Method for improving selectivity and stability of nickel liquid phase hydrogenation catalyst

A liquid-phase hydrogenation and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. problems such as decline and affecting the operation of production units, to achieve the effects of high selectivity, high activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

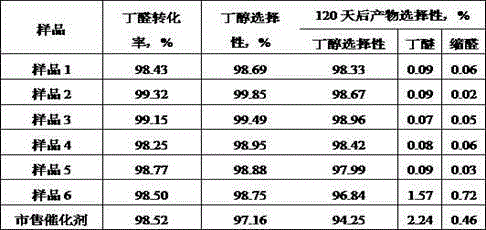

Examples

Embodiment 1

[0021] Take 800 grams of water glass and add 3 liters of water, heat it to 50°C in a sedimentation tank with stirring, take 334 grams of nickel nitrate hexahydrate and add 3 liters of water to make a solution, add 35 grams of magnesium nitrate, and evenly drop into the water glass solution for For co-precipitation, control the precipitation temperature to about 50°C, neutralize for 15 minutes, and adjust the pH to 7.0 with oxalic acid. Then, it was stirred and aged at 60°C for 30 minutes, washed, filtered, dried to plastic humidity, kneaded with 3.0 g of methyl cellulose, extruded, and calcined at 600°C for 2 hours to obtain catalyst sample 1.

Embodiment 2

[0023] Take 800 grams of water glass and add 3 liters of water, heat it to 60°C in a sedimentation tank with stirring, take 300 grams of nickel nitrate hexahydrate and add 3 liters of water to form a solution, add 35 grams of calcium nitrate, and evenly drop into the water glass solution for For co-precipitation, control the precipitation temperature to about 60°C, neutralize for 20 minutes, and adjust the pH to 7.2 with oxalic acid. Stir and age at 70°C for 30 minutes, wash, add 59 grams of zirconia to beat, filter, dry to plastic humidity, add 3.0 grams of methyl cellulose, knead, extrude, and roast at 400°C for 2 hours to obtain the catalyst sample 2.

Embodiment 3

[0025] Take 800 grams of water glass and add 3 liters of water, heat it to 80°C in a sedimentation tank with stirring, take 300 grams of nickel nitrate hexahydrate and add 3 liters of water to form a solution, and evenly drop it into the water glass solution for co-precipitation, and control the precipitation temperature At about 80°C, the neutralization time is 30 minutes, and the pH is adjusted to 8.0 with oxalic acid. Then it was stirred and aged at 80°C for 20 minutes, washed, filtered, and dried to a plastic humidity, added 59 grams of sodium carbonate and 3.0 grams of methyl cellulose, kneaded, extruded, and calcined at 600°C for 2 hours to obtain catalyst sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com