Paper inserting machine for iron core wire inserting groove

A technology of inserting wire grooves and paper inserting machines, which is applied in laying solid insulation and other directions, can solve the problems of scattering of insulating paper tubes, reducing the practicability of paper inserting machines, and inconvenient fixing of iron cores, etc., and achieves simple and fast fixing. , The effect of convenient and quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

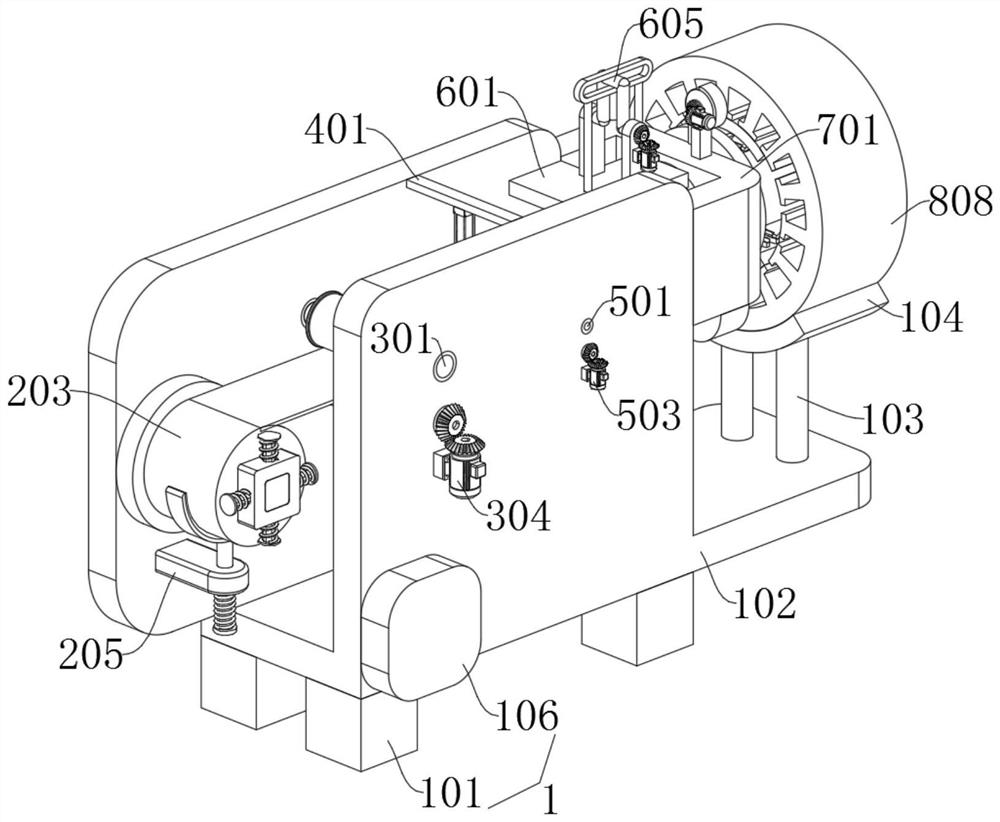

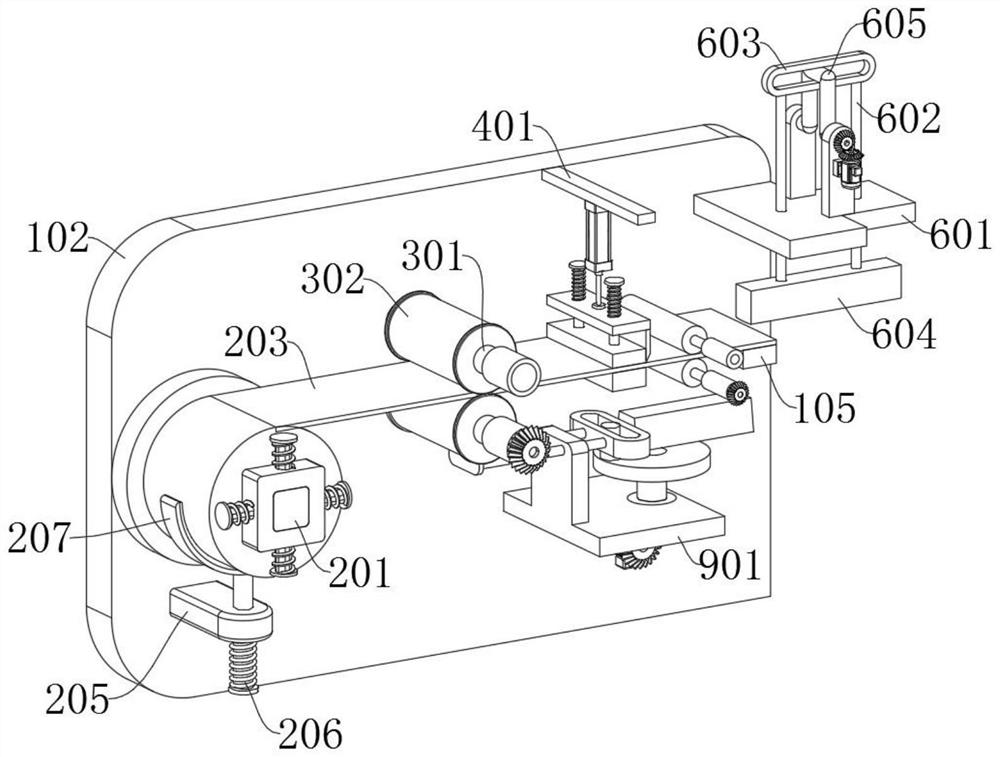

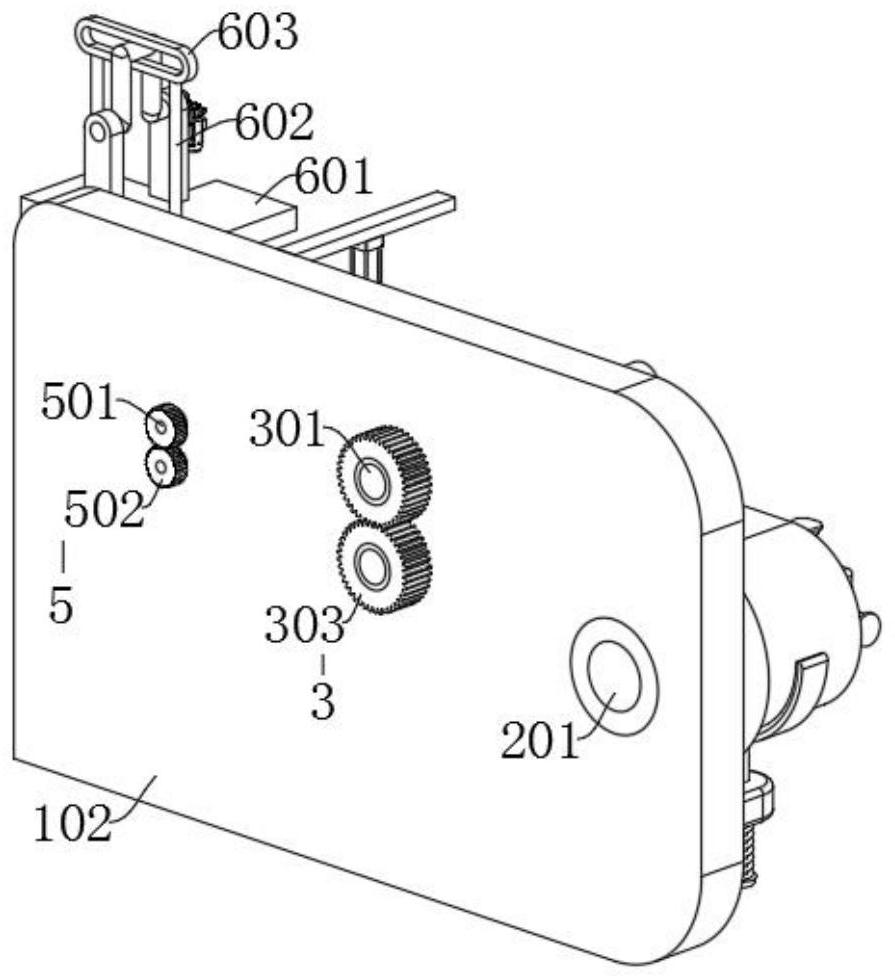

[0046] Example: Please refer to Figure 1 to Figure 10 :

[0047] The present invention proposes a paper insertion machine for iron core embedding slots, including: a supporting device 1,

[0048] The support device 1 includes: a support column 101, a support frame 102, a support rod 103, a support plate 104, a fixed plate 105 and a control module 106, the main body of the support column 101 is set to a square structure; The main body of the support frame 102 is set to a U-shaped structure; the support rod 103 is fixedly arranged on the top of the front side of the support frame 102, and the number of the support rods 103 is set to two groups; the support plate 104 is fixedly arranged on the top of the support rod 103, and the inside of the support plate 104 is installed There are balls, and the main body of the support plate 104 is set in an arc-shaped structure; the fixed plate 105 is fixedly arranged on the inside of the support frame 102, and the number of the fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com