Method for preparing dispersion strengthening ferritic alloy steel powder of nanometer yttrium oxide particles

A technology of particle dispersion strengthening and nano-yttrium oxide, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as laboriousness, affecting the mechanical properties of the final product, and large dispersion, and achieve easy Large-scale industry, energy-saving preparation method, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

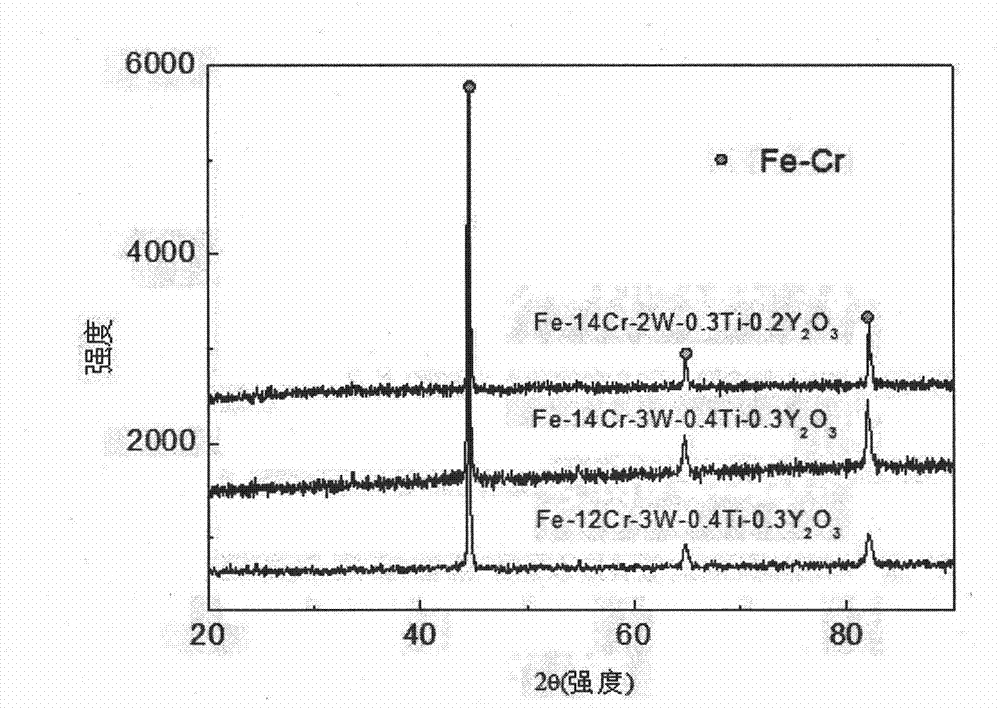

Embodiment 1

[0021] The concrete steps of preparation are:

[0022]Step 1, first add ethylenediaminetetraacetic acid and chromium nitrate to water, and stir at 50°C for 16 hours; wherein, the molar ratio between ethylenediaminetetraacetic acid, chromium nitrate and water is 1.8:0.8:800, and water is Ionized water to obtain a mixed solution. Then add citric acid, ferric nitrate, ammonium paratungstate, yttrium nitrate and tetrabutyl titanate to the mixed solution, and stir at 60°C for 5 hours; among them, the chromium nitrate and citric acid, ferric nitrate, ammonium paratungstate and yttrium nitrate in the mixed solution The molar ratio between tetrabutyl titanate and tetrabutyl titanate is 0.8:13:4.5:0.0020:0.0033:0.015 to obtain a sol.

[0023] Step 2, first add polyethylene glycol to the sol, and stir at 70°C until a gel is formed; wherein, the molar ratio between chromium nitrate and polyethylene glycol in the sol is 0.8:0.004, polyethylene glycol For polyethylene glycol-20000, a gel...

Embodiment 2

[0026] The concrete steps of preparation are:

[0027] Step 1, first add ethylenediaminetetraacetic acid and chromium nitrate to water, and stir at 53°C for 15 hours; wherein, the molar ratio between ethylenediaminetetraacetic acid, chromium nitrate and water is 1.9:0.9:900, and the water is distilled water , to obtain a mixture. Then add citric acid, ferric nitrate, ammonium paratungstate, yttrium nitrate and tetrabutyl titanate to the mixed solution, and stir at 63°C for 4.5h; among them, the chromium nitrate and citric acid, ferric nitrate, ammonium paratungstate, nitric acid in the mixed solution The molar ratio between yttrium and tetrabutyl titanate was 0.9:13.5:4.9:0.0024:0.0113:0.024 to obtain a sol.

[0028] Step 2, first add polyethylene glycol to the sol, and stir at 73°C until a gel is formed; wherein, the molar ratio between chromium nitrate and polyethylene glycol in the sol is 0.9:0.005, polyethylene glycol For polyethylene glycol-20000, a gel was obtained.

...

Embodiment 3

[0031] The concrete steps of preparation are:

[0032] Step 1, first add ethylenediaminetetraacetic acid and chromium nitrate to water, and stir at 55°C for 14 hours; wherein, the molar ratio between ethylenediaminetetraacetic acid, chromium nitrate and water is 2:1:1000, and water is Ionized water to obtain a mixed solution. Then add citric acid, ferric nitrate, ammonium paratungstate, yttrium nitrate and tetrabutyl titanate to the mixed solution, and stir at 65°C for 4 hours; among them, the chromium nitrate and citric acid, ferric nitrate, ammonium paratungstate and yttrium nitrate in the mixed solution The molar ratio between tetrabutyl titanate and tetrabutyl titanate is 1:14:5.3:0.0028:0.0183:0.033 to obtain a sol.

[0033] Step 2, first add polyethylene glycol to the sol, and stir at 75°C until a gel is formed; wherein, the molar ratio between chromium nitrate and polyethylene glycol in the sol is 1:0.006, polyethylene glycol For polyethylene glycol-20000, a gel was o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com