Submicron-nanometer level red ceramic pigment and manufacturing method thereof

A technology of ceramic pigments and manufacturing methods, applied in the field of ceramic pigments, to achieve the effects of simple process, cost reduction, and strong color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

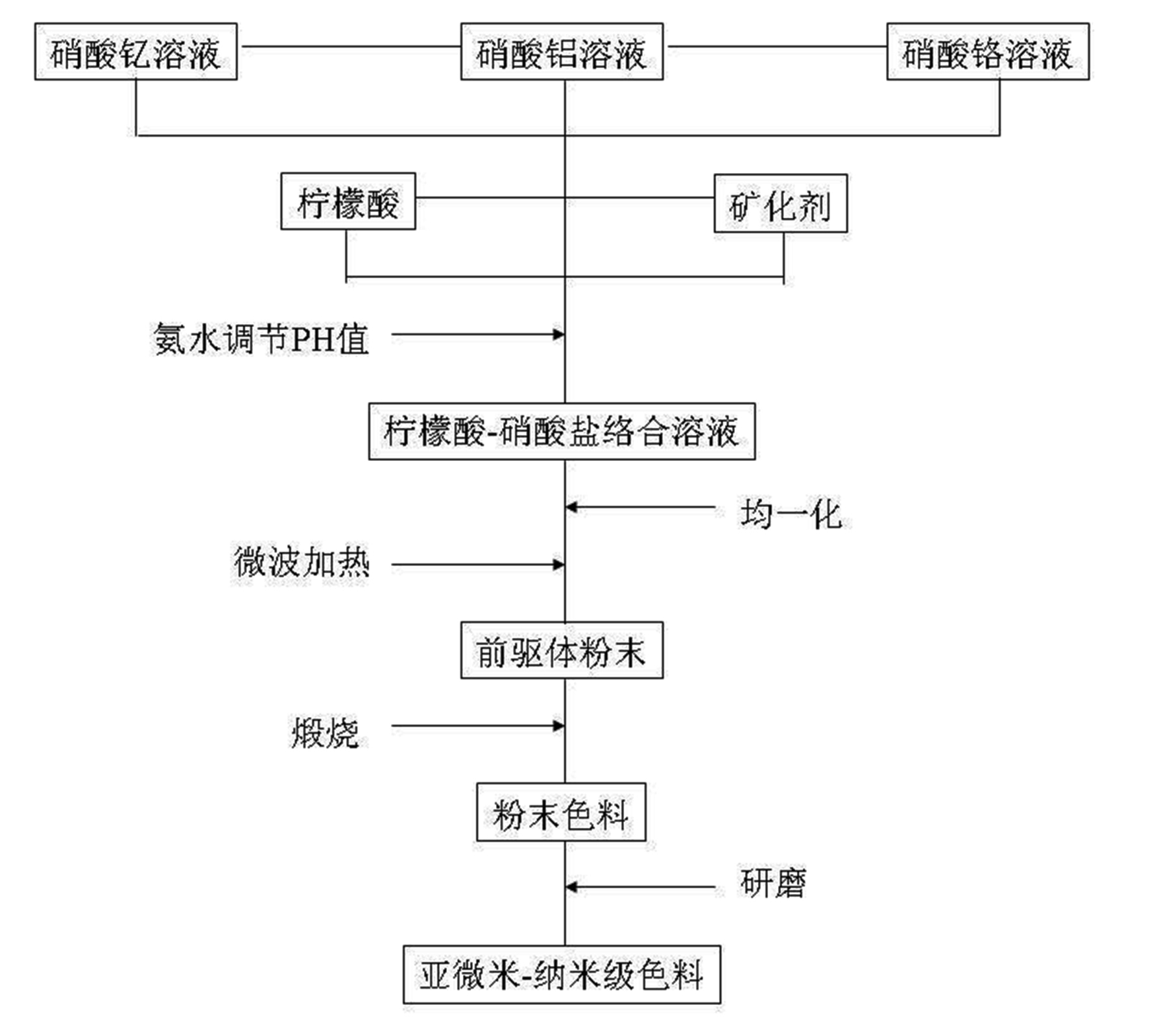

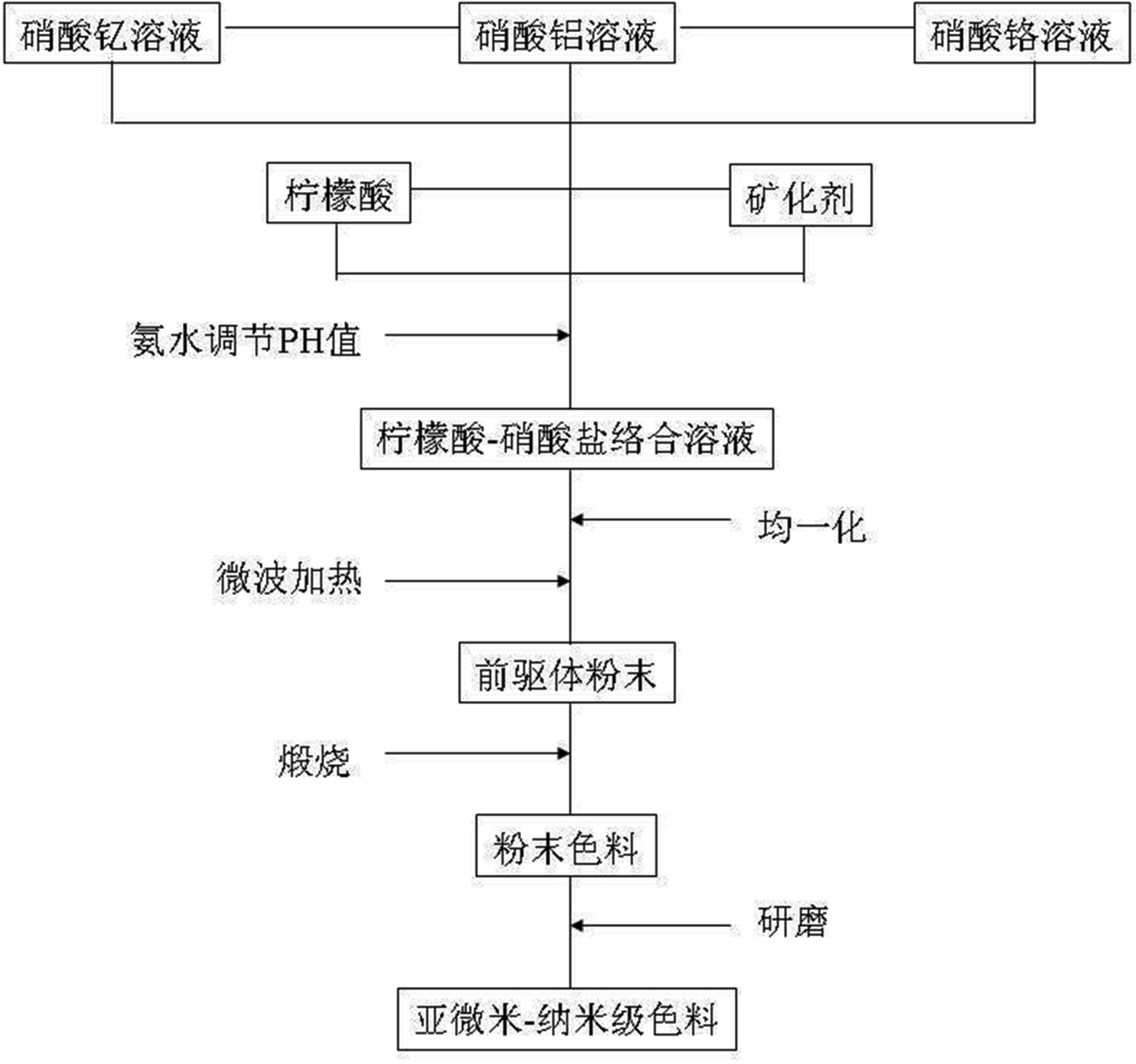

[0038] A kind of submicron-nanometer red ceramic pigment, the general formula of its composition is: YAl 1-x Cr x o 3 , where x = 0.01~0.1. The manufacture step of described submicron-nanometer red ceramic pigment is (see attached figure 1 ):

[0039] (1) Ingredients

[0040] Prepare mixed solution by mass percentage: chromium nitrate 2wt%, yttrium nitrate 15wt%, aluminum nitrate 15wt%, citric acid 20wt%, mineralizer (CaCO 3 , KCl, MgF 2 、Na 2 B 4 o 7 ) 5wt%, deionized water 43wt%, the starting material is mixed uniformly in deionized water;

[0041] (2) Mixing and heating

[0042] Adjust the pH value of the mixed solution prepared in step (1) to 7 with ammonia water, stir it fully, heat it in a microwave oven until bubbling, boiling, and evaporation to form a sol-gel; continue heating until a certain temperature is reached, and the gel Start to ignite and burn, and obtain a loose foamy precursor after burning;

[0043] (3) heat treatment

[0044] The precursor o...

Embodiment 2

[0048] In addition to the mineralizer in the raw material composition is 5wt% NaF, MgF 2 , Li 2 CO 3 Outside, other composition and implementation step are with embodiment 1. The obtained precursor was sintered in a muffle furnace at a sintering temperature of 1200°C and a sintering time of 1.5 hours to obtain chromium yttrium aluminum red ceramic pigments (YAl 1-x Cr x o 3 ) powder; the chromium yttrium aluminum red ceramic pigment powder is wet milled for 1 hour, and the particle size of the powder can reach D 50 0.4μm, D 90 is 0.8 μm, and its chromaticity value is shown in sample number 2 in Table 1.

