Process for making paper

a papermaking and paper technology, applied in the field of papermaking pulps, can solve problems such as instability of papermaking pulp, and achieve the effects of improving fine retention, drainage and formation, and long shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

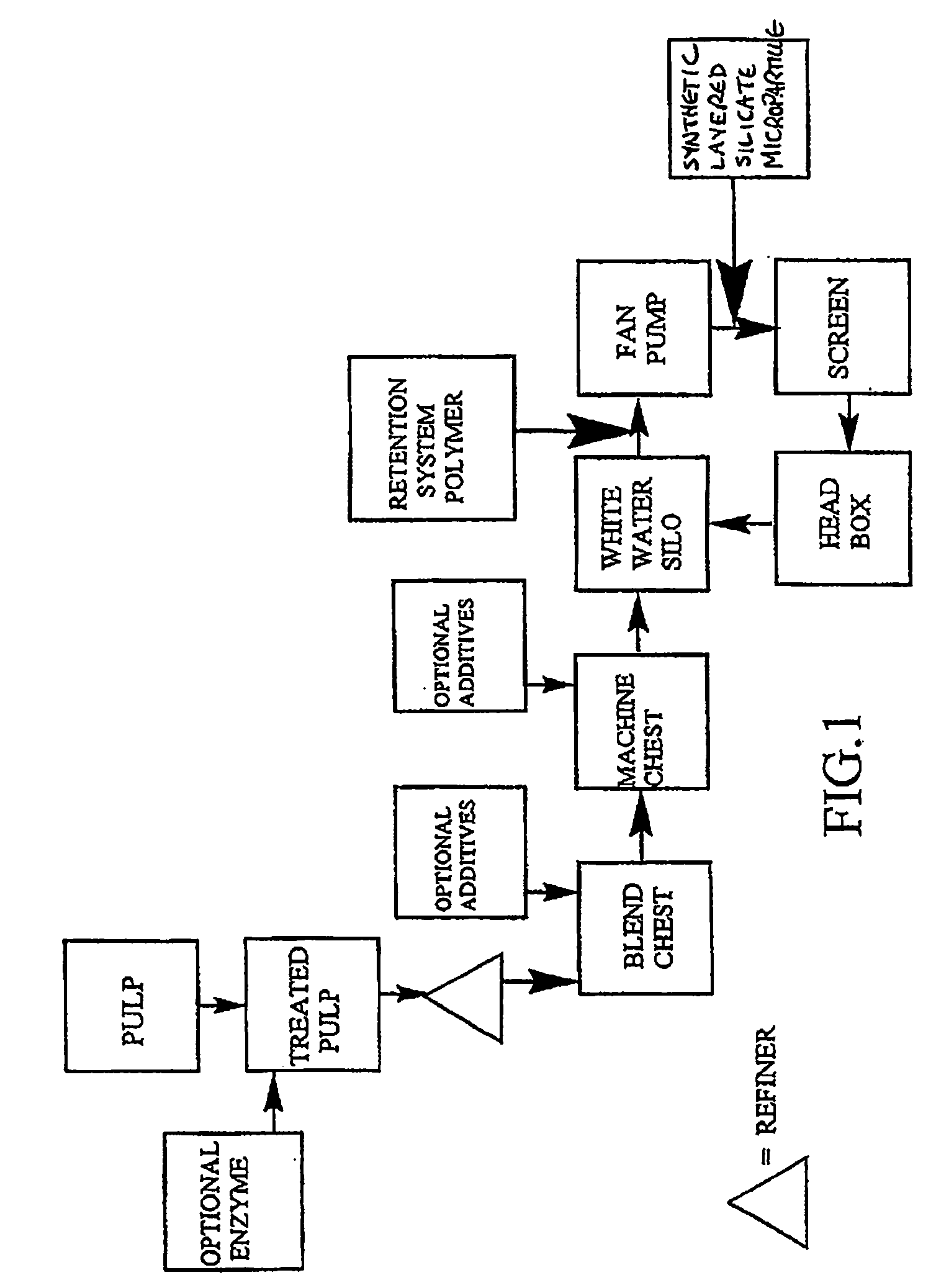

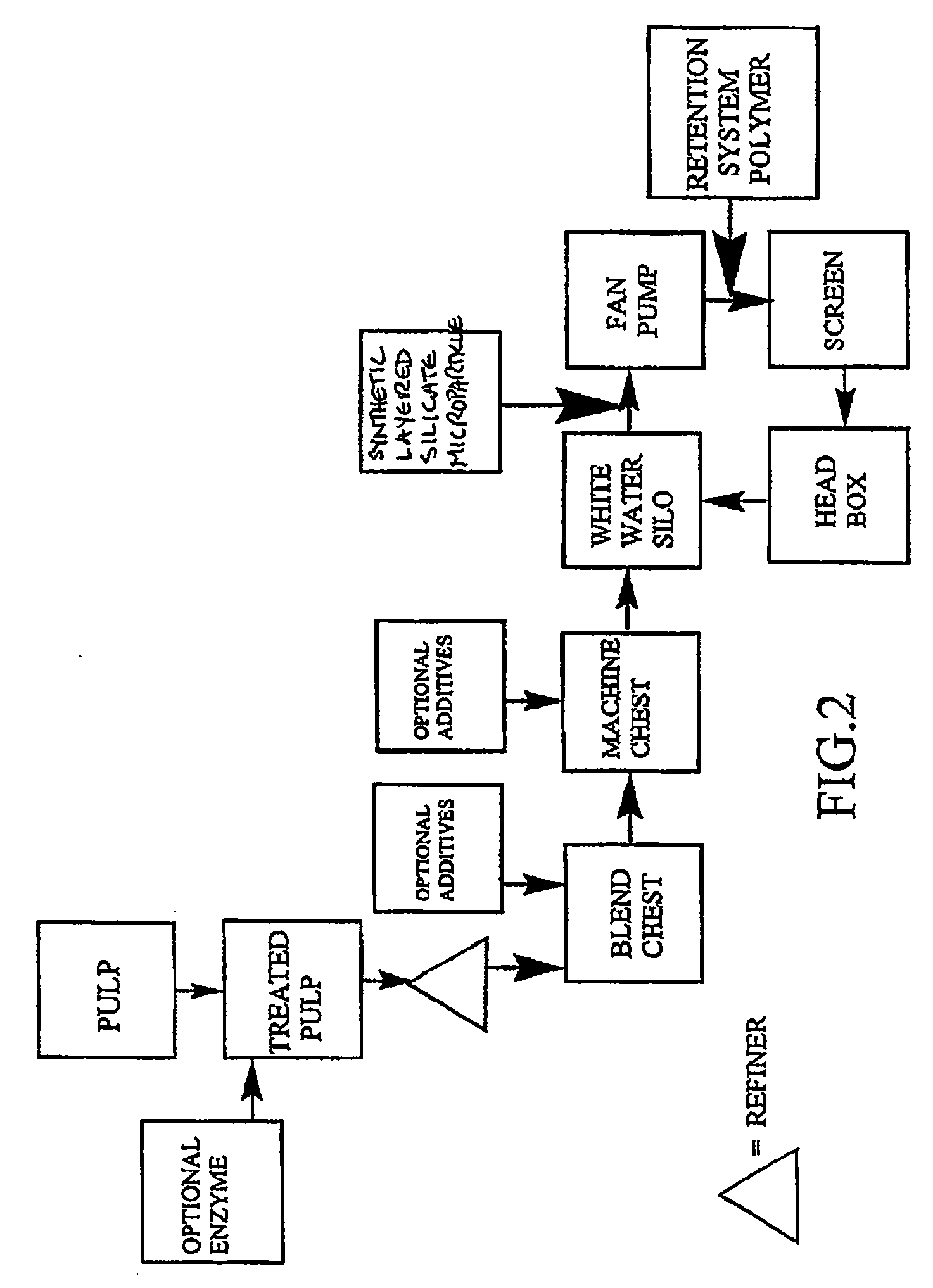

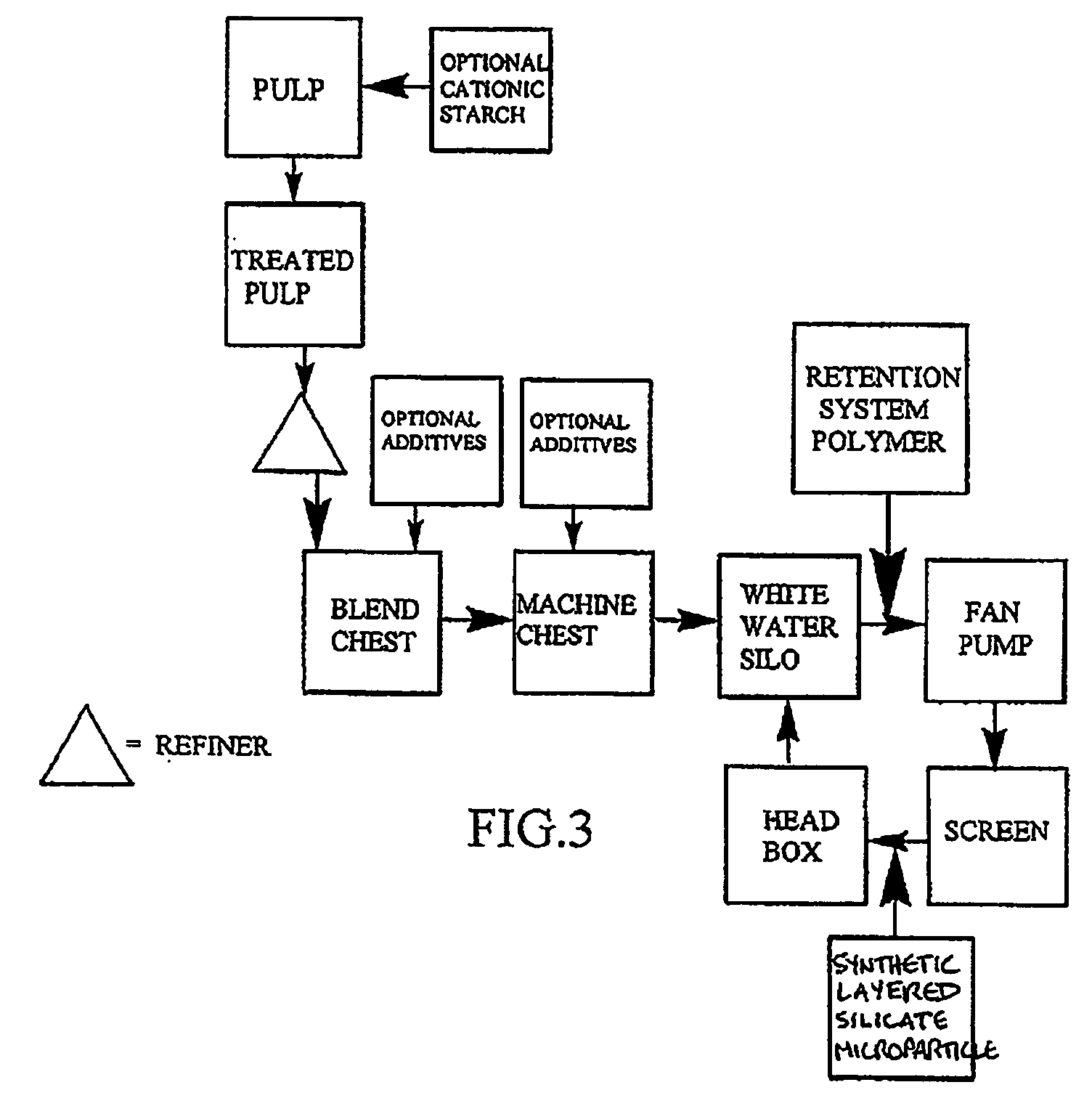

Method used

Image

Examples

examples

[0072] In the examples below, various components used in the examples are abbreviated. In the examples, the components identified as “RD”, “RDS” and “JS” are Laponite RD, Laponite RDS and Laponite JS respectively, available from Rockwood Additives Limited. Laponite RD is a hydrous sodium lithium magnesium silicate; Laponite RDS is a hydrous sodium lithium magnesium silicate with tetrasodium pyrophosphate; and Laponite JS is a hydrous sodium lithium magnesium fluorosilicate with tetrasodium pyrophosphate. When followed by a numerical value, for example, “RDS 0.5”, the numerical value represents the amount of pounds on a dry basis of the Laponite microparticles per ton of paperstock based on the dried solids weight of the paperstock.

