Black nanophase ceramics pigment and preparation method thereof

A technology of nano-ceramics and pigments is applied in the field of nano-black pigments and the preparation of black nano-pigments to achieve the effects of black color, stable color and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 68gMn(NO 3 ) 2 4H 2 O, 124gCr(NO 3 ) 3 9H 2 O, 208gFe(NO 3 ) 3 9H 2 O, 42gCo(NO 3 ) 2 ·6H 2 O, 30gH 2 O and 195g CH 3 COONH 4 And mix evenly, hold in Al 2 o 3 In the crucible, it is heated at 400°C, and the combustion reaction occurs until no more gas is released.

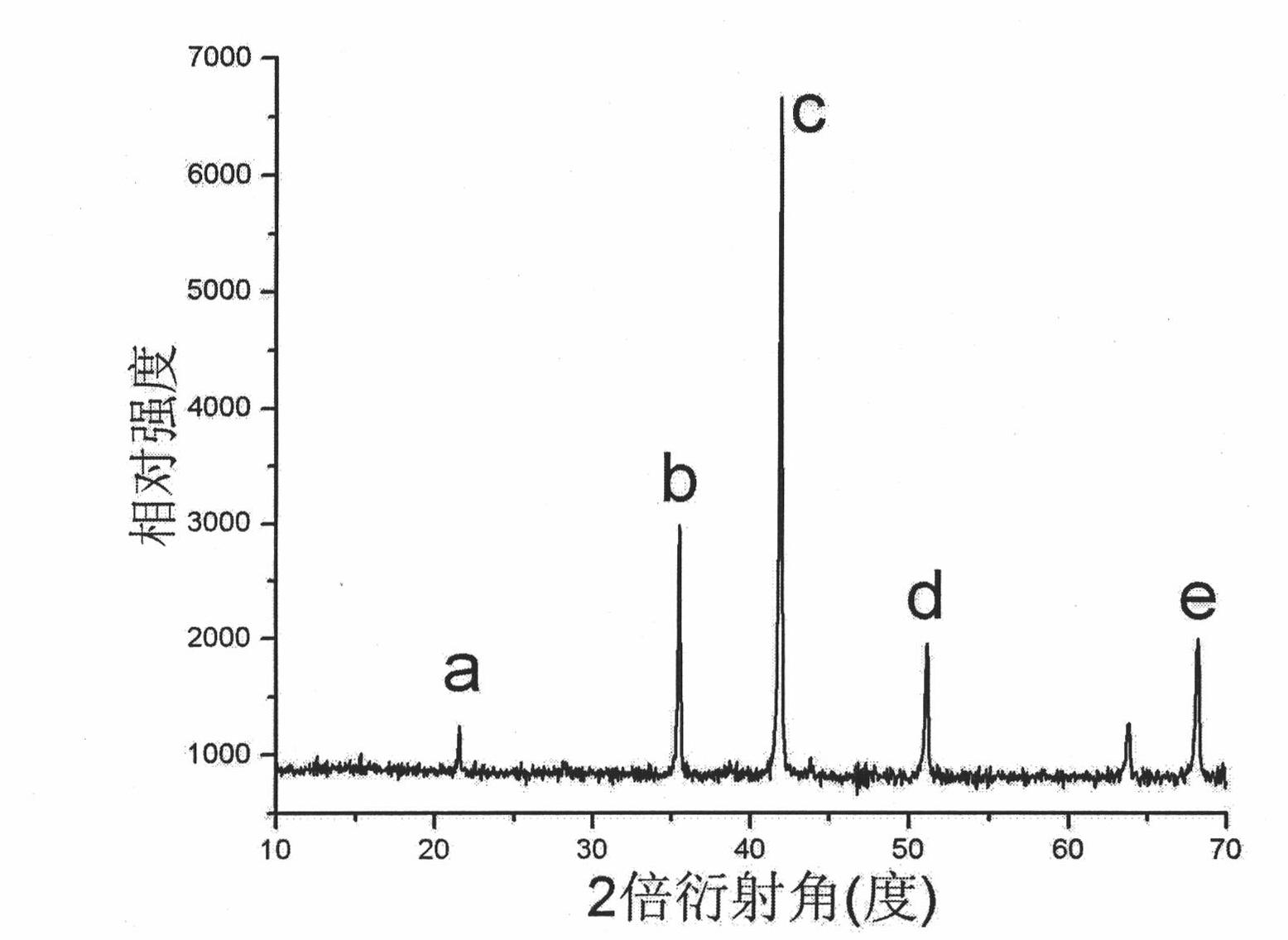

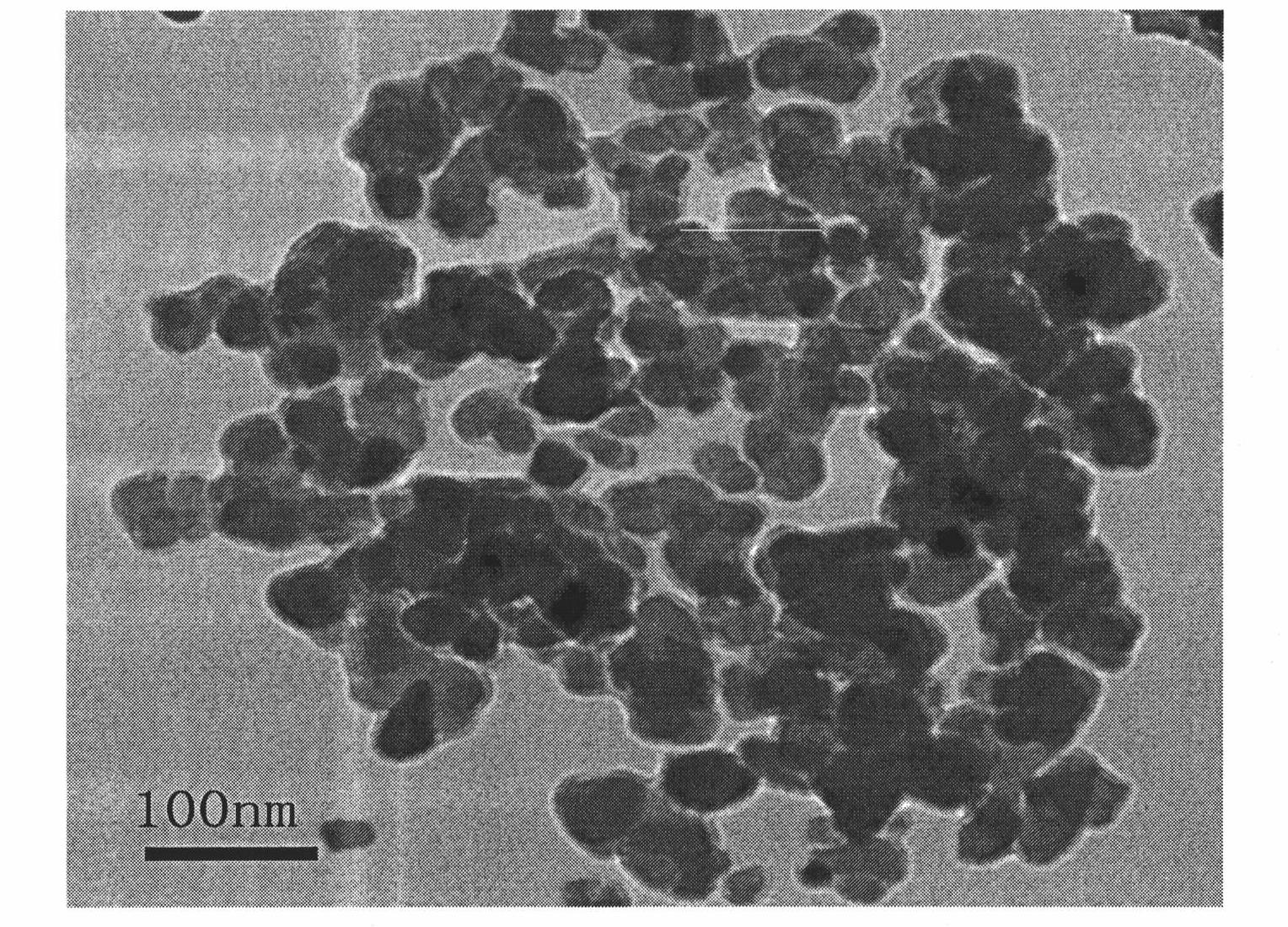

[0023] TEM photo ( figure 2 ) shows that its highly dispersed nanoparticle size is between 10-40nm, and the XRD pattern ( figure 1 ) to determine that the combustion product is a Co-Cr-Mn-Fe spinel solid solution structure. All performance indicators meet the technical requirements (see Table 1, the inspection method adopts QB / T2455.2-1999).

Embodiment 2

