Graphene-modified doped tin oxide composite material and preparation method thereof

A composite material and tin oxide technology, which is applied in the analysis of materials, material analysis by electromagnetic means, and measurement devices, can solve the problems that have not been found and reported, and achieve good gas-sensing properties, simple and easy preparation methods, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

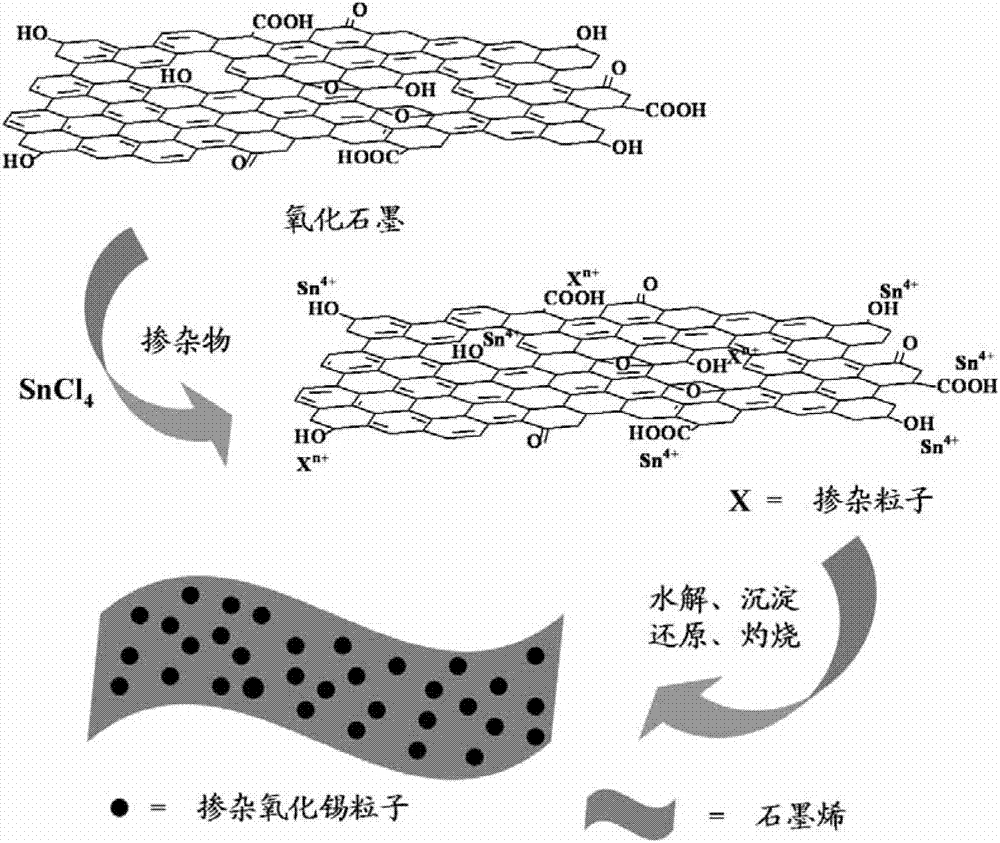

[0035] The preparation method of the doped tin oxide composite material modified by graphene provided by the invention can refer to figure 1 The schematic diagram of the preparation process includes the following steps:

[0036] a) disperse graphite oxide containing hydroxyl, carboxyl or epoxy groups into water, preferably ultrasonic dispersion or high-speed dispersion; add tin tetrachloride or crystalline tin tetrachloride and alcohol solution of dopant, dopant is preferably Antimony chloride, indium chloride, palladium chloride, manganese chloride, zinc chloride, ferric chloride or zinc sulfate, the alcohol solvent of the alcohol solution is preferably methanol, ethanol, 1-propanol, 2-propanol, 1 One or more of -butanol or 2-butanol, the mass ratio of graphite oxide to tin tetrachloride or crystalline tin tetrachloride can be 10:1~1:10, tin tetrachloride or crystalline tetrachloride The mass ratio of the tin oxide to the dopant may be 20:1˜1:20.

[0037] Then add ammonia w...

