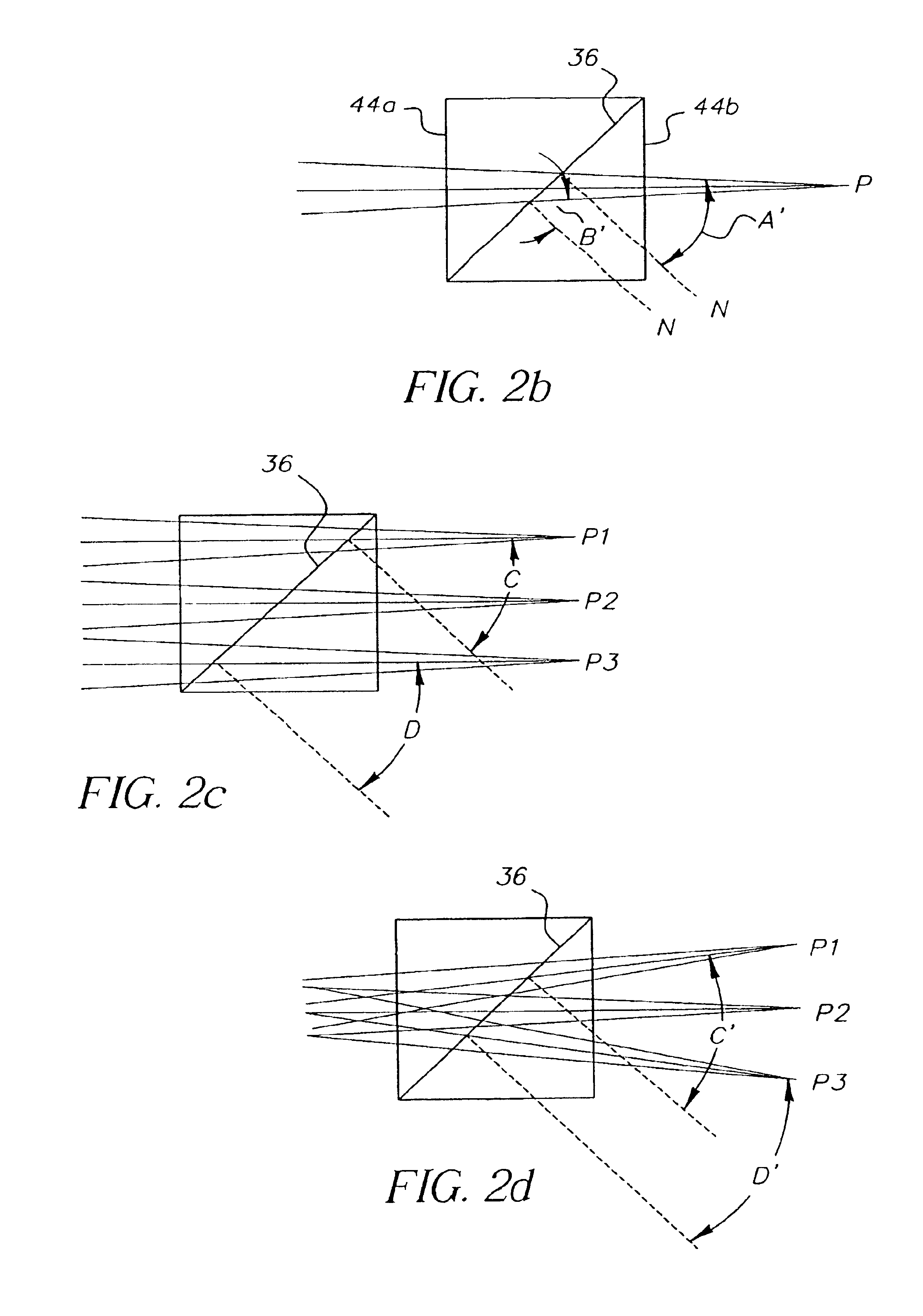

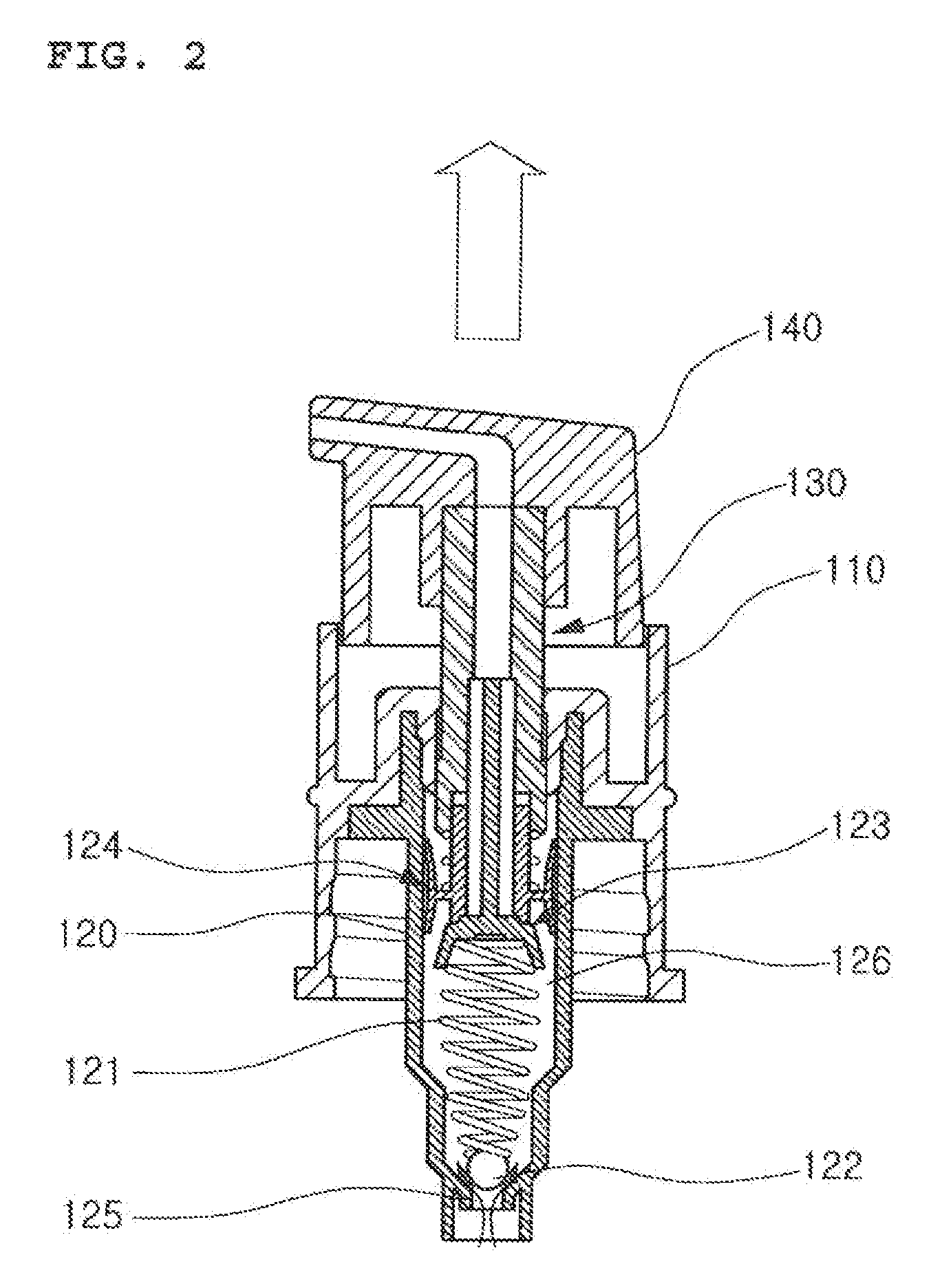

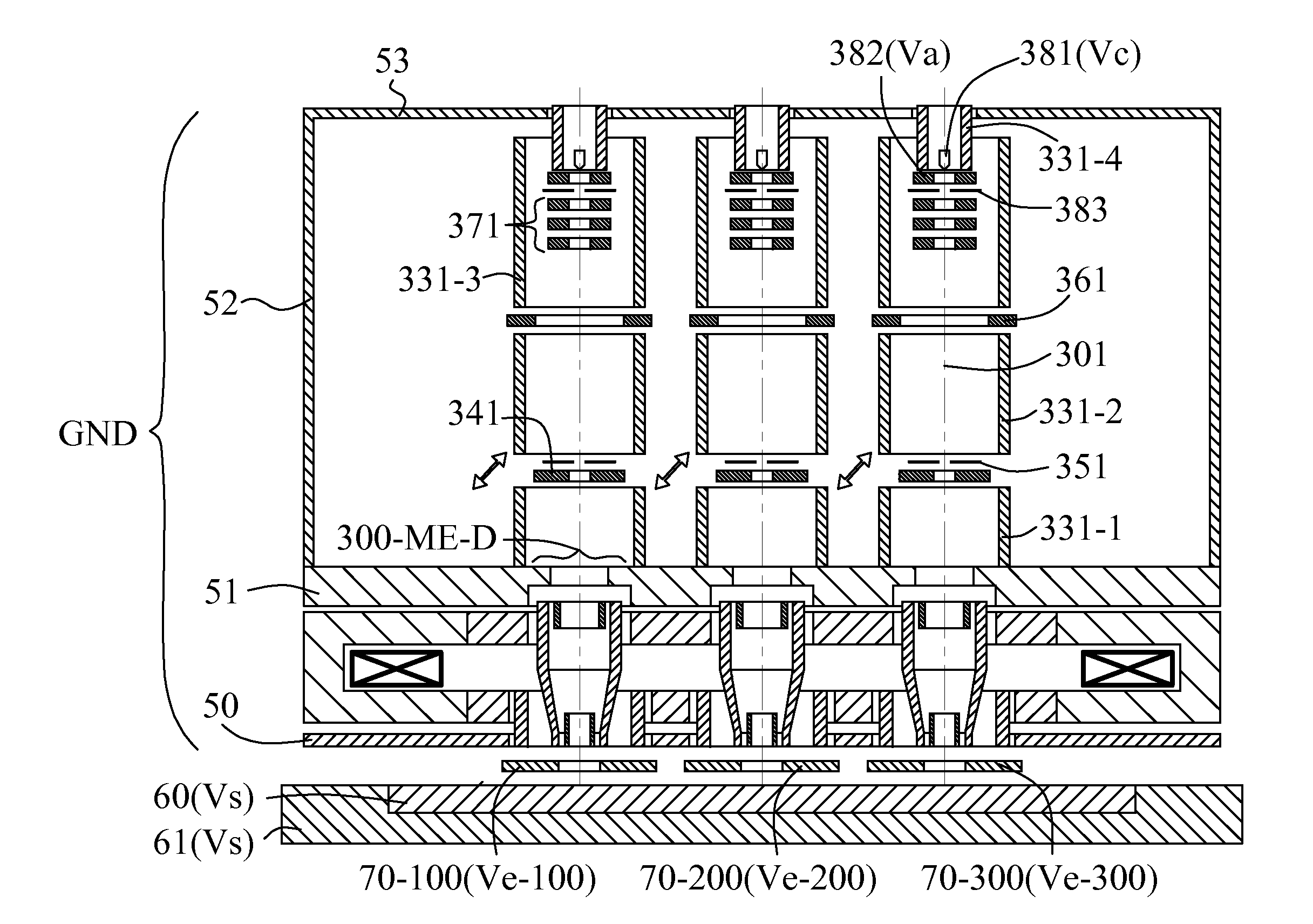

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS8445862B2Low aberration lowAvoid damageElectric discharge tubesMaterial analysis by optical meansCouplingOptical axis

An apparatus basically uses a simple and compact multi-axis magnetic lens to focus each of a plurality of charged particle beams on sample surface at the same time. In each sub-lens module of the multi-axis magnetic lens, two magnetic rings are respectively inserted into upper and lower holes with non-magnetic radial gap. Each gap size is small enough to keep a sufficient magnetic coupling and large enough to get a sufficient axial symmetry of magnetic scale potential distribution in the space near to its optical axis. This method eliminates the non-axisymmetric transverse field in each sub-lens and the round lens field difference among all sub-lenses at the same time; both exist inherently in a conventional multi-axis magnetic lens. In the apparatus, some additional magnetic shielding measures such as magnetic shielding tubes, plates and house are used to eliminate the non-axisymmetric transverse field on the charged particle path from each charged particle source to the entrance of each sub-lens and from the exit of each sub-lens to the sample surface.

Owner:ASML NETHERLANDS BV

Head-mounted display device and optical lens system thereof

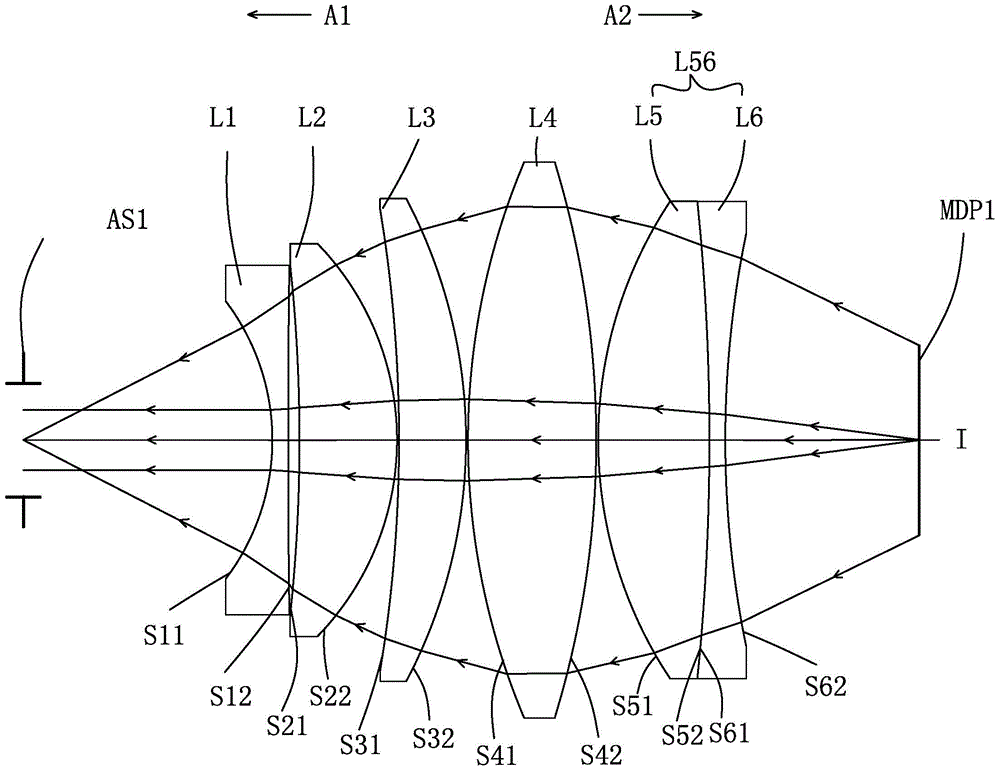

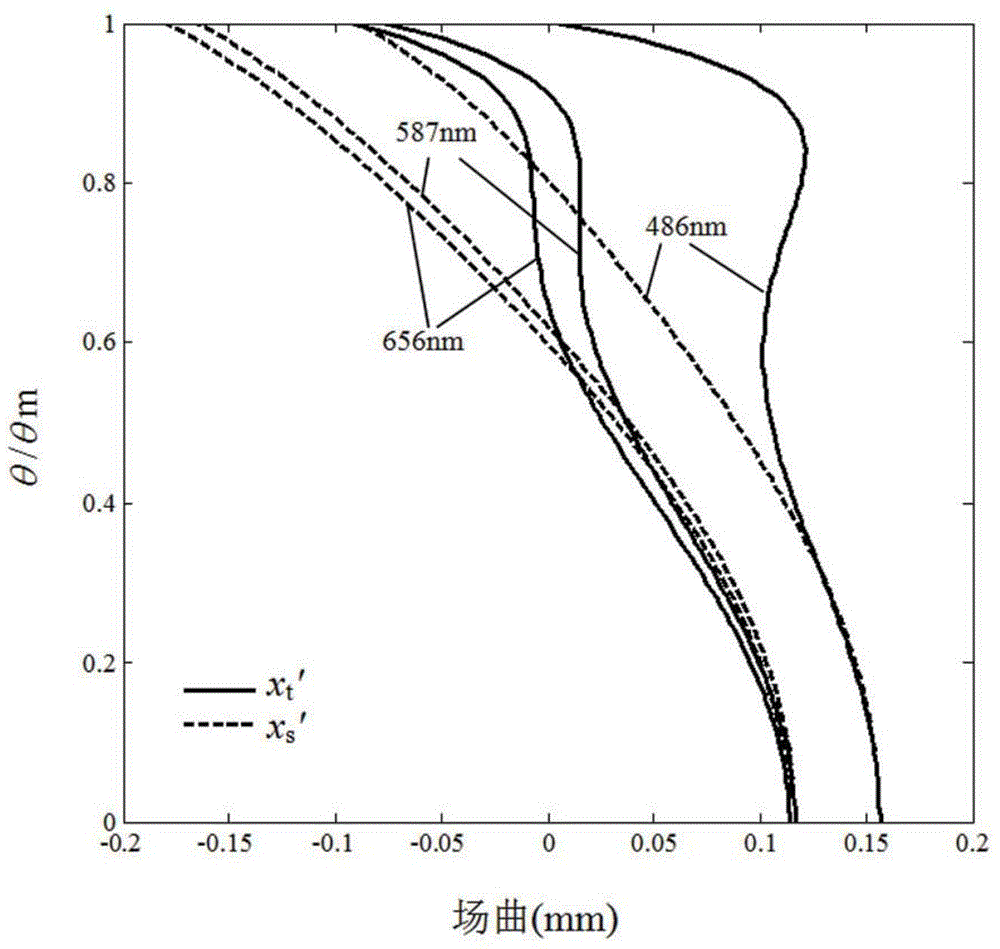

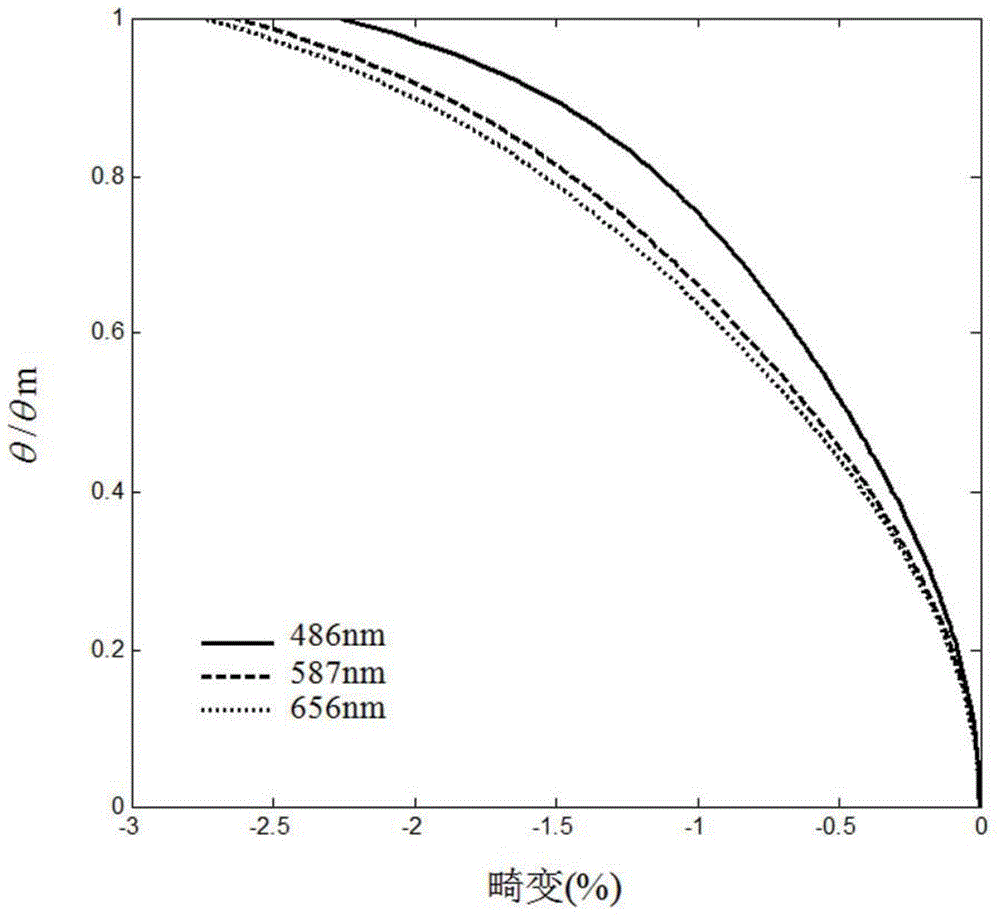

ActiveCN105068253AGuaranteed viewing fieldImprove image qualityOptical elementsCamera lensOptical axis

The invention relates to a head-mounted display device and an optical lens system thereof. The optical lens system comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens which are arranged in sequence from a light inlet side to a light outlet side along an optical axis, wherein each lens is a spherical lens with an refractive index, the first lens is a negative focal power lens, the second lens is a positive focal power lens, the third lens is a positive focal power lens, the fourth lens is a positive focal power lens, the fifth lens is a positive focal power lens, and the sixth lens is a negative focal power lens. The head-mounted display device provided by the invention comprises a machine shell and a display module which is installed in the machine shell, wherein the display module comprises at least one optical lens system disclosed in the invention and at least one display screen which is arranged on an optical axis, facing the light inlet side, of a second surface of the sixth lens. The head-mounted display device and the optical lens system thereof ensure angle of field of view, ensure good imaging quality, and have the advantages of short focal length and long working distance.

