Preparation method of lithium ion battery positive material of ferric metasilicate lithium

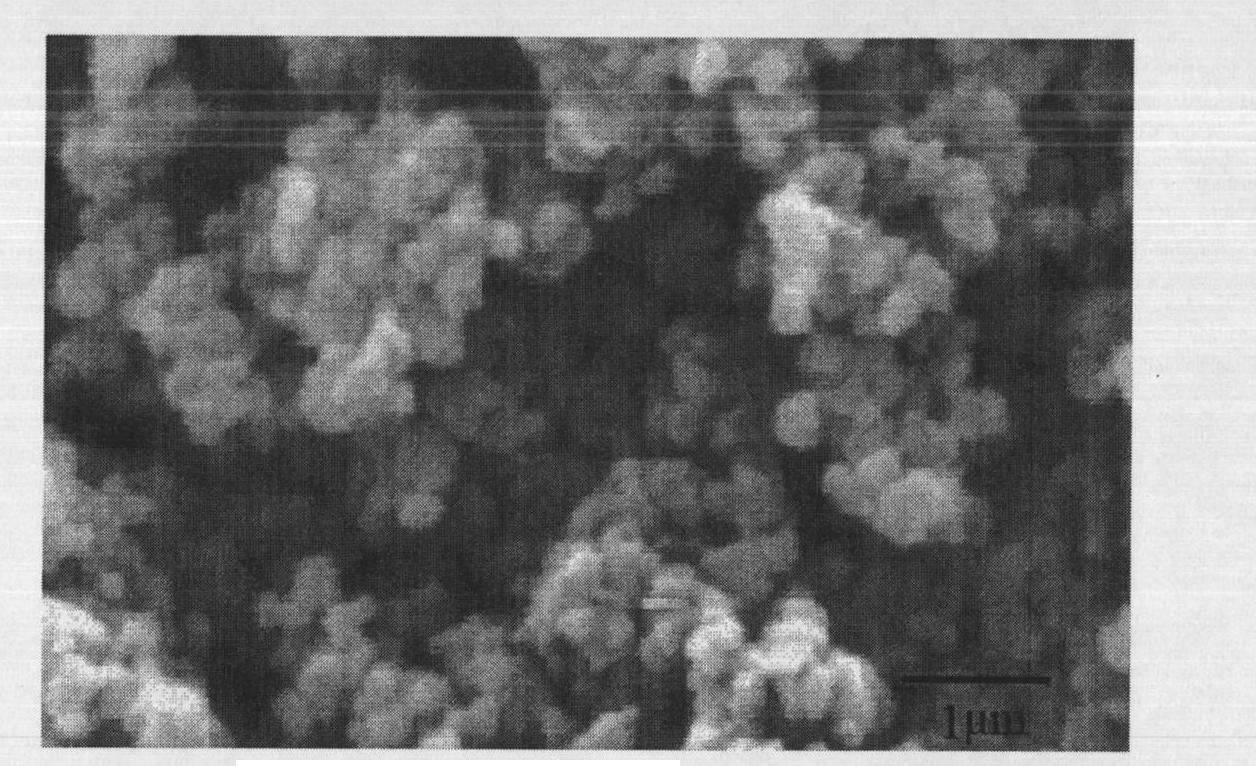

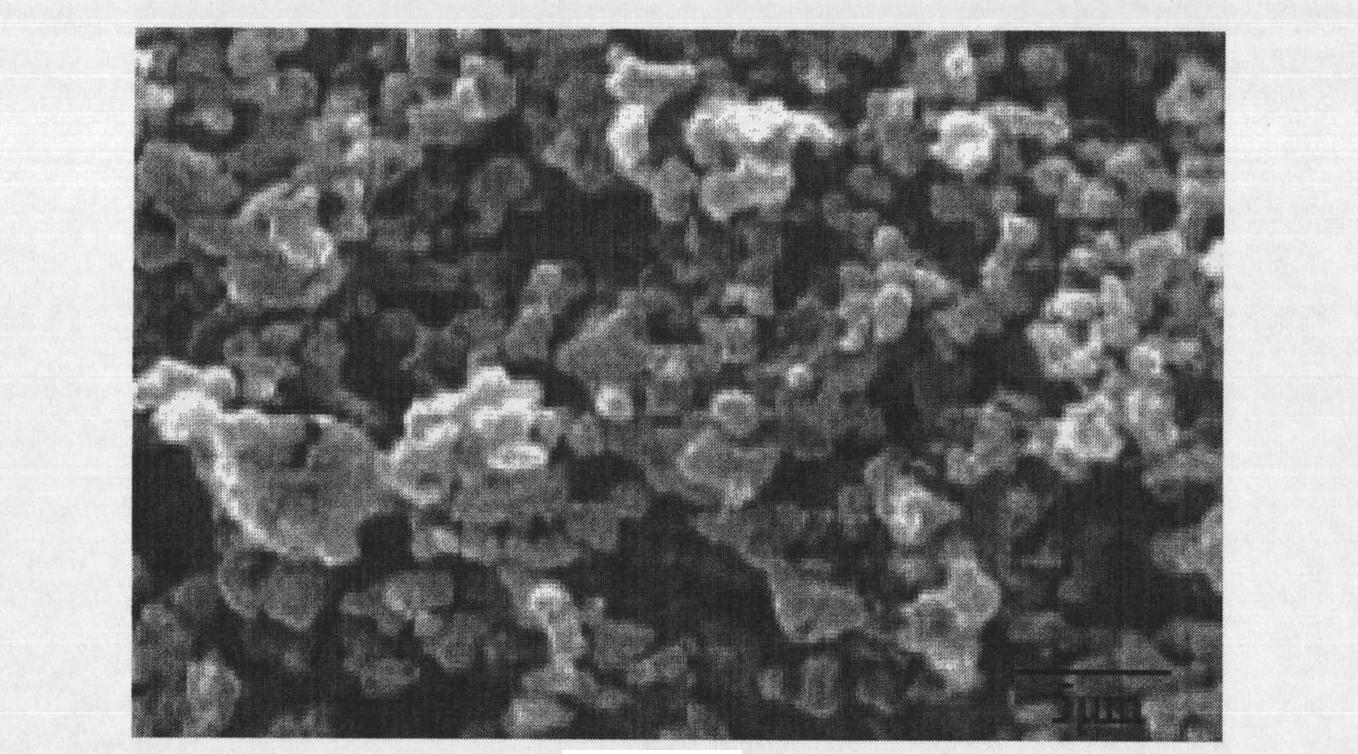

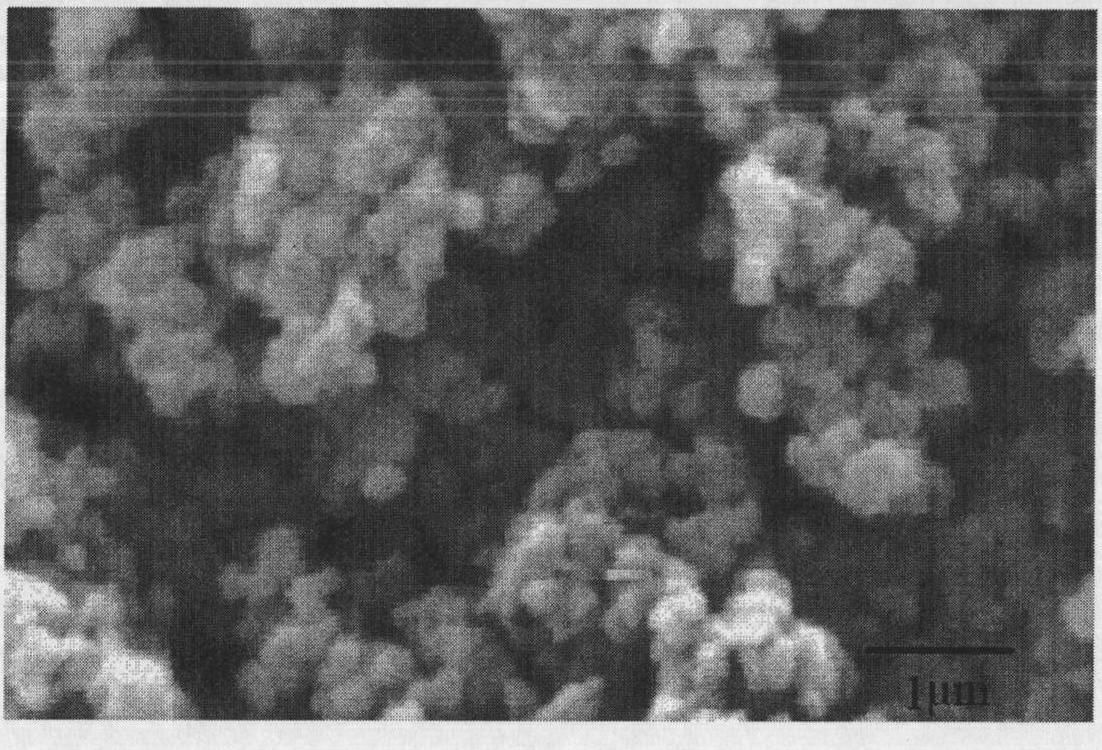

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problem of lithium ion diffusion that cannot be fundamentally solved, lithium iron phosphate has poor high-rate discharge performance, and increases the difficulty of lithium ion diffusion. and other problems, to achieve the effect of excellent discharge performance at high rate, uniform particle size and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Dissolve 0.50 mol of lithium acetate in 50 ml of water, 0.65 mol of ferrous chloride in 70 ml of water and 0.60 mol of phosphoric acid in 80 ml of water, and fully mix the three aqueous solutions to obtain 200 ml of mixed aqueous solution, turn on ultrasonic stirring, and add 0.2 g Sodium dodecylbenzenesulfonate and 0.2g TX-10, then slowly add dropwise 1mol / L sodium hydroxide aqueous solution to adjust the pH of the solution to 8, react in a sealed container with nitrogen protection for 20 hours, filter, and use The obtained filter cake was washed with ionic water until the filtrate was neutral, and