Living polymerization preparation method for polyacrylic acid ball brush and application of polyacrylic acid ball brush

A technology of polyacrylic acid and active polymerization, which is applied in the direction of chemical instruments and methods, carrier binding/immobilization of peptides, peptides, etc., can solve problems such as cumbersome synthetic routes, achieve improved reaction efficiency, high grafting density and carboxyl content, and increase protein The effect of immobilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

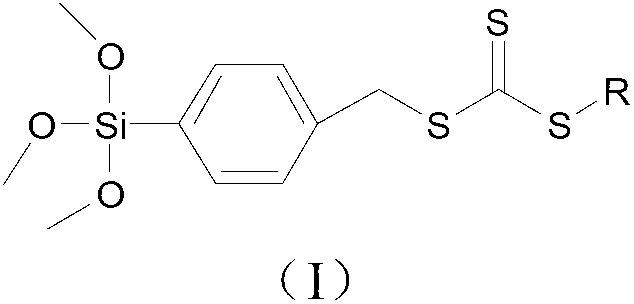

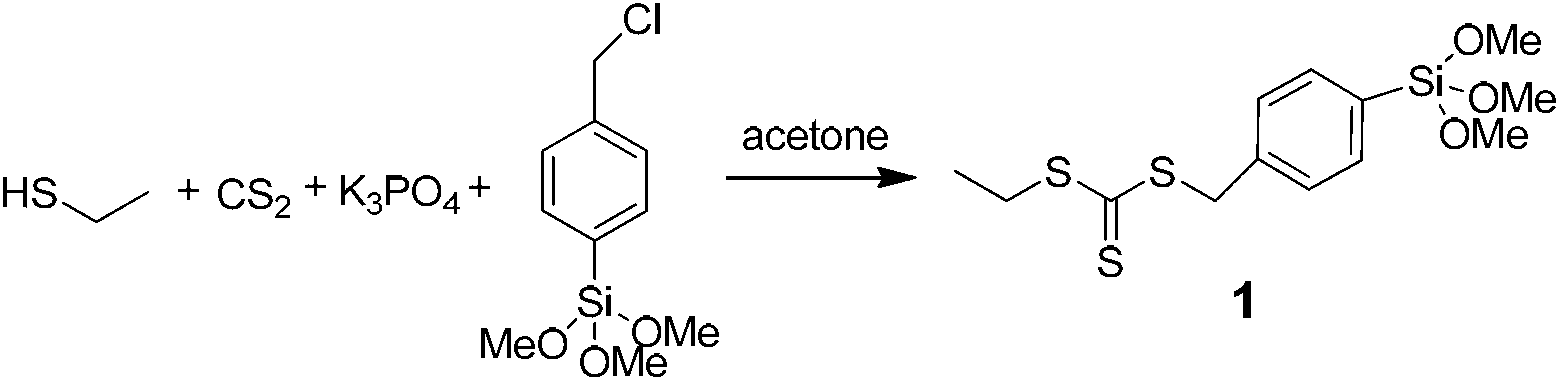

[0052] Synthesis of silylated RAFT chain transfer reagents:

[0053]

[0054] Add C to a 50 mL vial 2 h 5 SH (6.6mmol) and K 3 PO 4 (6.6mmol), add acetone (20mL) as a solvent, stir at 25°C for 10mins, there is white insoluble matter in the reaction system; then add CS to the system dropwise 2 (18.0mmol), after adding, continue to stir and react for 10mins, the solution turns light yellow, and there are still insoluble matter. Finally, after the system was deoxygenated, p-chloro 4-phenyltrimethoxysilane (6.6 mmol) was added to the system for 13 hours, the solution turned yellow and turbid, and a large amount of solids were precipitated; the organic phase was concentrated, and two Chloromethane (25 mL), filtered, and the filtrate was concentrated to obtain a yellow liquid; the concentrated solution was subjected to column chromatography, and the eluent was EA:PE=1:20 to obtain a yellow liquid 1 with a yield of 76%.

[0055] 1 H NMR (400MHz, CDCl 3 )δ7.60(d, J=7.9Hz, 2H...

Embodiment 2

[0059] Prepare polyacrylic ball brushes:

[0060] 1. Prepare monodisperse silica microspheres with a size of 80nm; wash and disperse the prepared silica microspheres in absolute ethanol, wherein the content of the microspheres is 3wt.%.