Owner:宿州飞目光电科技有限公司

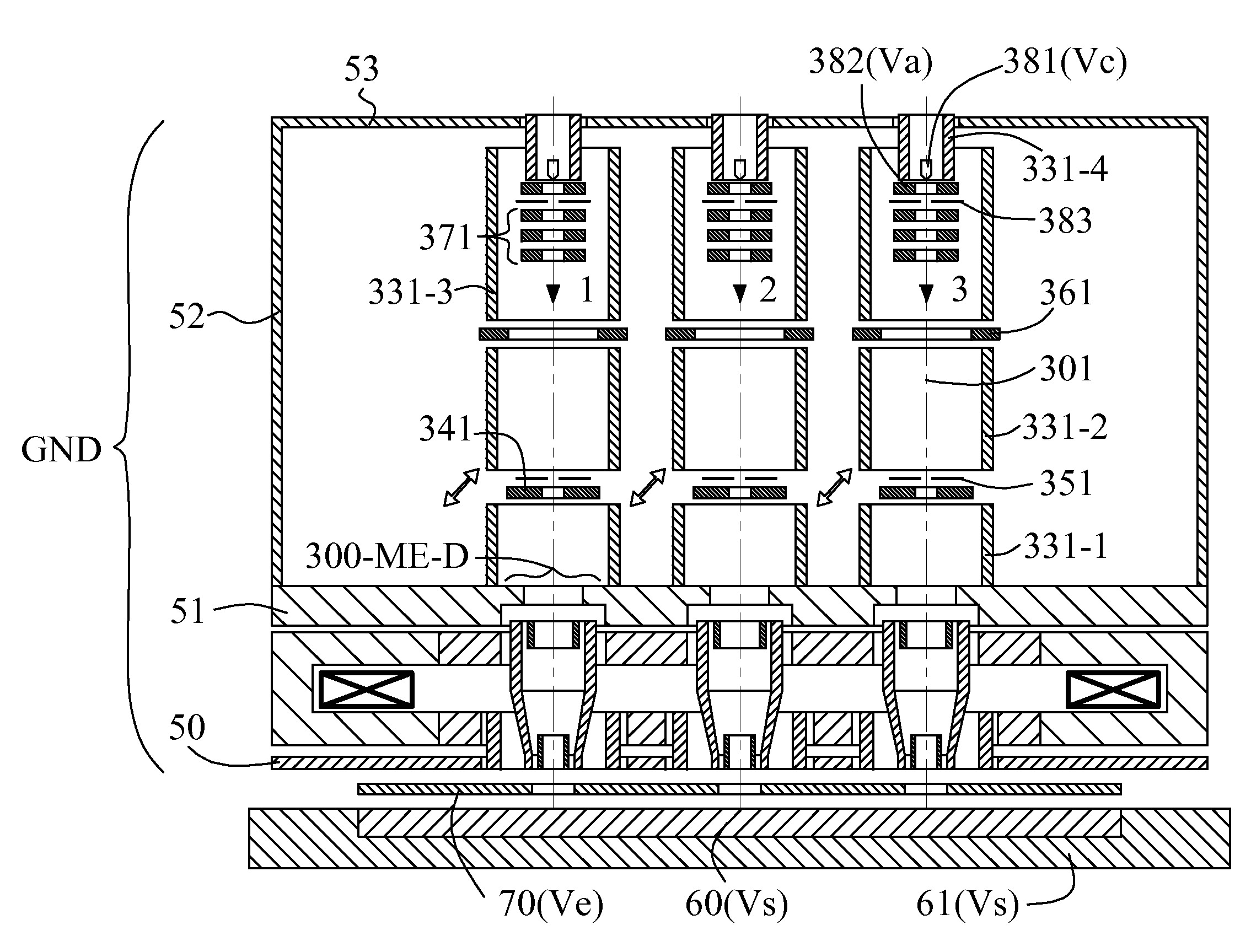

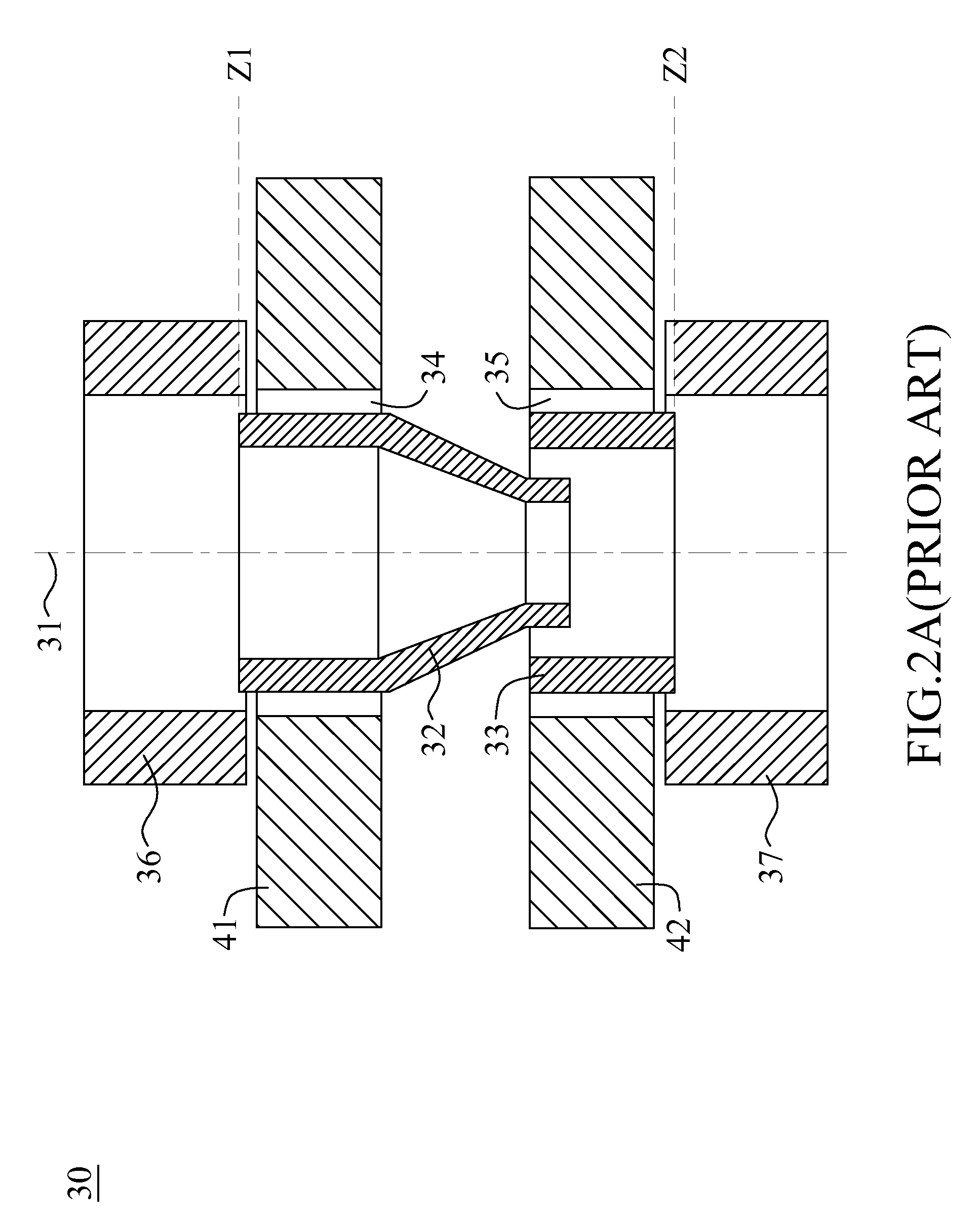

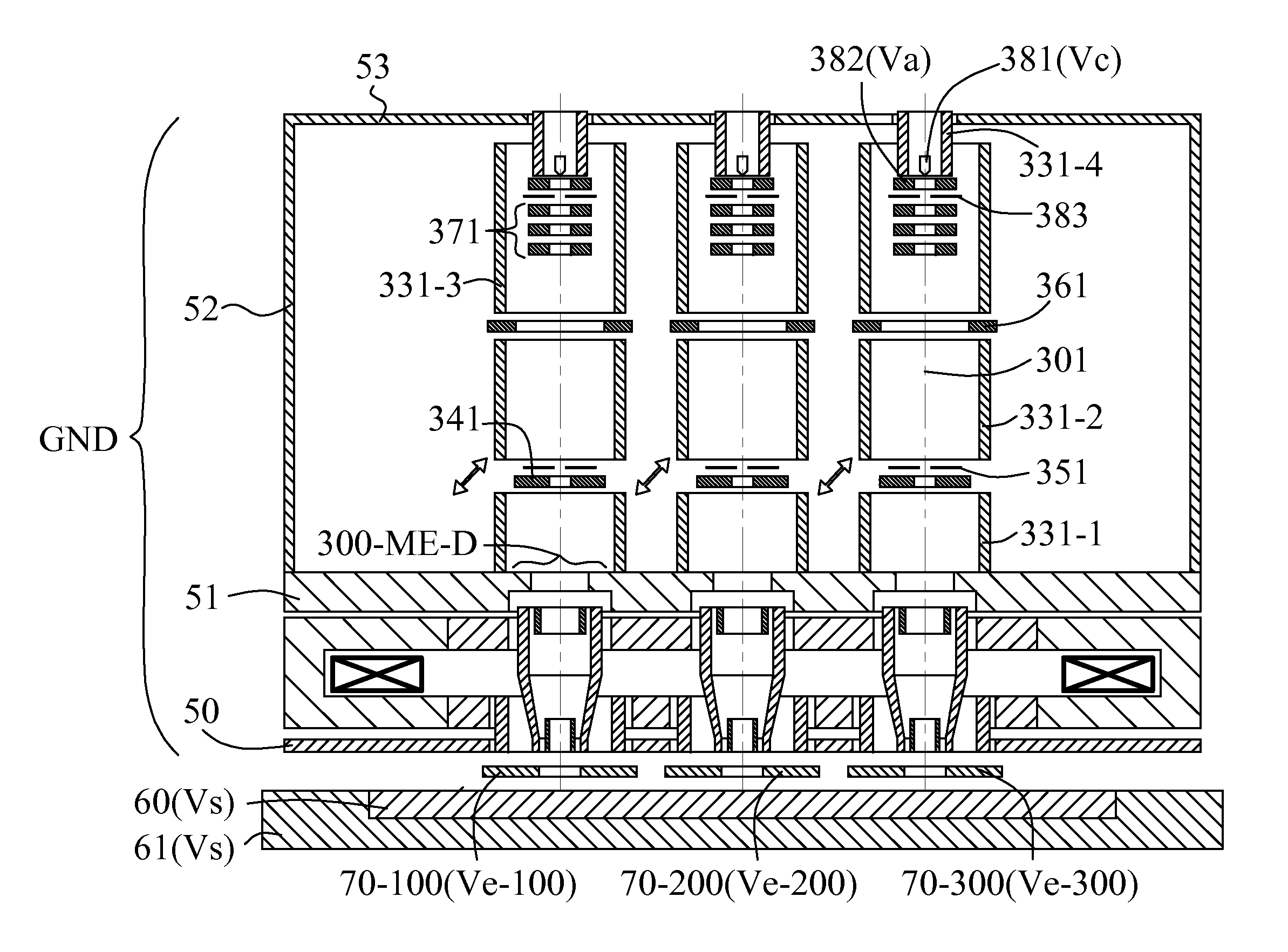

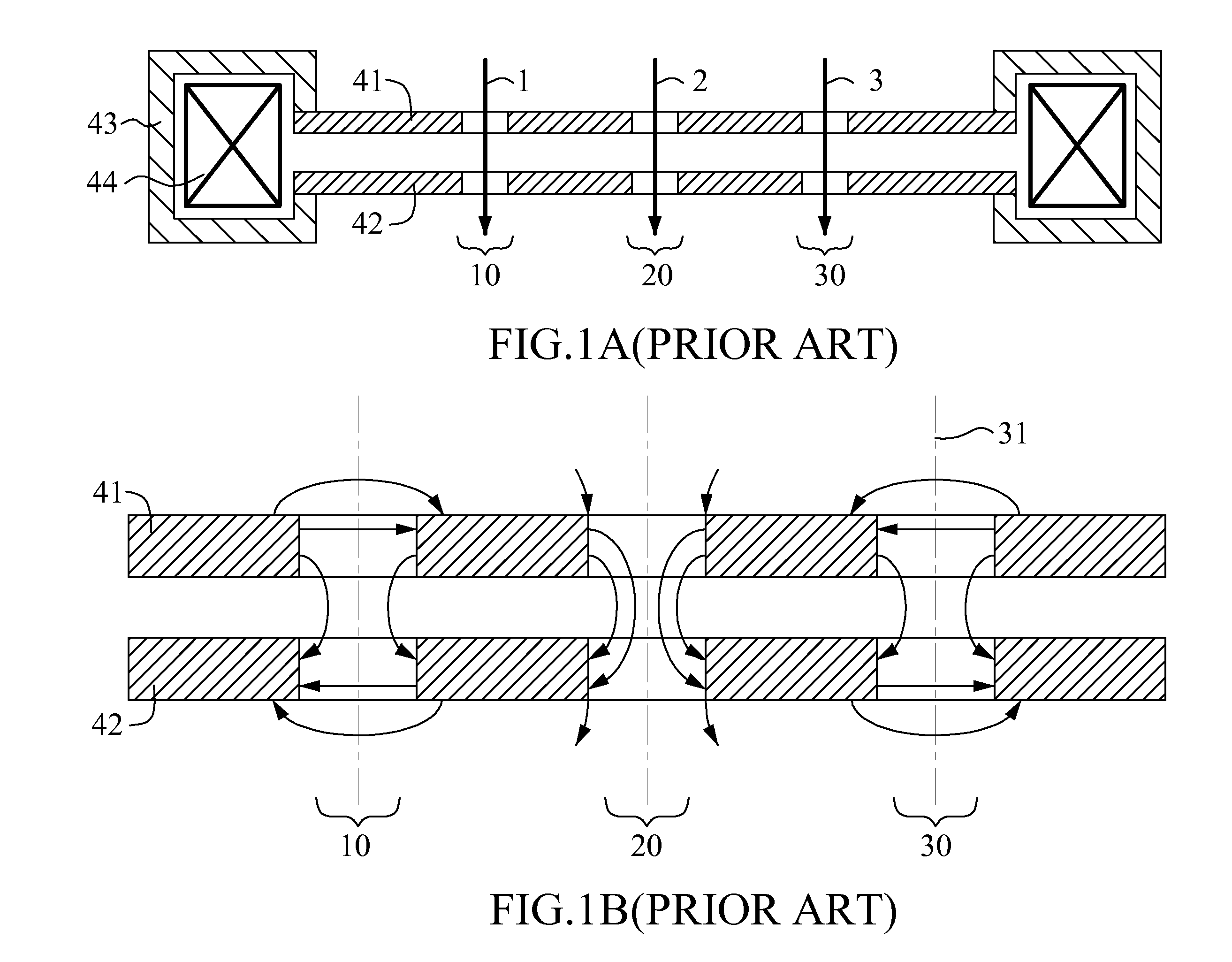

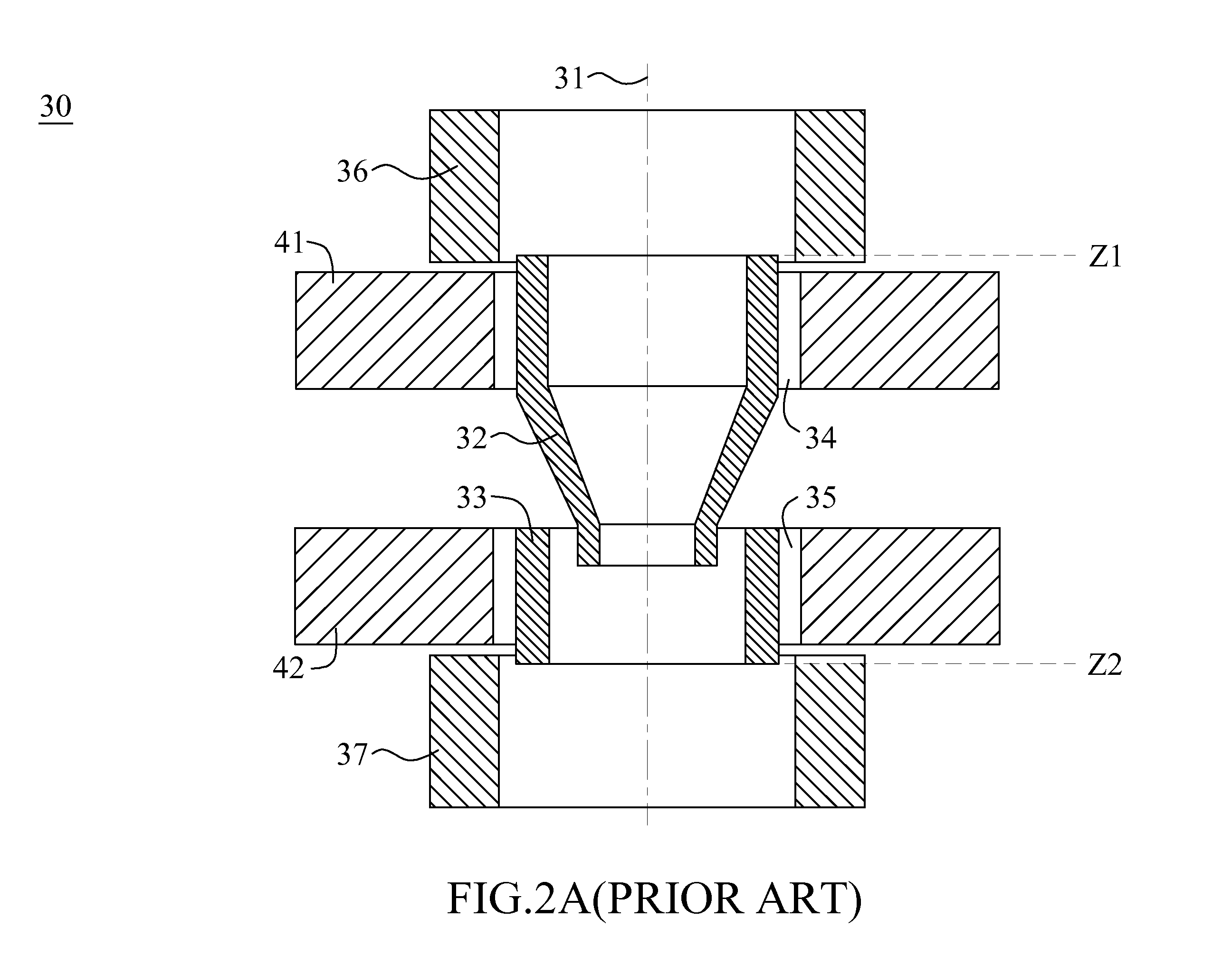

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS20120145900A1Low aberration lowAvoid damageElectric discharge tubesMaterial analysis by optical meansCouplingOptical axis

An apparatus basically uses a simple and compact multi-axis magnetic lens to focus each of a plurality of charged particle beams on sample surface at the same time. In each sub-lens module of the multi-axis magnetic lens, two magnetic rings are respectively inserted into upper and lower holes with non-magnetic radial gap. Each gap size is small enough to keep a sufficient magnetic coupling and large enough to get a sufficient axial symmetry of magnetic scale potential distribution in the space near to its optical axis. This method eliminates the non-axisymmetric transverse field in each sub-lens and the round lens field difference among all sub-lenses at the same time; both exist inherently in a conventional multi-axis magnetic lens. In the apparatus, some additional magnetic shielding measures such as magnetic shielding tubes, plates and house are used to eliminate the non-axisymmetric transverse field on the charged particle path from each charged particle source to the entrance of each sub-lens and from the exit of each sub-lens to the sample surface.

