Method for preparing Tb/Cr-codoped high-remanent-polarization BiFeO3 film by sol-gel process

A sol-gel method and polarization strength technology, applied in the field of functional materials, can solve problems such as limited application, and achieve the effects of good uniformity, easy experimental conditions, and good ferroelectric stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Bi(NO 3 ) 3 ·5H 2 O (excess 5%), Fe(NO 3 ) 3 9H 2 O, Tb(NO 3 ) 3 ·6H 2 O and Cr(NO 3 ) 3 9H 2 O is dissolved in a mixed solution of ethylene glycol methyl ether and acetic anhydride (volume ratio 3:1 to 4:1) at a molar ratio of 0.94:0.99:0.11:0.01 to form a mixed solution, and ethanolamine is added to the mixed solution to adjust the viscosity and degree of complexation to obtain stable BiFeO 3 The precursor liquid, the total metal ion concentration in the precursor liquid is 0.3mol / L.

[0025] Step 2: Spin coating and layer-by-layer annealing at 550°C on the FTO substrate (dry the dry film after uniform coating and anneal quickly at 550°C for 7-12 minutes, then cool to room temperature with the furnace, repeat the above process to obtain the required thick film) to obtain Tb and Cr co-doped crystalline BiFeO 3 film. With simultaneous incorporation of Tb and Cr into BiFeO 3 , making Bi 0.89 Tb 0.11 Fe 0.99 Cr 0.01 o 3 The saturated remnant po...

Embodiment 2

[0027] Step 1: Bi(NO 3 ) 3 ·5H 2 O (excess 5%), Fe(NO 3 ) 3 9H 2 O, Tb(NO 3 ) 3 ·6H 2 O and Cr(NO 3 ) 3 9H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride (volume ratio 3:1 to 4:1) in a molar ratio of 0.94:0.98:0.11:0.02 to form a mixed solution, and ethanolamine is added to the mixed solution to adjust the viscosity and degree of complexation to obtain stable BiFeO 3 The precursor liquid, the total metal ion concentration in the precursor liquid is 0.3mol / L.

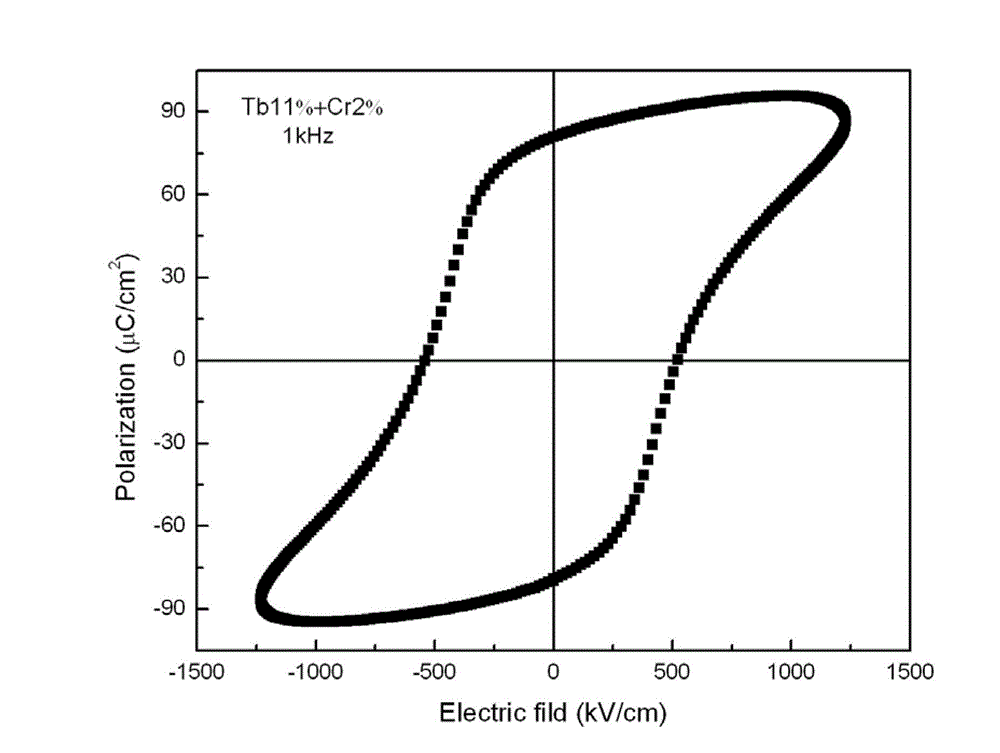

[0028] Step 2: Spin-coating and layer-by-layer rapid annealing at 550°C on the FTO substrate to obtain Tb and Cr co-doped BiFeO 3 film. With simultaneous incorporation of Tb and Cr into BiFeO 3 , making Bi 089 Tb 0.11 Fe0.98 Cr 0.02 o 3 thin film, making BiFeO 3 The crystal lattice is severely distorted, and the original rhomboid structure is transformed into a pseudo-tetragonal structure, so that the film is in a low-energy state where multiple phases coexist. The ...

Embodiment 3

[0030] Step 1: Bi(NO 3 ) 3 ·5H 2 O (excess 5%), Fe(NO 3 ) 3 9H 2 O, Tb(NO 3 ) 3 ·6H 2 O and Cr(NO 3 ) 3 9H 2 O is dissolved in a mixture of ethylene glycol methyl ether and acetic anhydride (volume ratio 3:1 to 4:1) in a molar ratio of 0.94:0.97:0.11:0.03 to form a mixed solution, and ethanolamine is added to the mixed solution to adjust the viscosity and degree of complexation to obtain stable BiFeO 3 The precursor liquid, the total metal ion concentration in the precursor liquid is 0.3mol / L.

