Method for preparing estradiol molecularly imprinted magnetic microsphere

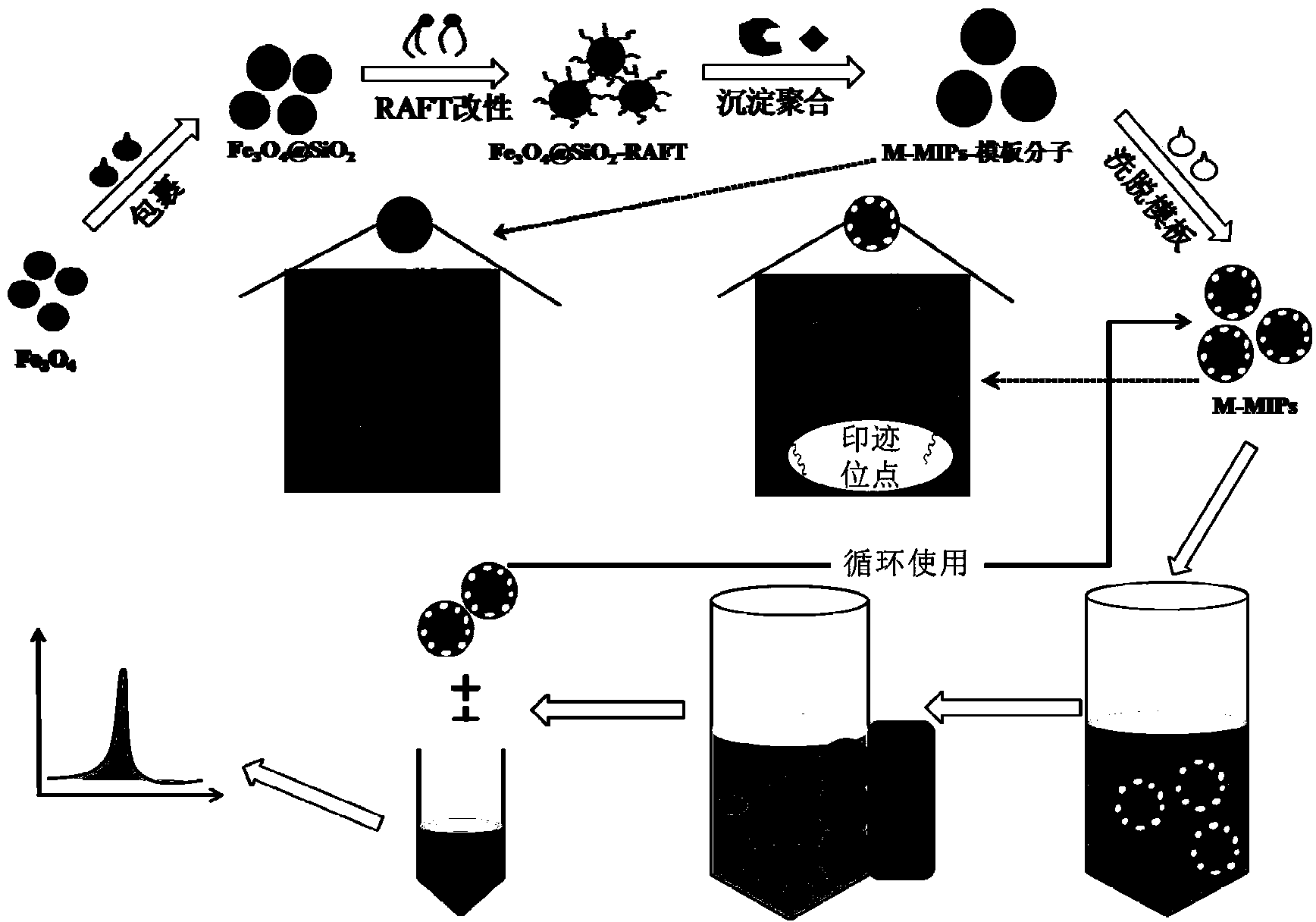

A technology of molecular imprinting and magnetic microspheres, applied in the fields of materials science and engineering and environmental science, can solve the problems that restrict the preparation and application of MIPs, and achieve the effect of improving the recognition rate, regular morphology and good monodispersity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