Owner:ASML NETHERLANDS BV

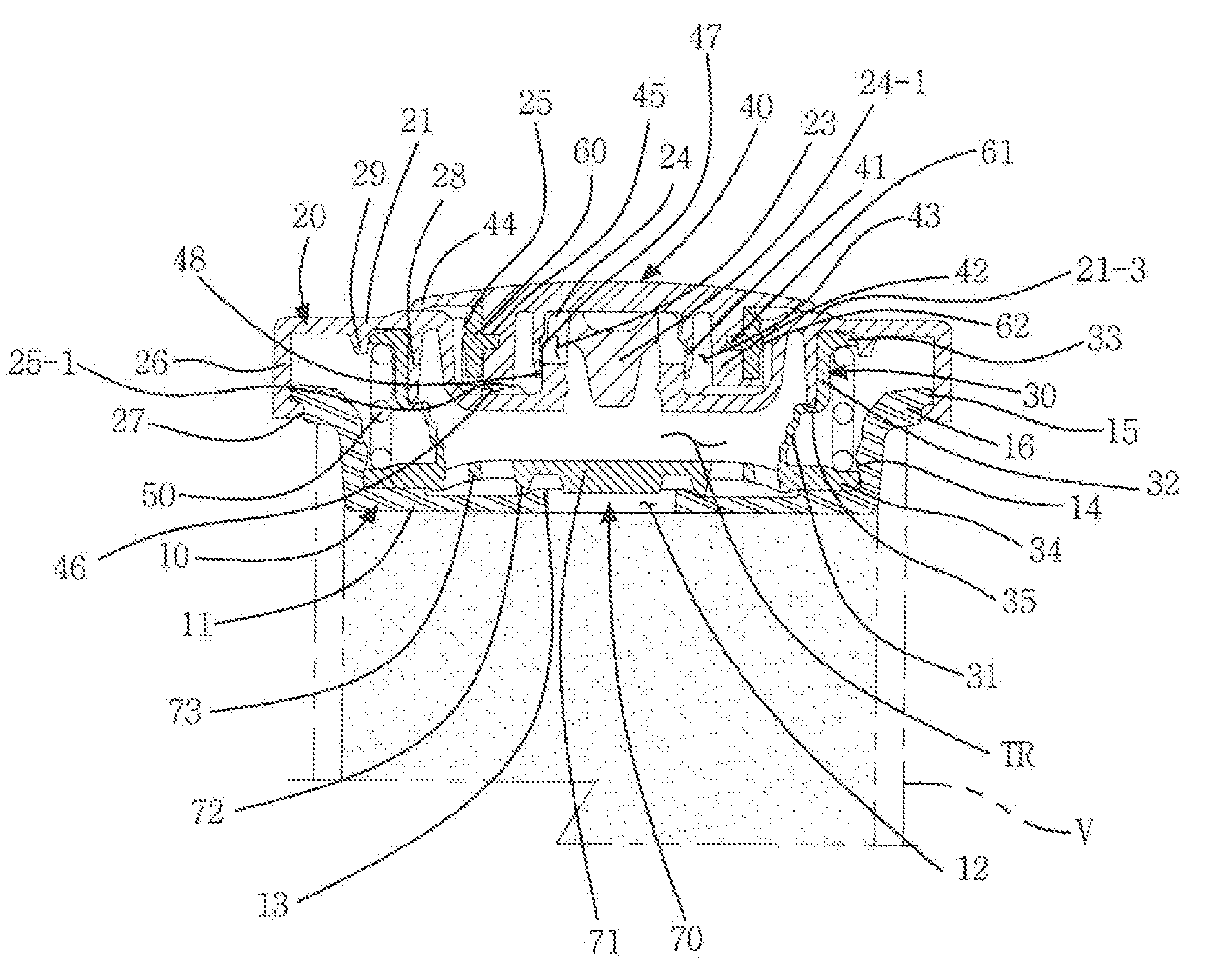

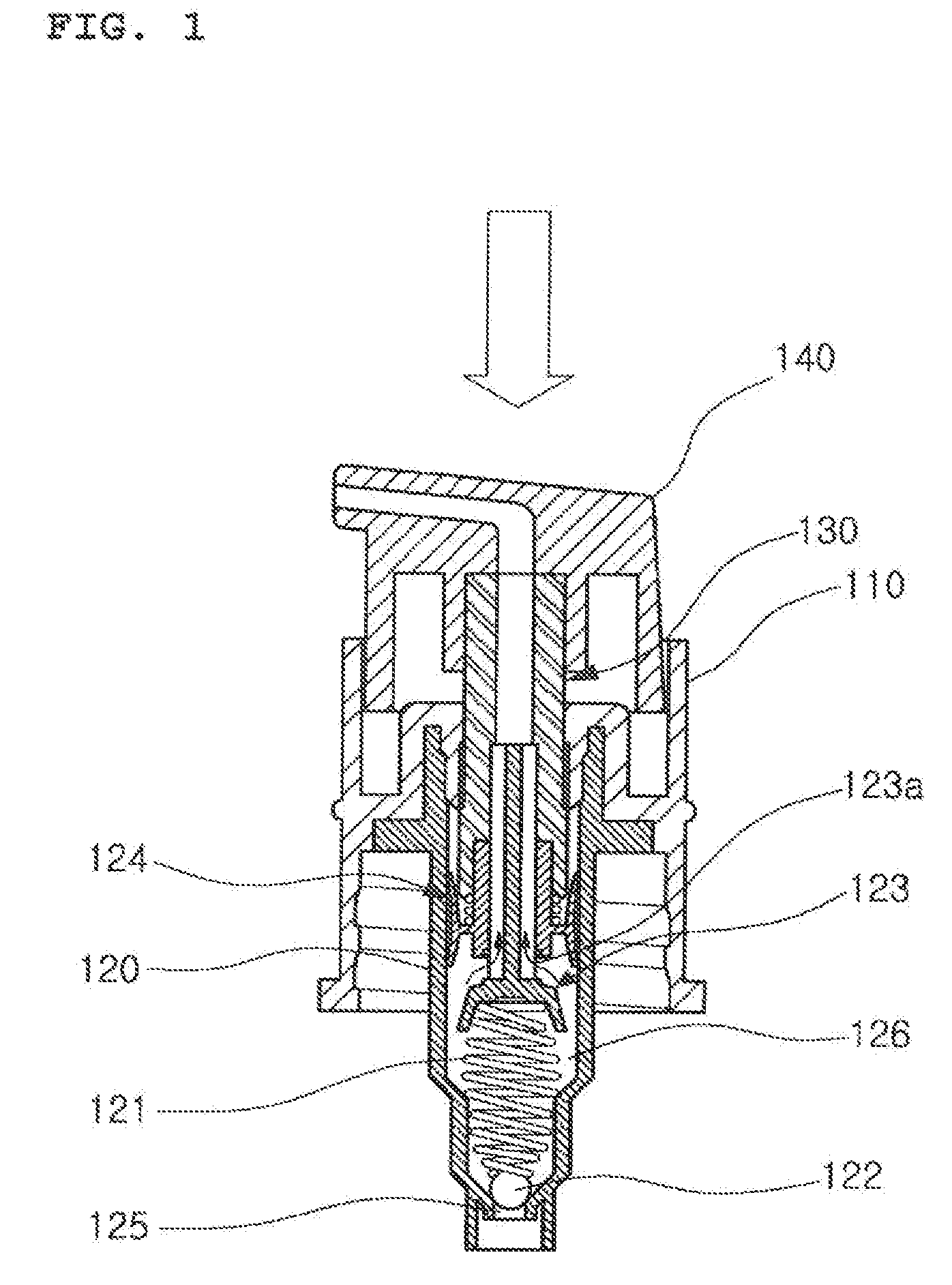

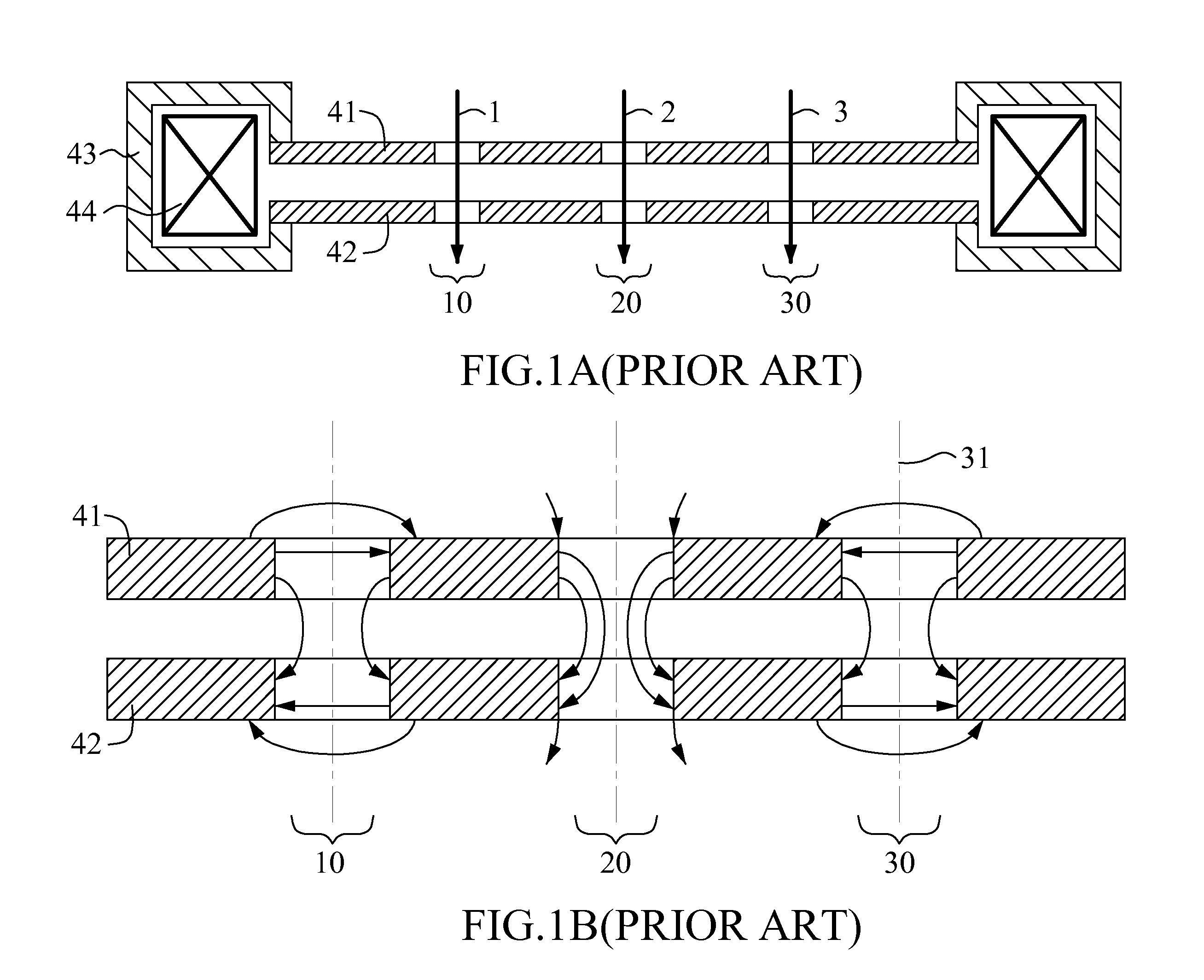

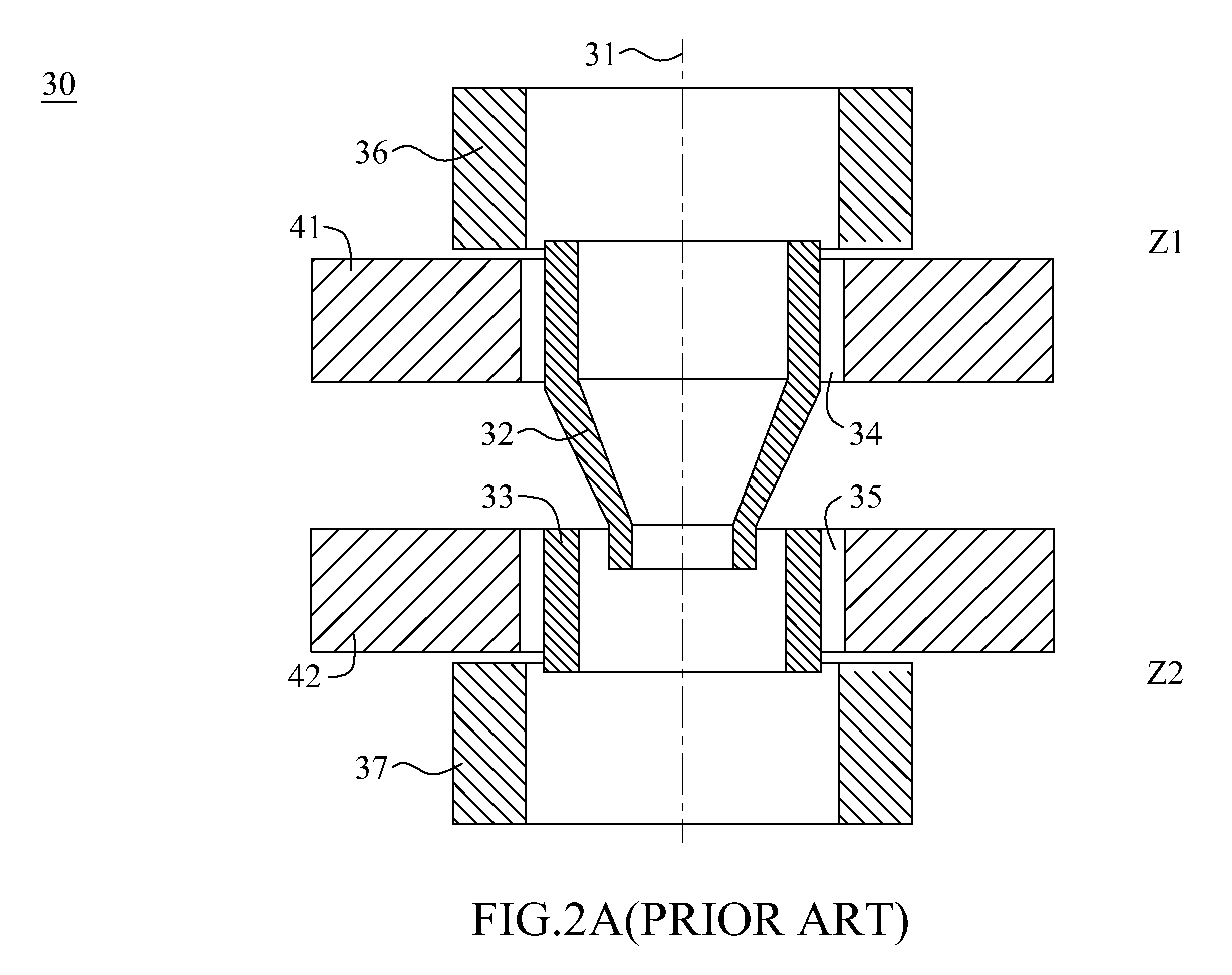

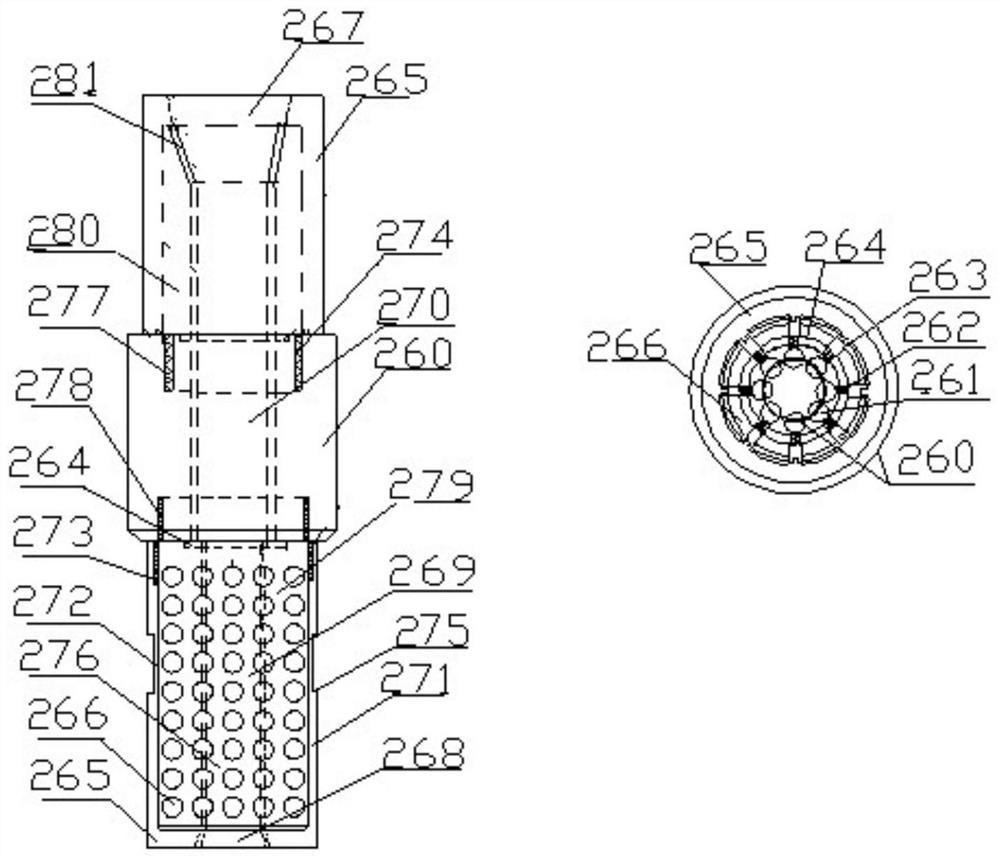

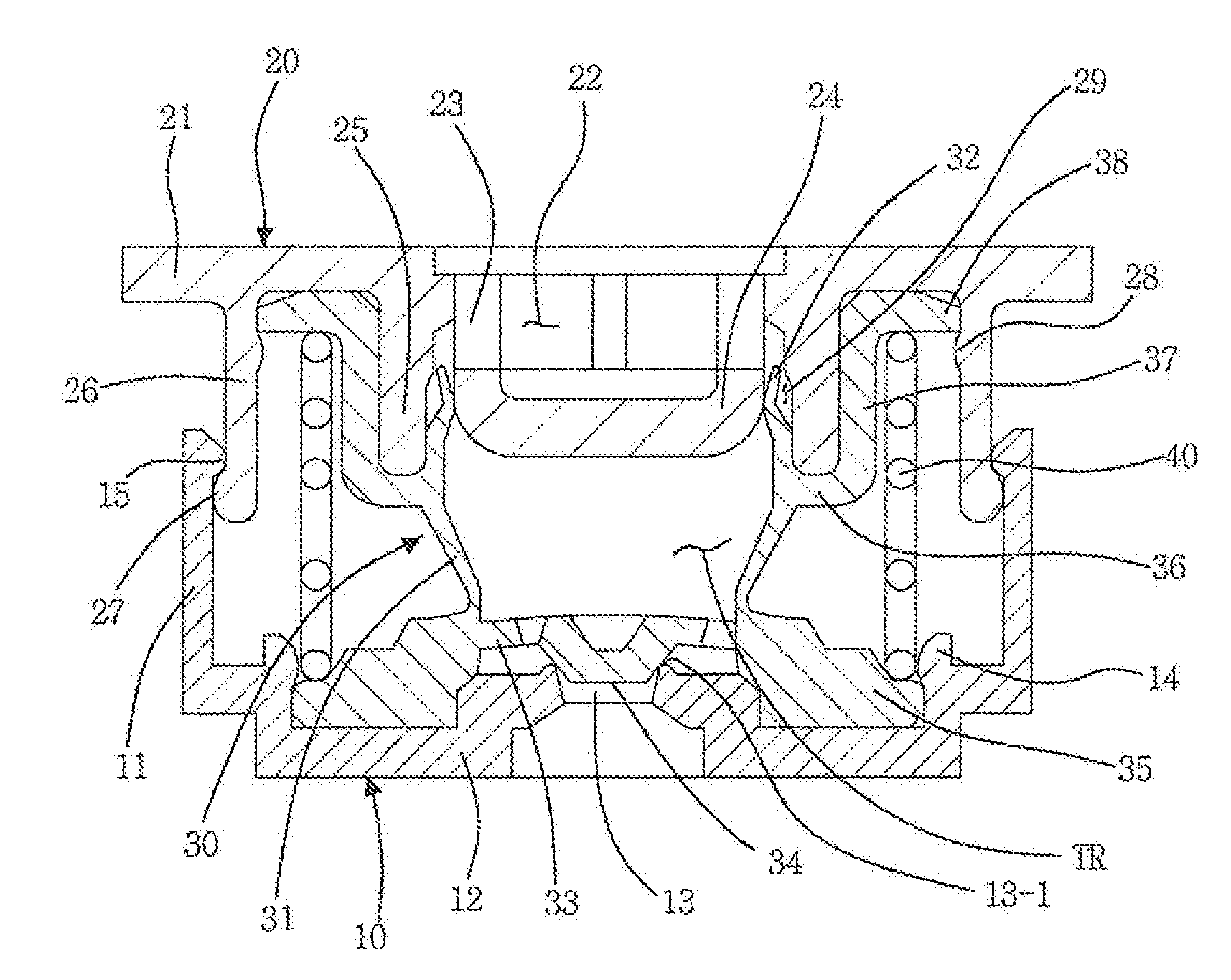

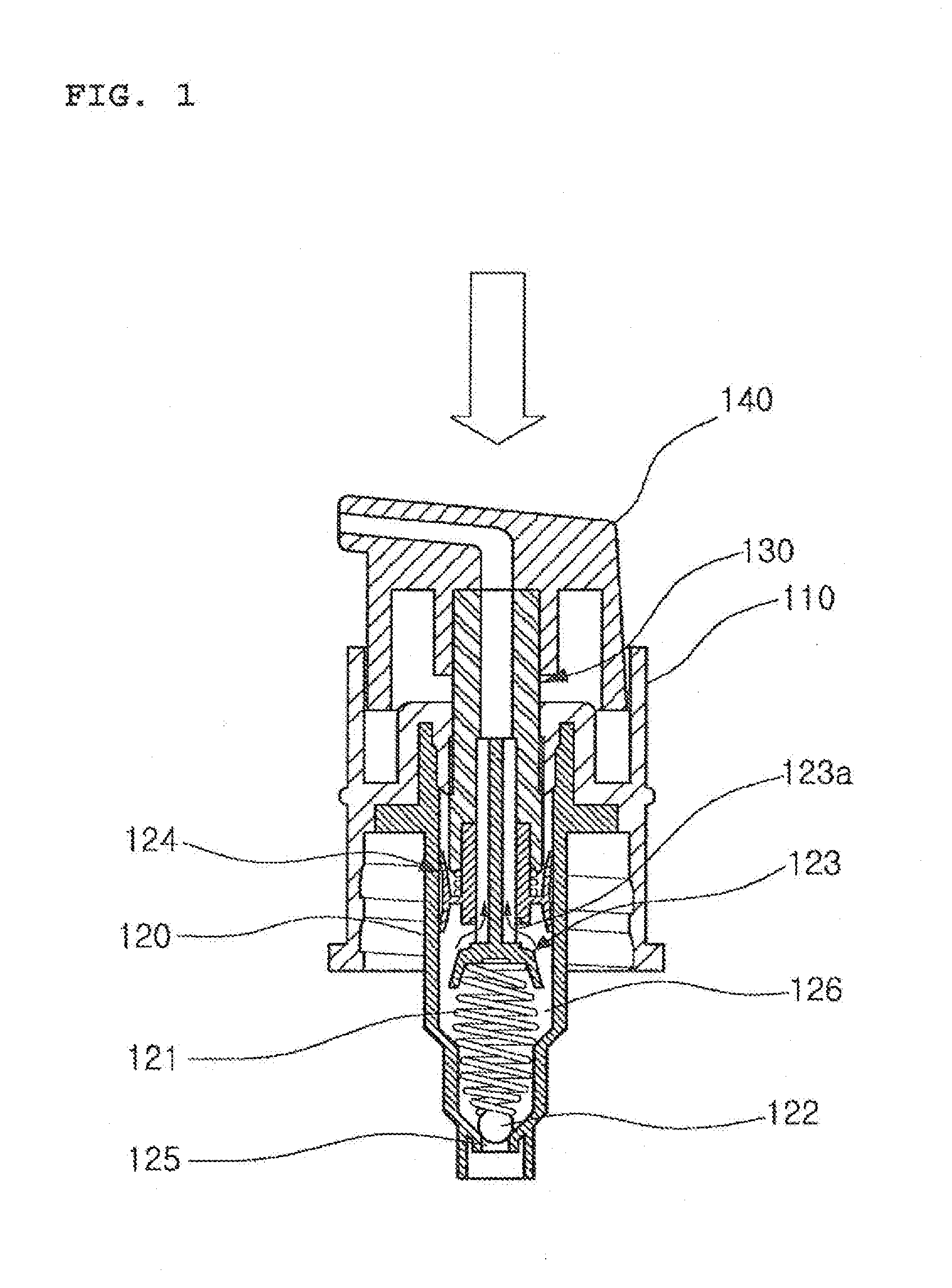

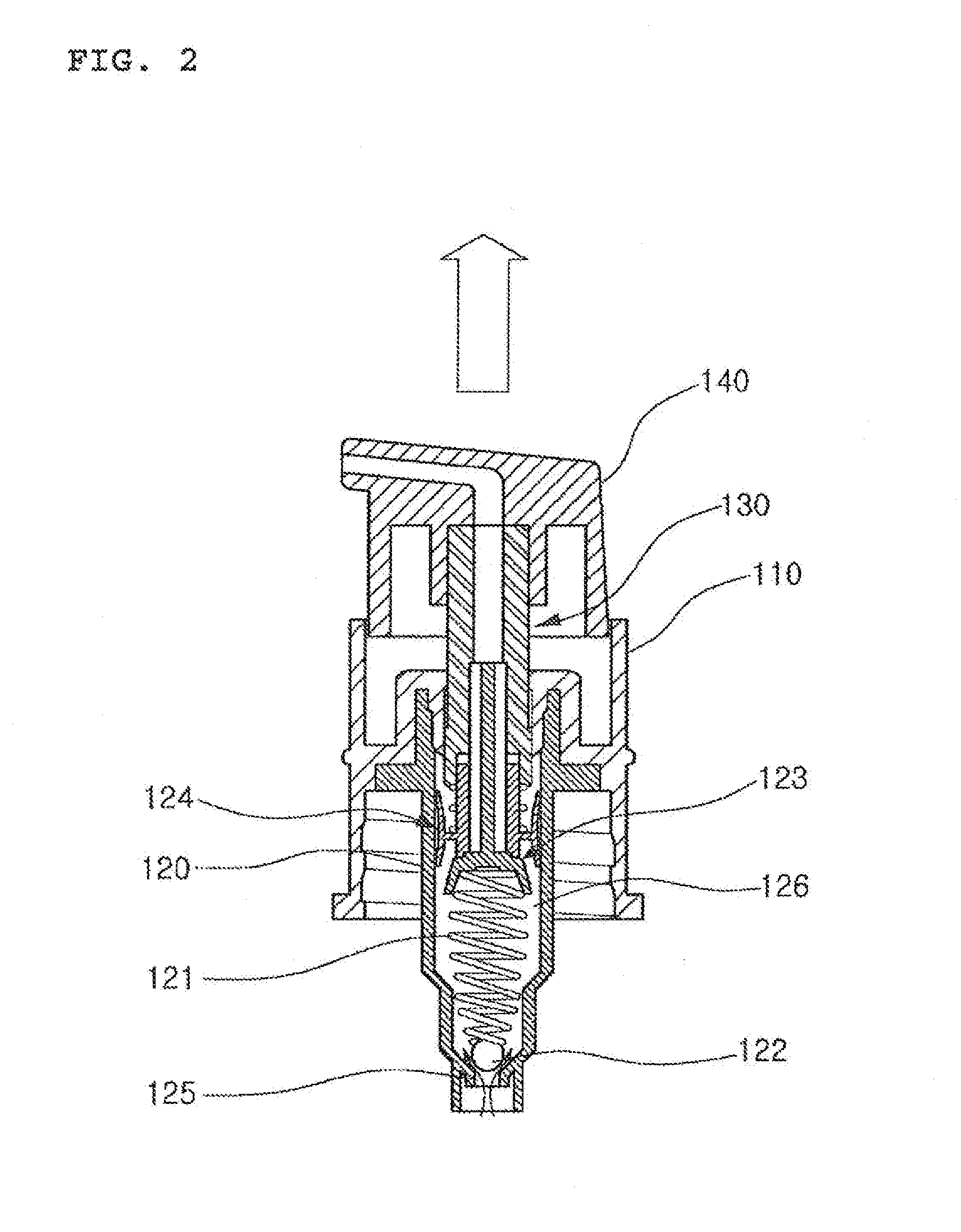

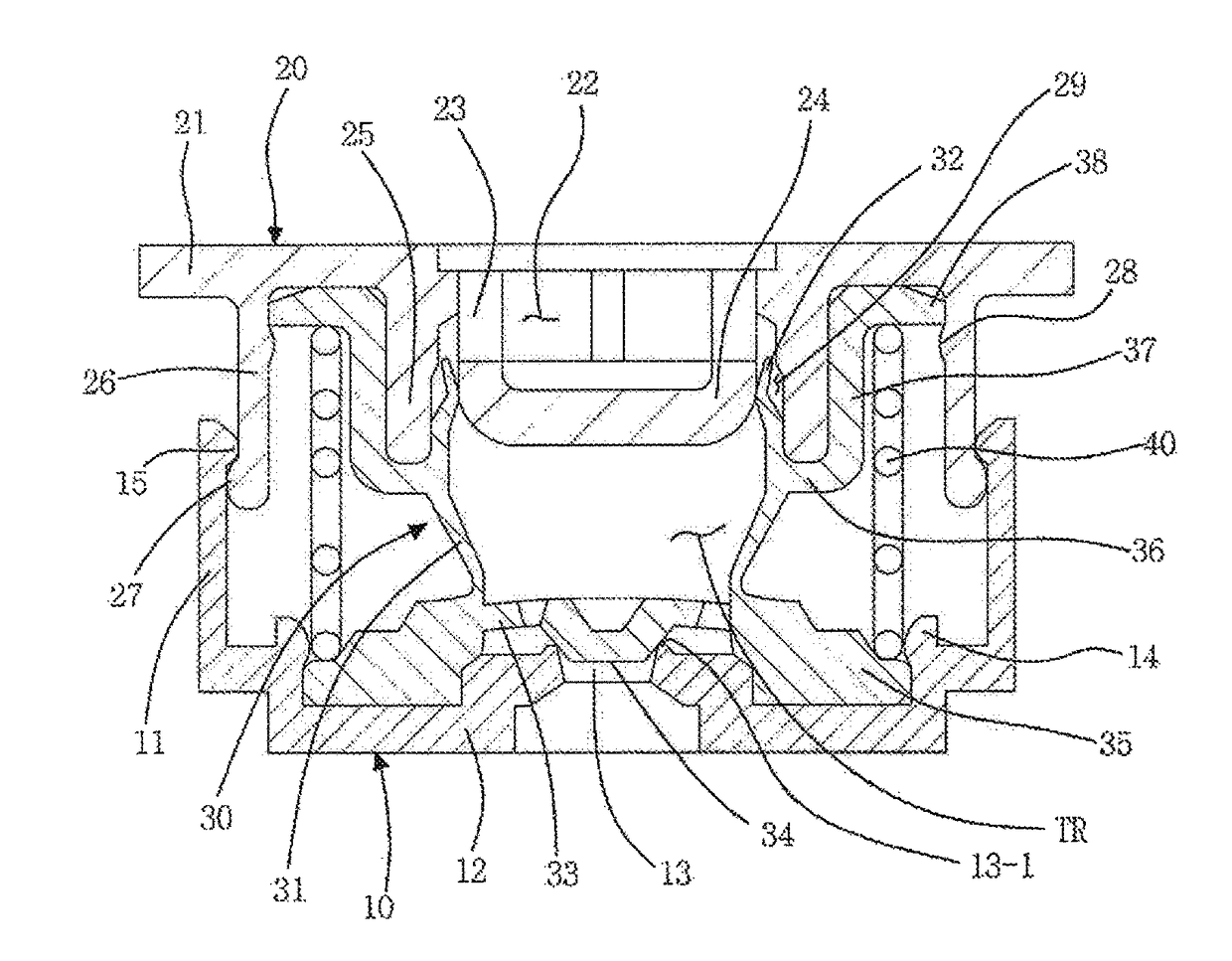

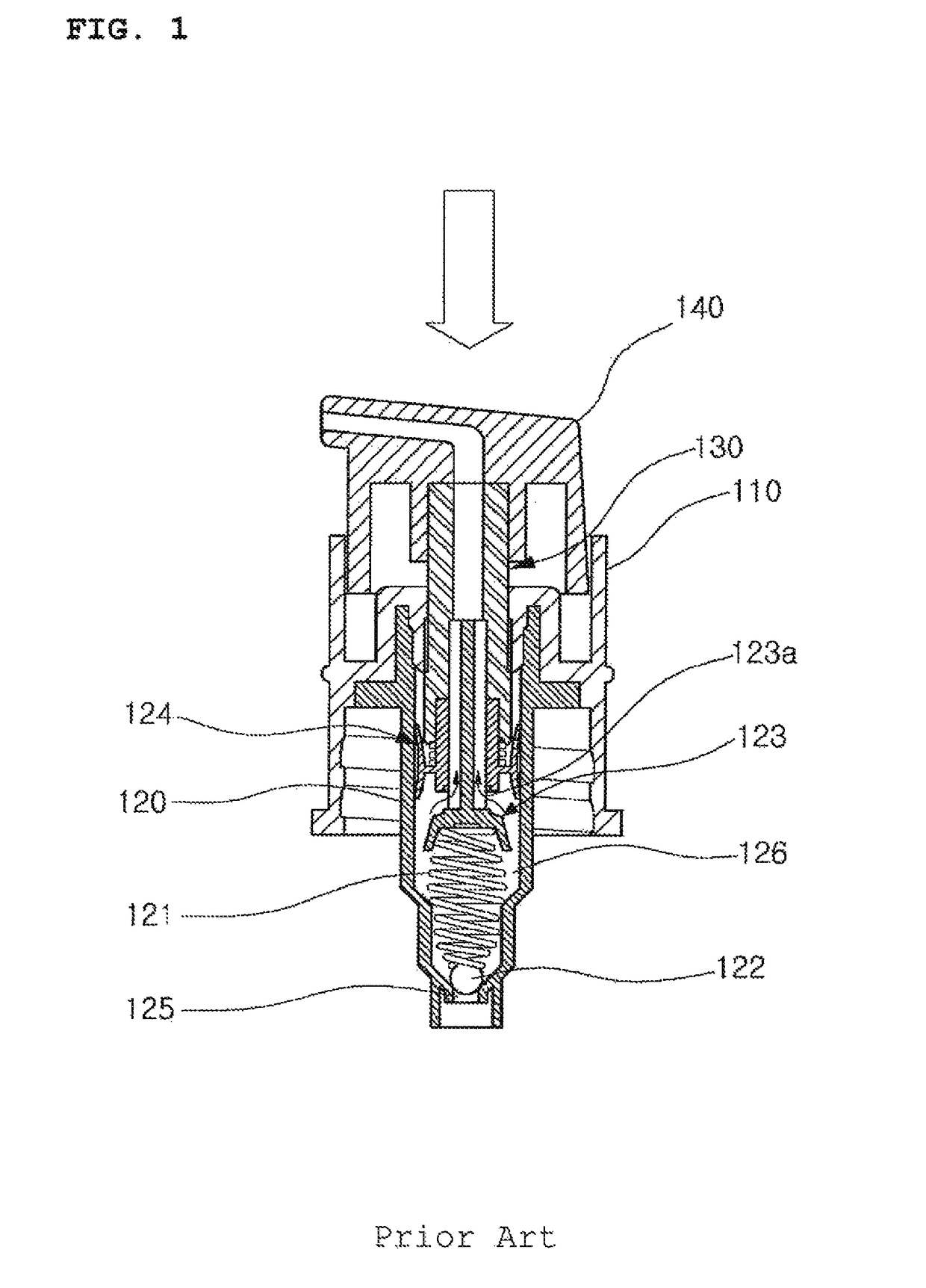

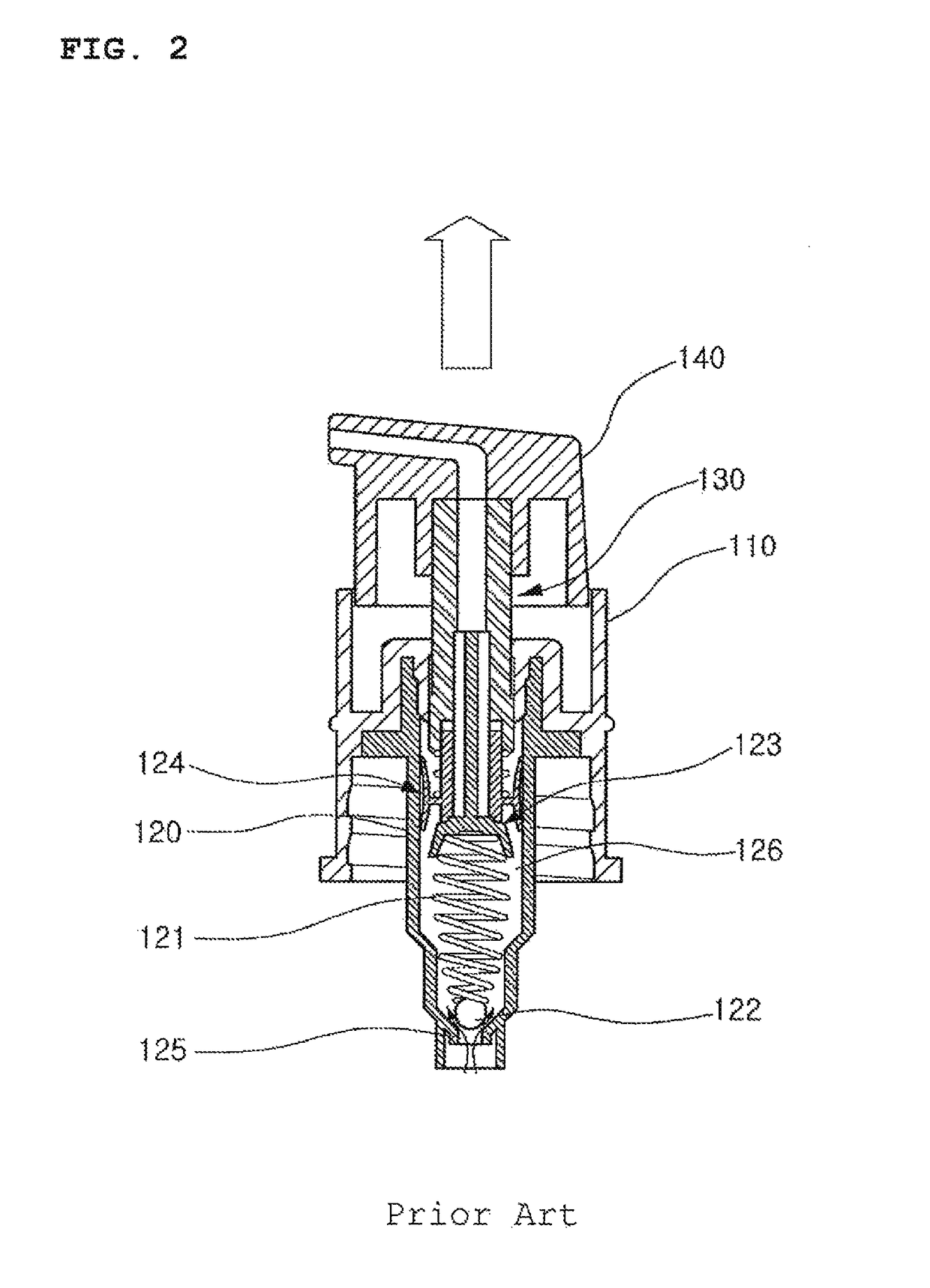

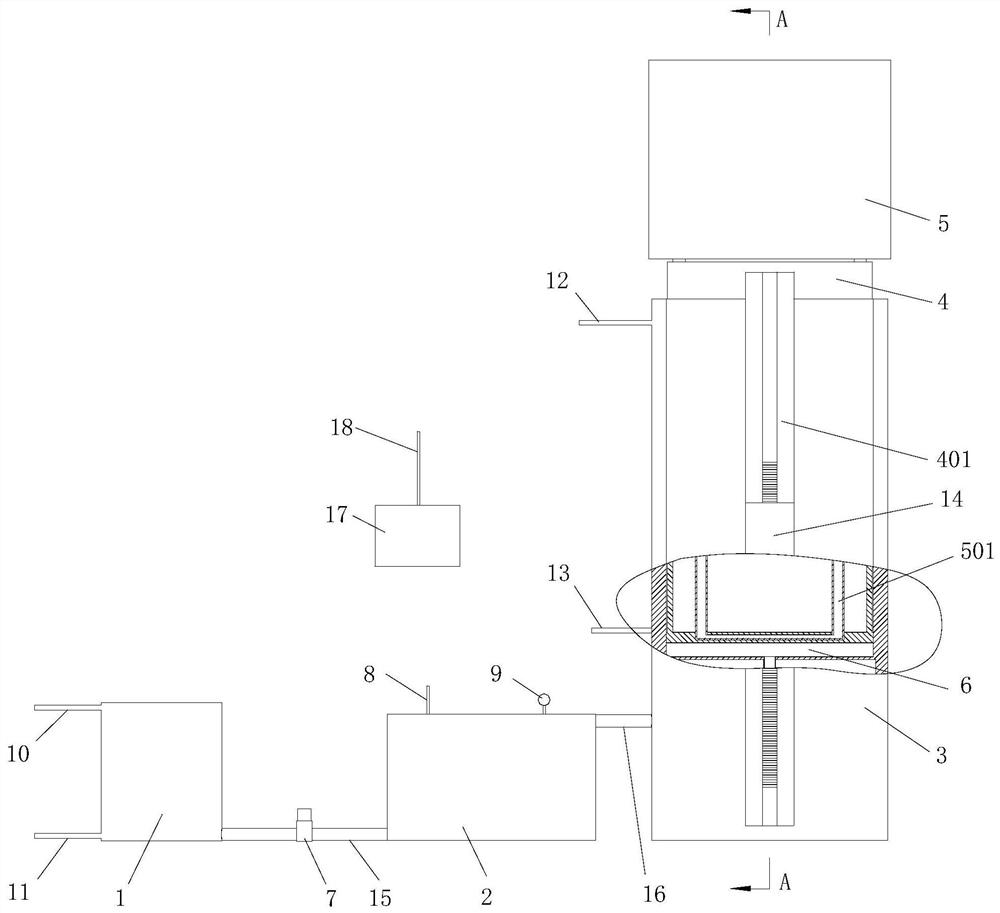

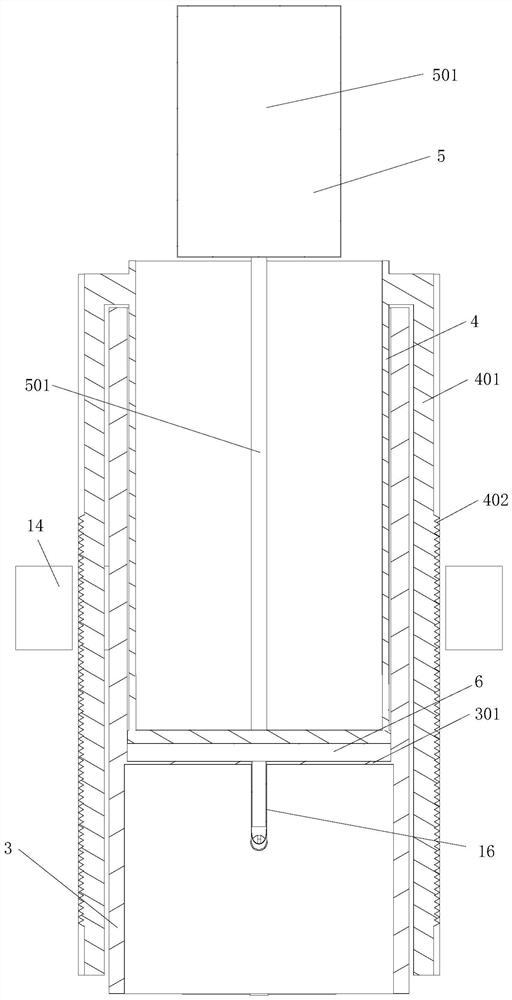

Contents dispensing pump

ActiveUS20160303602A1Improve reliabilityAvoid defectsClosuresDispensing apparatusInlet valveEngineering

The present invention relates to a contents dispensing pump which is coupled to a container (V) for accommodating the contents therein and dispenses the contents, comprising; a pump main body (10); a pump upper body (20); a pump inner body (30); a dispensing valve (40); and an elastic member (50). The pump upper body (20) is coupled to the upper side of the pump main body (10) so that a pumping operation is made by an up and down movement with respect to the pump main body (10). The pump inner body (30) has a bowl shape with the middle thereof formed to be dented so that an inlet valve plate (70) is integrally formed on the lower surface. The dispensing valve (40) is coupled to the upward side of the pump upper body (20), and has, formed therein, a valve protrusion wheel (41) for opening and closing the content outlet (23). The elastic member (50) is positioned between the upper lateral surface extension piece (33) and the lower lateral surface extension piece (34) of the pump inner body (30) so as to draw the pump inner body (30) and simultaneously elastically support the pump main body (10) and the pump upper body (20).

