Method for preparing magnesium metal and by-product by vacuum carbothermic reduction with serpentine minerals

A technology of serpentine and metal magnesium, which is applied in the field of reduction and preparation of metal magnesium, and achieves the effects of good crystallization, reduced pollution and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

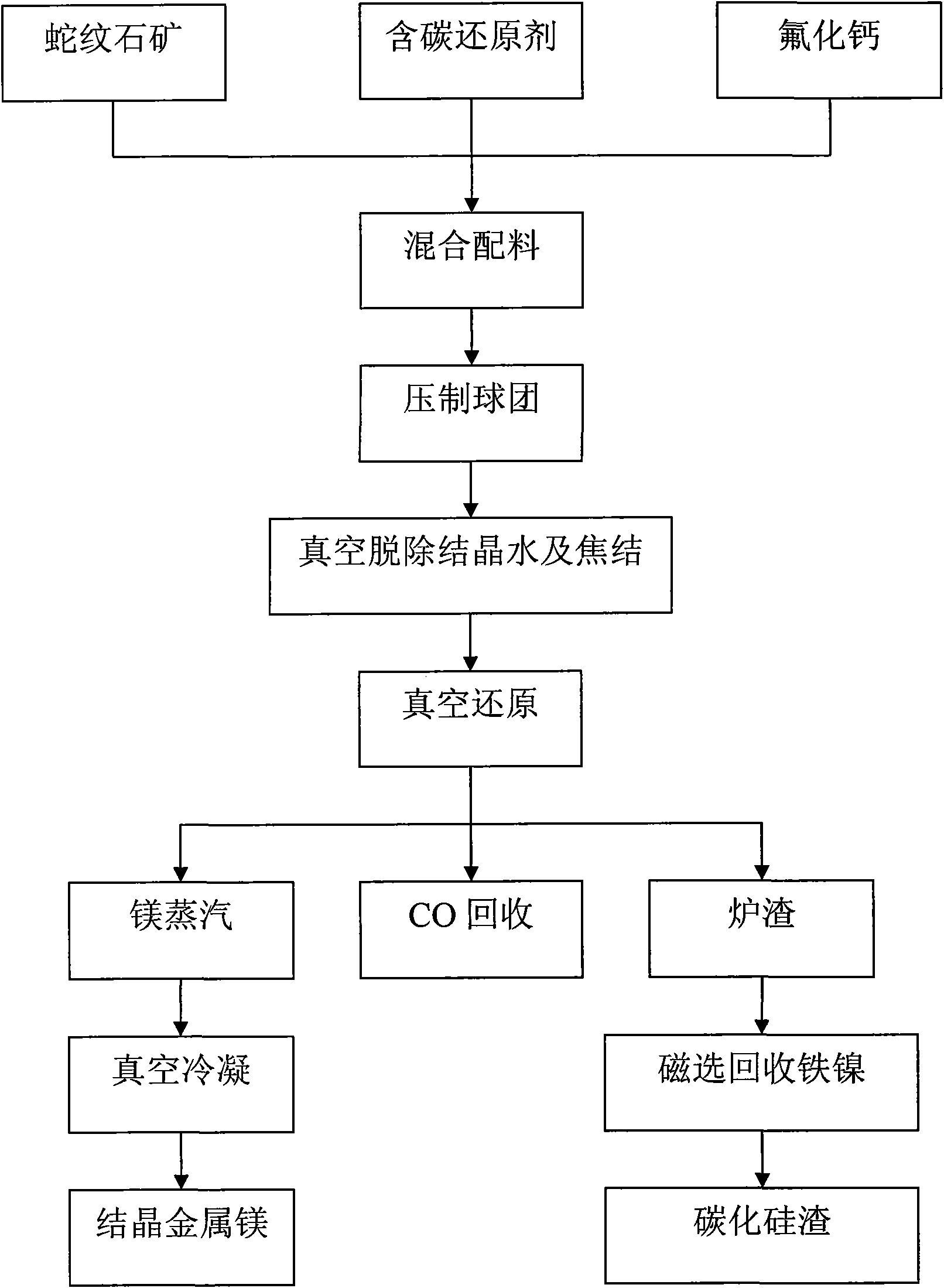

[0026] Embodiment 1 prepares the method for metallic magnesium and by-products with serpentine ore vacuum carbothermal reduction