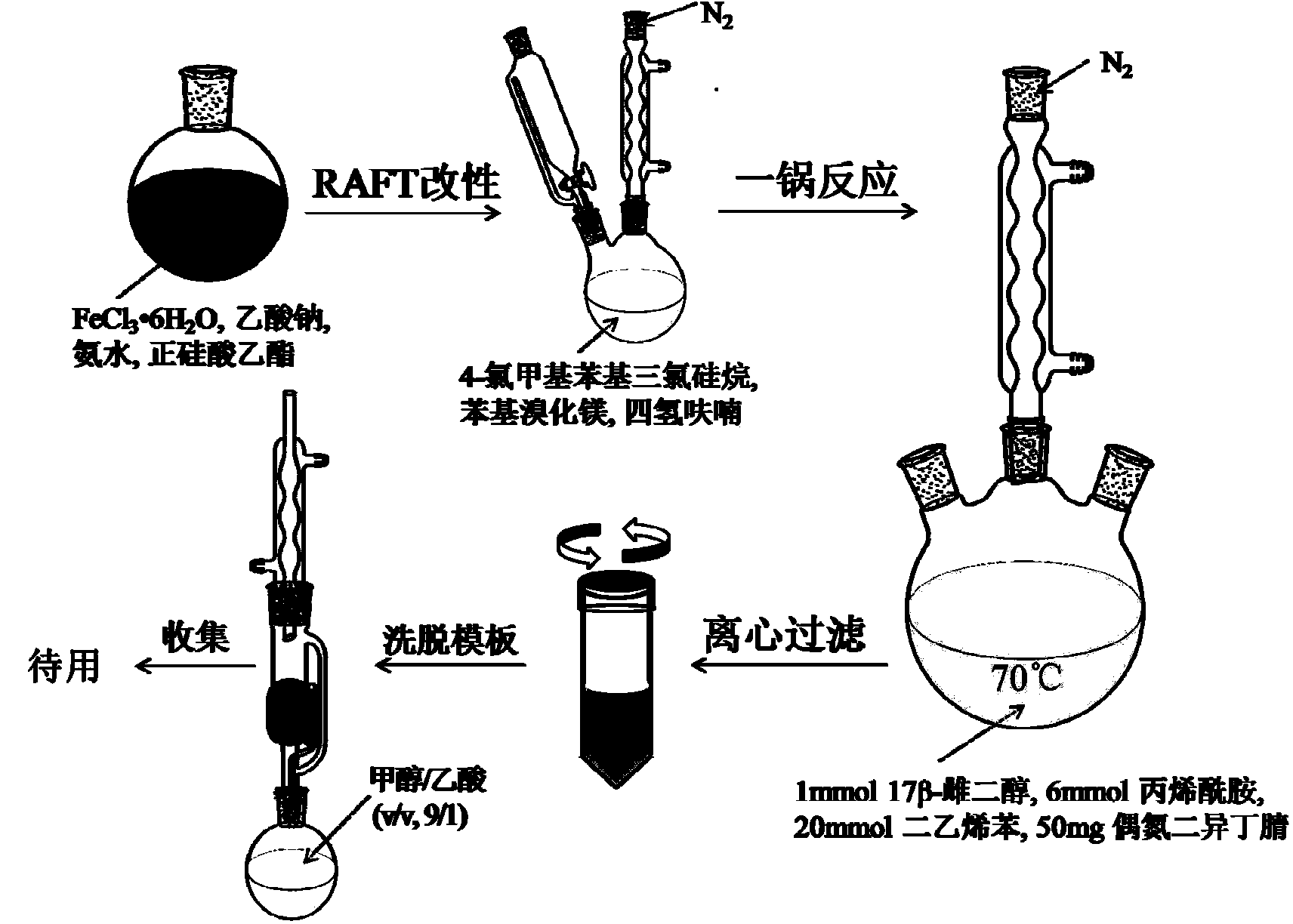

Method used

Image

Examples

Embodiment 1

[0038] a.Fe 3 o 4 Magnetic material preparation: Accurately weigh 1.35g of FeCl 3 6H 2 O is placed in a 100mL small beaker, and 40mL of ethylene glycol is added. After stirring evenly, add 2.17g of anhydrous sodium acetate, sonicate for 30 minutes, add 3g of polyethylene glycol 4000 after the dissolution is complete, and stir in a water bath at 60°C until dissolved. Then the solution was transferred to a 50mL reaction kettle, placed in an oven at 200°C for 10h, and taken out after natural cooling. The product was washed 5 times with absolute ethanol and deionized water, and then placed in a fume hood to dry naturally. The resulting pure black Fe 3 o 4 The product is sealed and stored.