Owner:KANG SUNGIL

Apparatus of plural charged particle beams with multi-axis magnetic lens

ActiveUS20120145917A1Low aberration lowAvoid damageThermometer detailsBeam/ray focussing/reflecting arrangementsCouplingOptical axis

An apparatus basically uses a simple and compact multi-axis magnetic lens to focus each of a plurality of charged particle beams on sample surface at the same time. In each sub-lens module of the multi-axis magnetic lens, two magnetic rings are respectively inserted into upper and lower holes with non-magnetic radial gap. Each gap size is small enough to keep a sufficient magnetic coupling and large enough to get a sufficient axial symmetry of magnetic scale potential distribution in the space near to its optical axis. This method eliminates the non-axisymmetric transverse field in each sub-lens and the round lens field difference among all sub-lenses at the same time; both exist inherently in a conventional multi-axis magnetic lens. In the apparatus, some additional magnetic shielding measures such as magnetic shielding tubes, plates and house are used to eliminate the non-axisymmetric transverse field on the charged particle path from each charged particle source to the entrance of each sub-lens and from the exit of each sub-lens to the sample surface.

Owner:ASML NETHERLANDS BV

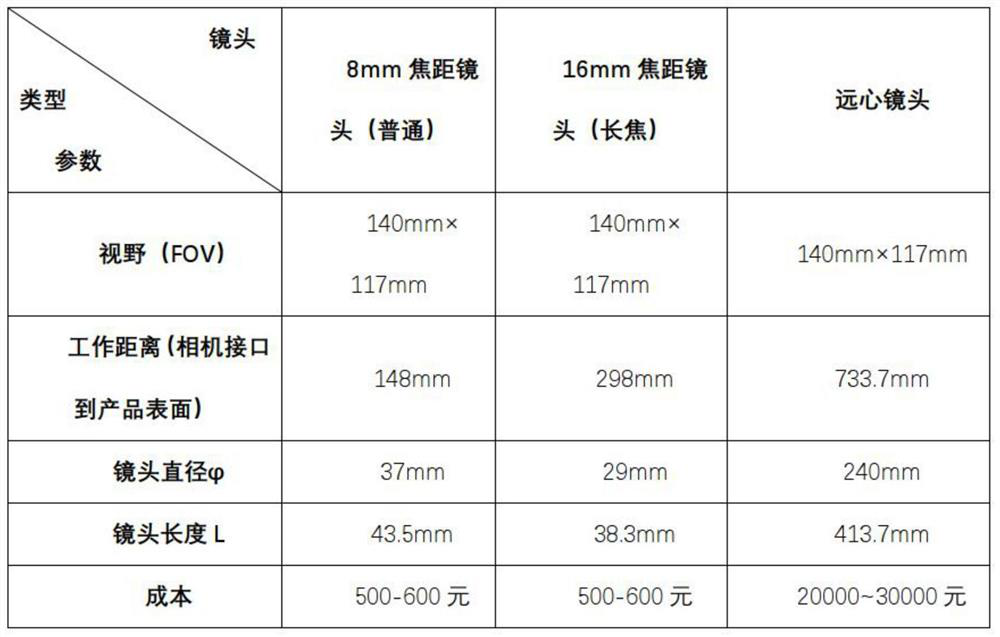

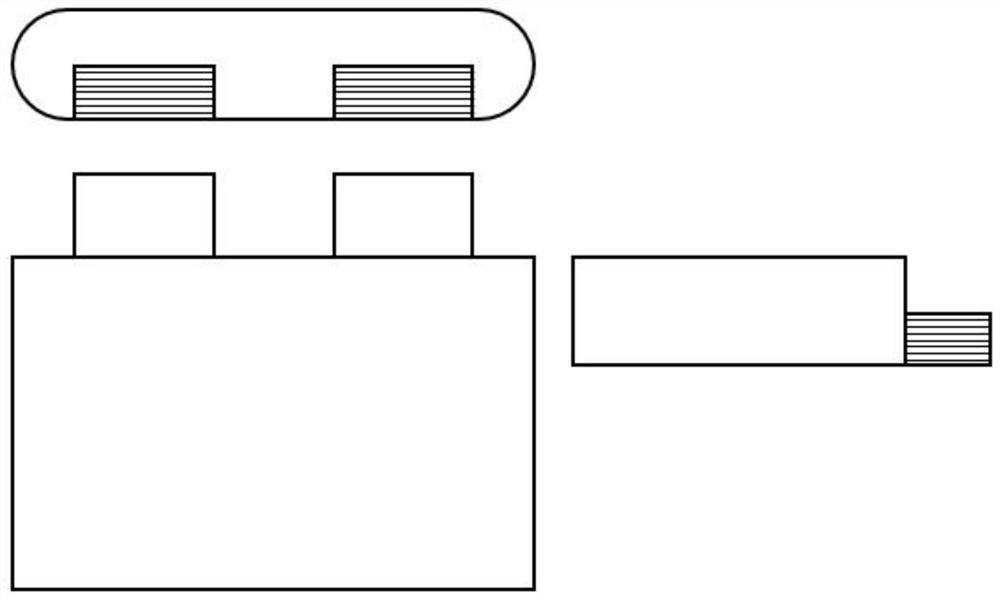

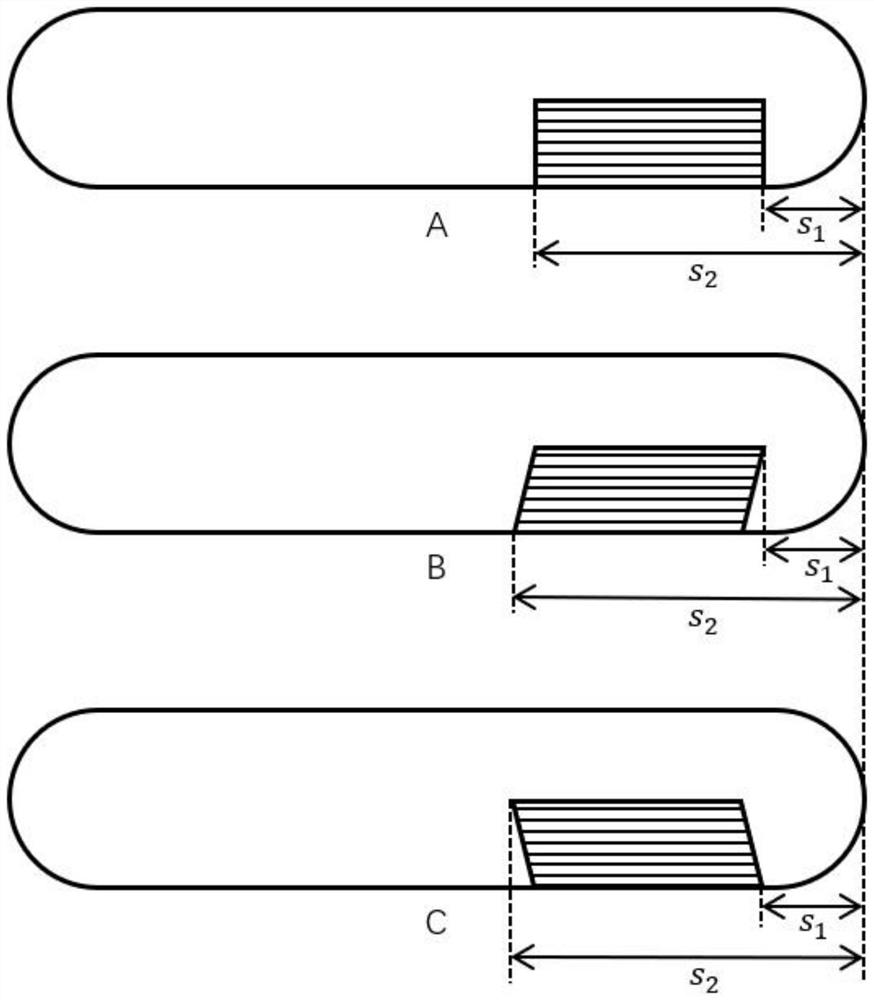

Monocular vision detection method for dislocation defect of bare cell tab of power battery

