Method for depositing tin oxide and titanium oxide coatings on flat glass and the resulting coated glass

a technology of tin oxide coating and flat glass, which is applied in the direction of coating, chemical vapor deposition coating, coating process, etc., to achieve the effect of improving the mechanical strength of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 5

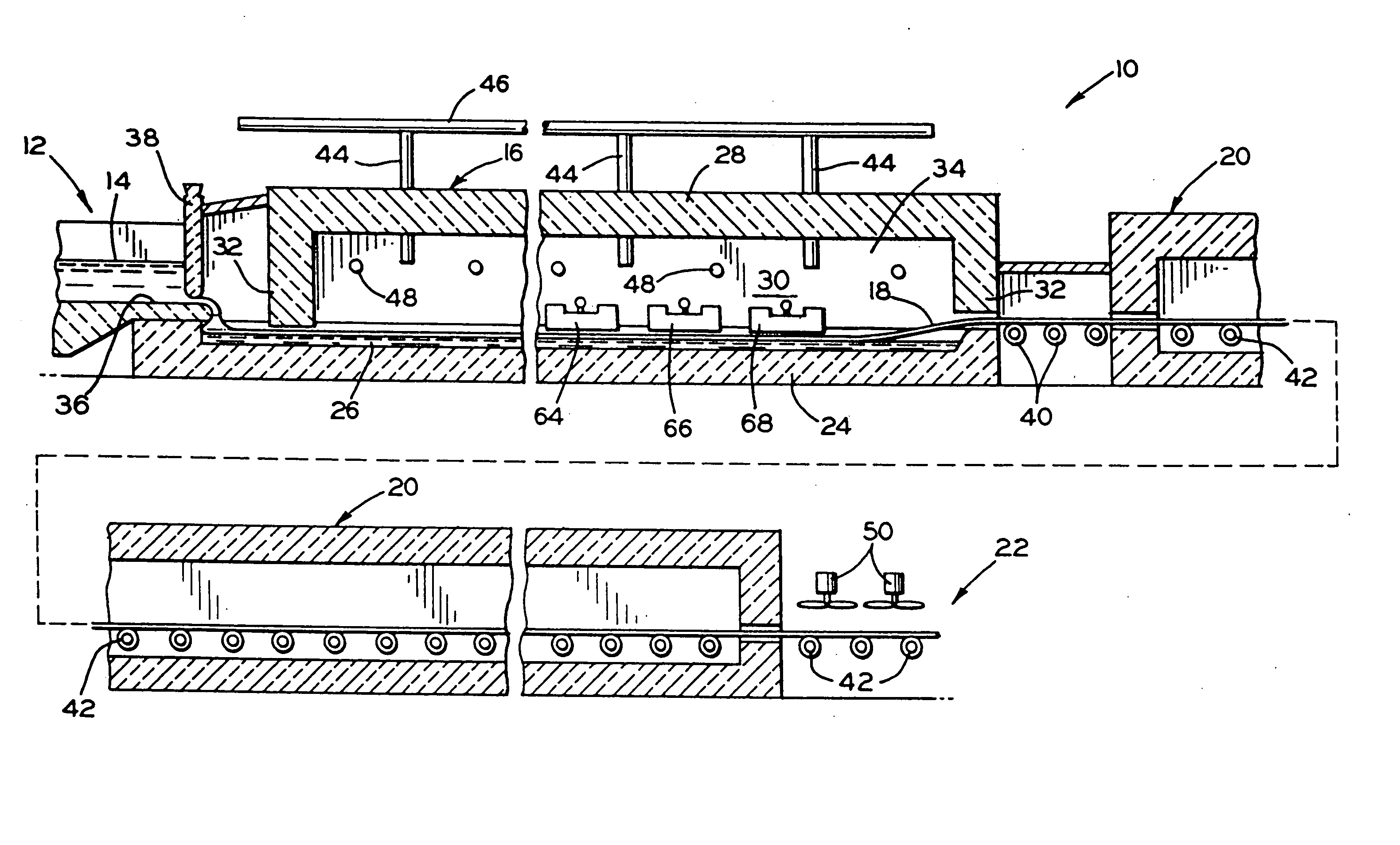

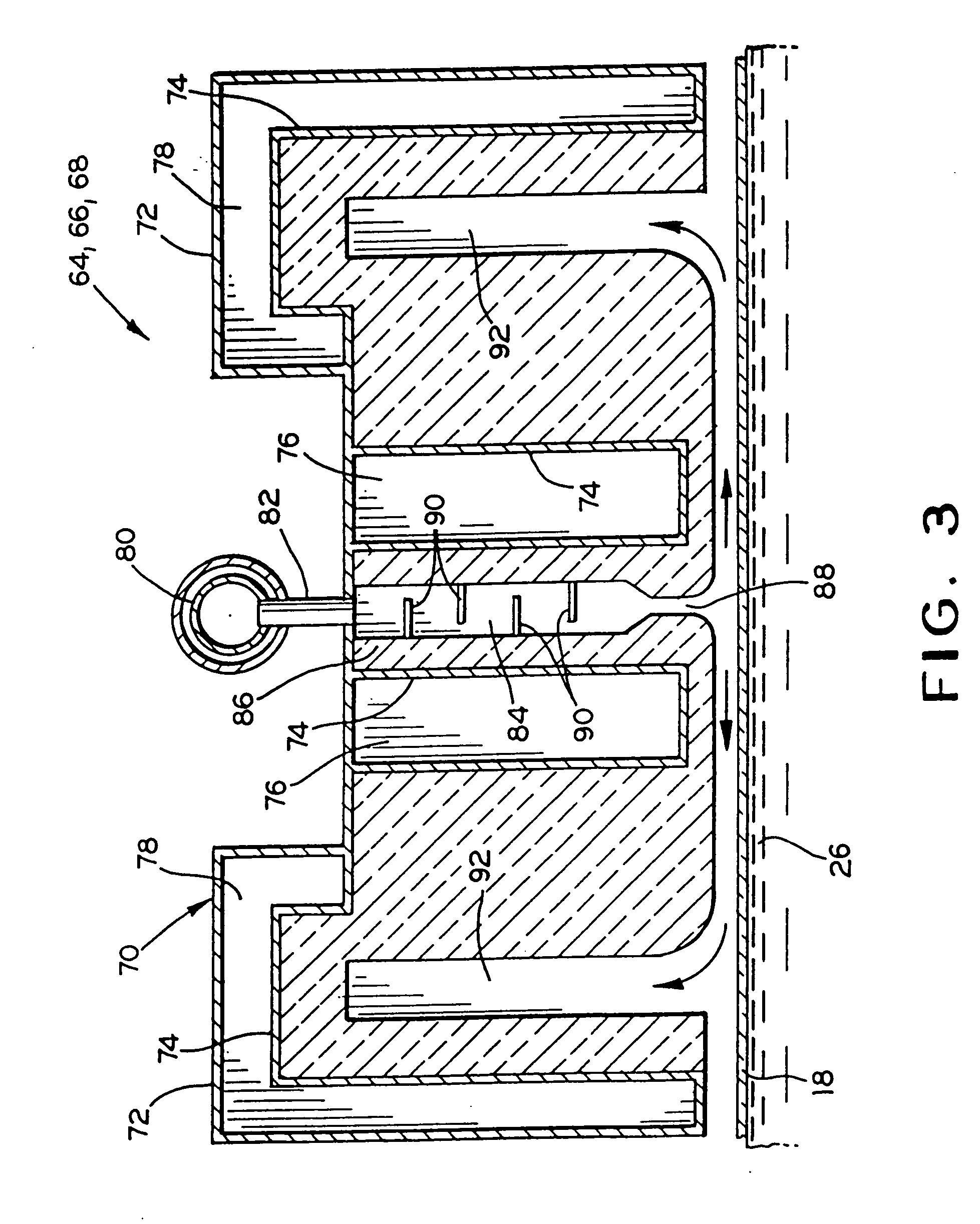

[0054] In this series of Examples, a bi-directional coating reactor of the type shown in FIG. 3 was employed in the laboratory to deposit a titanium oxide coating.

[0055] In Examples 1, 2 and 3, the glass was heated on a conveyor furnace to simulate the coating reaction conditions of a float glass process in order to test the method of the present invention. The furnace utilized in-line rollers to convey a glass substrate through a heating zone prior to practicing the method of the present invention. In Example 1, the glass substrate was float glass which had been initially provided with a silica coating. The silica coating was deposited on the float glass through a known chemical vapour deposition process utilizing a precursor of monosilane in an oxygen enriched atmosphere. The silica deposition forms no part of the present invention.

[0056] In accordance with the present invention, a titanium oxide coating was deposited on the silica coated substrate. The substrate was at a temper...

example 6

[0064] A float glass process was used in producing a continuous glass ribbon having a thickness of 0.125 inches / 3 mm at a line speed of 434 inches / 11 metres per minute. The glass temperature was at 1140° F. / 615° C. at the desired point of application in the float bath section of a titanium oxide coating using a coating reactor similar to that shown in FIG. 3. The temperature at the precursor tower was 400° F. / 205° C. and the temperature at the reactor face was 500° F. / 260° C. Prior to practicing the method of the present invention, a silica coating was deposited on the glass substrate in the float bath section at a thickness of about 339 Å. The same chemical vapor deposition process as described in Example 1 was used to deposit the silica coating. The silica deposition forms no part of the present invention.