[0061] 2. Take 70 mL of the ethanol dispersion of silica microspheres and add it to a 100 mL dry round bottom flask, and add 0.5% (v / v) of silanized RAFT chain transfer reagent compound 1. A condensing reflux device and a nitrogen balloon were installed on the round-bottom flask, and the atmosphere of the system was replaced with nitrogen by means of vacuuming and filling with nitrogen, and then the temperature was raised to 80°C for reflux reaction for 24 hours to obtain the silanized RAFT chain transfer reagent-modified oxidation Silicon microsphere product; the product was washed three times with ethanol and then stably dispersed in absolute ethanol, wherein the content of microspheres was 3wt.%.

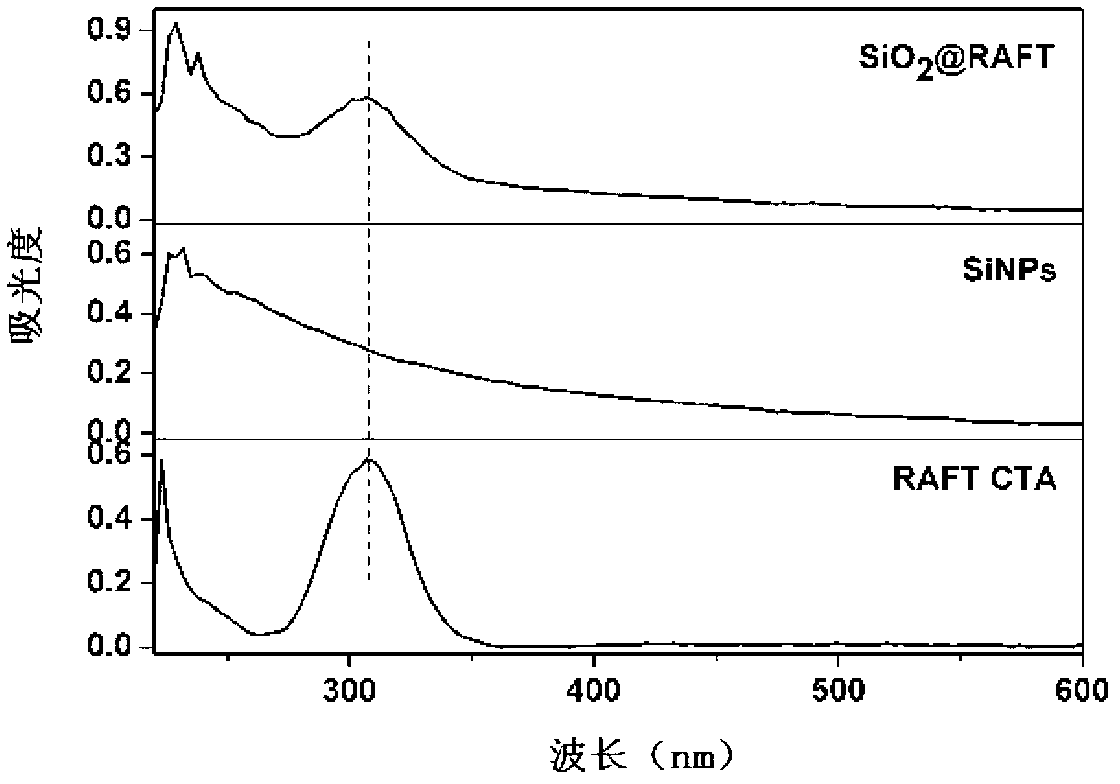

[0062] The prepared RAFT chain transfer ...

Embodiment 3

[0066] The polyacrylic acid ball brush with silica as the core prepared in Example 2 was used for protein immobilization. Among them, streptavidin is selected as the protein, and the specific process is as follows:

[0067] First, take the ethanol dispersion of the polyacrylic acid ball brush (which contains 1.5 mg of the ball brush) prepared in Example 2, and redisperse it into 10 mM sodium dihydrogen phosphate / disodium hydrogen phosphate buffer solution (pH=7.6, containing 0.05 wt.% Tween-20), EDC and NHS were added so that the volume of the final system was 400 μL, and the concentrations of EDC and NHS were 25 mg / mL and 12.5 mg / mL, respectively. Mix at room temperature for 15 minutes to activate the polyacrylic acid ball brush, and the activated polyacrylic acid ball brush is washed 3 times with the above-mentioned phosphate buffer solution.

[0068] Then, disperse the activated polyacrylic acid ball brush in the above phosphate buffer, add excess streptavidin protein, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrodynamic diameter | aaaaa | aaaaa |

| Hydrodynamic diameter | aaaaa | aaaaa |

| Graft density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com