ActiveCN112557390AEasy to take picturesLow costMaterial analysis by optical meansUsing optical meansTelephoto lensPower battery

The invention discloses a monocular vision detection method for a dislocation defect of a naked battery cell tab of a power battery. The monocular vision detection method comprises the steps a to g. The invention has the advantages that: 1, the monocular vision tab dislocation detection method is based on a perspective projection camera model, so that the photographing scheme is simple, a telecentric lens or a telephoto lens is not needed, the cost is low and the space is saved; for example, under the same visual field condition, the working distance of the lens needed by the monocular visiontab dislocation detection method is generally about 50% shorter than that of the telephoto lens needed by a method based on a weak perspective projection camera model, wherein compared with a telecentric lens required by a method based on an orthogonal projection camera model, the working distance is shortened by about 80%, and the cost is reduced by about 98%; 2, three-dimensional target distancemeasurement under the condition of a single camera is realized, and a calculation model is highly matched with the actual situation; and 3, the problem of three-dimensional measurement of the distance from the monocular tab to the side edge of the battery cell is greatly simplified, and the method is easy to understand and implement.

Owner:HUIZHOU XUXIN PRECISION ELECTRONICS EQUIP

Ocular lens

The invention discloses an ocular lens. The ocular lens comprises a reflective polaroid, a 1 / 4 wave plate and a lens set with positive focal power from a human eye side to an image source side in sequence along an optical axis, wherein the lens set comprises one or more lenses, and an aspherical mirror surface of any lens is plated with semi-permeable and semi-reflective optical thin film, and thedistance Lm between the reflective polaroid and the semi-permeable and semi-reflective optical thin film on the optical axis and the distance Ld between the reflective polaroid and an image source plane of the ocular lens on the optical axis satisfy the condition that Lm / Ld is larger than 0.25 and smaller than 0.75.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

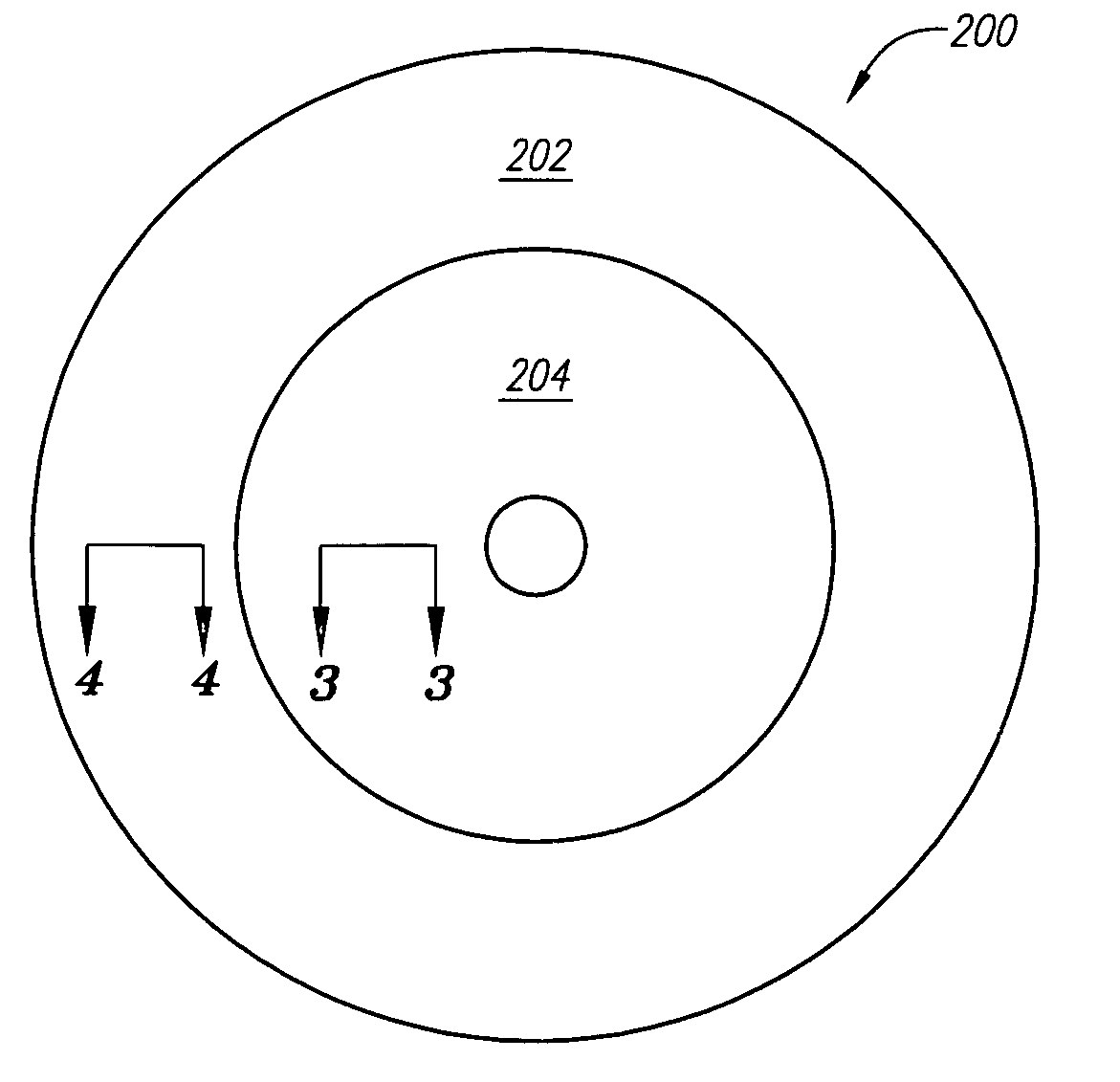

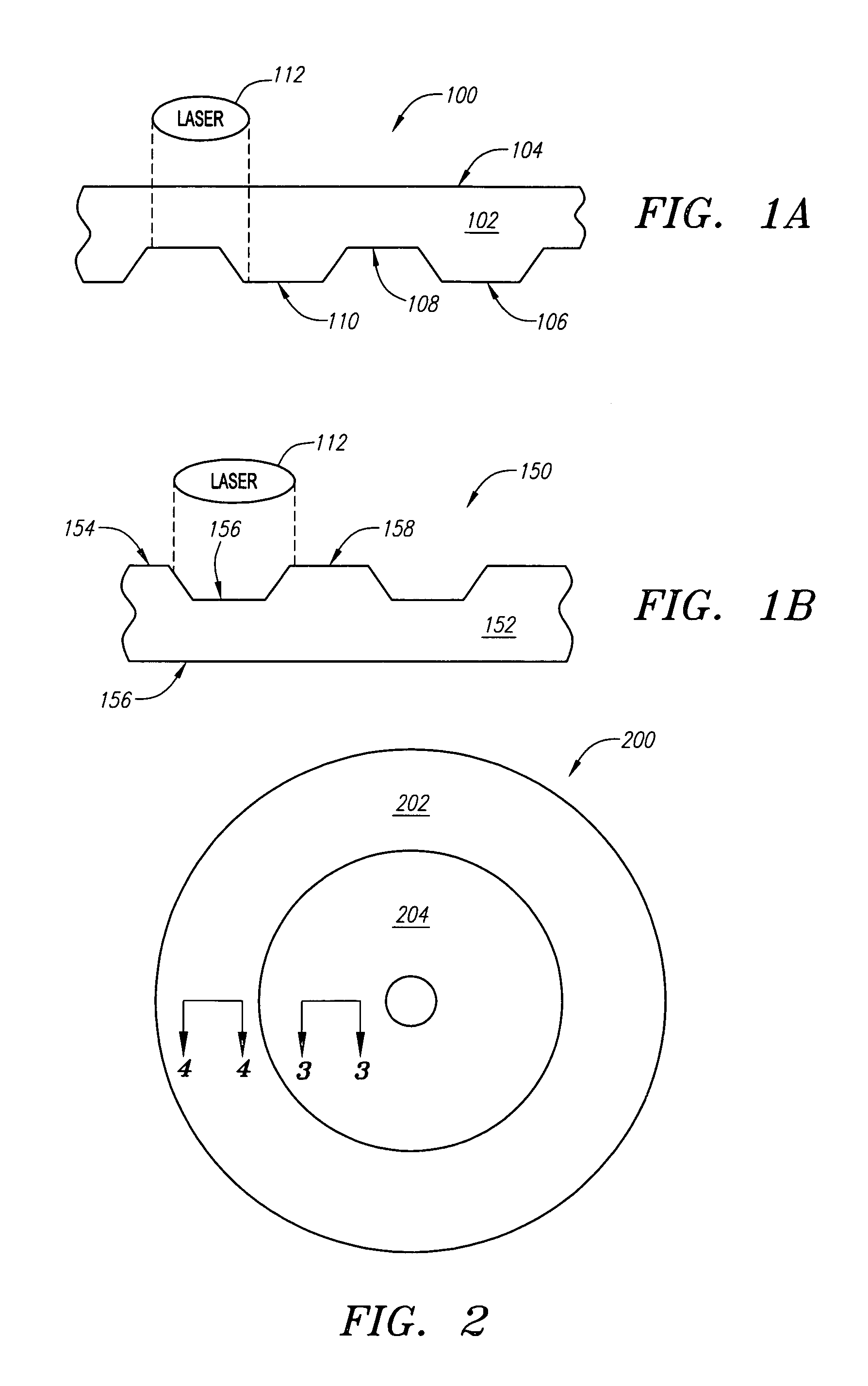

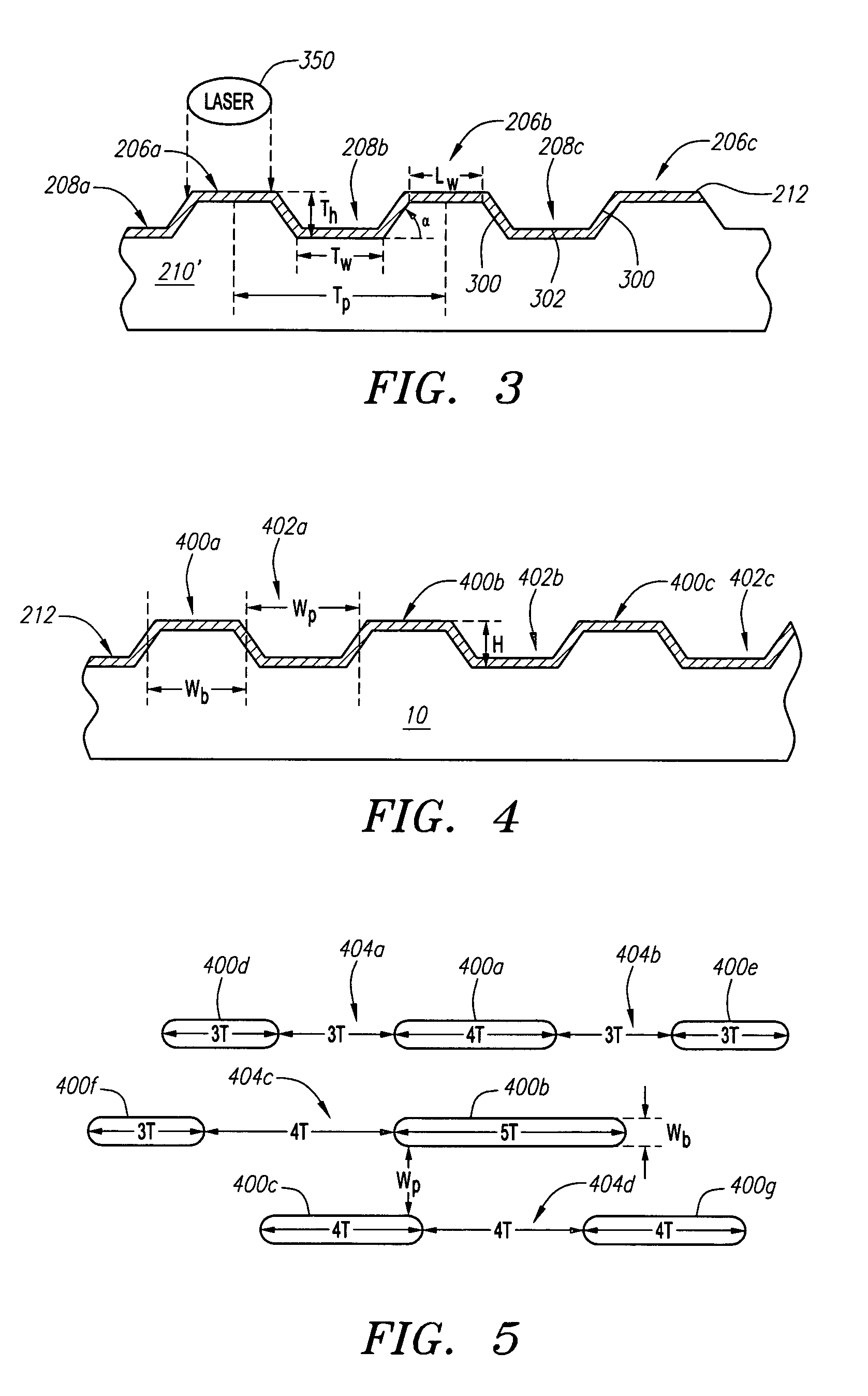

Dual density disc with associated properties

InactiveUS7554898B2Reduce the total massGreat degreeMechanical record carriersRecord information storageOptical storagePhase-change material

An optical storage disc has portions for storing pre-recorded or mastered information and portions for storing user writable information, where the mastered portion and the writable portions have different storage capacities or areal data densities. During manufacture, a substrate is formed with a sequence of bumps to represent the mastered information and a series of grooves and lands, where information can later be written on the lands. A phase-change material is deposited over the substrate, the phase-change material changing both physical structure and optical constants when written to, e.g., by a laser.