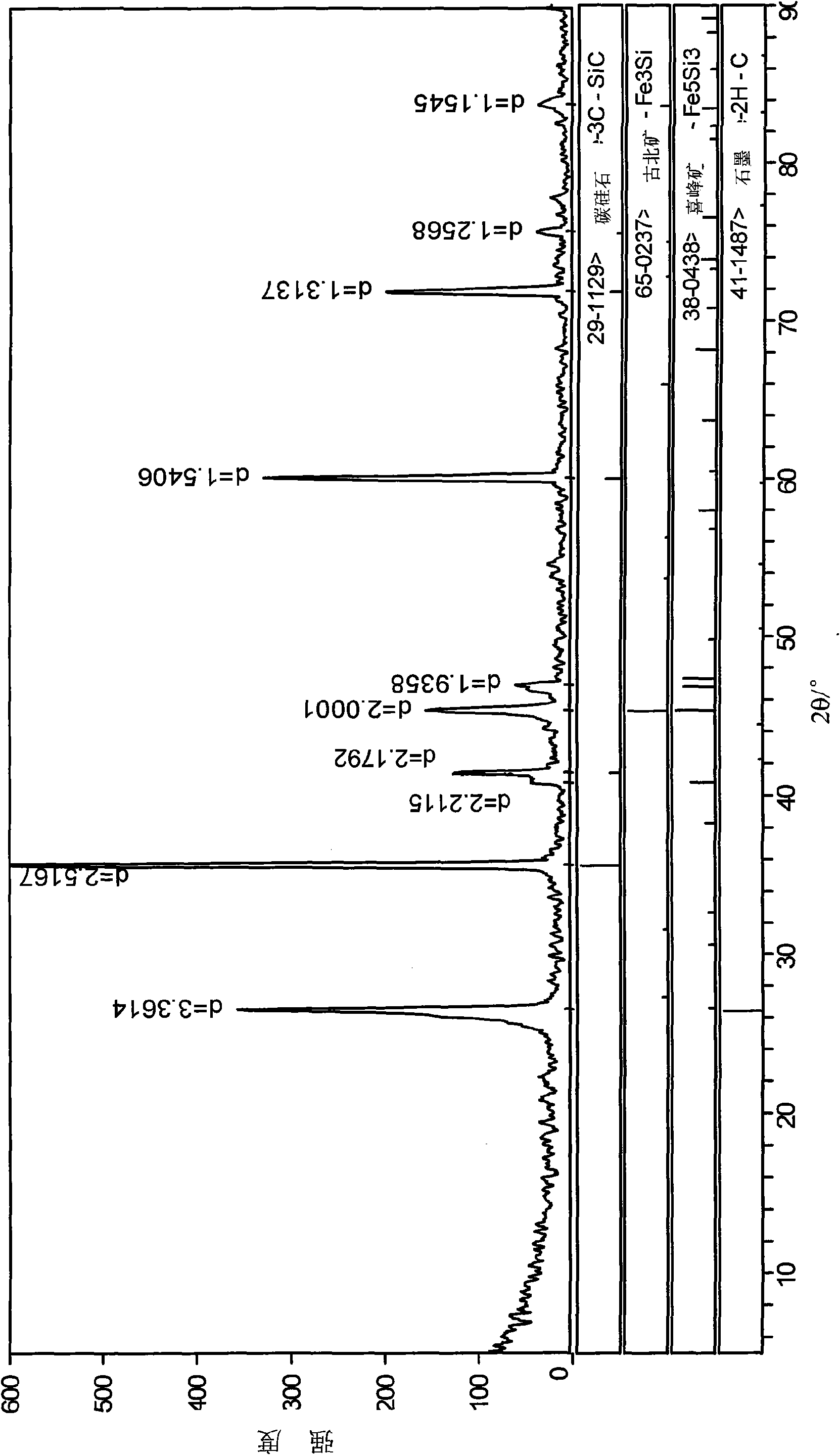

[0027] Serpentine is a natural magnesium-containing silicate mineral. It is a metamorphic rock of olivine. It is a 1:1 type layered silicate mineral composed of silicon-oxygen tetrahedral wafers and magnesium hydroxide octahedral wafers. According to the shape of its internal structural layer, it is divided into lizardite, antigorite and fiber serpentine. Its theoretical composition is MgO43.0%, SiO 2 44.1%, H 2 O12.9%, but the composition and proportion of the actual minerals will be different, often containing Fe, Ni, Mn, Al and other mixed elements. The purpose of the test is to reduce the magnesium silicate minerals in serpentine to metal magnesium by thermal reduction of carbon (coke, coke coal, petroleum coke or graphite powder, etc.), and at the same time reduce the SiO in serpentine 3 2- Reduction to gaseous SiO, SiO reacts with CO or C...

Embodiment 2

[0048] Embodiment 2 Catalyst calcium fluoride addition is on the influence of magnesium recovery rate

[0049] The role of the catalyst calcium fluoride is mainly to destroy the structure of the serpentine crystal, and the amount of its addition plays an important role in the recovery rate of magnesium in the serpentine ore. Using the same preparation process as in Example 1, the effect of the added calcium fluoride on the recovery of magnesium was investigated by adjusting the proportion of the added calcium fluoride in the mixed raw material. The results are shown in Table 5. It can be seen that when the amount of calcium fluoride added is 1%, the recovery rate is 68.60%, which can be used in industrial production; when the amount of calcium fluoride is added at 1% to 4%, the recovery rate of magnesium increases significantly with the increase of calcium fluoride; At that time, the recovery rate of magnesium has tended to be stable, about 95-96%. It can be seen that when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com