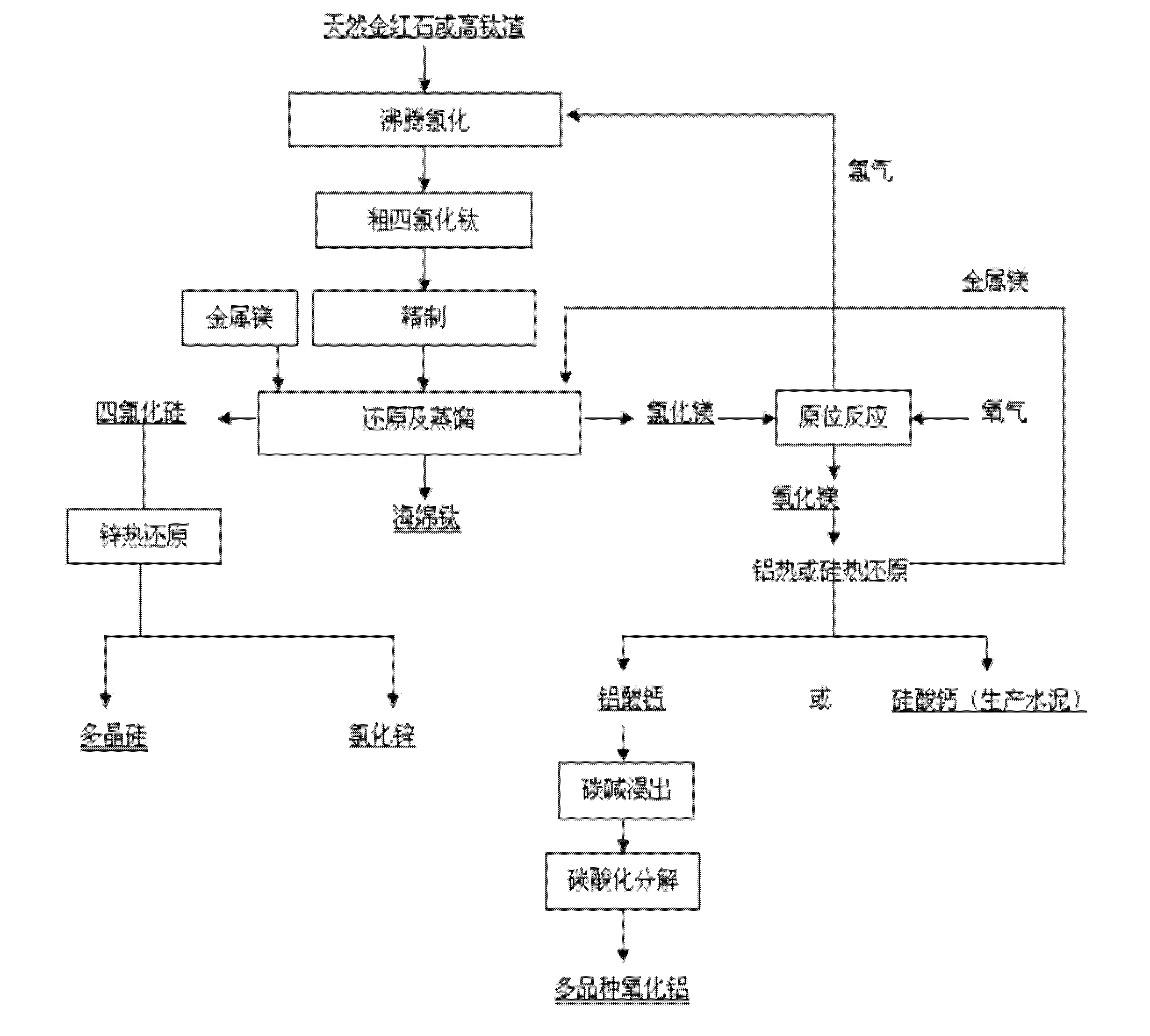

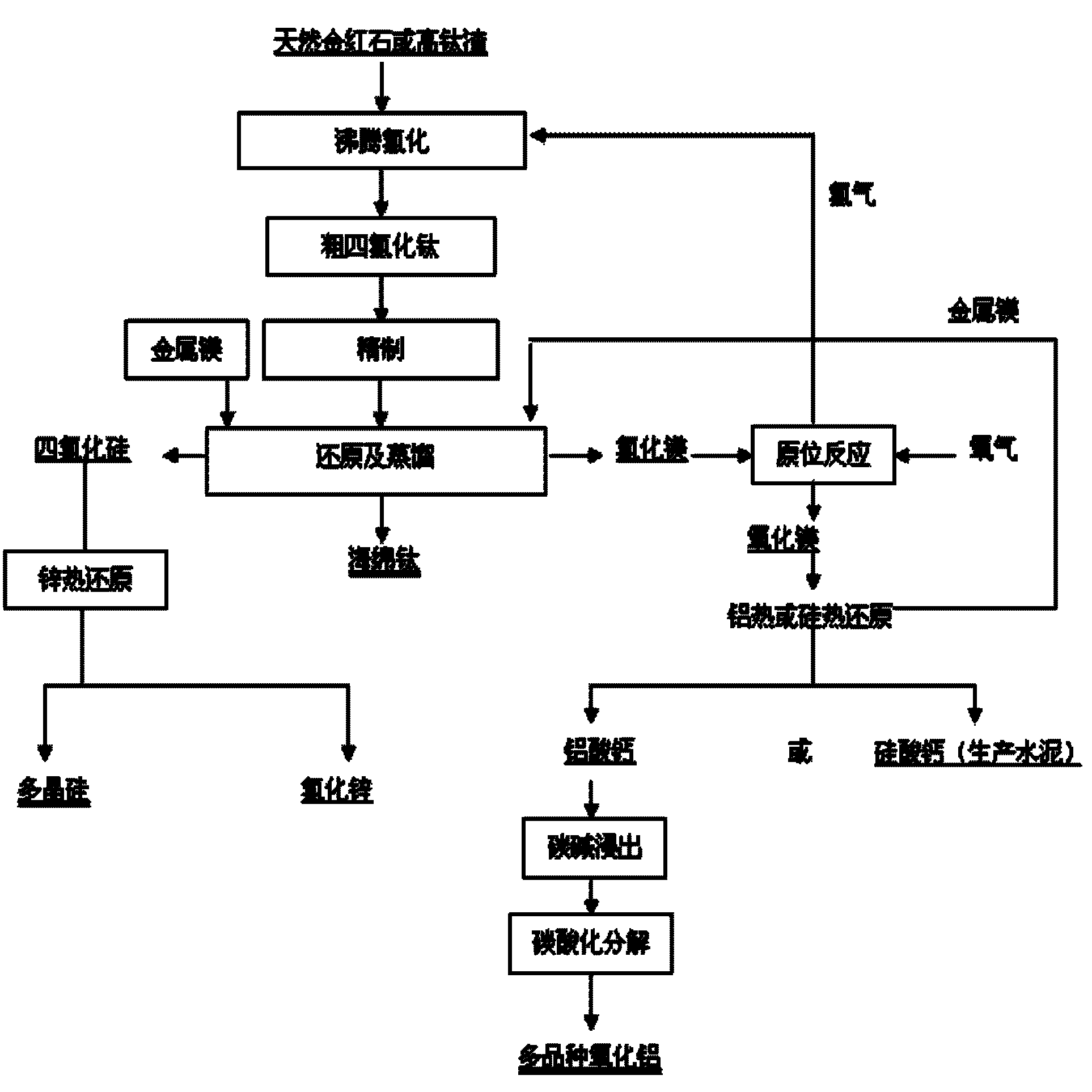

Method for preparing titanium sponge through magnesium and chlorine recycling

A technology of sponge titanium and titanium tetrachloride, applied in the direction of improving process efficiency, can solve the problem of high investment in magnesium and chlorine cycle equipment, and achieve the effects of reducing economic benefits, reducing production costs, and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Example 1: Firstly, the natural rutile was crushed and finely ground to -0.25mm, and then crude titanium tetrachloride was obtained under the conditions of chlorination temperature of 800°C, chlorination time of 60min, and operating fluidization number of 10. The crude titanium tetrachloride was obtained by After iron removal in a distillation tower with a bottom temperature of 140°C and a top temperature of 137°C, silicon is removed through a rectification tower with a bottom temperature of 140°C and a top temperature of 57°C, and then vanadium is removed with copper wire at a temperature of 136°C , to obtain a titanium tetrachloride product with a purity greater than 99wt%, the refined titanium tetrachloride and metal magnesium are in a ratio of 1.3:1 according to the mass ratio of magnesium and titanium, the reaction temperature is 700 ° C, and the reaction time is 8 hours, and sponge titanium and magnesium chloride and The mixture of silicon tetrachloride, distilling ...

Embodiment 2

[0037] Example 2: Firstly, the natural rutile is crushed and finely ground to -0.25mm, and then crude titanium tetrachloride is obtained under the conditions of chlorination temperature of 1050°C, chlorination time of 10min, and operating fluidization number of 5. The crude