[0065] The precursor gas mixture was developed comprising titanium tetrachloride and ethyl acetate in a helium carrier gas. Oxygen was not used in the precursor as result of ear...

example 7

[0067] The same procedure carried out Example 6 was utilized in this Example. The substrate comprised coatings of silicon and then silica over the glass substrate. The coatings were deposited by a known chemical vapor deposition process in the float bath section. The silicon coating was deposited by CVD from monosilane with a non-oxidizing carrier gas. The silica coating was then deposited onto the silicon coating through the use of the same procedure as described in Example 1.

[0068] The precursor for the titanium oxide coating included titanium tetrachloride and ethyl acetate in a helium carrier gas. The volume percent composition of the precursor was 0.5% titanium tetrachloride, 1.9% ethyl acetate, and 97.6% helium. The corresponding flow rates for the components were 480.0 l / m of helium, 2.4 l / m of titanium tetrachloride, 9.2 l / m of ethyl acetate. The total flow rate for the precursor mixture was 491.6 1 / m.

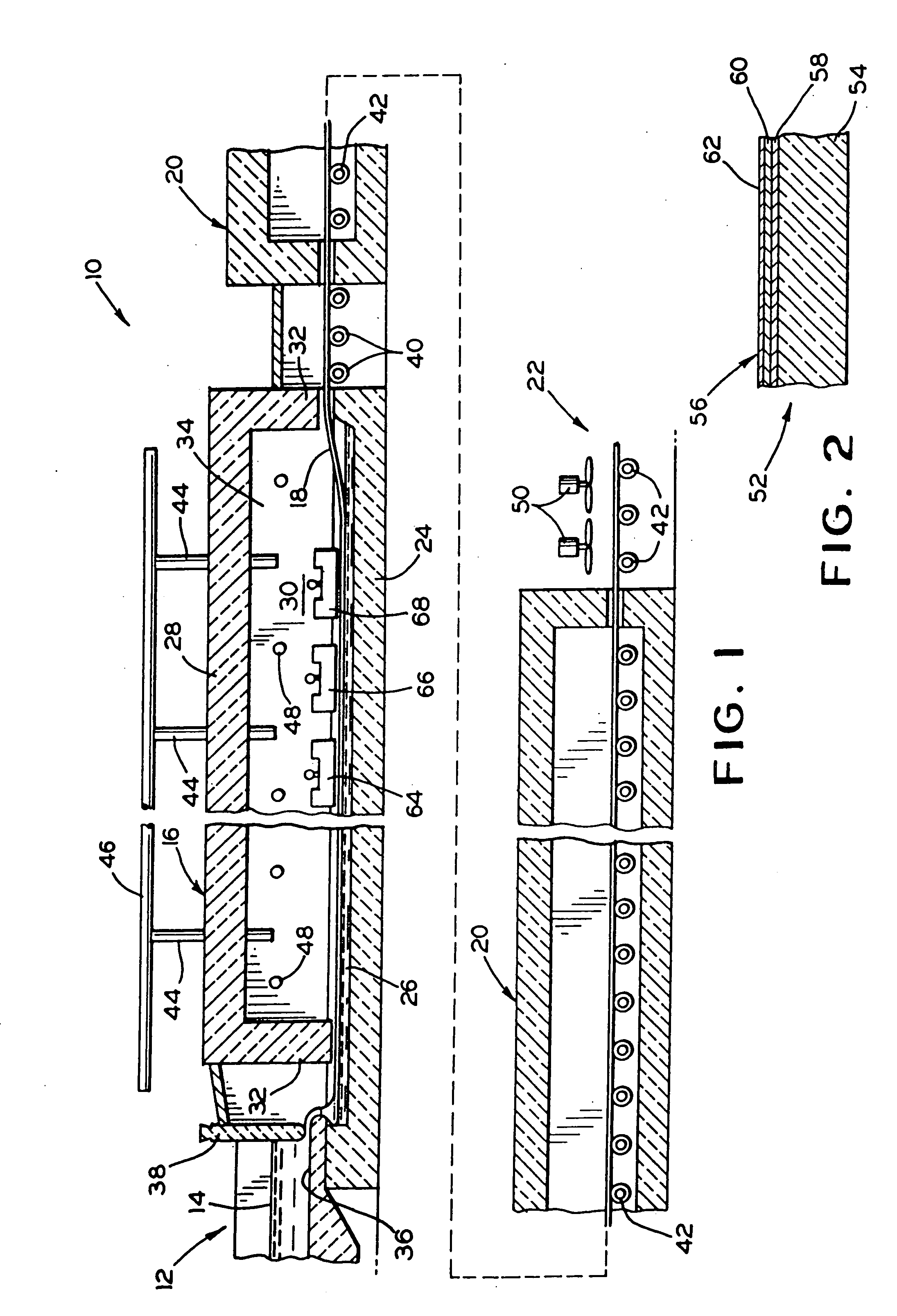

[0069] The resulting coated article 52 is illustrated in FIG. 2. The gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com