Embodiment 1

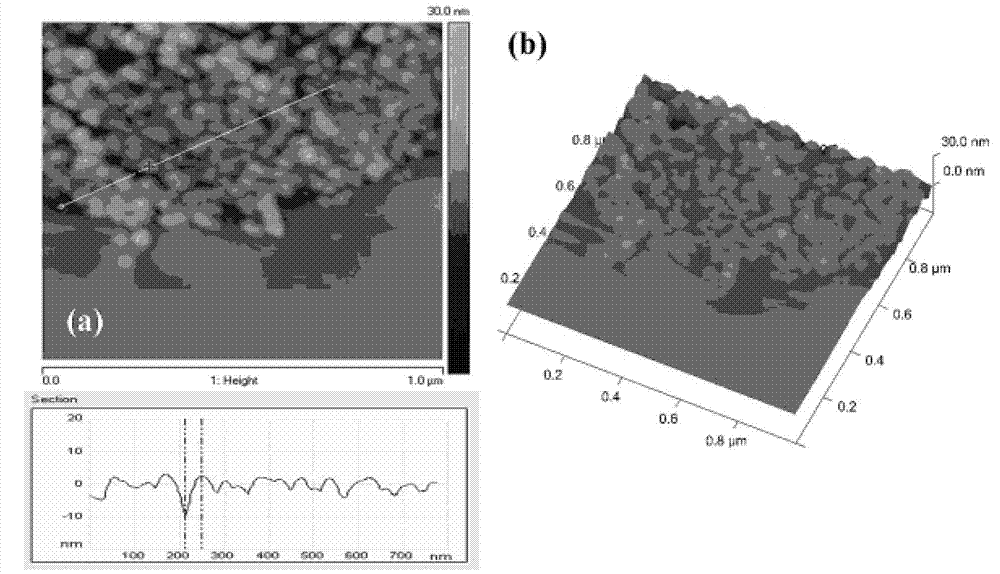

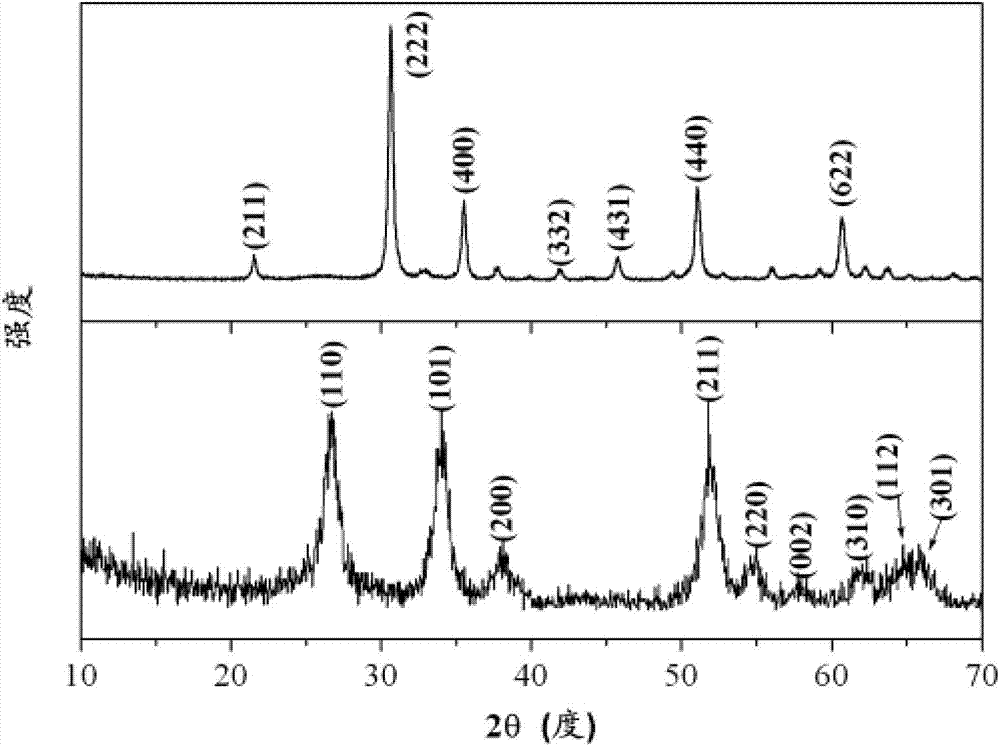

[0044] Add 1.0g of tin tetrachloride and 0.1g of antimony chloride to 50ml of ethanol to form a solution, add 0.1g of graphite oxide powder into 100ml of deionized water, and ultrasonically disperse for 1 hour, then add the above-mentioned tin tetrachloride and antimony chloride Ethanol solution, after mixing evenly, add 10ml of ammonia water and 1ml of hydrazine hydrate, react at 60°C for 2h, then raise the temperature to 100°C and continue to react for 4h, cool and centrifuge to obtain the precipitate, wash it with deionized water for 3 times, dry it, and put it in a tube furnace under nitrogen Burn at 400°C for 2 hours under protection to obtain a graphene-modified tin-antimony oxide composite material.

[0045] Mix the graphene-modified tin-antimony oxide composite material and kaolin evenly to make a slurry, coat the slurry on a high-resistance silicon wafer with a conductive electrode and cover the electrode, sinter at 400°C, and connect the leads to obtain Graphene modi...

Embodiment 2

[0048] Add 0.1g of tin tetrachloride and 1.0g of indium chloride into 50ml of ethanol to make a solution, add 0.1g of graphite oxide powder into 100ml of deionized water, ultrasonically disperse for 1 hour, and then add the above-mentioned tin tetrachloride and indium chloride Ethanol solution, after mixing evenly, add 10ml of ammonia water and 1g of sodium borohydride, react at 35°C for 2h, then raise the temperature to 100°C and continue to react for 4h, cool and centrifuge to obtain a precipitate, wash it with deionized water for 3 times, dry it, and put it in a tube furnace Burning at 600°C for 2 hours under the protection of nitrogen, the graphene-modified tin-antimony oxide composite material was obtained.

[0049] Mix the graphene-modified indium tin oxide composite material and silicon dioxide evenly to make a slurry, coat the slurry on a ceramic sheet with a conductive electrode and cover the electrode, sinter at 600°C, connect the lead wires, and obtain graphite Alke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com