Magnesite-chrome bimetallic MOFs adsorbent MIL-101 (Cr, Mg) and preparation method thereof

A bimetallic and adsorbent technology, applied in the field of adsorption materials, can solve the problems of low applicability and poor water stability, and achieve the effects of good repeatability, low production cost and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

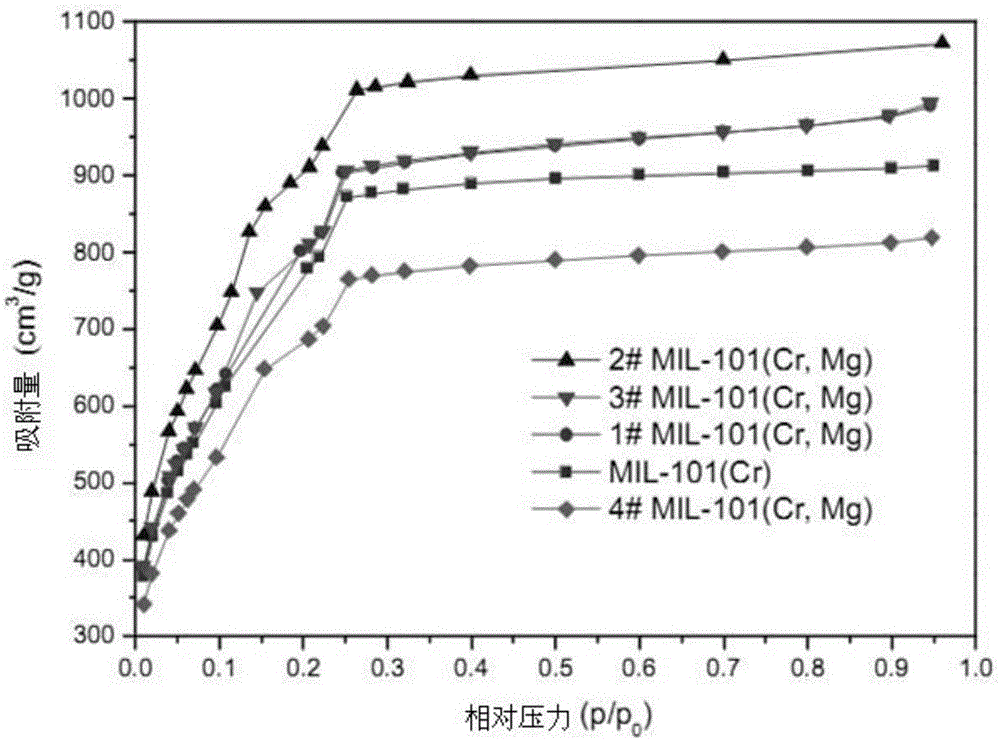

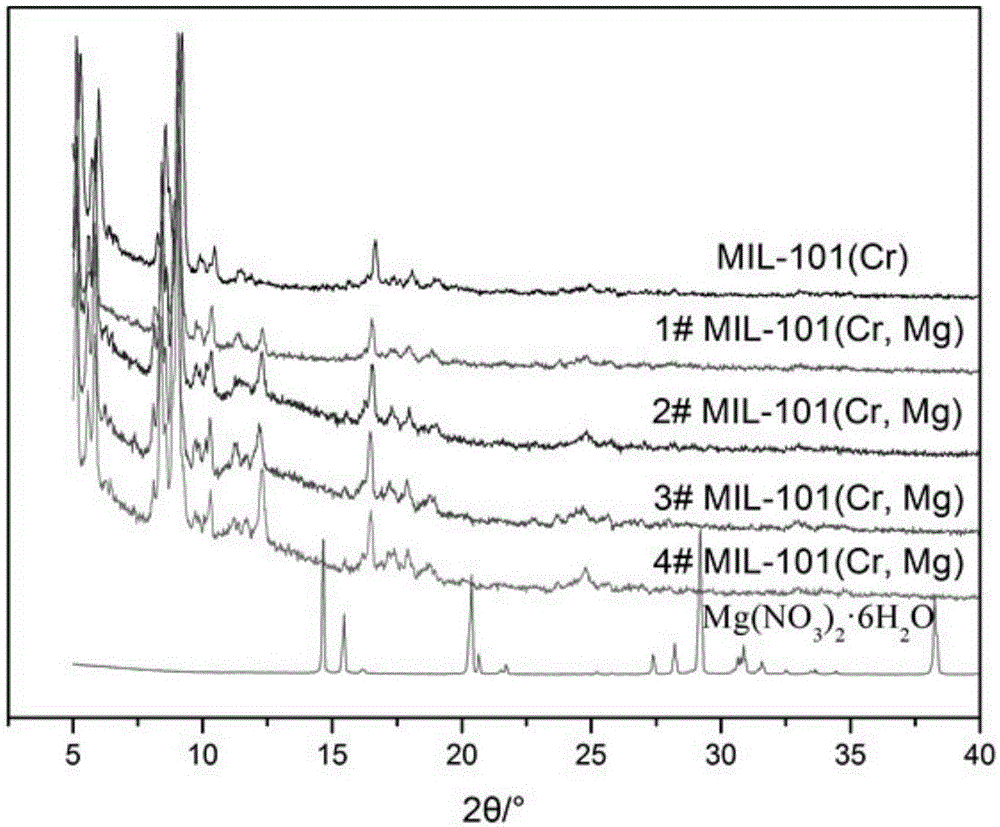

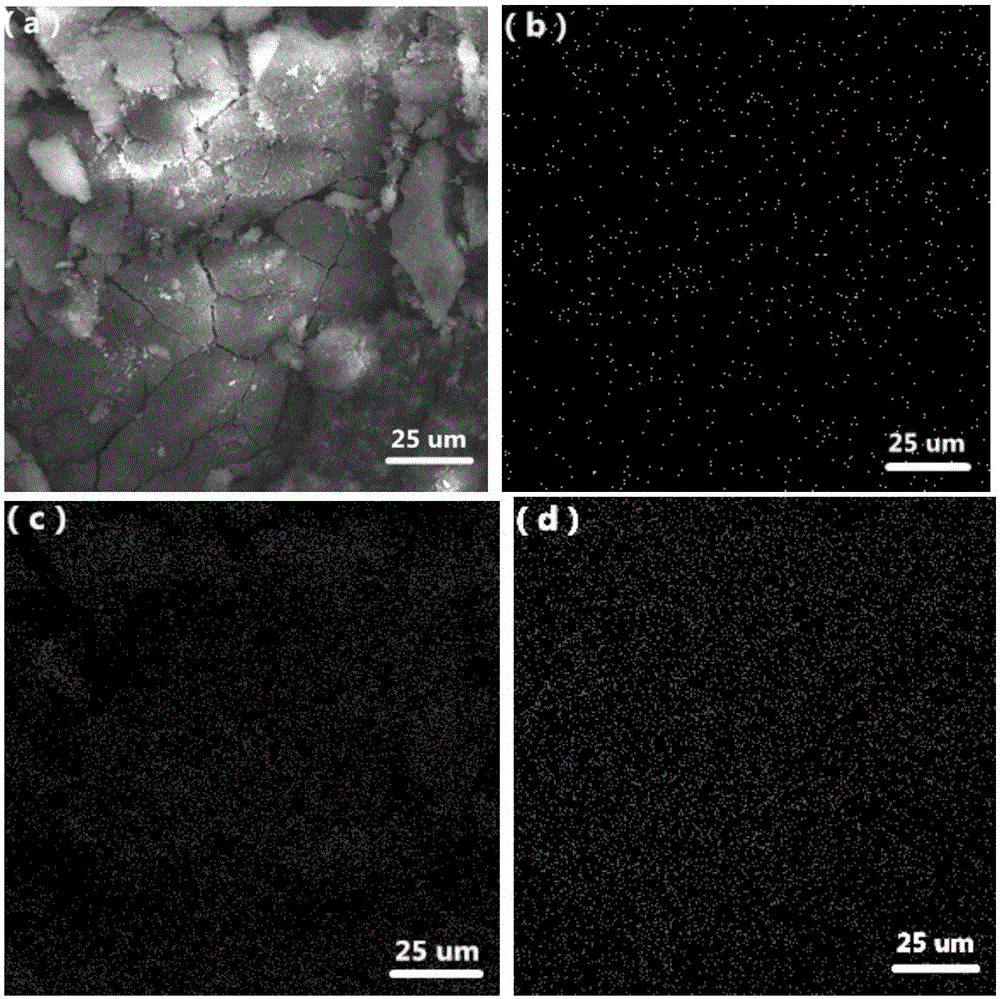

Embodiment 1

[0032] (1) Magnesium nitrate hexahydrate (0.5mmol), chromium nitrate nonahydrate (10mmol), terephthalic acid (8mmol), distilled water (45ml), and 40% HF solution (0.3ml) are mixed, then at 40°C Stir and mix for 10 minutes, place the mixture in a reactor and heat to 200°C for 8 hours, then cool to room temperature (25°C);

[0033] (2) the reaction liquid of step (1) is used G 1 Filter through a funnel to remove most of the unreacted ligands, then add 20mlDMF to the filtrate for stirring and washing, then centrifuge with a centrifuge at 8000r / min to obtain a solid substance, and then soak the solid substance with 40ml ethanol and place Heat treatment at 80°C for 10 hours, repeat ethanol soaking and heat treatment twice, after centrifugation, rinse with warm water at 60°C for 3 times, and then centrifuge to obtain green solid particles;