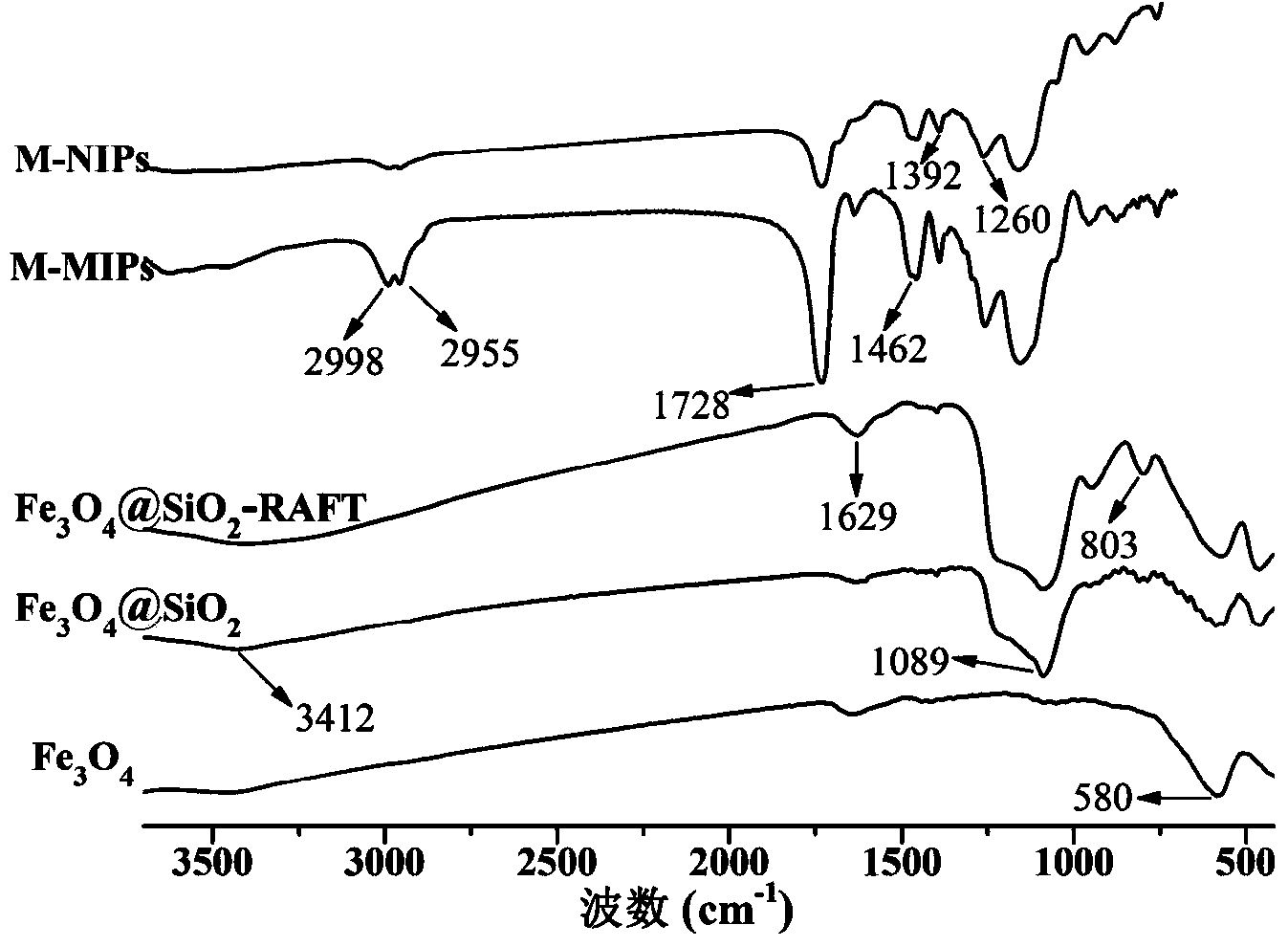

[0039] b.Fe 3 o 4 SiO 2 Preparation of core layer material: 2.0g of the above Fe 3 o 4 Disperse in 60mL ethanol and 10mL deionized water, put in a 250mL single-necked round bottom flask, ultrasonically treat for 15min, then add 1mL ammonia water drop by drop while stirring mechanical...

Embodiment 2

[0045] At room temperature, weigh 0.5 mg of 17β-estradiol standard substance, dissolve it with acetonitrile and dilute it into a 100 mL volumetric flask to obtain a 5 mg / L 17β-estradiol solution, which is stored for future use. Put 20 mg of magnetic molecularly imprinted polymers (M-MIPs) into 2 mL of acetonitrile solution containing the above 5 mg / L 17β-estradiol, and after 3 h of shaking adsorption at room temperature, use a magnet to adsorb on one side of the vial for 10 min , the imprinted microspheres can be adsorbed to one side, and a clear solution can be obtained again. Such as image 3 As shown in the inset, the microspheres have a strong adsorption capacity for 17β-estradiol, and the separation process is fast and simple. see image 3 The hysteresis loop indicates that the M-MIPs have a high magnetic intensity.

Embodiment 3

[0047] At room temperature, weigh 20 mg of 17-β-estradiol standard substance, dissolve it with acetonitrile and dilute it into a 100-mL volumetric flask to obtain a 200 mg / L 17-β-estradiol solution, which is stored for future use. Then dilute to 1, 10, 20, 40, 60, 80, 100mg / L with acetonitrile solution, take 2mL respectively and place them in seven 10mL test tubes with ground mouth and stoppers, and add 20mg of magnetic molecularly imprinted polymer ( M-MIPs). As a comparison, 20 mg of magnetic non-imprinted polymers (M-NIPs) were added to the other 7 vials. At room temperature, shake and adsorb for 12 hours, then centrifuge the mixture and filter it with a 0.45 μm microporous membrane. The concentration of 17β-estradiol in the supernatant is determined by HPLC-UV. The original concentration of 17β-estradiol is reduced The remaining concentration in the supernatant was the adsorption amount of the imprinted microspheres, and each experiment was measured 3 times in parallel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com