the obtained filter cake was centrifuged and dried with a centrifuge, wherein the speed of the centrifuge was 1000r / min, and the centrifugation time was 100min to obtain 10g of the precursor. The precursor is added into the aqueous glucose solution, the concentration of the aqueous glucose solution used is 5% (based on the weight of the aqueous glucose solution), and the weig...

Embodiment 2

[0050] Dissolve 0.50 mol of lithium chloride in 50 ml of water, 0.50 mol of ferrous acetate in 70 ml of water and 0.50 mol of diammonium hydrogen phosphate in 80 ml of water, and fully mix the three aqueous solutions to obtain 200 ml of mixed aqueous solution, turn on ultrasonic stirring, Add 0.3g hexadecyltrimethylammonium bromide and 0.3g TX-10, then slowly add dropwise 1mol / L potassium hydroxide aqueous solution to adjust the pH to 8, and react for 5 hours in a sealed container protected by argon gas , filtered, washed the obtained filter cake with deionized water, and centrifuged and dried the obtained filter cake with a centrifuge, wherein the rotating speed of the centrifuge was 1500r / min, and the centrifugation time was 10min to obtain 9g of the precursor. The precursor is added in the sucrose aqueous solution, the concentration of the sucrose aqueous solution used is 10% (based on the weight of the sucrose aqueous solution), wherein the weight of the sucrose is 4.5g, an...

Embodiment 3

[0052] Dissolve 0.50 mol of lithium nitrate in 50 ml of water, 0.55 mol of ferrous sulfate in 70 ml of water and 0.55 mol of potassium dihydrogen phosphate in 80 ml of water, and fully mix the three aqueous solutions to obtain 200 ml of mixed aqueous solution, turn on ultrasonic stirring, add 0.6g hexadecyltrimethylammonium bromide and 0.6g TX-10, then slowly drop 1mol / L ammonia water to adjust the pH to 9, react in a sealed container protected by nitrogen-argon mixed gas for 30 hours, filter, The obtained filter cake was washed with deionized water, and the obtained filter cake was centrifuged and dried with a centrifuge, wherein the rotation speed of the centrifuge was 3500 r / min, and the centrifugation time was 120 min to obtain 10 g of the precursor. Precursor is added in the aqueous solution of citric acid, the concentration of used aqueous citric acid is 3% (based on the weight of aqueous citric acid), wherein, the weight of citric acid is 1.5g, in the microwave oven prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com