[0031] Step 2: Spin-coating and layer-by-layer rapid annealing at 550°C on the FTO substrate to obtain Tb and Cr co-doped BiFeO 3 film. With simultaneous incorporation of Tb and Cr into BiFeO 3 , making Bi 0.89 Tb 0.11 Fe 0.97 Cr 0.03 o 3 film.

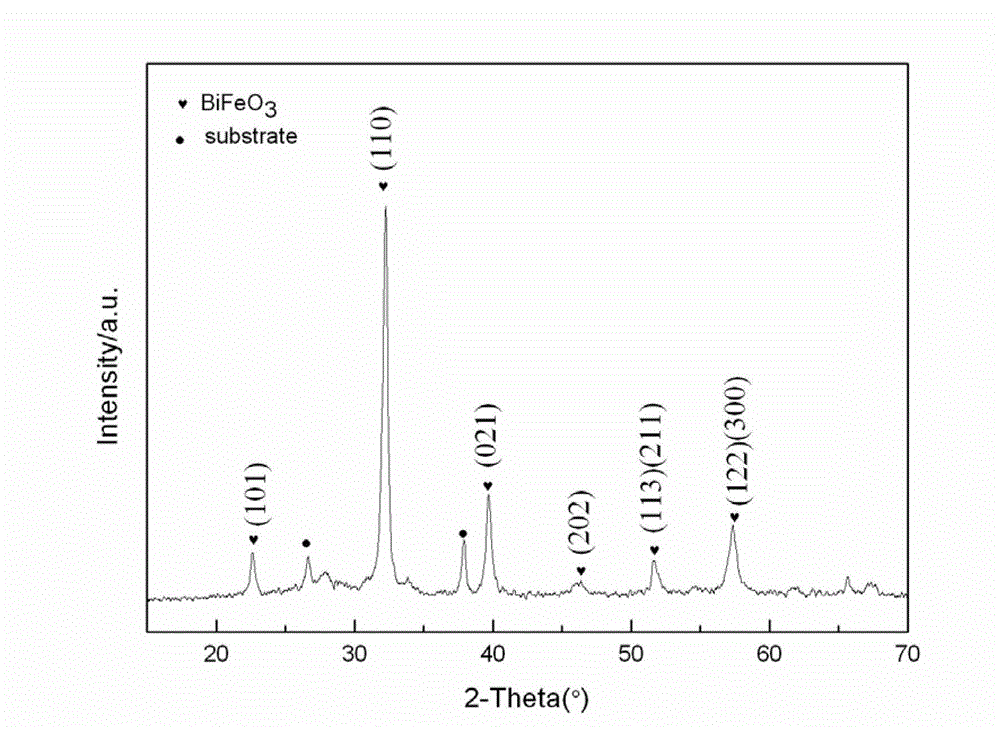

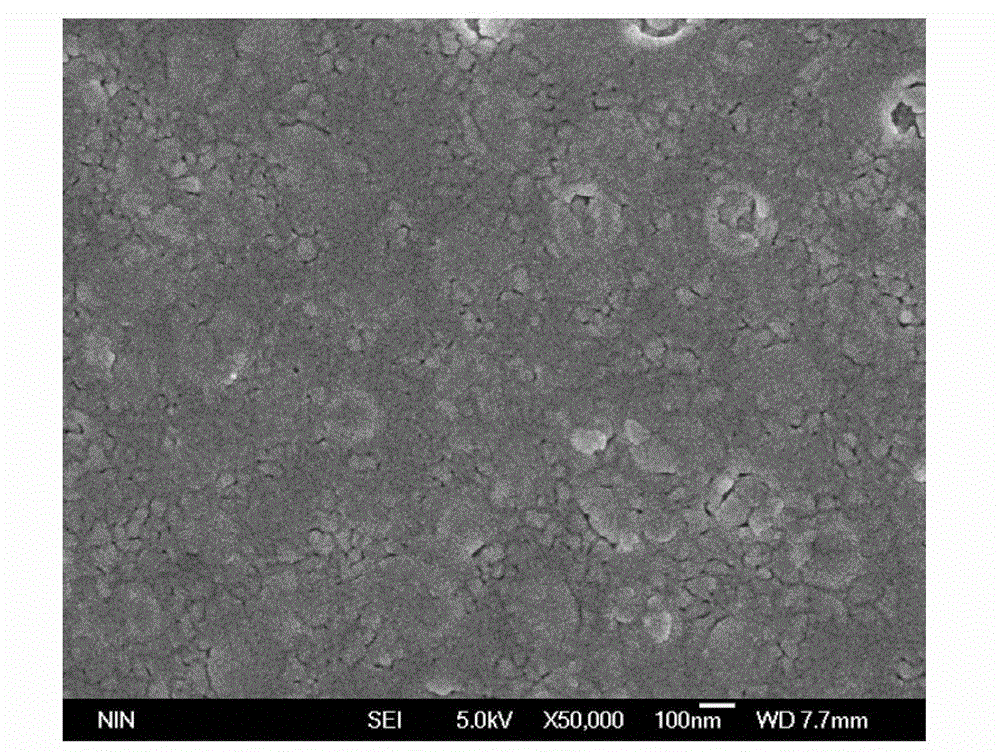

[0032] Determination of BiFeO by XRD 3 Phase composition and structure of thin films, determined by FE-SEM for BiFeO 3 Microscopic morphology of thin film, BiFeO was tested with TF2000 ferroelectric analyzer 3 Ferroelect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com