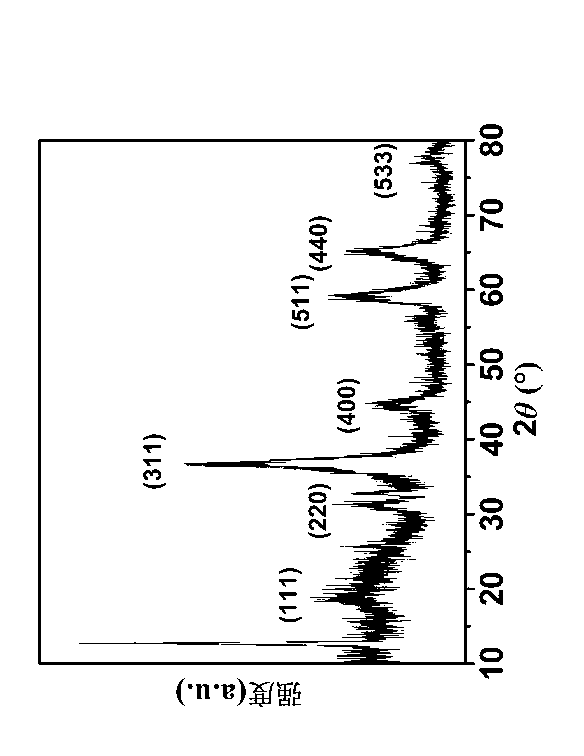

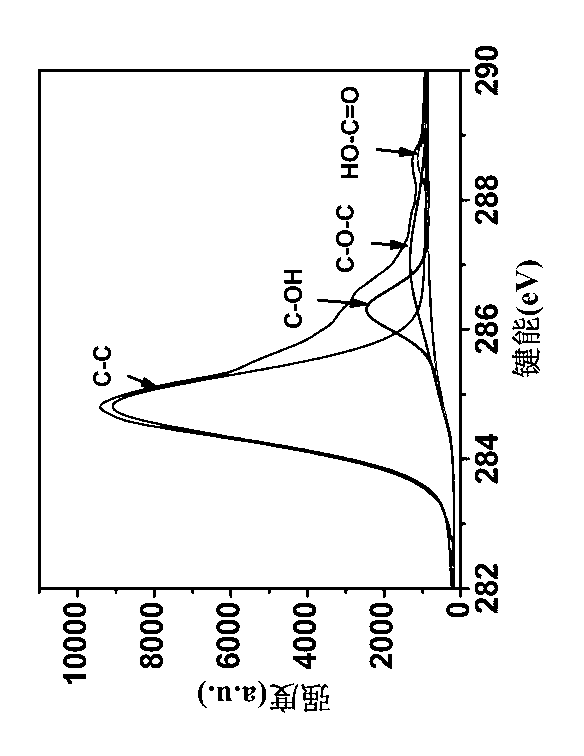

Preparation method for nano metal oxide graphene composite material

A technology of composite materials and nano-metals, which is applied in the field of nano-materials, can solve problems such as performance impact of composite materials, difficult control of reduction degree, pollution, etc., and achieve the effect of industrialized production, good crystal structure, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, a kind of preparation method of nanometer metal oxide graphene composite material, its steps are as follows:

[0025] (1) Mix graphite oxide and water into a graphite oxide aqueous dispersion with a mass percentage concentration of 0.01%, then put the graphite oxide aqueous dispersion into the ball mill tank of a ball mill, add nitrate for ball milling, and the graphite oxide and nitrate The mass ratio is 1:0.1, and the nitrate is selected from silver nitrate, cobalt nitrate, manganese nitrate, iron nitrate, nickel nitrate, bismuth nitrate, copper nitrate, cerium nitrate, vanadium nitrate, chromium nitrate, titanium nitrate, beryllium nitrate, One of vanadium nitrate;

[0026] (2) After the ball milling is completed, the mixed liquid obtained by the ball milling is dispersed with an appropriate amount of deionized water, and then stratified. The suspended part of the upper layer is poured out, and the precipitate is filtered out, washed with water, and dri...

Embodiment 2

[0027] Embodiment 2, a kind of preparation method of nanometer metal oxide graphene composite material, its steps are as follows:

[0028] (1) Mix graphite oxide and water to form a graphite oxide aqueous dispersion with a mass percentage concentration of 10%, then put the graphite oxide aqueous dispersion into the ball mill tank of a ball mill, add nitrate for ball milling, and the graphite oxide and nitrate The mass ratio is 1:10, and the nitrate is selected from silver nitrate, cobalt nitrate, manganese nitrate, iron nitrate, nickel nitrate, bismuth nitrate, copper nitrate, cerium nitrate, vanadium nitrate, chromium nitrate, titanium nitrate, beryllium nitrate, Mixtures of the two components in vanadium nitrate;

[0029] (2) After the ball milling is completed, the mixed liquid obtained by the ball milling is dispersed with an appropriate amount of deionized water, and then stratified. The suspended part of the upper layer is poured out, and the precipitate is filtered out,...

Embodiment 3

[0030] Embodiment 3, a kind of preparation method of nanometer metal oxide graphene composite material, its steps are as follows:

[0031] (1) Mix graphite oxide and water into a graphite oxide aqueous dispersion with a mass percentage concentration of 0.1%, then put the graphite oxide aqueous dispersion into the ball mill tank of a ball mill, add nitrate for ball milling, and the graphite oxide and nitrate The mass ratio is 1:5, and the nitrate is selected from silver nitrate, cobalt nitrate, manganese nitrate, iron nitrate, nickel nitrate, bismuth nitrate, copper nitrate, cerium nitrate, vanadium nitrate, chromium nitrate, titanium nitrate, beryllium nitrate, A mixture of three components in vanadium nitrate;

[0032] (2) After the ball milling is completed, the mixed liquid obtained by the ball milling is dispersed with an appropriate amount of deionized water, and then stratified. The suspended part of the upper layer is poured out, and the precipitate is filtered out, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com