Side wall structure kiln tool of foamed ceramic firing kiln car frame kiln tool system

A technology of foam ceramics and kiln furniture, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of unsatisfactory automatic production, inability to use manipulator operation, and adding triangular baffles, so as to realize mechanized automation and save materials , prevent the effect of material diffusion or material scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

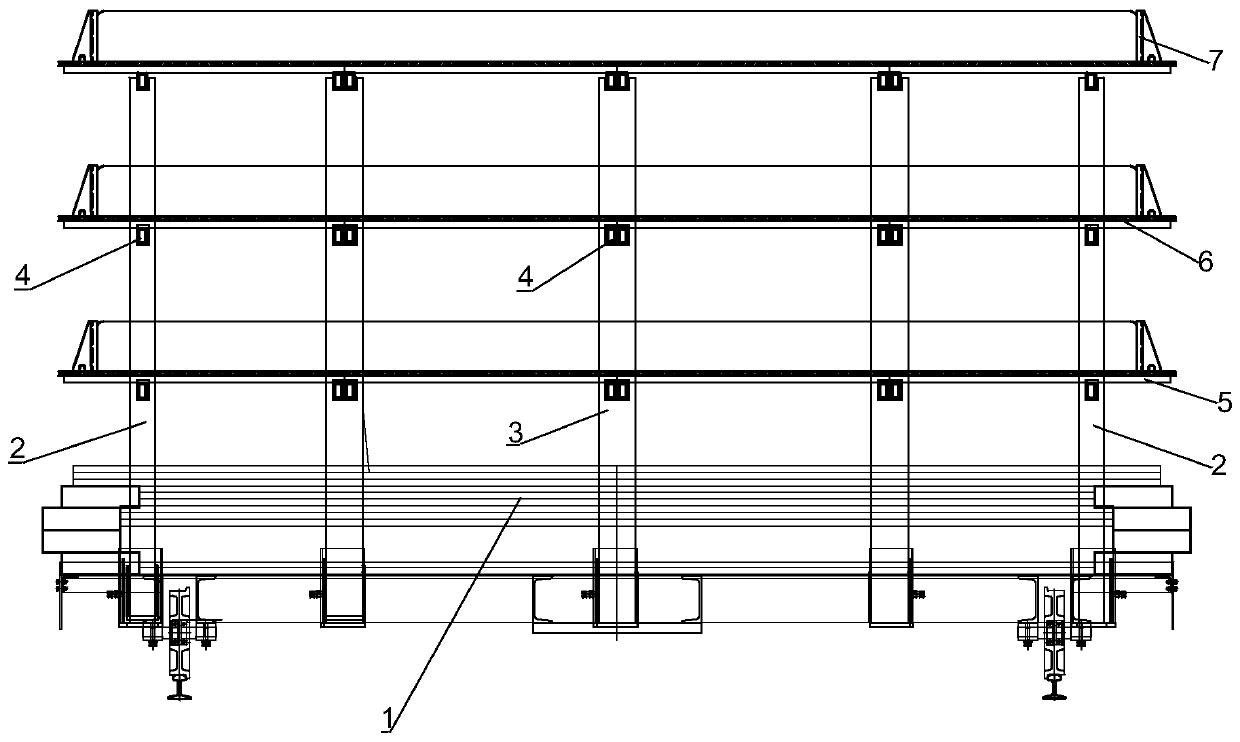

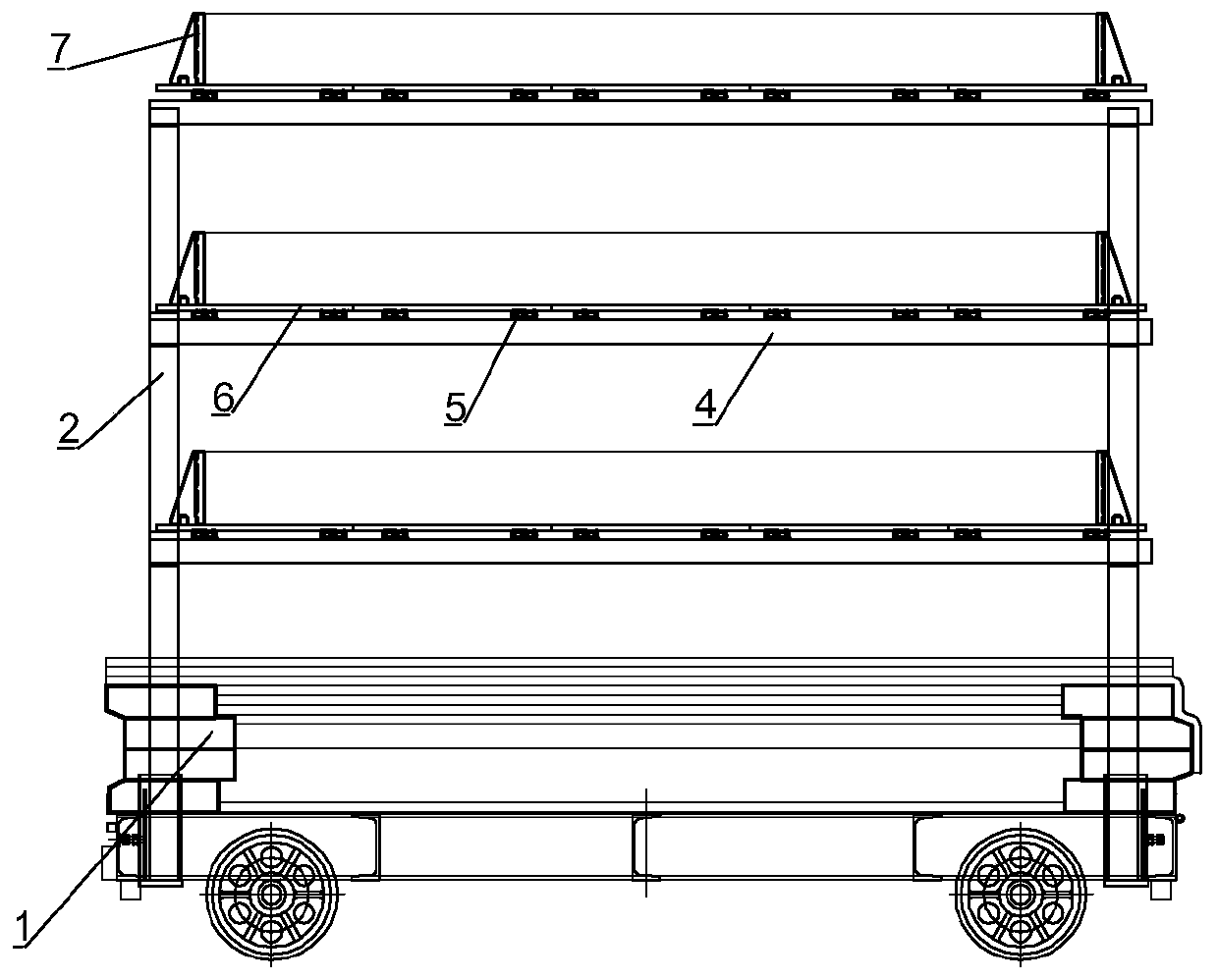

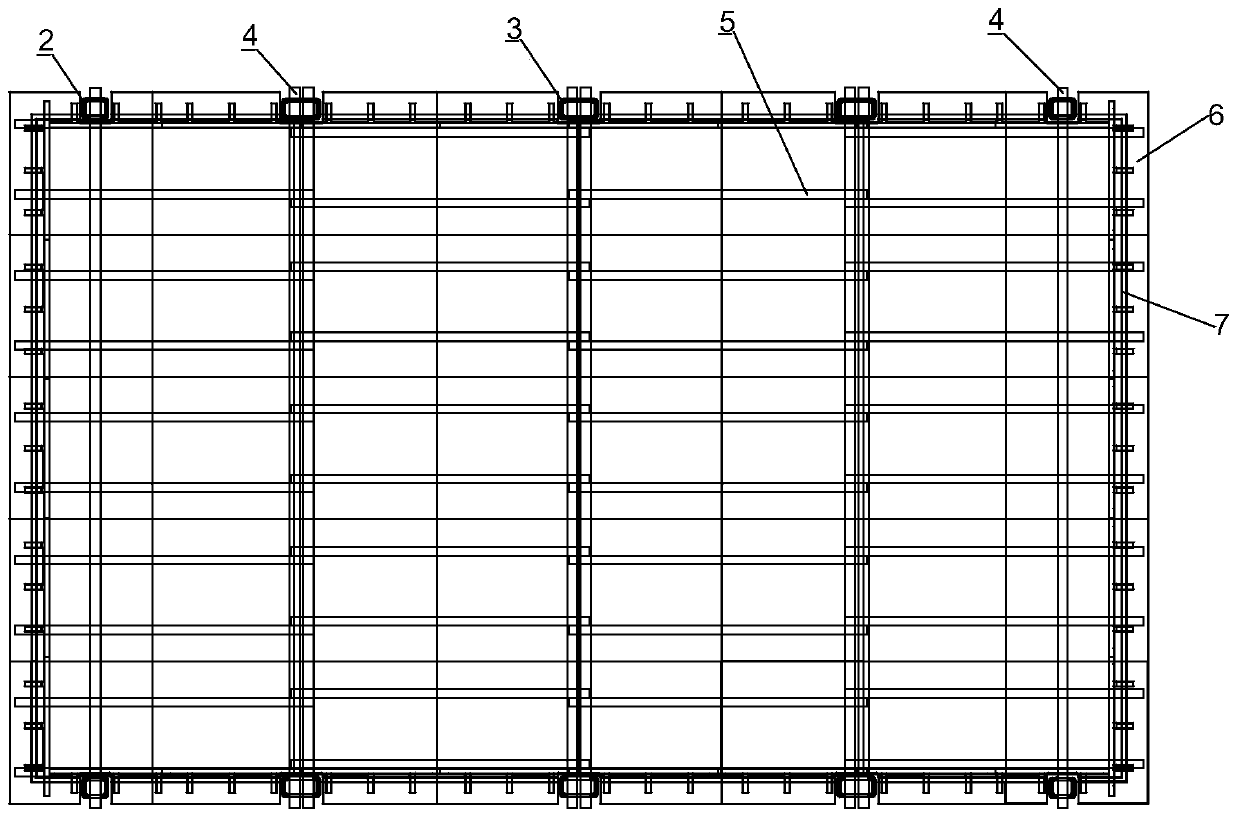

[0026] refer to Figure 1-Figure 13 , a kiln furniture with a side wall structure for firing foam ceramics kiln car frame kiln furniture system. On the kiln car frame kiln furniture system composed of auxiliary beams 5, the kiln furniture of the side wall structure includes a combined supporting plate and a side wall baffle 7, and the combined supporting plate is composed of a plurality of middle supporting plates 6, side supporting plates 61 and Angle supporting plate 62 is assembled and combined to form, on the top of side supporting plate 61 and angle supporting plate 62, is provided with edge surround baffle 7, and edge enclosing baffle 7 comprises vertical panel 71 and the support plate 72 placed on the back side of vertical panel 71, Between the side support plate 61 and the corner support plate 62 and the side wall baffle 7, a positioning device is provided, and the positioning device is arranged on the outer side of the upper surface of the side support plate 61 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com