Amidoxime group modified MOF material and preparation method thereof

A technology based on amidoxime and amidoxime, which is applied in the field of amidoxime-modified MOF materials and its preparation, can solve the problems of undiscovered MOF materials, expensive synthetic raw materials, and great impact on human health, and achieve selective adsorption The effect of good performance, fast adsorption rate and novel synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

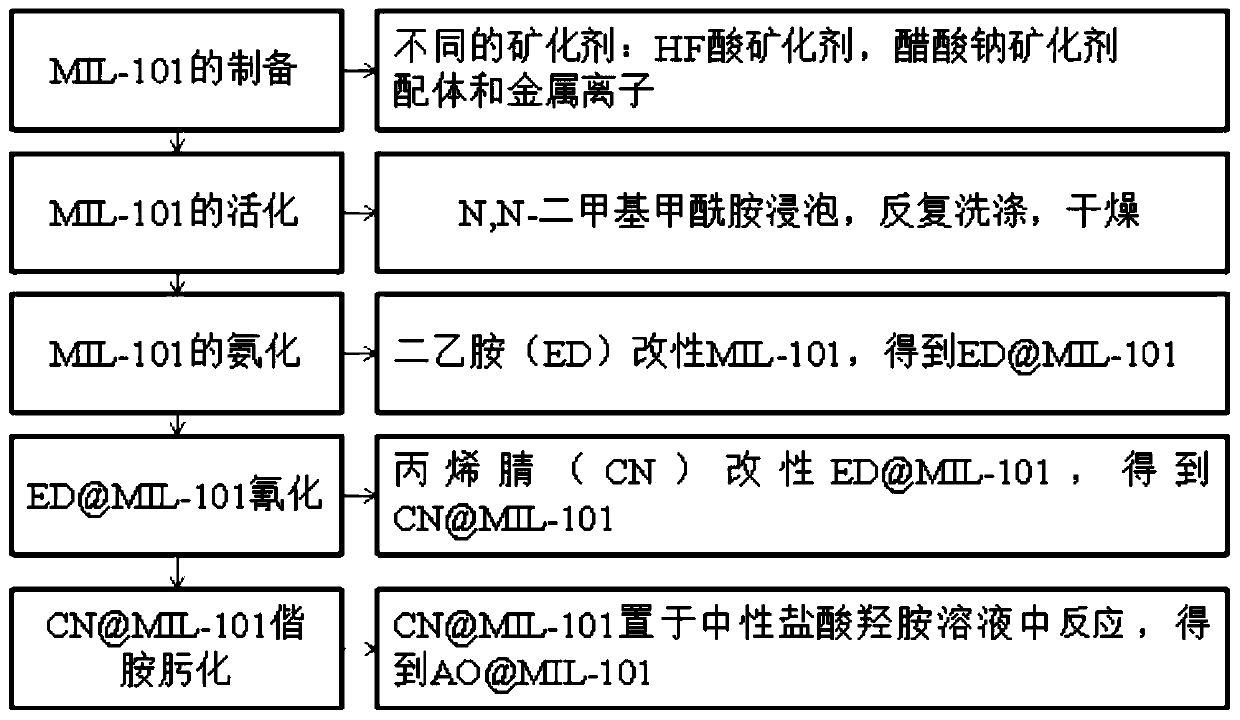

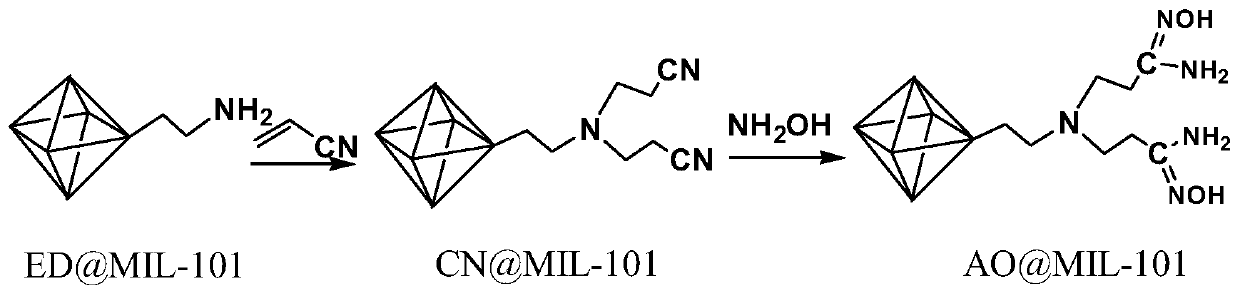

[0061] Preferably, the MIL-101(Cr) is prepared by the following method:

[0062] Fully disperse terephthalic acid and chromium nitrate nonahydrate in deionized water, then add mineralizer, and quickly package, at 200 ° C ~ 220 ° C, heat preservation reaction for 12 ~ 24 hours, purified to MIL-101 (Cr);

[0063] Wherein, the molar ratio of terephthalic acid, chromium nitrate nonahydrate and mineralizer is 4.8~5.0:4.8~5.0:2.0~4.0;

[0064] Preferably, the mineralizer is at least one of sodium acetate or hydrofluoric acid;

[0065] The mineralizer is preferably hydrofluoric acid, and the concentration of the hydrofluoric acid solution is preferably 40 wt%.

[0066] Preferably, the dehydration described in step (1) is:

[0067] Add dehydrating agent to MIL-101(Cr) to immerse MIL-101(Cr), oscillate ultrasonically for 2-4 hours, filter, wash with alcohol and deionized water alternately, and dry at 60-70°C for 12-24 hours;

[0068] The dehydrating agent is preferably at least one ...

Embodiment 1

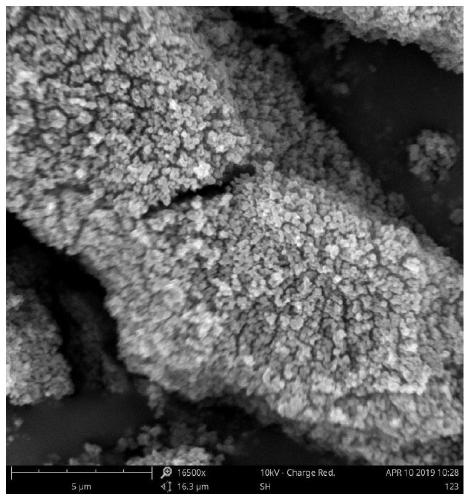

[0079] (1) Preparation of MIL-101(Cr) with sodium acetate as a mineralizer: Weigh 0.01mol of terephthalic acid and 0.01mol of chromium nitrate nonahydrate, and disperse them in 80mL of 0.05mol / L sodium acetate solution in turn, Fully stir for half an hour, put it into a polytetrafluoroethylene-lined hydrothermal synthesis reactor at a temperature of 200° C., and keep it warm for 12 hours.

[0080] Naturally cool to room temperature after the reaction is completed, and then perform suction filtration. First, filter the turbid liquid with a medium-speed filter paper to remove most of the unreacted terephthalic acid, and then use a filter membrane with a pore size of 0.45 μm for suction filtration and deionized water and alcohol. Rinse alternately to remove terephthalic acid remaining on the surface and pores of MIL-101(Cr). The filtered product was dried in an oven at 70°C for 8 hours, and finally a pure green product MIL-101(Cr) was obtained.

[0081] (2) Activation of MIL-101...

Embodiment 2

[0088] (1) Preparation of MIL-101(Cr) with hydrofluoric acid as mineralizer: Weigh 0.01mol of terephthalic acid and 0.01mol of chromium nitrate nonahydrate, then disperse them into 50mL of deionized water, stir thoroughly for half an hour Put it into a hydrothermal synthesis reaction kettle with polytetrafluoroethylene lining, measure 0.20g of hydrofluoric acid solution with a mass fraction of 40%, quickly add it to the reaction kettle and package it quickly, then put it into a high-temperature oven, set the temperature At 220°C, keep warm for 14h. The suction filtration and drying operations are the same as the preparation of MIL-101 with hydrofluoric acid as mineralizer. Green MIL-101 (Cr) (hydrofluoric acid) was obtained after suction filtration and drying.

[0089] (2) Activation of MIL-101(Cr): Take an appropriate amount of MIL-101(Cr) and put them in a beaker for use, add an appropriate amount of N,N-dimethylformamide into the beaker to soak MIL-101(Cr) , Ultrasonic os...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com