P type doping CuCrO2 based diluted magnetic semiconductor material and preparation thereof

A technology of dilute magnetic semiconductors and bulk materials, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., to achieve the effect of simple technology and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

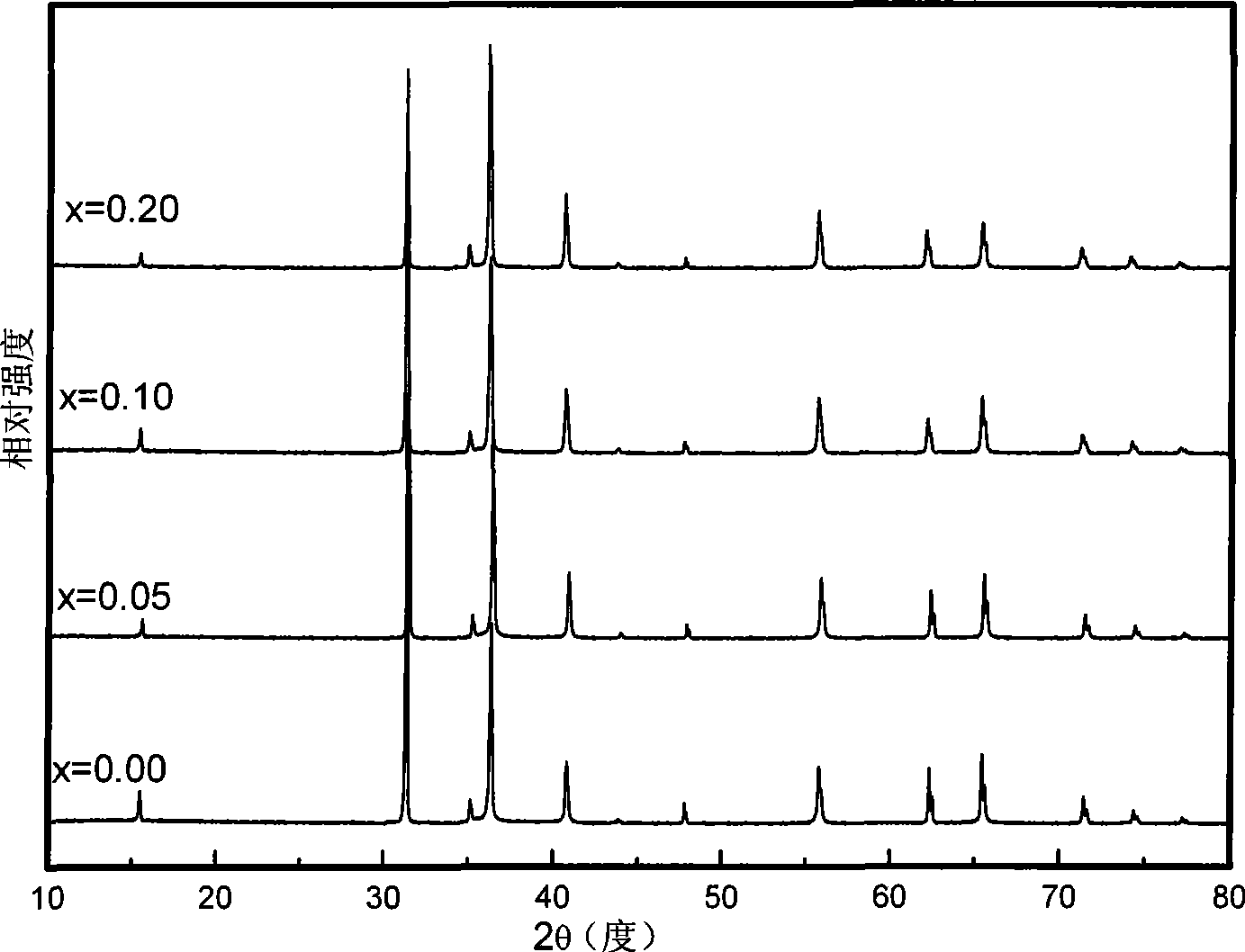

[0029] Embodiment 1: complete the preparation according to the following steps:

[0030] (a) According to the molar ratio of copper, chromium and manganese as 1:0.90:0.10, weigh copper acetate, chromium nitrate and manganese acetate, add powder into distilled water and add appropriate amount of citric acid, stir at room temperature until completely dissolved , to obtain a uniformly mixed solution;

[0031] (b) drying the stirred solution in an oven at 100° C. to obtain a precursor powder;

[0032] (c) Grinding the precursor powder and putting it into a furnace for pre-sintering at 300-500° C. for 3 hours to remove organic matter in the powder.

[0033] (d) The powder obtained by pre-calcination was sintered at 1100°C for 10 hours to prepare CuCr 0.90 mn 0.10 o 2 powder.

[0034] (e) Press the obtained powder into a circular sheet-like block with a tablet machine, and sinter at 1100°C for 10 hours to obtain CuCr 0.90 mn 0.10 o 2 bulk material.

Embodiment 2

[0035] Embodiment 2: complete the preparation according to the following steps:

[0036] (a) According to the molar ratio of copper, chromium and manganese as 1:0.80:0.20, weigh copper acetate, chromium nitrate and manganese acetate, add powder into distilled water and add appropriate amount of citric acid, stir at room temperature until completely dissolved , to obtain a uniformly mixed solution;

[0037] (b) drying the stirred solution in an oven at 100° C. to obtain a precursor powder;

[0038] (c) Grinding the precursor powder and putting it into a furnace for pre-sintering at 300-500° C. for 3 hours to remove organic matter in the powder.