Owner:CLEARWATER INNOVATIONS +1

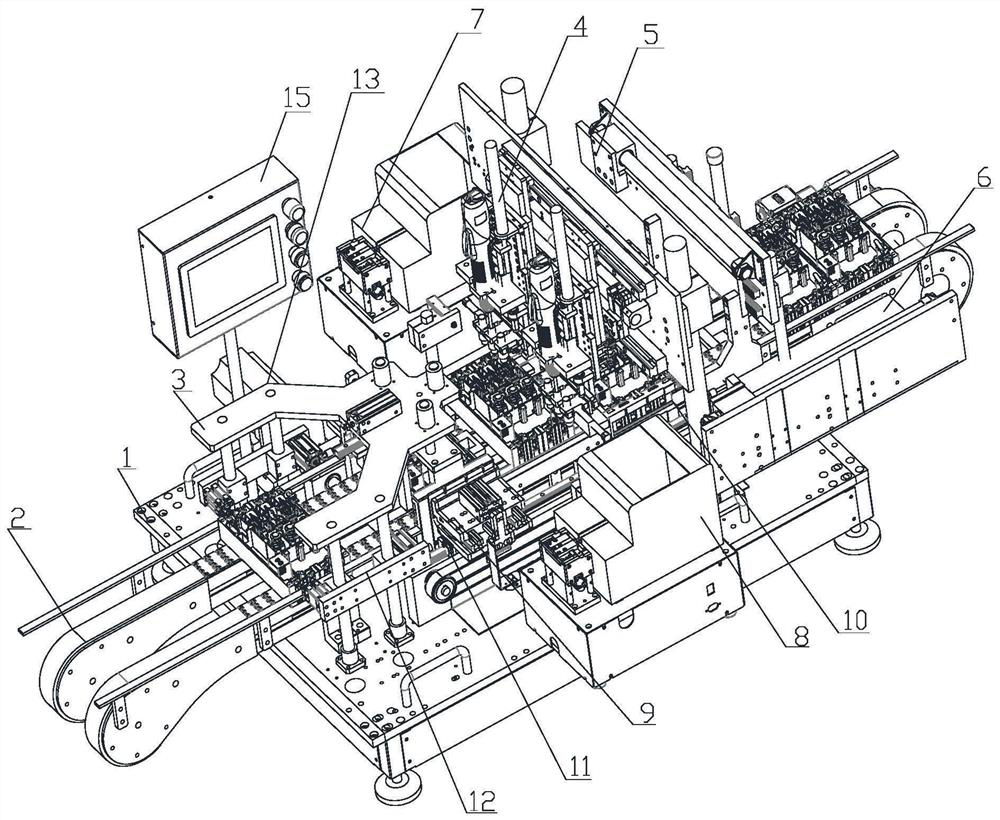

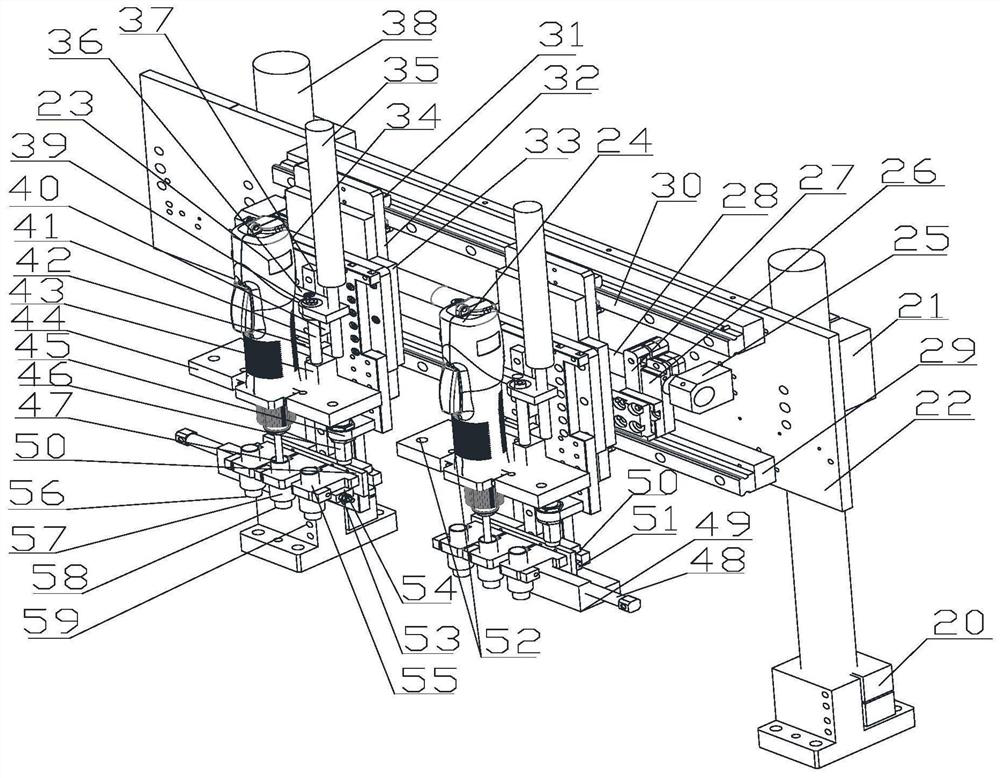

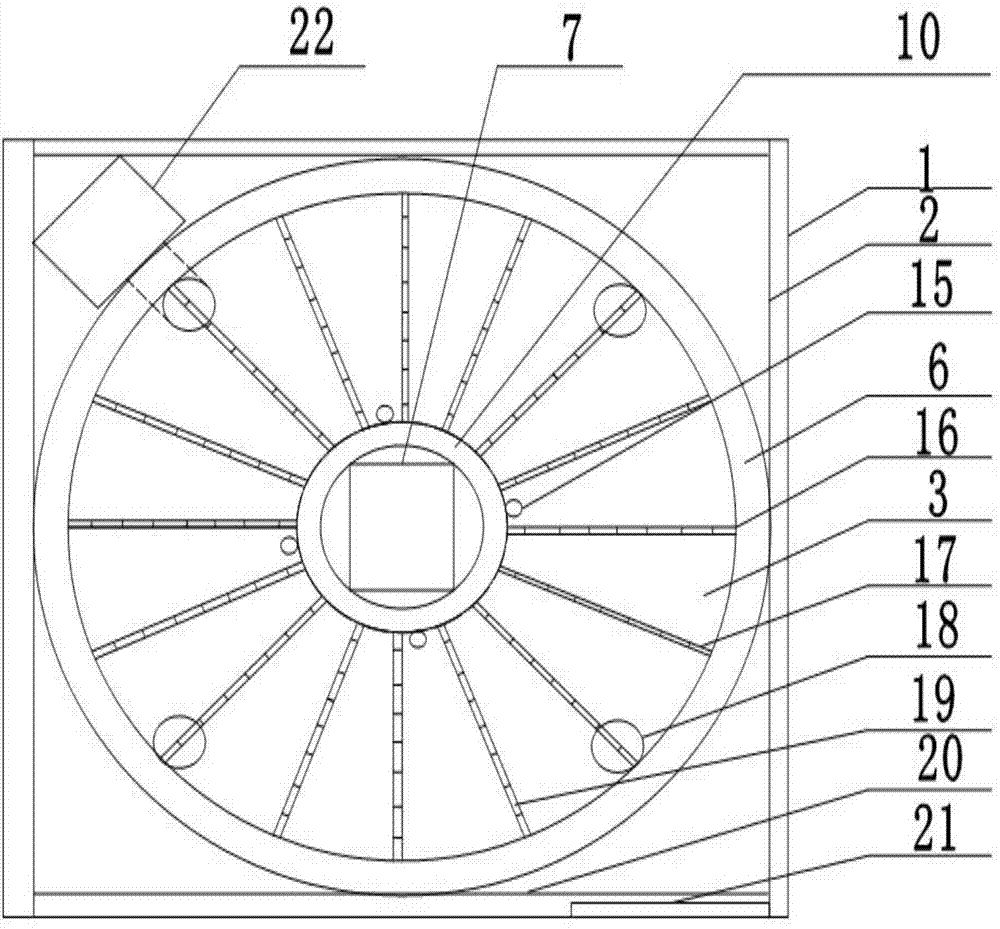

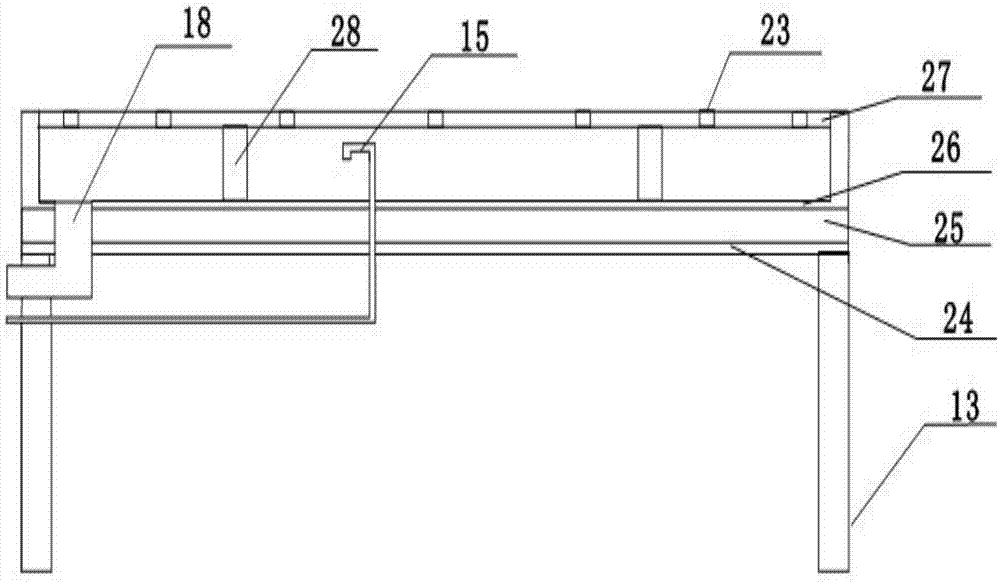

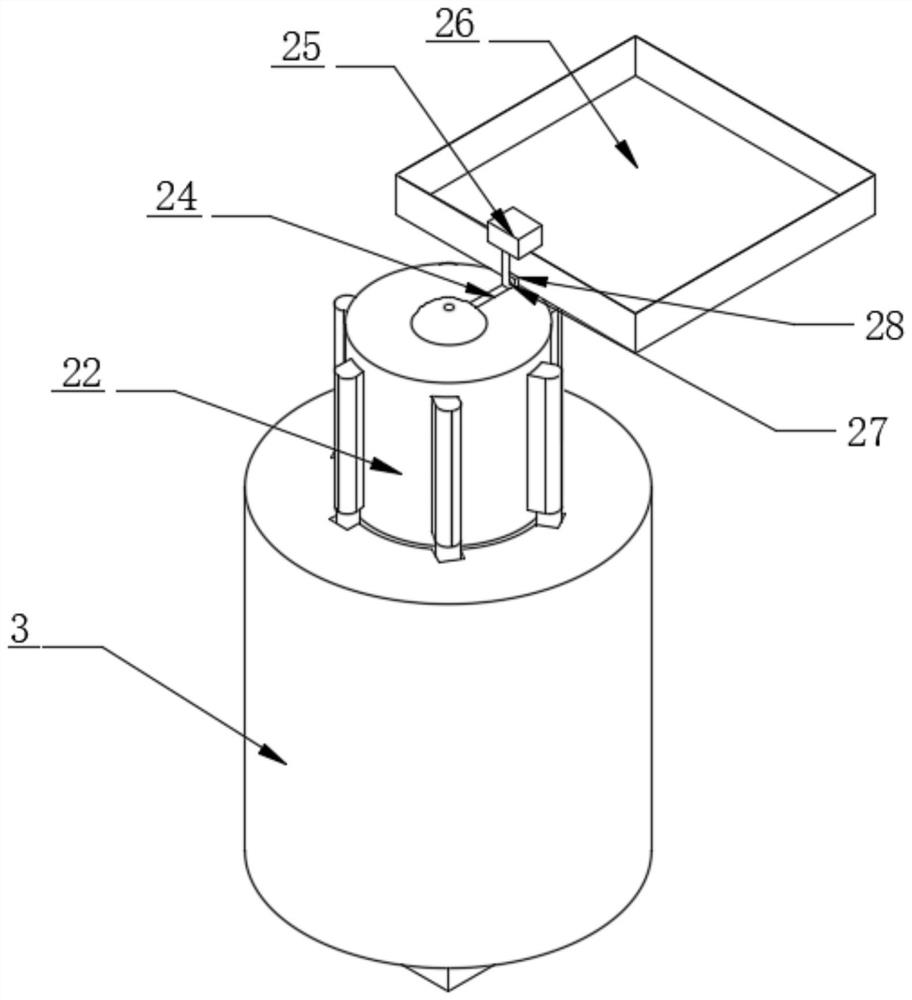

Full-automatic equipment for locking various screws

ActiveCN112008386AShort working distanceShort timeMetal working apparatusStructural engineeringAssembly line

The invention discloses full-automatic equipment for locking various screws. The full-automatic equipment comprises a base with a foot cup support, wherein a positioning stepping conveying mechanism is transversely mounted at the top of the base; a material separating and discharging assembly, a double-head multi-variety screw locking mechanism, an unqualified material sorting mechanism and an unqualified material pushing mechanism are sequentially mounted at the top of the base in the conveying direction; an electric appliance control box is further mounted on one side of the material separating and discharging assembly; an automatic feeder is mounted on the side surface of the double-head multi-variety screw locking mechanism; a feeding, positioning and conveying assembly is arranged between the material separating and discharging assembly and the double-head multi-variety screw locking mechanism; and a synchronous driving conveyor combination used for discharging is mounted betweenthe double-head multi-variety screw locking mechanism and the unqualified product sorting mechanism. Products are automatically positioned, automatically assembled and locked, conveyed and sorted in alinear assembly line in the whole automatic process, the operation distance is short, the assembling speed is high, the quality is guaranteed, the equipment structure is simple, a standard part building mechanism is adopted, the cost is low, and the delivery time is short.

Owner:杭州野陆机电技术有限公司

Optical pickup device

InactiveUS20080080071A1Easily and freely extendedEasily and freely and contractedRecord information storageMountingsOptical pickupEngineering

A lens tilt adjusting mechanism is configured by a piezoelectric element, a lens holder formed into a ring shape, and a holder fit-in part arranged in a tubular form in the movable part of an actuator. An objective lens is fixed on an inner side of the lens holder, the lens holder is fitted to the inner side of the holder fit-in part and held in the holder fit-in part in a tiltable manner when an outer peripheral surface contacts and slides along an inner peripheral surface of the holder fit-in part; the piezoelectric element is attached on the inner side of the holder fit-in part so that one end in an extending and contracting direction of the piezoelectric element contacts a step surface formed on the inner side of the holder fit-in part and the other end contacts the surface on the side away from an optical recording medium side of the lens holder; and other members are not interposed between the objective lens and the optical recording medium.

Owner:FUNAI ELECTRIC CO LTD

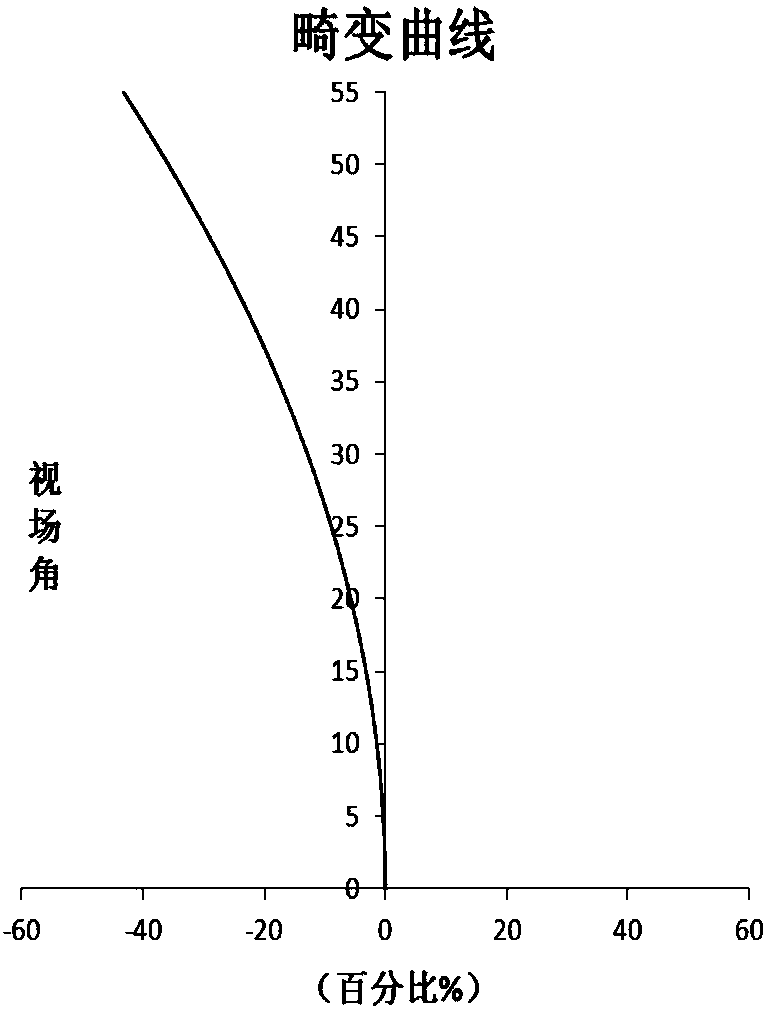

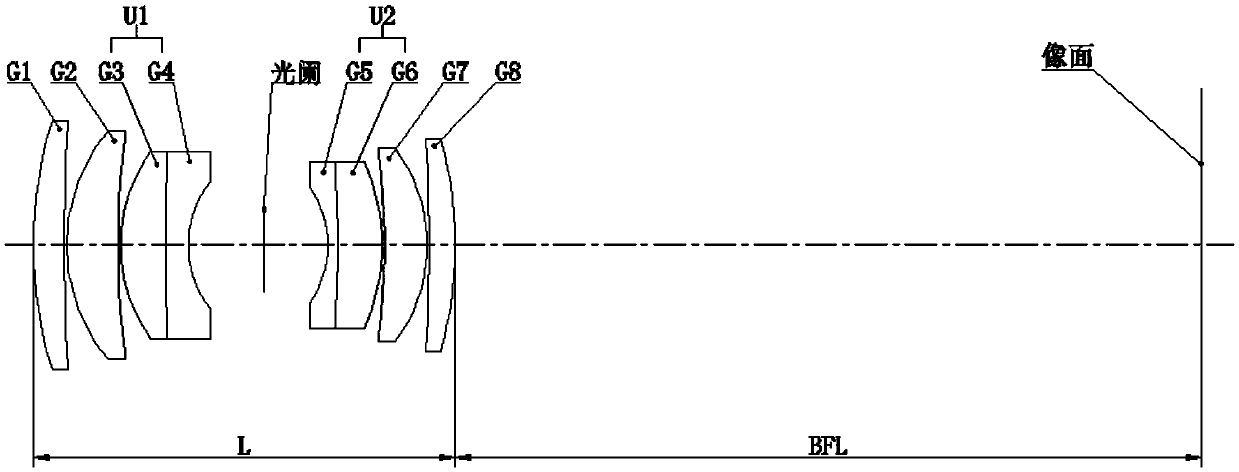

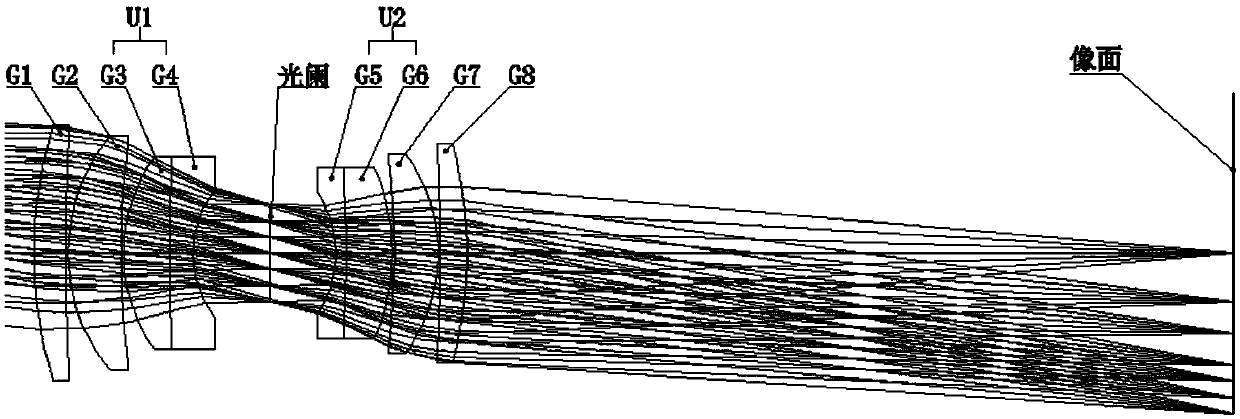

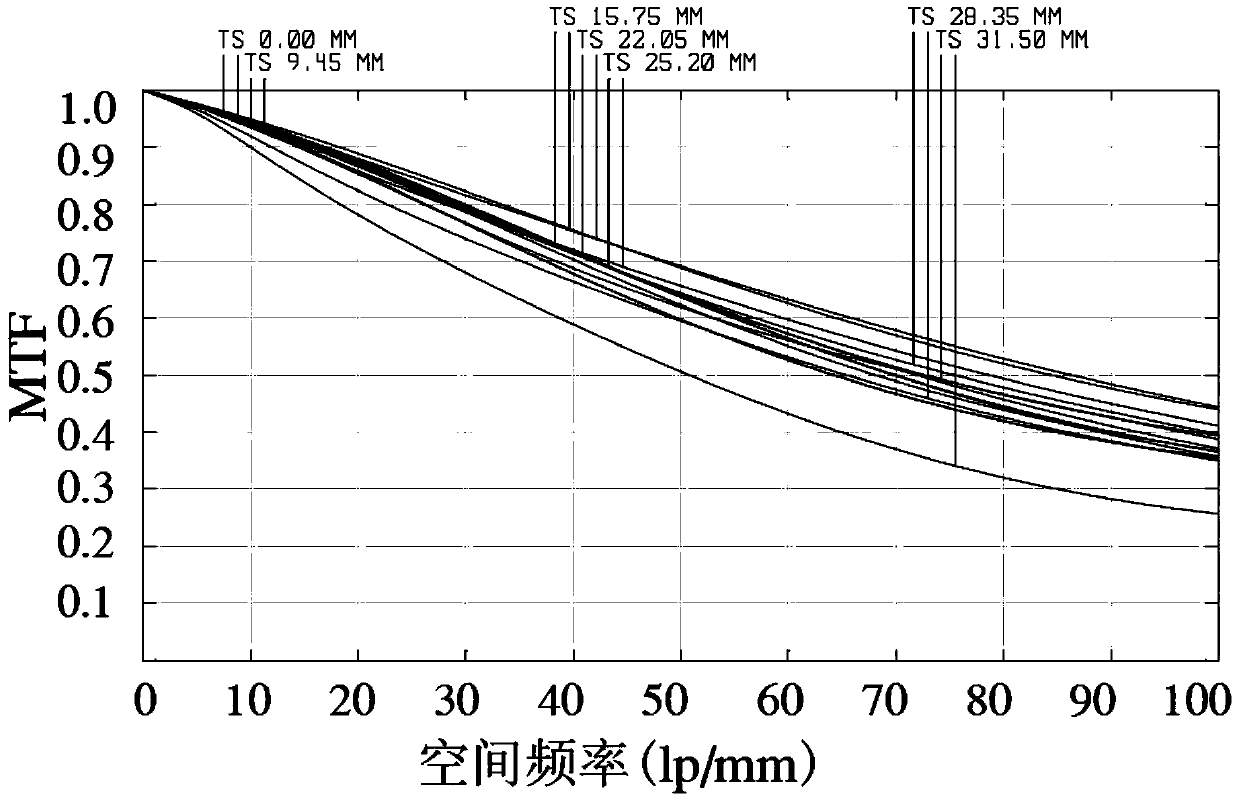

Large-aperture low-distortion fixed-focal-line scanning machine vision lens

The invention relates to the technical field of visual lenses, in particular to a large-aperture low-distortion fixed-focal-line scanning machine vision lens. The large-aperture low-distortion fixed-focal-line scanning machine vision lens sequentially comprises a first lens having the positive focal power and a meniscus structure, a second lens having the positive focal power and a meniscus structure, a third lens having the positive focal power and a meniscus structure, a fourth lens having a negative focal power and a meniscus structure, a fifth lens having a negative focal power and a meniscus structure, a sixth lens having the positive focal power and a meniscus structure, a seventh lens having the positive focal power and a meniscus structure, an eighth lens having the positive focalpower and a meniscus structure and a diaphragm located between the fourth lens and the fifth lens from the object surface side to the image surface side; the third lens and the fourth lens are glued to form a first lens group having the negative focal power, and the focal length is fU1; the fifth lens and the sixth lens are glued to form a second gluing lens group having the negative focal power,the focal length is fU2, and the following relationships that 0.35<|fU1 / f|<0.7, and 0.35<|fU2 / f|<0.7 are achieved. The large-aperture low-distortion fixed-focal-line scanning machine vision lens can meet the application requirements of large aperture, low distortion and the short working distance, and the clear aperture of the large-aperture low-distortion fixed-focal-line scanning machine visionlens can be flexibly adjusted.

Owner:GUANGDONG AOPUTE TECH CO LTD

Pump for discharging contents

ActiveUS20160303601A1Minimize the numberImprove assembly productivityPositive displacement pump componentsClosuresEngineeringMechanical engineering

The present invention relates to a pump for discharging contents, in which a pump upper body having contents outlets formed therein is inserted into the upper part of a pump main body having a contents inlet formed therein, a pump inner body is fitted into the inside of the pump main body and the pump upper body, the pump inner body integrally includes the serving as a temporary content reservoir for temporarily storing the contents, a suction valve plate for sucking the contents, and a discharge valve protruding ring for discharging the contents, and thus the contents are discharged as the volume of the temporary content reservoir in the pump inner body is changed by vertically moving the pump upper body relative to the pump main body.

