Ecological plant factory

An ecological plant and plant technology, applied in the fields of botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of waste of resources, large growth space, waste, etc., and achieve high utilization rate of nutrient solution and large number of seedlings. , the effect of short working distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing.

[0055] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

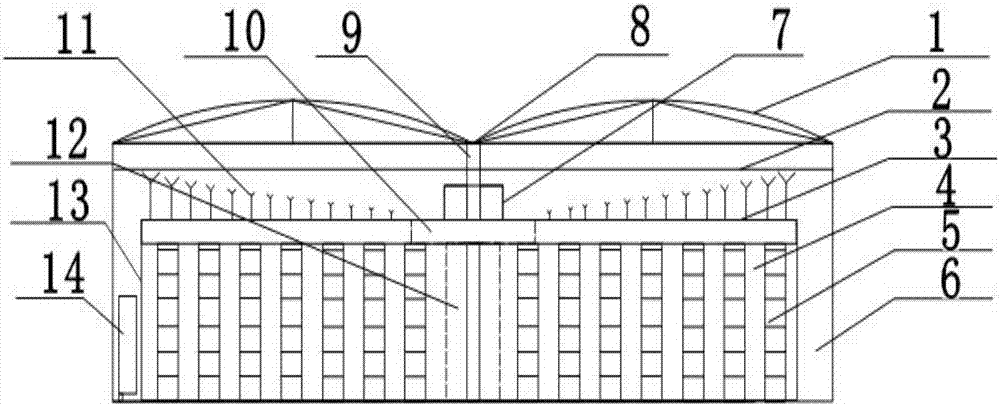

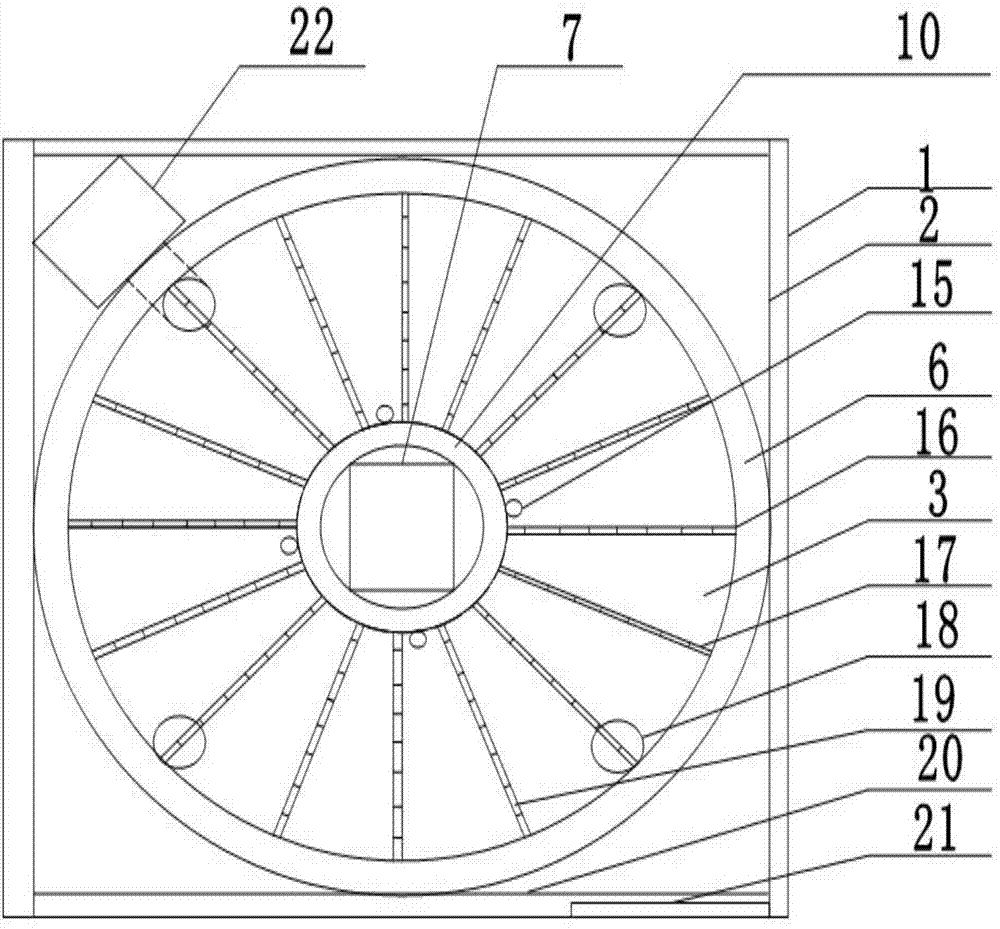

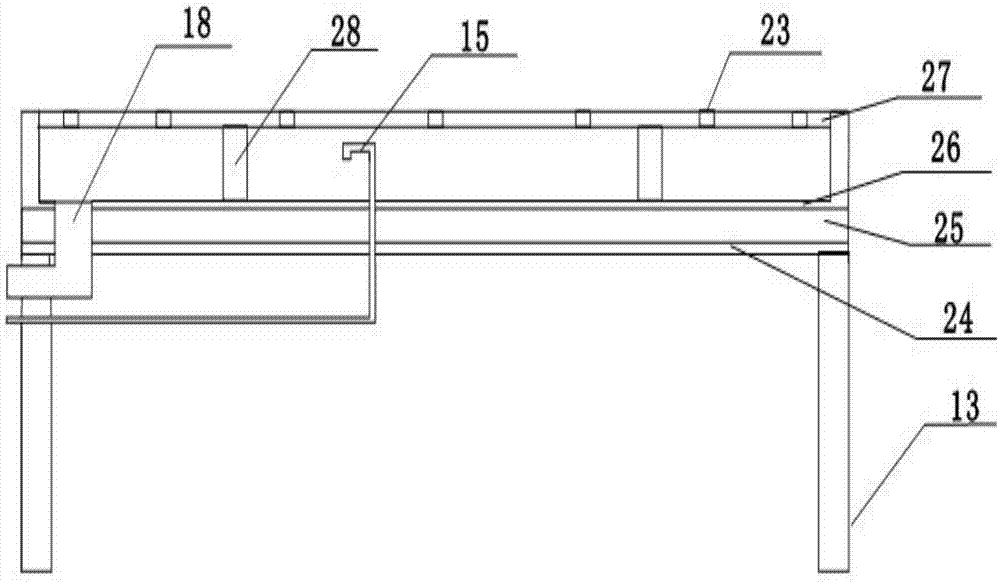

[0056] figure 1 Shown is the front view of the ecological plant factory. In the figure, the ecological plant factory includes a multi-span thermal insulation greenhouse 1 and a plant planting room; the greenhouse 1 can also be a thermal insulation greenhouse, the upper layer of the greenhouse 1 is a plant planting room, and the lower layer is an edible fungus room; There are seedling room 7 and radial disc plant planting bed 3 in the plant planting room. The seedling room 7 is located in the center hole of the radial disc plant planting bed 3. There is a seedling room working between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com