[0039] (d) The powder obtained by pre-calcination was sintered at 1100°C for 10 hours to prepare CuCr 0.80 mn 0.20 o 2 powder.

[0040] (e) Press the obtained powder into a circular sheet-like block with a tablet machine, and sinter at 1100°C for 10 hours to obtain CuCr 0.80 mn 0.20 o 2 bulk material.

Embodiment 3

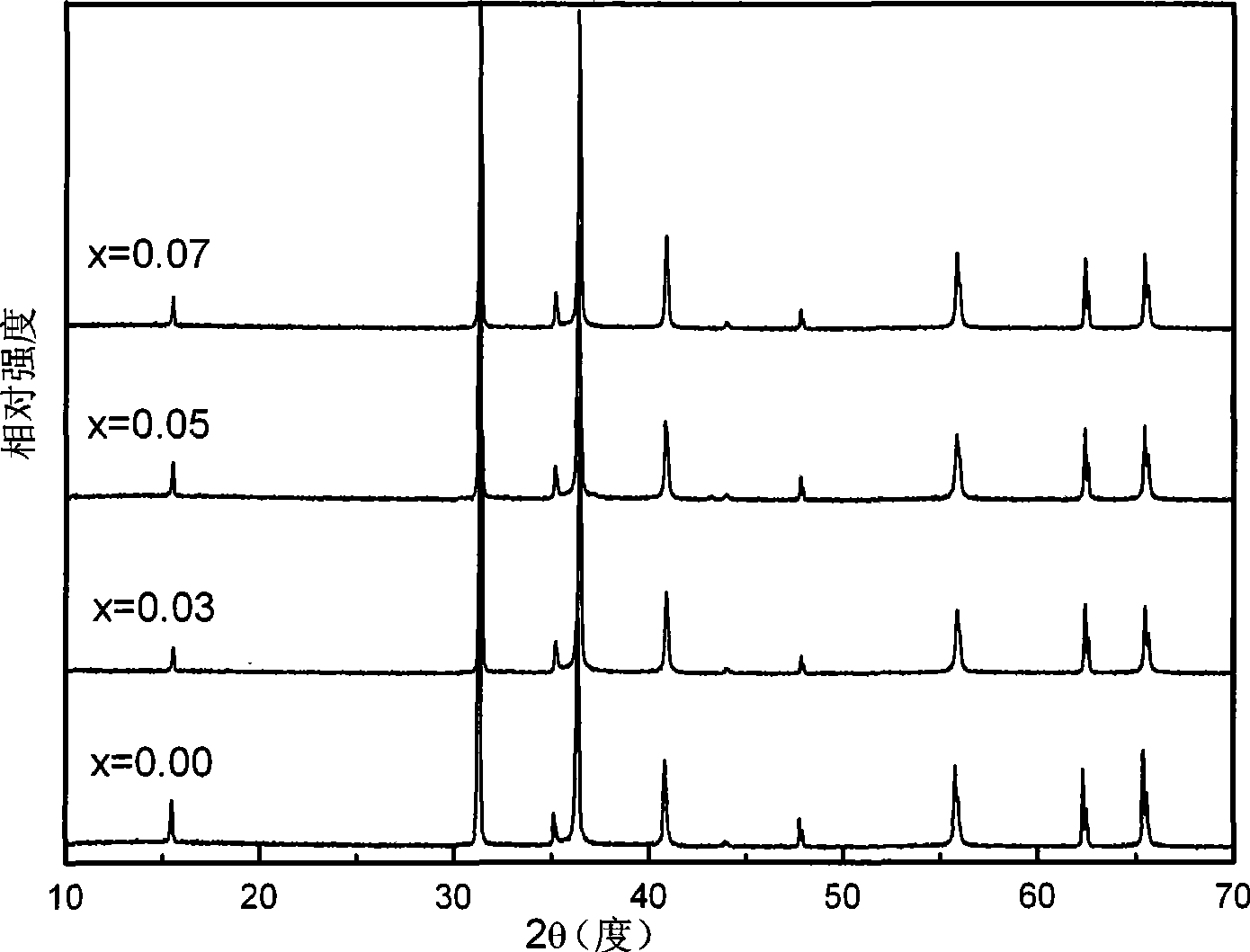

[0041] Embodiment 3: complete the preparation according to the following steps:

[0042] (a) According to the molar ratio of copper, chromium and nickel is 1:0.95:0.05, weigh copper acetate, chromium nitrate and nickel acetate, add powder into distilled water and add appropriate amount of citric acid, stir at room temperature until completely dissolved , to obtain a uniformly mixed solution;

[0043] (b) drying the stirred solution in an oven at 100° C. to obtain a precursor powder;

[0044] (c) Grinding the precursor powder and putting it into a furnace for pre-sintering at 300-500° C. for 3 hours to remove organic matter in the powder.

[0045] (d) The powder obtained by pre-calcination was sintered at 1100°C for 10 hours to prepare CuCr 0.95 Ni 0.05 o 2 powder.

[0046] (e) Press the obtained powder into a circular sheet-like block with a tablet machine, and sinter at 1100°C for 10 hours to obtain CuCr 0.95 Ni 0.05 o 2 bulk material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com