Owner:KANG SUNGIL

Pump for discharging contents

ActiveUS9718073B2Minimize the numberImprove assembly productivityPositive displacement pump componentsClosuresEngineeringVALVE PORT

Owner:KANG SUNGIL

Endoscopic objective optical system and imaging apparatus

ActiveUS9459443B2Back focal lengthMakes it very inaccurateSurgeryEndoscopesConditional expressionEngineering

Owner:OLYMPUS CORP

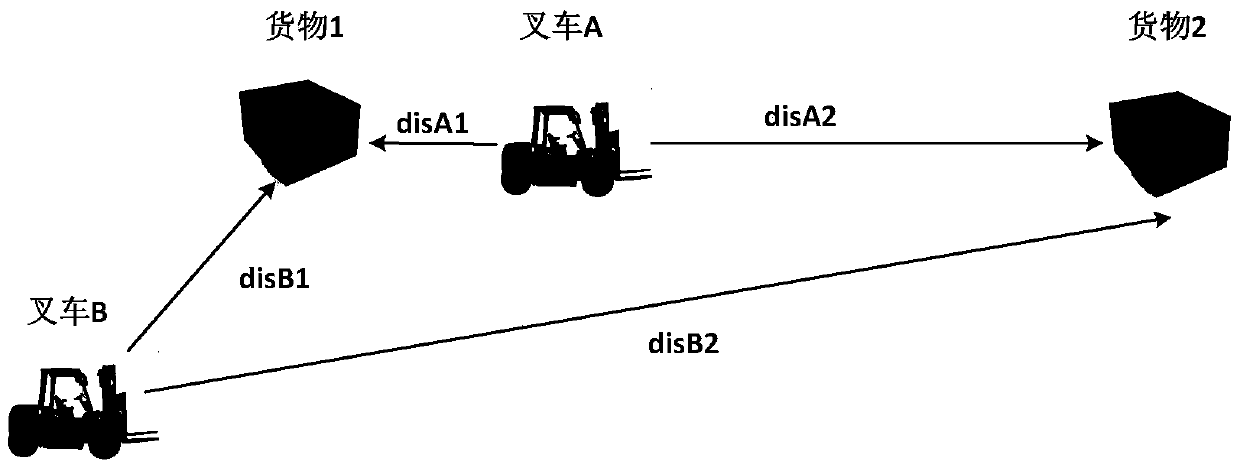

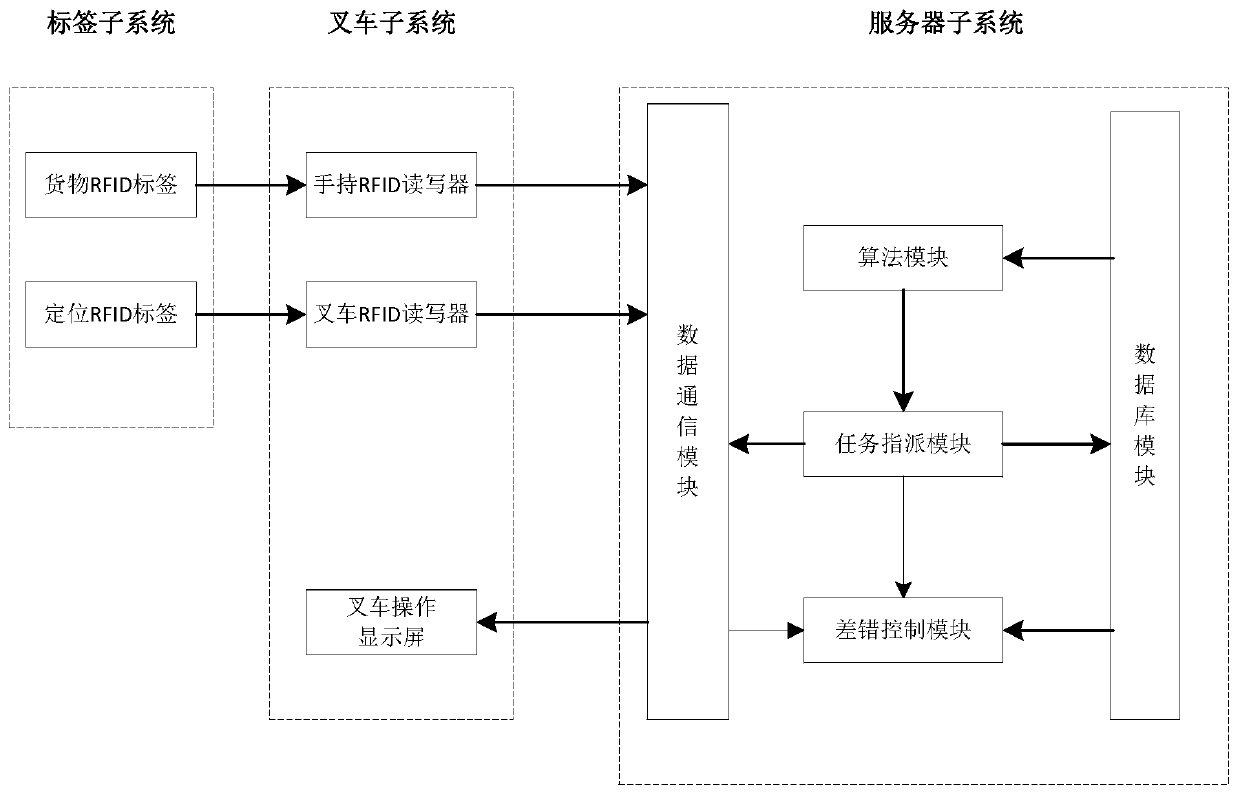

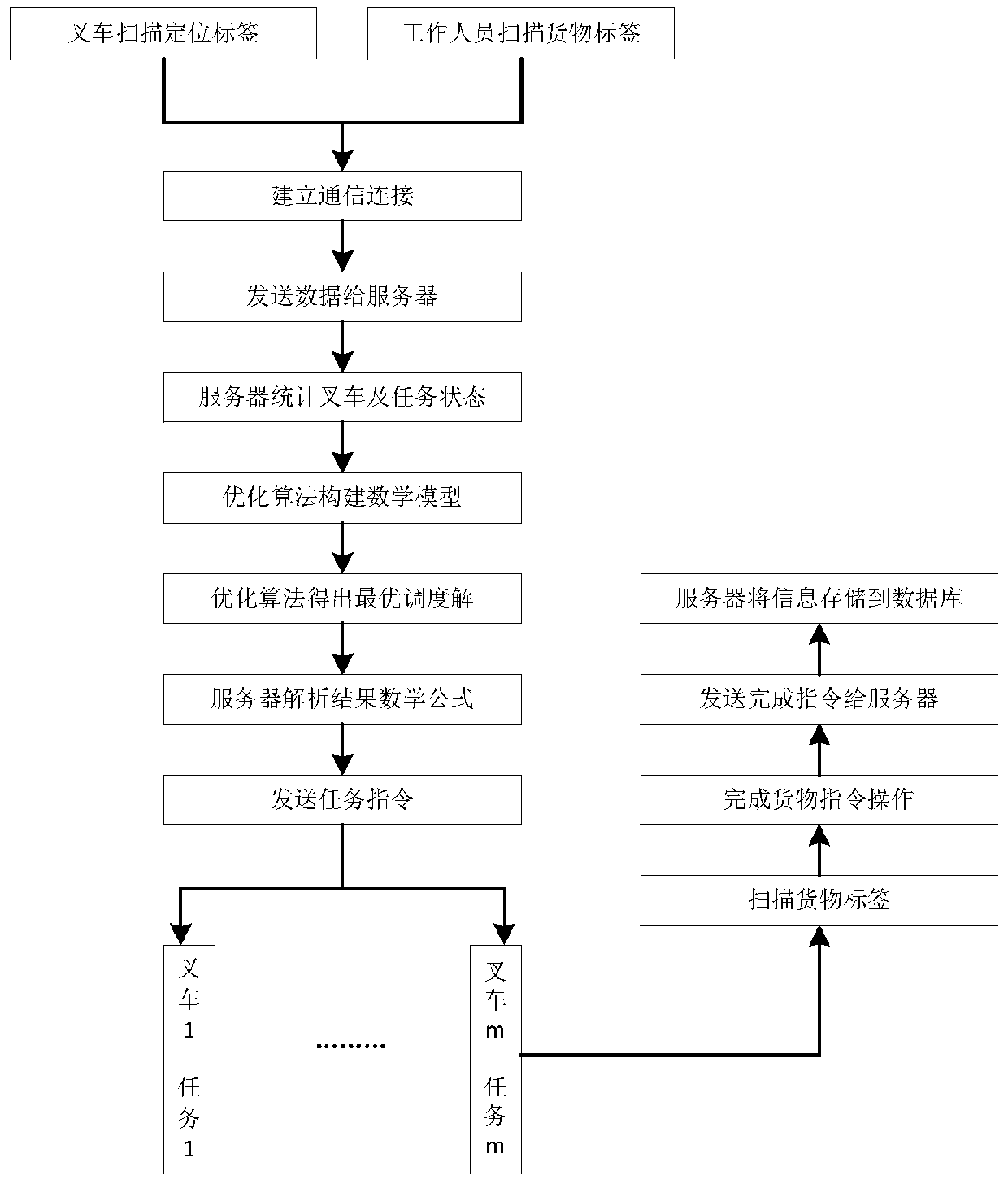

Method and system for optimizing dispatching based on RFID (Radio Frequency Identification Device)

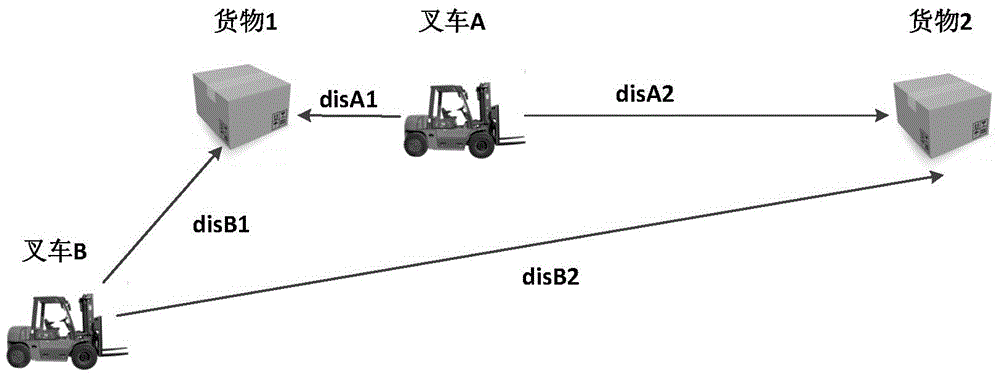

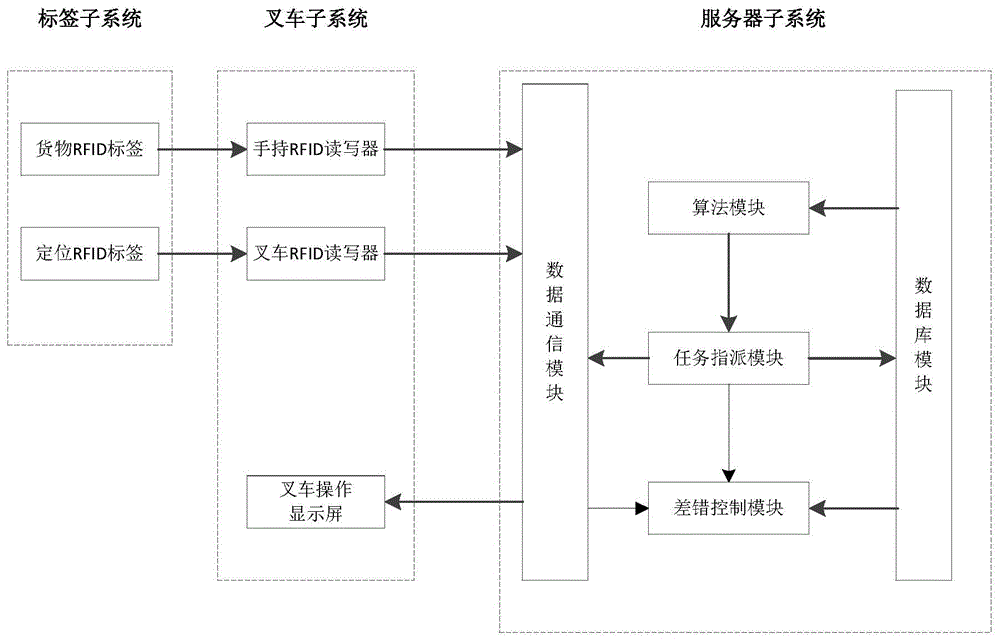

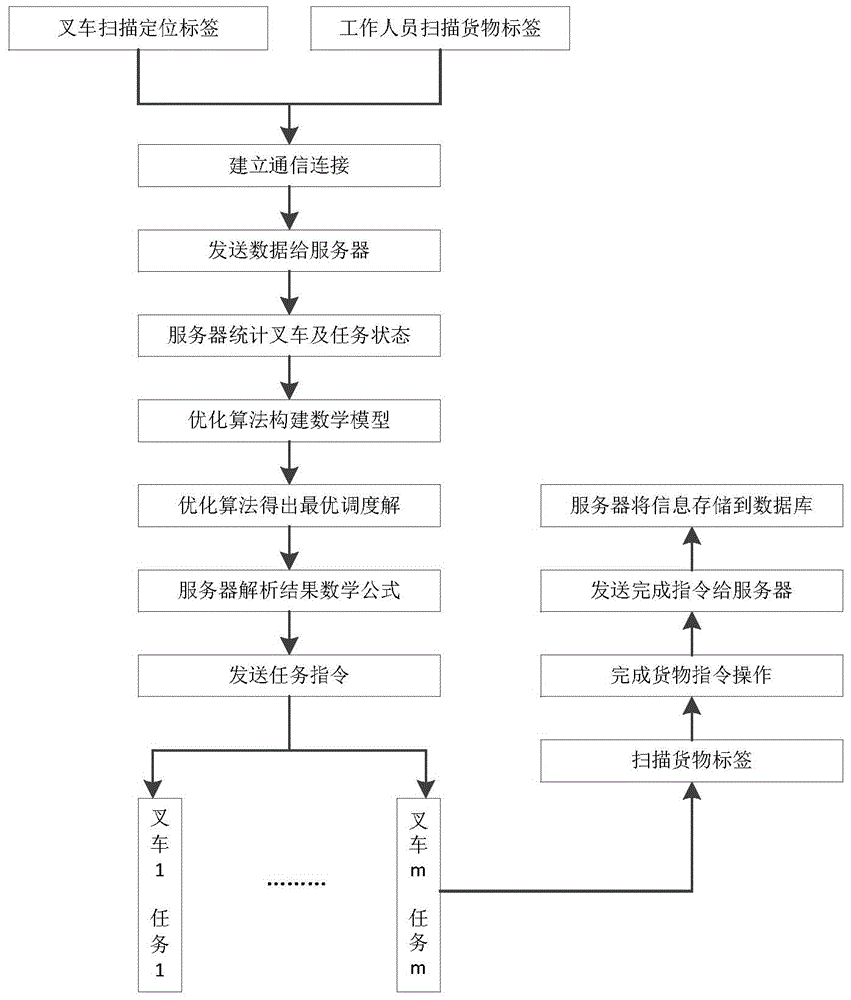

ActiveCN104616128ARealize optimal schedulingShort working distanceCo-operative working arrangementsLogisticsLifting capacityTotal work

The invention discloses a method and a system for optimizing dispatching based on RFID, belonging to the technical field of RFID radio frequency identification. In the dispatching optimizing method, the product of the distance d between a forklift and cargos and the rated load-lifting capacity w of the forklift is used as the reference of estimating the work cost f of the forklift, the task dispatching problem of the forklift is abstracted into an appointing problem of m forklifts and n tasks and the optimal dispatching scheme is realized by calculating the lowest total work cost of all forklifts. According to the method and system for optimizing dispatching, the optimization to the traditional forklift dispatching problem is realized, the RFID technique can be positioned more real-timely and precisely, the measurement standard of the calculation method is more scientific, the forklift dispatching in a factory is more systemized, the work efficiency of the forklift is improved and the work cost of the forklift is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

