Full-automatic equipment for locking various screws

A fully automatic, screw-locking mechanism technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems that automatic assembly and automatic locking cannot be realized, and achieve low cost, fast assembly speed, and high-quality equipment. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The present invention takes a 4-pole molded case circuit breaker as an example;

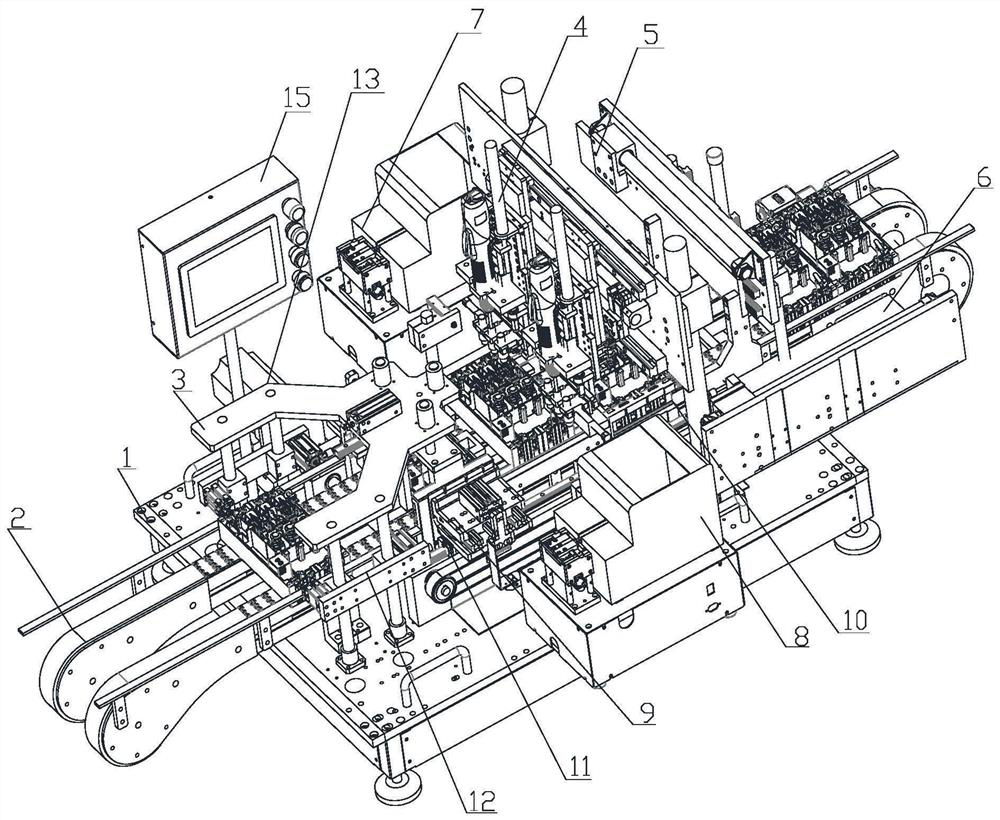

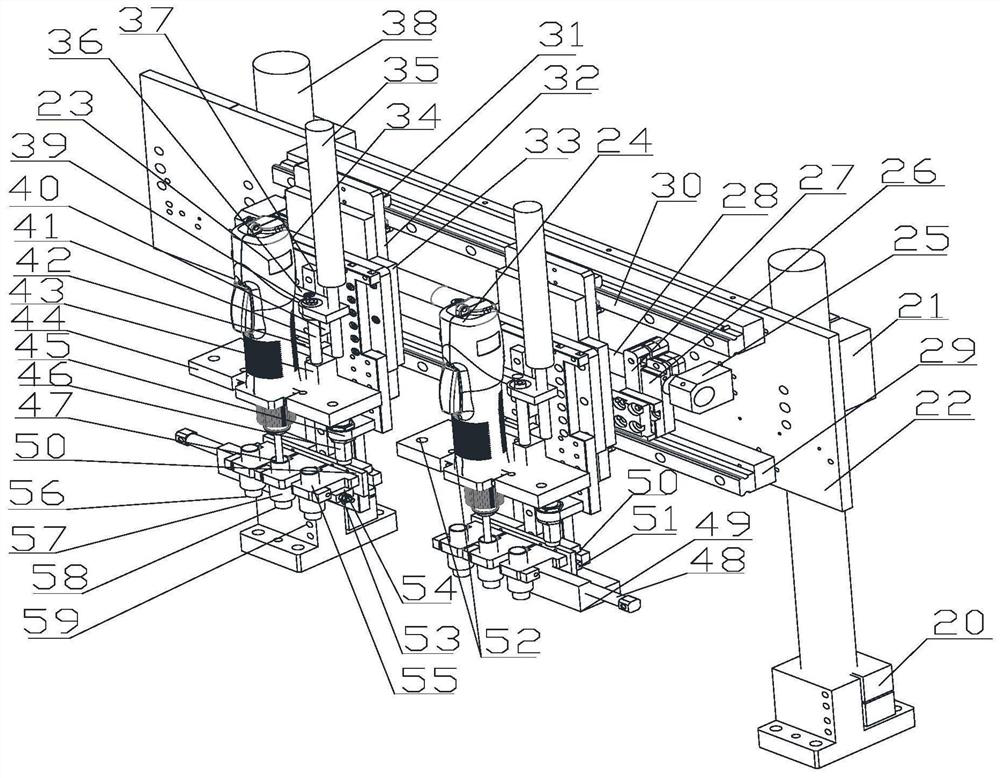

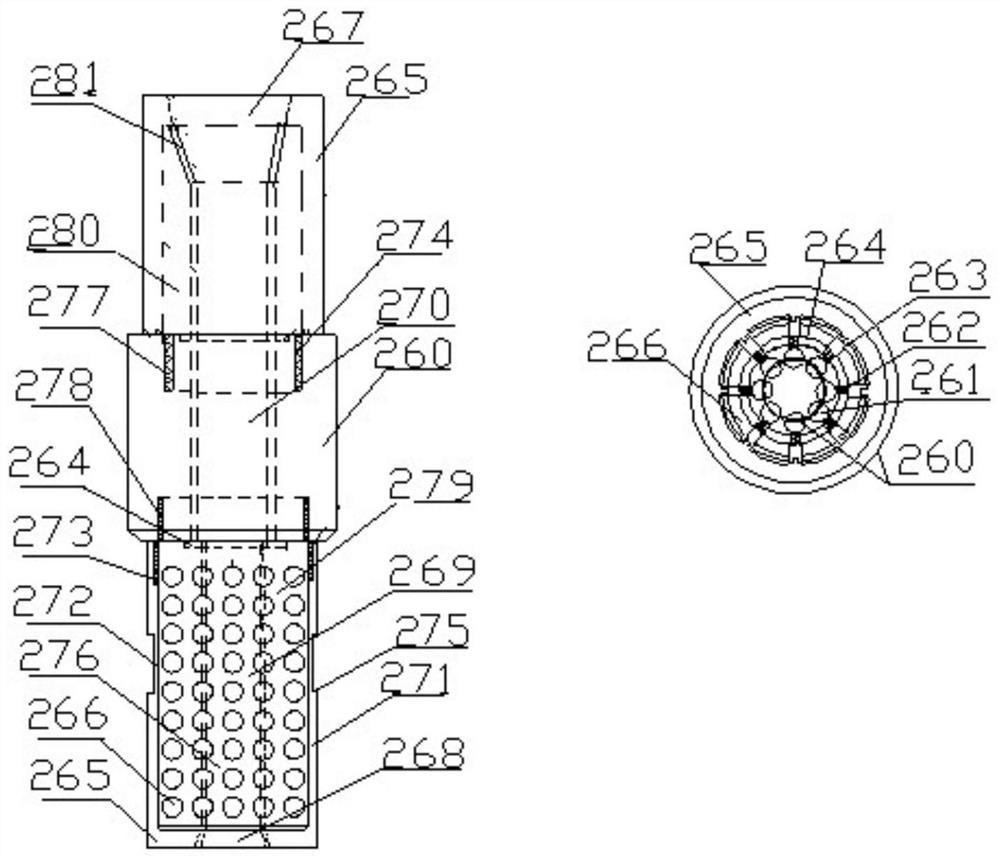

[0029] like figure 1 and image 3 Shown is a fully automatic device for locking various screws, including a base 1 supported by a foot cup, and a positioning stepping conveying mechanism 2 is installed horizontally on the top of the base 1; the top of the base 1 is stepped and conveyed according to the positioning 2, the conveying direction is successively equipped with a spacer discharge assembly 3, a double-head multi-variety locking screw mechanism 4, an unqualified sorting mechanism 5, and an unqualified push mechanism 6; one side of the spacer discharge assembly 3 is also installed with Electrical control box 15; double-headed multi-variety locking screw mechanism 4 is equipped with automatic feeder I7 and automatic feeder II8; the spacer feeding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com