titanium tetrachloride is obtained by using After removing iron in the distillation tower with a bottom temperature of 145°C and a top temperature of 137°C, silicon is removed through a rectification tower with a bottom temperature of 140°C and a top temperature of 70°C, and then copper wire is used to remove vanadium at a temperature of 140°C , to obtain a titanium tetrachloride product with a purity greater than 99wt%, the refined titanium tetrachloride and metal magnesium are in a ratio of 1.8:1 according to the mass ratio of magnesium and titanium, the reaction temperature is 1000°C, and the reaction time is 5h, and sponge titanium and magnesium chloride and The mixture of silicon tetrachloride, the mixt...

Embodiment 3

[0038] Example 3: Firstly, the high titanium slag was crushed and finely ground to -0.25mm, and then crude titanium tetrachloride was obtained under the conditions of chlorination temperature of 900°C, chlorination time of 40min, and operating fluidization number of 7, crude titanium tetrachloride After iron removal by a distillation tower with a bottom temperature of 142°C and a top temperature of 137°C, silicon is removed by a rectification tower with a bottom temperature of 140°C and a top temperature of 60°C, and then copper wire is used to remove silicon at a temperature of 138°C. Vanadium, to obtain titanium tetrachloride products with a purity greater than 99wt%, the refined titanium tetrachloride and metal magnesium are in a ratio of 1.5:1 according to the mass ratio of magnesium and titanium, the reaction temperature is 900 ° C, and the reaction time is 6 hours to obtain sponge titanium and magnesium chloride The mixture of sponge titanium, magnesium chloride and silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com