Full refraction projection optical system

A projection optical system and full refraction technology, applied in the field of projection optical systems, can solve the problems that aberrations cannot meet bumps, do not conform to lithography technology, etc., and achieve the effects of reducing processing, improving imaging quality, and correcting aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The omni-refractive projection optical system of the present invention will be further described in detail below.

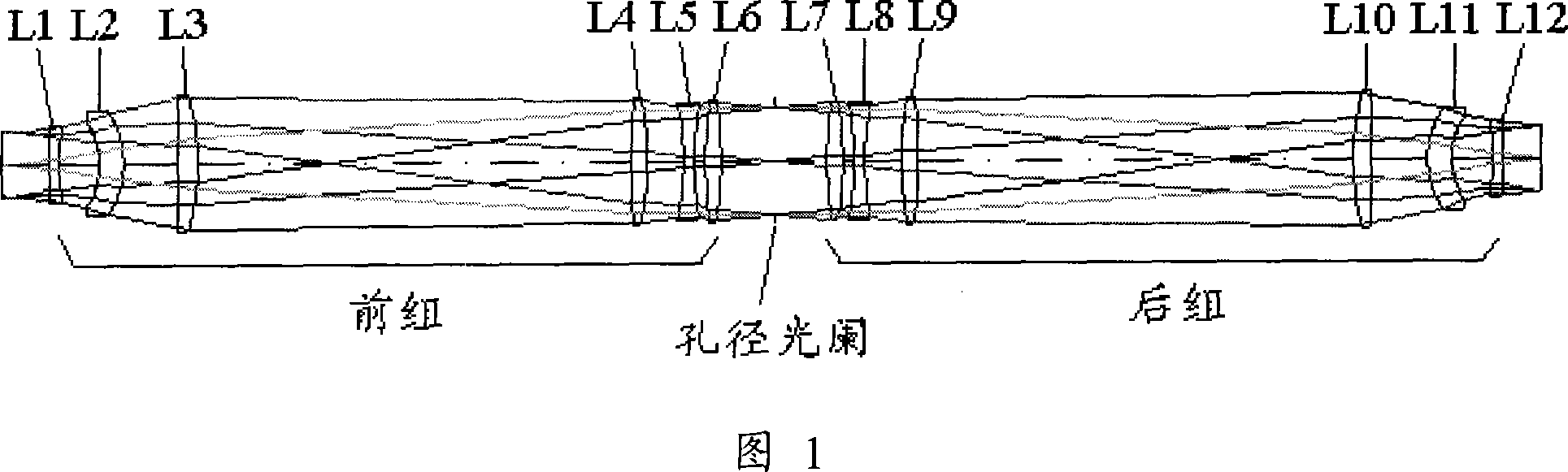

[0023] The present invention provides a total refraction projection optical system. As shown in FIG. 1, the projection optical system has a symmetrical structure, that is, it includes a front group, an aperture stop, and a rear group sequentially from the side of the object plane, and the front group and Each lens component of the rear group takes the aperture stop surface as the symmetry plane, and the optical structure is completely symmetrical (the surface radius and interval are equal, and the optical material is consistent), and the magnification is -1. The advantage of the symmetrical structure with a magnification of -1 is that according to the primary aberration theory, the vertical axis aberrations: coma, distortion, and chromatic aberration of magnification are automatically corrected to 0, and then the axial aberrations are corrected separately b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com