Embodiment 3

[0050] In addition to the mineralizer in the raw material composition is 5wt% CaCO 3 , except KCl, other composition and implementation steps are with embodiment 1. The obtained precursor was sintered in a muffle furnace, the sintering temperature was 1000°C, and the sintering time was 3 hours to obtain chromium yttrium aluminum red ceramic pigment (YAl 1-x Cr x o 3 ) powder; the chromium yttrium aluminum red ceramic pigment powder is wet milled for 1 hour, and the particle size of the powder can reach D 50 0.4μm, D 90 is 0.6 μm, and its chromaticity value is shown in sample number 3 in Table 1.

[0051] Table 1. Chroma values of chromium yttrium aluminum red ceramic pigments

[0052]

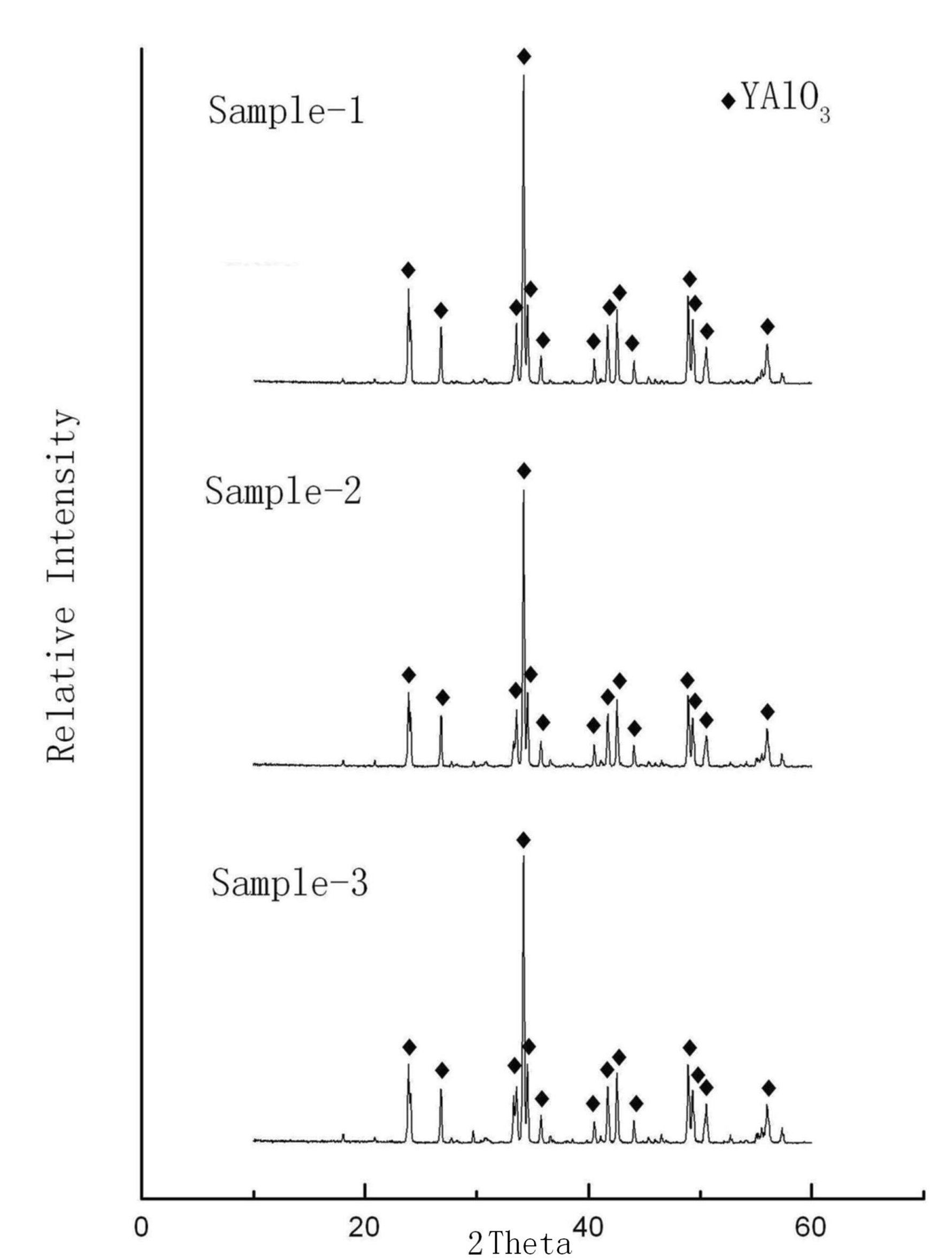

[0053] attached figure 2 X-ray diffraction analysis (XRD) images of the chromium yttrium aluminum red ceramic pigments obtained for Examples 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com