ABS (acrylonitrile-butadiene-styrene)/regenerated PET (polyethylene terephthalate) resin composition and preparation method thereof

A resin composition and composition technology, which is applied in the field of ABS/regenerated PET resin composition and preparation, can solve the problems of material performance degradation and achieve the effect of improving compatibility and high impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

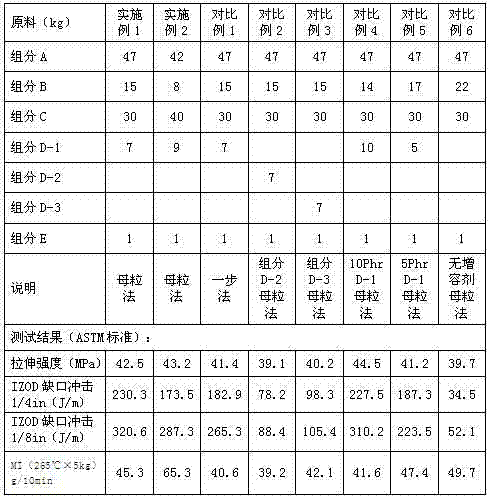

[0034] Prepare materials according to the components in Table 1. in,

[0035] Component A: ABS high rubber powder. The butadiene content of ABS is 54%, the styrene content is 34%, and the acrylonitrile content is 12%, produced by Kumho Petrochemical in South Korea;

[0036] Component B: Styrene Acrylonitrile Copolymer (SAN). The molecular weight of SAN is 125000, wherein styrene: butadiene=72:28, South Korea Kumho Petrochemical production;

[0037] Component C: Recycled PET, derived from recycled PET beverage bottles, is broken into after thorough cleaning;

[0038] Component D-1: Styrene-acrylonitrile copolymer-glycidyl methacrylate terpolymer (SAN-GMA), GMA content is 5%;

[0039] Component E: processing aids, including lubricant ethylene bis stearamide, phosphite antioxidant IRGAFOS?? 168, hindered phenol IRGANOX1076 and silicone mold release agent Dow Corning MB-50, the weight ratio of the four is 2:1:2:1.

[0040] The ABS high rubber powder, styrene acrylonitrile co...

Embodiment 3

[0054] Prepare materials according to the following components: ABS 15kg, SAN 25kg, PET 50kg, compatibilizer D-1 1kg, antioxidant (hindered phenol + phosphite) 0.1kg, lubricant 0.1kg.

[0055] First, the ABS high rubber powder, styrene acrylonitrile copolymer (SAN), and compatibilizer are fully mixed in a high mixer and then exported, and then put into a screw machine to extrude and granulate. The speed of the screw machine is 300-400rpm. The temperature is 200-220°C to make compatibilized masterbatch. Then fully mix the compatibilizing masterbatch and the rest of the above components in a high-mixer and then export them, and then put them into a screw machine for extrusion and granulation. The speed of the screw machine is 300-500rpm and the temperature is 225-260°C. ABS / recycled PET resin composition. The performance of the ABS / regenerated PET resin composition was tested in the same way as in Example 1-2, and the results are shown in Table 2.

Embodiment 4

[0057] Prepare materials according to the following components: ABS 60kg, SAN 5kg, PET 5kg, compatibilizer D-1 10kg, antioxidant (hindered phenol + phosphite) 1kg, lubricant 2kg.

[0058] First, the ABS high rubber powder, styrene acrylonitrile copolymer (SAN), and compatibilizer are fully mixed in a high mixer and then exported, and then put into a screw machine to extrude and granulate. The speed of the screw machine is 300-400rpm. The temperature is 200-220°C to make compatibilized masterbatch.

[0059] Then fully mix the compatibilizing masterbatch and other components in a high-speed mixer, then export them, and then put them into a screw machine to extrude and granulate. / Recycled PET resin composition. The performance of the ABS / regenerated PET resin composition was tested in the same way as in Example 1-2, and the results are shown in Table 2. From the results in Table 2, it can be seen that the ABS / regenerated PET resin compositions prepared in Example 3 and Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com