[0025] Weigh 7gMn(NO 3 ) 2 4H 2 O, 124gCr(NO 3 ) 3 9H 2 O, 268gFe(NO 3 ) 3 9H 2 O, 11gCo(NO 3 ) 2 ·6H 2 O, 10gH 2 O and 110g HCOONH 4 And mix evenly, hold in Al 2 o 3 In the crucible, it is heated at 430°C, and the combustion reaction occurs until no more gas is released.

[0026] The TEM photos show that the size of its highly dispersed nanoparticles is between 20-50nm, and the XRD pattern determines that the combustion product is a Co-Cr-Mn-Fe spinel solid solution structure. .

Embodiment 3

[0028] Weigh 100gMn(NO 3 ) 2 4H 2 O, 30gCr(NO 3 ) 3 9H 2O, 300gFe(NO 3 ) 3 9H 2 O, 6gCo(NO 3 ) 2 ·6H 2 O, 50gH 2 O and 204g CH 3 CH 2 COONH 4 And mix evenly, hold in Al 2 o 3 In the crucible, it is heated at 450°C, and the combustion reaction occurs until no more gas is released.

[0029] The TEM photos show that the size of the highly dispersed nanoparticles is between 10-80nm, and the XRD pattern determines that the combustion product is a Co-Cr-Mn-Fe spinel solid solution structure. Table 1 shows that the performance indicators of the black nano-pigment prepared by this method all meet the technical requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com