[0034] (3) The obtained solid particles were dried at 80°C for 4 hours, and then activated in vacuum at 120°C for 8 hours to obtain the chromium...

Embodiment 2

[0036] (1) Magnesium nitrate hexahydrate (1mmol), chromium nitrate nonahydrate (10mmol), terephthalic acid (9mmol), distilled water (48ml), and 40% HF solution (0.4ml) are mixed, then stirred at 50°C Mix for 15 minutes, place the mixture in a reaction kettle and heat it to 210°C for 8 hours, then cool to room temperature (25°C);

[0037] (2) the reaction liquid of step (1) is used G 1 Filter through a funnel to remove most of the unreacted ligands, then add 25ml of DMF to the filtrate for stirring and washing, then centrifuge with a centrifuge at 8000r / min to obtain a solid substance, and then soak the solid substance with 50ml of ethanol and place Heat treatment at 80°C for 12 hours, repeat ethanol soaking and heat treatment twice, after centrifugation, wash with warm water at 70°C for 4 times, and then centrifuge to obtain green solid particles;

[0038] (3) The obtained solid particles were dried at 100°C for 5h, and then activated in vacuum at 150°C for 8h to obtain the c...

Embodiment 3

[0040] (1) Magnesium nitrate hexahydrate (2mmol), chromium nitrate nonahydrate (10mmol), terephthalic acid (9.8mmol), distilled water (48ml), and 40% HF solution (0.3ml) are mixed, then at 60°C Stir and mix for 20 minutes, place the mixture in a reactor and heat to 220°C for 9 hours, then cool to room temperature (25°C);

[0041] (2) the reaction liquid of step (1) is used G 1 Filter through a funnel to remove most of the unreacted ligands, then add 25ml of DMF to the filtrate for stirring and washing, then centrifuge with a centrifuge at 8000r / min to obtain a solid substance, and then soak the solid substance with 60ml of ethanol and place Heat treatment at 90°C for 20 hours, repeat ethanol soaking and heat treatment twice, after centrifugation, rinse with warm water at 70°C for 5 times, and then centrifuge to obtain green solid particles;

[0042] (3) The obtained solid particles were dried at 110°C for 6h, and then activated in vacuum at 180°C for 10h to obtain the chromiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com