[0073] In the examples below, the abbreviations “B 594” and “594” represent BUFLOC™ 594, available from Buckman Laboratories International, Inc., which is a high molecular weight cationic polyacrylamide having an average molecular weight of from about 5,0...

example i

Drainage and Turbidity Tests

[0076] Tests were conducted at a paper mill. Drainage was performed using a small screen through which 500 ml samples were drained using a modified Schopper Riegler method. Mixing was carried out in a food blender.

[0077] Equipment used for the modified Shopper Riegler drainage test included the following: a Modified Schopper Riegler (MSR); a 1000 ml graduated cylinder; a stopwatch; a 5-gallon (18.9 I) plastic bucket; wires for MSR; a vacuum flask and funnel (for retention); Whatman ashless filter papers (for ash retention); a turbidity meter; a hemocytometer; and a microscope.

[0078] Samples to be tested were taken from the headbox of the papermaking apparatus. For each test, 1000 ml was required. Because temperature has an impact on drainage, each test was run immediately after the sample was taken. For lab studies with the retention aids, the furnish was kept at the same temperature as the headbox temperature.

[0079] If the MSR was cold and the sample...

example 2

Retention Tests

[0087] Britt Jar tests were performed at 1,000 rpm to evaluate performance of the retention aid system according to the invention based on increased first pass retention and increased first pass ash retention. In the Britt Jar, the furnish is under continuous movement, so no fiber mat is formed and the water can drain continuously through the wire. This simulates the stock and water dewatering occurring on the paper machine.

[0088] The furnish used in the Britt Jar tests was identical to the furnish used in Example 1.

[0089] In the Britt Jar tests, the chemicals are applied in the correct sequence and the furnish is mixed to a degree to simulate the treatment of the furnish by paper machine equipment such as fan pumps and centri-screens. As it is sheared, the stock spends a second (at the most) actually in the fan pump or the screens. Another way to simulate the shear and to represent the actual short contact time is to carry out all chemical mixing outside the Britt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com