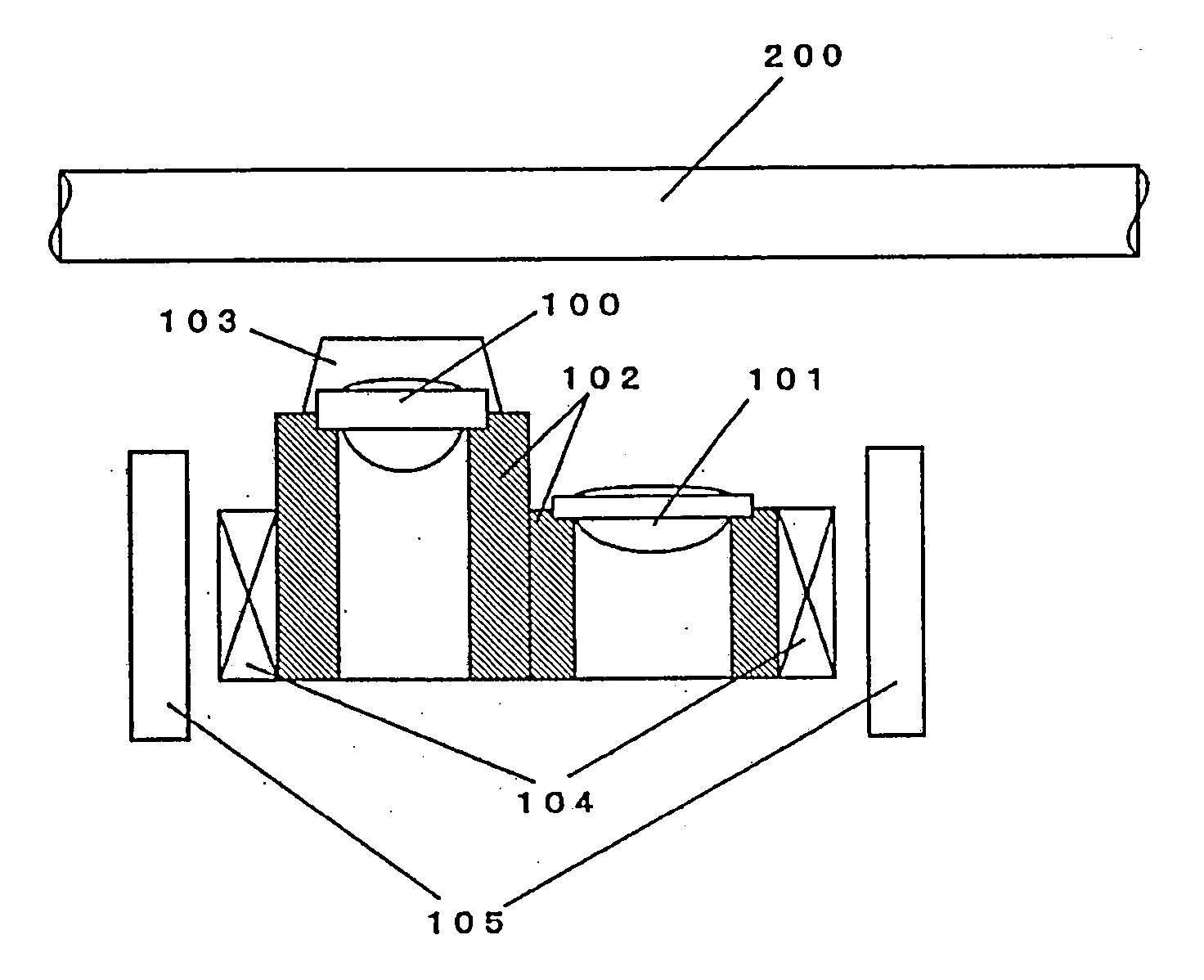

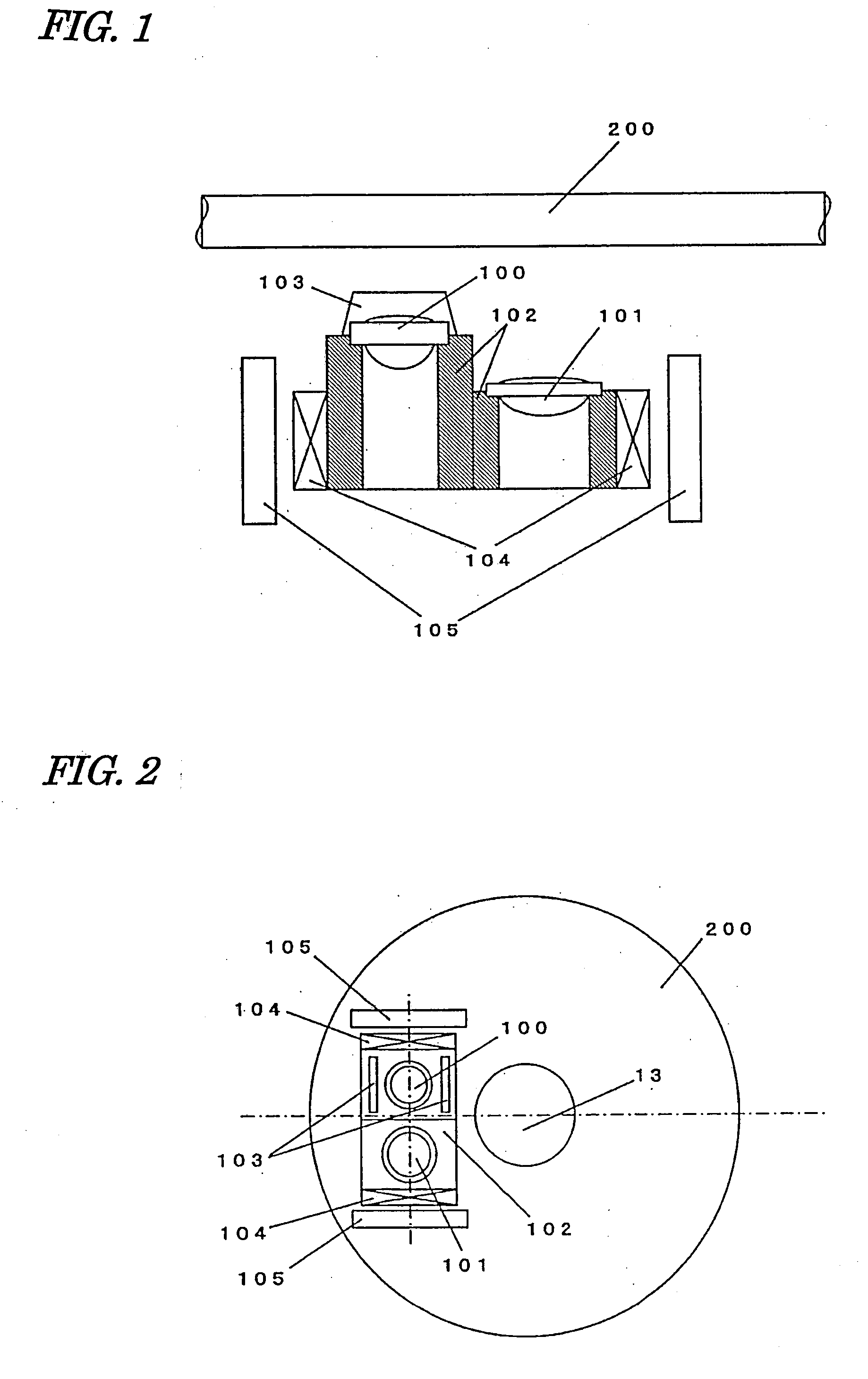

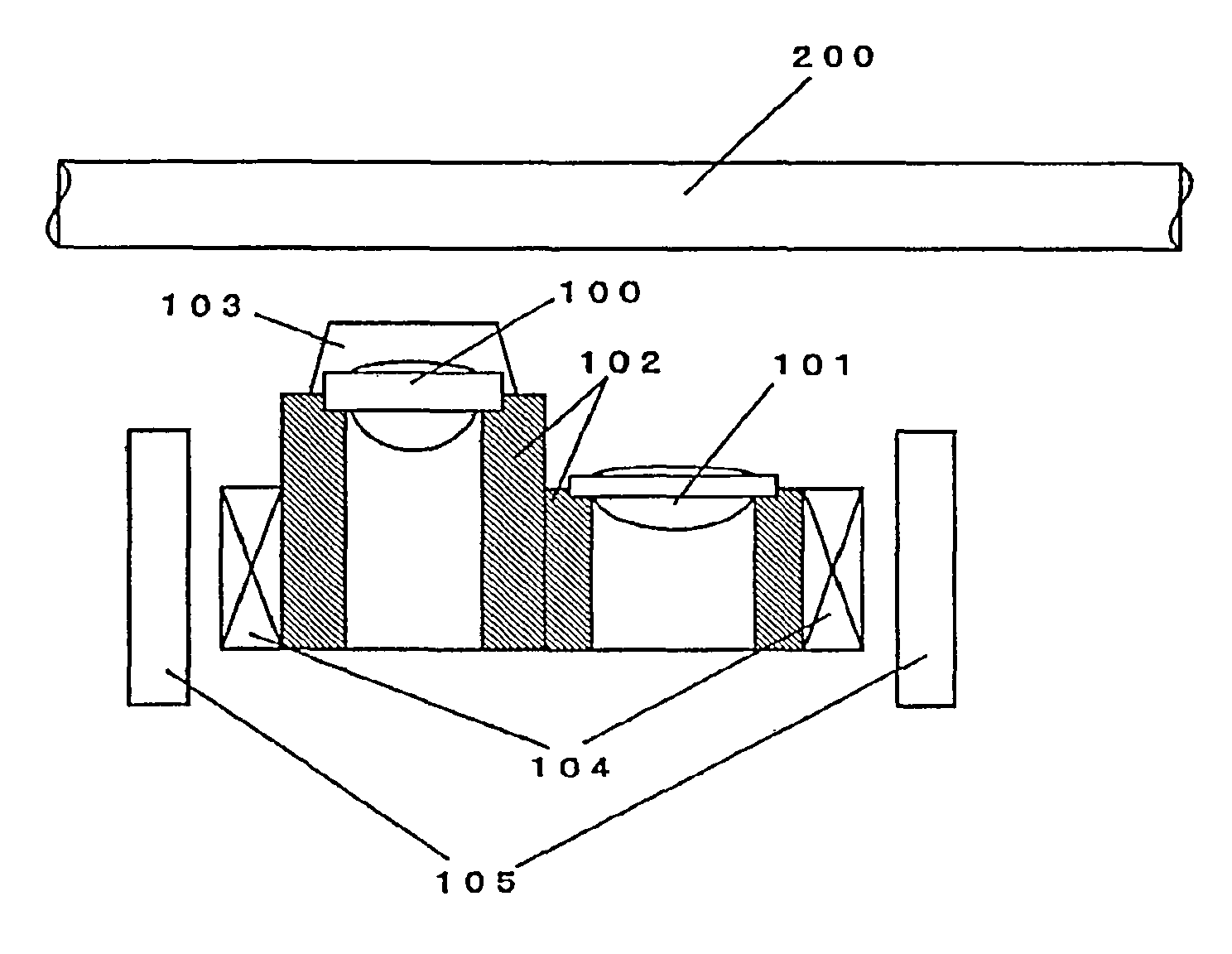

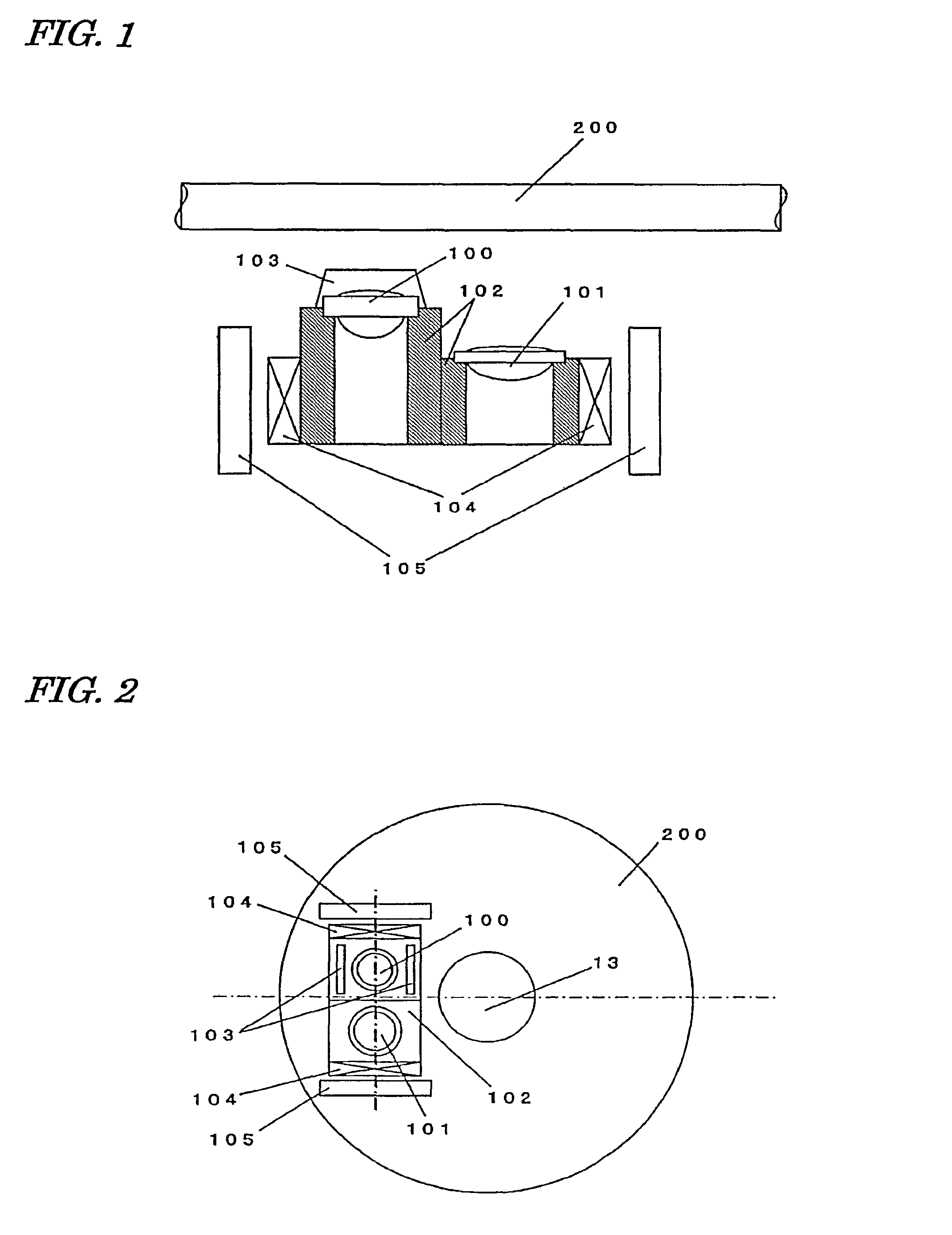

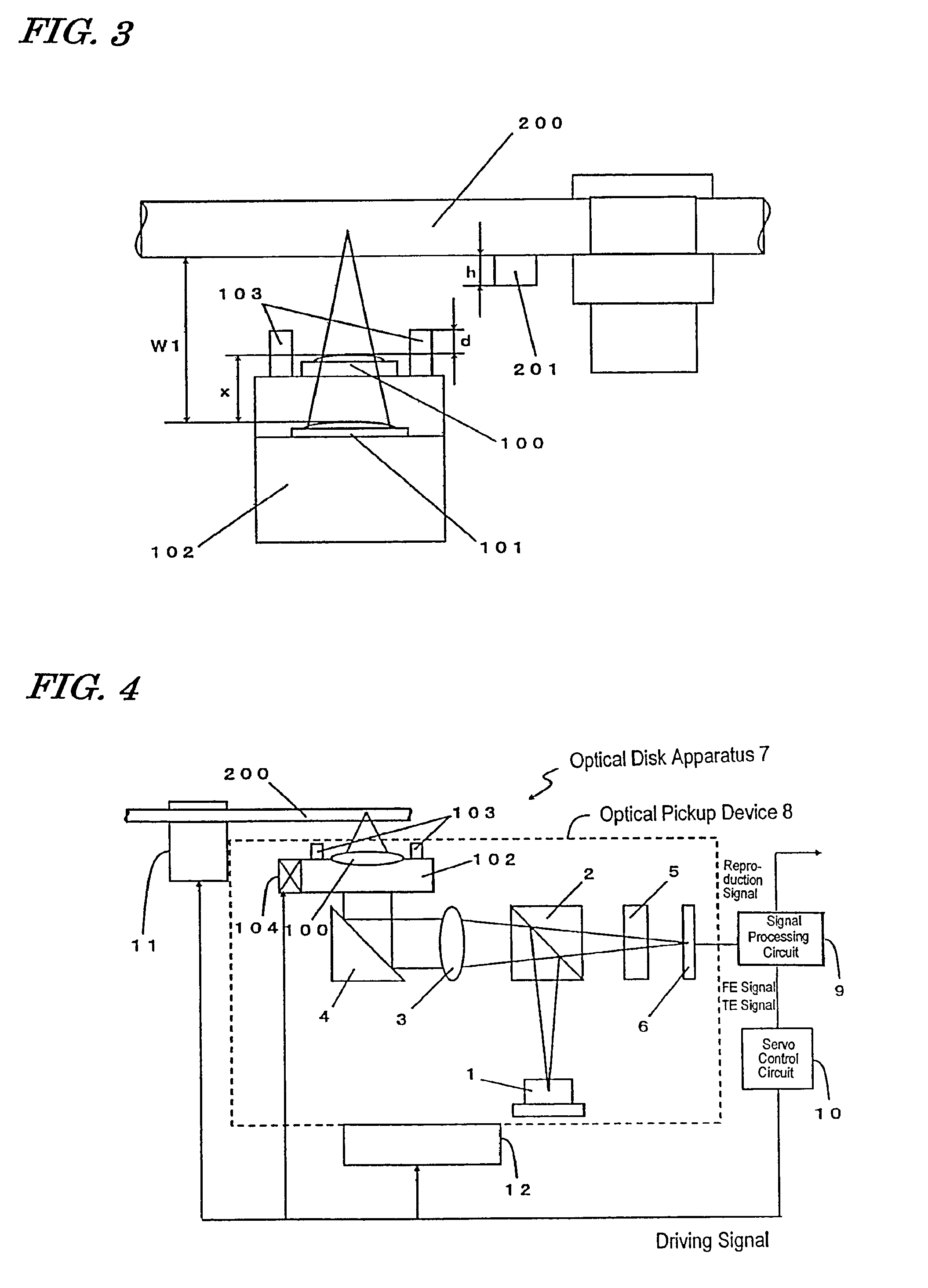

Optical pickup device and information processing apparatus incorporating the optical pickup

ActiveUS20070014206A1Short working distanceCombination recordingOptical head protectionOptical pickupInformation processing

A highly reliable optical pickup which is not likely to collide with an optical disk is provided. Relative positions of two objective lenses 100 and 101 (along a focus direction) on a lens holder 102 are determined so that, while the objective lens 101 having a longer working distance is focused on an optical disk 200, the objective lens 100 having a shorter working distance and a protective member 103 are at positions which are more distant from the optical disk 200 than a height h of a protrusion which is present in an inner peripheral region of the optical disk optical disk 200.

Owner:PANASONIC CORP

Method and device for optically examining a plurality of microscopic samples

ActiveUS20200284715A1Convenient recordingIncrease the number ofMicroscopesIndividual particle analysisMechanical engineeringMaterials science

Owner:CARL ZEISS MICROSCOPY GMBH

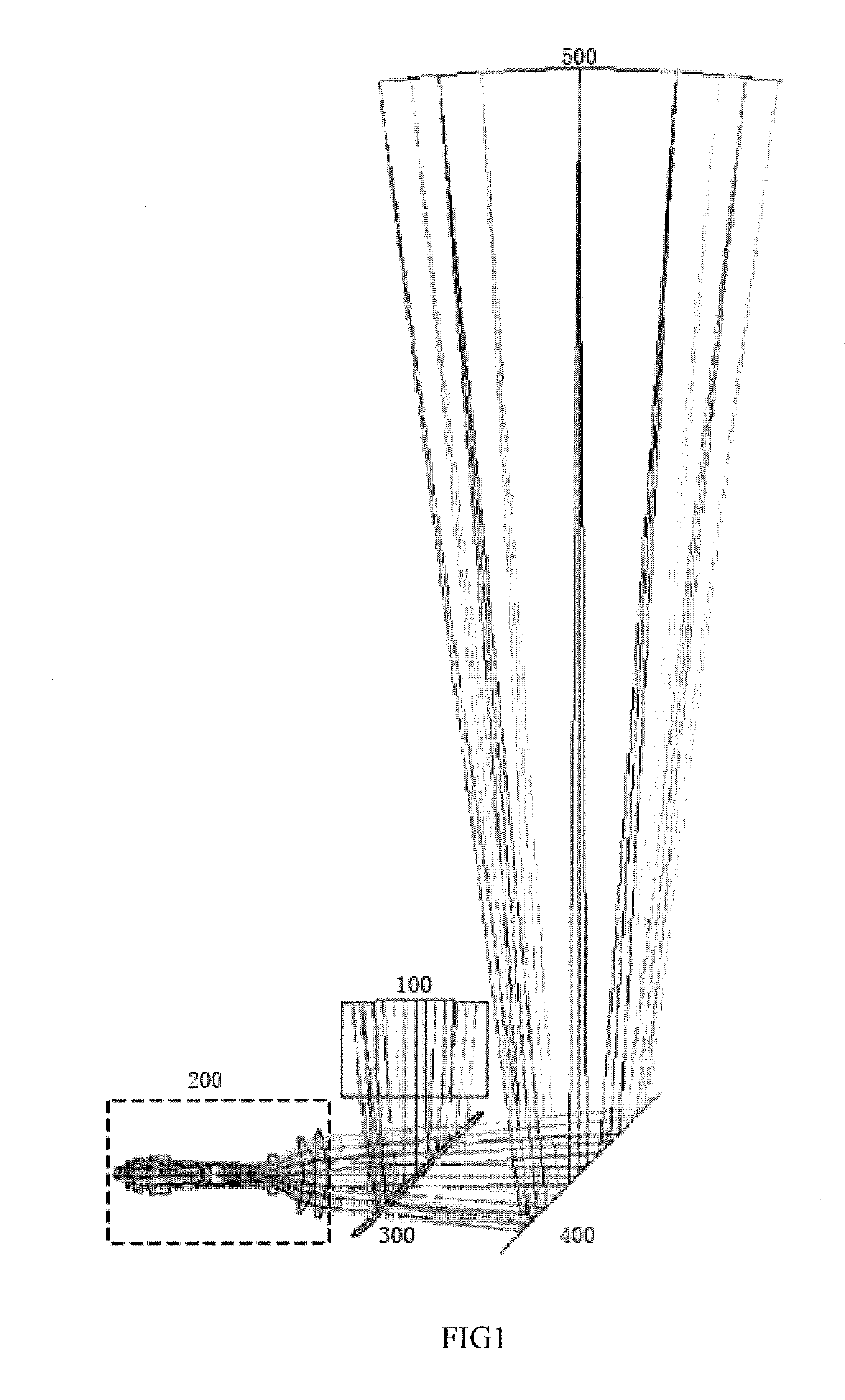

A micro-objective lens and a high-resolution broadband imaging system with such micro-objective lens

The present invention discloses a micro-objective lens, comprising the first lens group, the second lens group, the third lens group, the fourth lens group, the fifth lens group, the sixth lens group, the seventh lens group, the eighth lens group, the ninth lens group and the tenth lens group with optical axis arranged in a sequence from the left to the right; the focal length of the first lens group is negative; the second lens group belongs to doublet, in which the focal length of the first and second lens is positive and negative respectively; the focal length of the third lens group is positive; the fourth and fifth lens groups belongs to doublets, in which the focal length of the first and second lens in each group is negative and positive respectively; the focal length of the sixth lens group is positive; the focal length of the seventh and eighth lens groups is negative; the focal length of the ninth and tenth lens groups is positive. The present invention also discloses a high-resolution broadband imaging system with aforesaid micro-objective lens.

Owner:ZHEJIANG UNIV

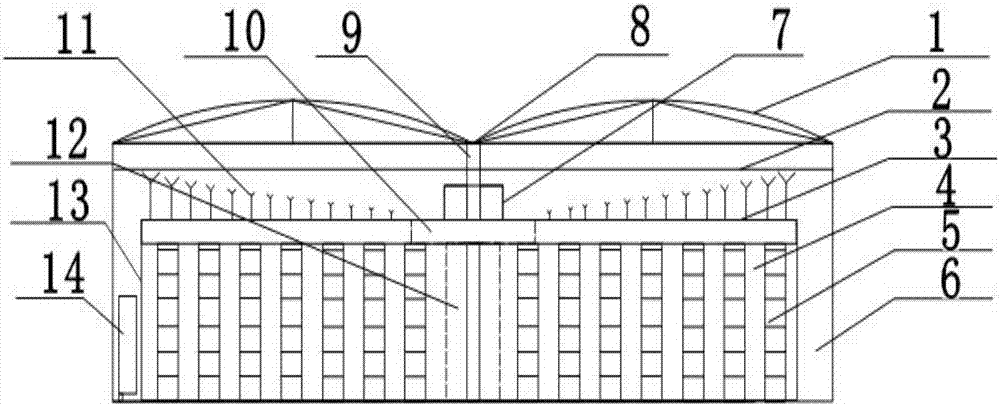

Ecological plant factory

InactiveCN107278705AMany seedlingsImprove germination rateClimate change adaptationAgriculture gas emission reductionNutrient solutionOxygen

The invention relates to an ecological plant factory. The ecological plant factory comprises a greenhouse, a plant cultivation room and an edible fungi room. The plant cultivation room comprises a seedling-raising room, a radial disc type plant cultivation bed, a nutrition liquid pool and a nutrient liquid regeneration system. The edible fungi room is arranged below the plant cultivation room and provided with edible fungi racks. The ecological plant factory has the following beneficial effects: artificial light is utilized for growing seedlings and natural light is utilized for plantation; seeds and seedlings are planted in the seedling-raising room; grown seedlings are transplanted to the inner-most part of the cultivation bed; plants which can be harvested after growing up are cultivated in the outermost part of the cultivation bed; edible fungus are planted in the lower layer; due to the fact that circular water cultivation and a unique plantation method are adopted, plant cultivation density is increased by more than one time; harvested output is increased by more than one time; edible fungus are planted below the plant cultivation room; sufficient oxygen is provided for edible fungus by plant photosynthesis in the daytime; CO2, as a gaseous fertilizer, for growth of plants are generated by respiration effect of edible fungus at night; therefore, the ecological plant factory is little in investment, high in yield and efficiency and low in composite cost and helps save fertilizers.

Owner:于葵 +1

Optical pickup device and information processing apparatus incorporating the optical pickup

ActiveUS7936644B2Short working distanceCombination recordingOptical head protectionOptical pickupInformation processing

A highly reliable optical pickup which is not likely to collide with an optical disk is provided. Relative positions of two objective lenses 100 and 101 (along a focus direction) on a lens holder 102 are determined so that, while the objective lens 101 having a longer working distance is focused on an optical disk 200, the objective lens 100 having a shorter working distance and a protective member 103 are at positions which are more distant from the optical disk 200 than a height h of a protrusion which is present in an inner peripheral region of the optical disk optical disk 200.

Owner:PANASONIC CORP

An RFID-based optimal scheduling method and system

ActiveCN104616128BRealize optimal schedulingShort working distanceCo-operative working arrangementsLogisticsLifting capacityTotal work

The invention discloses a method and a system for optimizing dispatching based on RFID, belonging to the technical field of RFID radio frequency identification. In the dispatching optimizing method, the product of the distance d between a forklift and cargos and the rated load-lifting capacity w of the forklift is used as the reference of estimating the work cost f of the forklift, the task dispatching problem of the forklift is abstracted into an appointing problem of m forklifts and n tasks and the optimal dispatching scheme is realized by calculating the lowest total work cost of all forklifts. According to the method and system for optimizing dispatching, the optimization to the traditional forklift dispatching problem is realized, the RFID technique can be positioned more real-timely and precisely, the measurement standard of the calculation method is more scientific, the forklift dispatching in a factory is more systemized, the work efficiency of the forklift is improved and the work cost of the forklift is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

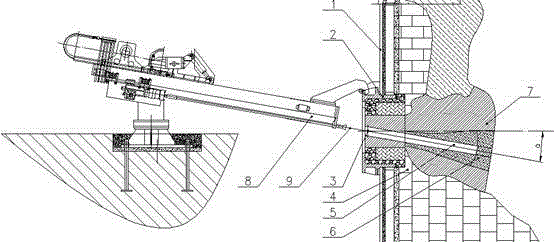

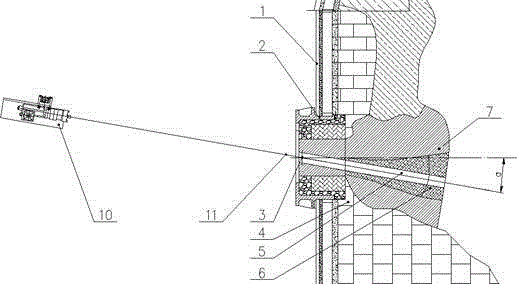

A method for tapping a blast furnace taphole and a blast furnace taphole equipment system

ActiveCN104141021BAvoid wear and tearReduce consumptionBlast furnace componentsBlast furnace detailsEngineeringMechanical engineering

The invention relates to a method and an equipment system for forming a tapping hole in a blast furnace. The method comprises the following steps: firstly, drilling a hole in the blast furnace along a preset tapping channel from a tapping hole reference point by adopting a mechanical tapping hole forming machine, and withdrawing a drilling rod of the mechanical tapping hole forming machine from the tapping channel when the drilling rod reaches a preset position; and secondly, generating laser by adopting a laser tapping hole forming machine to break through the tapping channel along the hole drilled by the mechanical tapping hole forming machine. The equipment system comprises a mechanical tapping hole forming machine and a laser tapping hole forming machine capable of generating laser, wherein the mechanical tapping hole forming machine and the laser tapping hole forming machine cooperate for breaking through and forming the tapping channel of the blast furnace. The method and the equipment system have the beneficial effects that the wear of a drill bit of the mechanical tapping hole forming machine is reduced; the formed tapping channel is smooth and convenient in tapping; tapping hole forming machine equipment can be prevented from being damaged during splashing at the tapping hole; and the remote operation can be carried out, so that the personal safety of operators is ensured.

Owner:WISDRI ENG & RES INC LTD

Optical system of optical pick-up

ActiveUS7209428B2Sufficiently suppressing aberrationAstigmatism can be reducedMechanical record carriersRecord information storageCouplingLight beam

An optical system of an optical pick-up, which is provided with a light source that emits a light beam, and an objective lens that converges the light beam emitted by the light source onto a data recording layer of an optical disc. The optical system satisfies a condition: 0.75<d·(M−1) / (M·L)<1.0, where d (mm) represents a thickness of the objective lens, M represents magnification of the optical system, and L (mm) represents an O / I distance which is defined as a distance between an object and an image. A beam spot suitable for the optical disc is formed by the objective lens on the data recording layer of the objective lens without using a coupling lens.

Owner:KONICA MINOLTA INC

Prime mover and working method

PendingCN112502798AAvoid lossSimple structureHydro energy generationSteam engine plantsPrime moverMechanical energy

The invention belongs to a prime mover, and particularly relates to a prime mover and a working method. The prime mover comprises an evaporator, a machine body and an energy body, wherein the energy body is arranged in the machine body in a sliding mode; a closed cavity is formed between the bottom of the energy body and the inner wall of the machine body; the evaporator communicates with the cavity and continuously absorbs heat to evaporate a liquid working medium, and the volume of the working medium expands due to evaporation so as to push the energy body to move upwards to do work until the upper limit stroke; and when the ambient temperature is lower than the evaporation temperature, the energy body moves downwards to compress the gaseous working medium due to self weight to completethe liquefaction. According to the prime mover and the working method, the evaporator evaporates the liquid working medium, the volume expansion pushes the energy body to move upwards to do work, andthe mechanical energy is output; when the ambient temperature meets the set value of the liquefaction stroke, the gaseous working medium is compressed by the self weight of the energy body to carry out the liquefaction stroke; the whole working stroke and liquefaction stroke do not need other auxiliary equipment, so that unnecessary energy loss is avoided; and the whole structure is simple, the cost is low, the performance is stable, the efficiency is high, and the positive economic value is realized.

Owner:钟学斌

Full refraction projection optical system

ActiveCN100468119CEffective correctionImprove image qualityOptical elementsImaging qualityOptical axis

This invention provides one total reflection projection optical system for object plane to form imaging plane, wherein the said system is divided into front and back sets to form hole diaphragm as symmetric surfaces; the front set comprises first to sixth lens with one to three lens form reverse distant structure; the back set orderly comprises seven to twelve lens symmetric to six to one lens about hole radium; the said whole reflection projection optical system all surface types are of sphere or plane without non-sphere surface.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com