Catalyst and preparing method thereof, and use in hydrogenation-dechlorination of carbon tetrachloride

A catalytic hydrogenation and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of good activity and stability and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

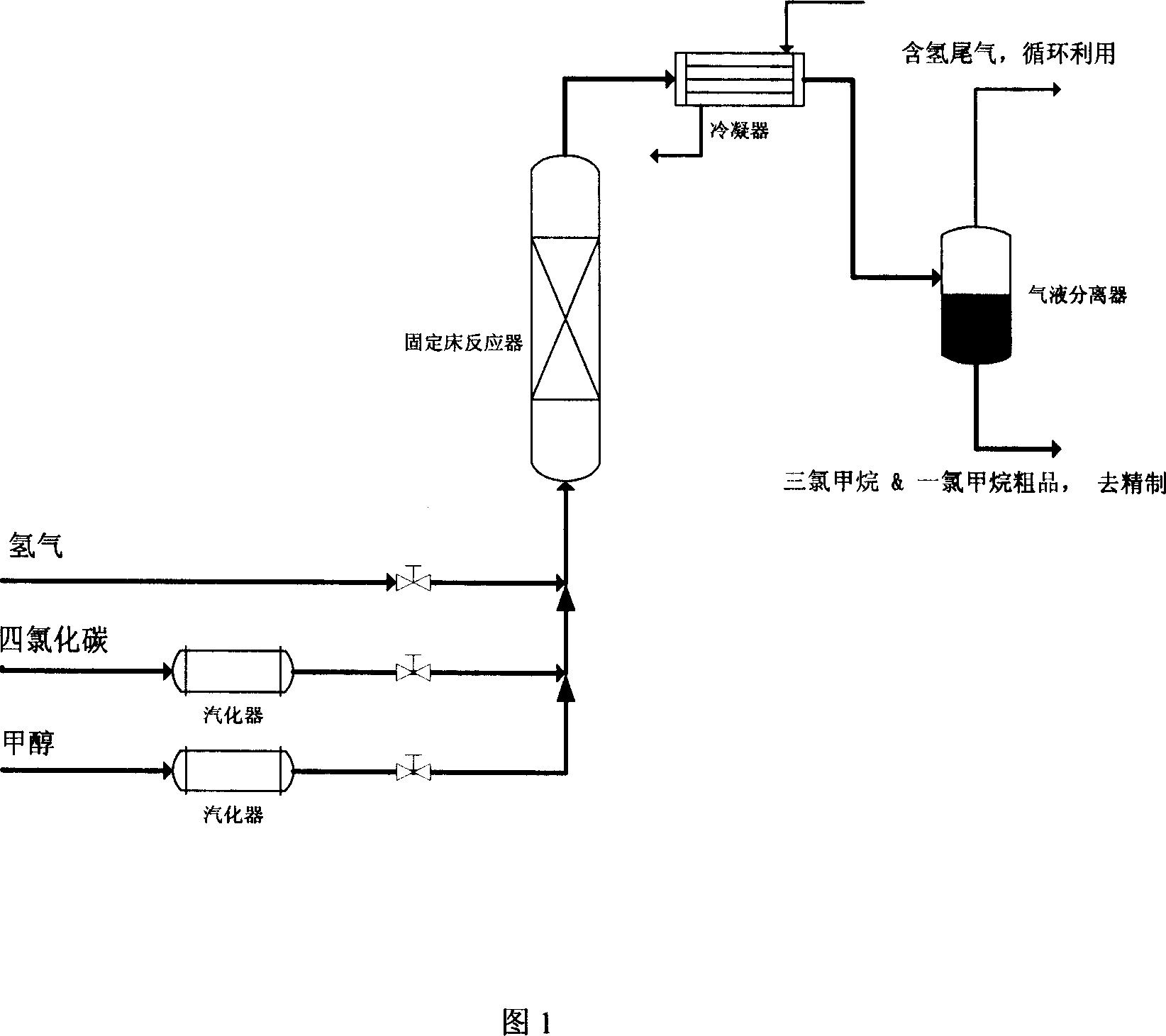

Method used

Image

Examples

Embodiment 1

[0023] Zirconium chloride and chromium acetate are used as raw materials, dissolved in deionized water, and 15% ammonia water is used as a precipitant, and a co-precipitation method is used to prepare the catalyst carrier. The mixed solution of ammonia water, zirconium chloride and chromium acetate is slowly added dropwise into a small amount of deionized water at the same time, and under the condition of stirring, the pH value of the solution is kept at 8-8.5 to form a colloidal precipitate. After aging, concentration, filtration, washing and other steps, it was dried at 120°C for 4 hours. Place in a muffle furnace and bake at 500°C for 3 hours to obtain a catalyst carrier. where Cr 2 o 3 The mass percentage in the catalyst carrier is 9.5%. According to BET analysis, the specific surface area of the prepared catalyst carrier is 142m 2 / g, the pore volume is 0.25cm 3 / g.

[0024] Metal Pt is supported on the prepared catalyst carrier by impregnation method. Take 100 g...

Embodiment 2

[0026] Replace the zirconium chloride in embodiment 1 with titanium tetrachloride, replace the chromium acetate in embodiment 1 with manganese nitrate, adopt the co-precipitation method described in embodiment 1 to make containing 10% (mass) Mn 2 o 3 titanium oxide support. Its specific surface area is 136m 2 / g, the pore volume is 0.235cm 3 / g.

[0027] Take 1.327g H 2 PtCl 6 .6H 2 O and 38.92g Ni(NO 3 ) 2 .6H 2 O was dissolved in deionized water to obtain 85 ml of an impregnation solution containing 0.030 mol / L of platinum and 1.574 mol / L of nickel. Under the condition of stirring, the obtained solution was uniformly dispersed on 100 g of the above-mentioned pre-dried catalyst carrier. The prepared catalyst precursor was dried in air at 120°C for 4 hours, and then calcined at 450°C for 5 hours to obtain 112.2g of catalyst 0.5%Pt-10%NiO / Mn 2 o 3 -TiO 2 .

Embodiment 3

[0029] Replace the zirconium chloride in the embodiment 1 with titanium tetrachloride, adopt the co-precipitation method described in the embodiment 1 to obtain the compound containing 30% (mass) Cr 2 o 3 titanium oxide support. Its specific surface area is 113m 2 / g, the pore volume is 0.183cm 3 / g. Take 1.327g H 2 PtCl 6 .6H 2 O was dissolved in deionized water to obtain 85 ml of an impregnation solution containing 0.030 mol / L of platinum and 1.574 mol / L of nickel. Under the condition of stirring, the chloroplatinic acid solution was uniformly dispersed on 100 g of the above-mentioned pre-dried catalyst carrier. The prepared catalyst precursor was dried in air at 120°C for 4 hours, and then calcined at 450°C for 5 hours to obtain 111.8g of catalyst 0.5%Pt / Cr 2 o 3 -TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com