Preparation method for polymeric nanometer microsphere

A nano-microsphere and polymer technology, which is applied in the field of preparation of polymer nano-microspheres, can solve the problems of complicated post-processing steps, difficulty in obtaining surface-functionalized nano-microspheres, and difficulty in controlling the preparation process, and the method is simple and easy to achieve. performance, improved stability and uniformity, narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention discloses a method for preparing polymer nanospheres, comprising the following steps:

[0029] (A) select the trithiocarbonate compound represented by formula (I) as a chain transfer agent, and synthesize a gradient copolymer through RAFT active polymerization;

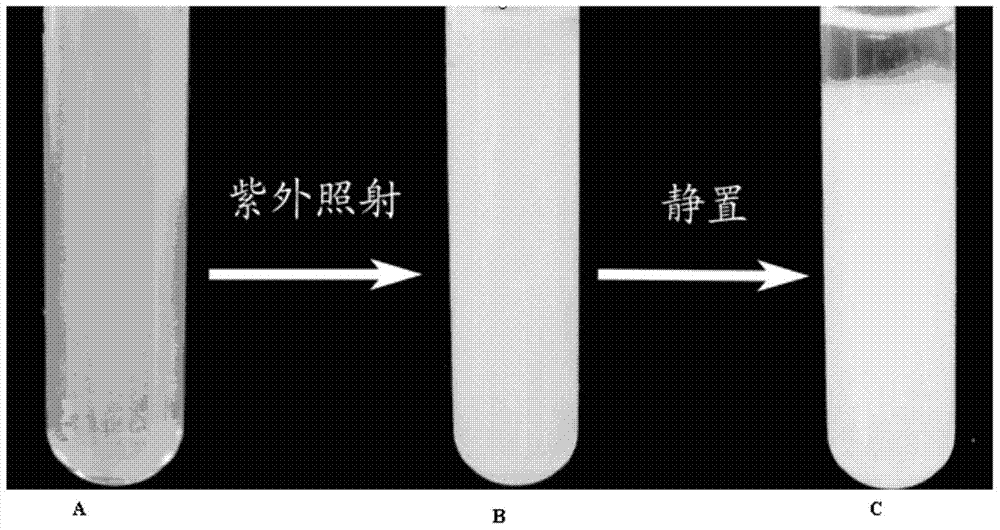

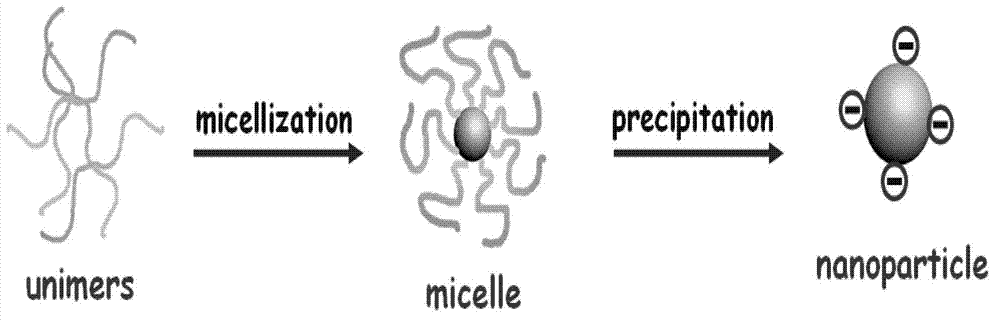

[0030] (B) dissolving the gradient copolymer in an organic solvent, and then adding water to form a polymer micelle solution; the organic solvent is miscible with water;

[0031] (C) adding the polymer micelle solution to an aqueous solution of an inorganic salt, and performing solvent replacement to obtain polymer nanospheres; the volume ratio of the polymer micelle solution to the aqueous solution of an inorganic salt is 0.01 to 1;

[0032]

[0033] Wherein, Z is a group with a carboxyl group at the end, and R is a leaving group.

[0034] The present invention makes full use of the convenience of the reversible addition-fragmentation chain transfer polymerization (R...

Embodiment 1

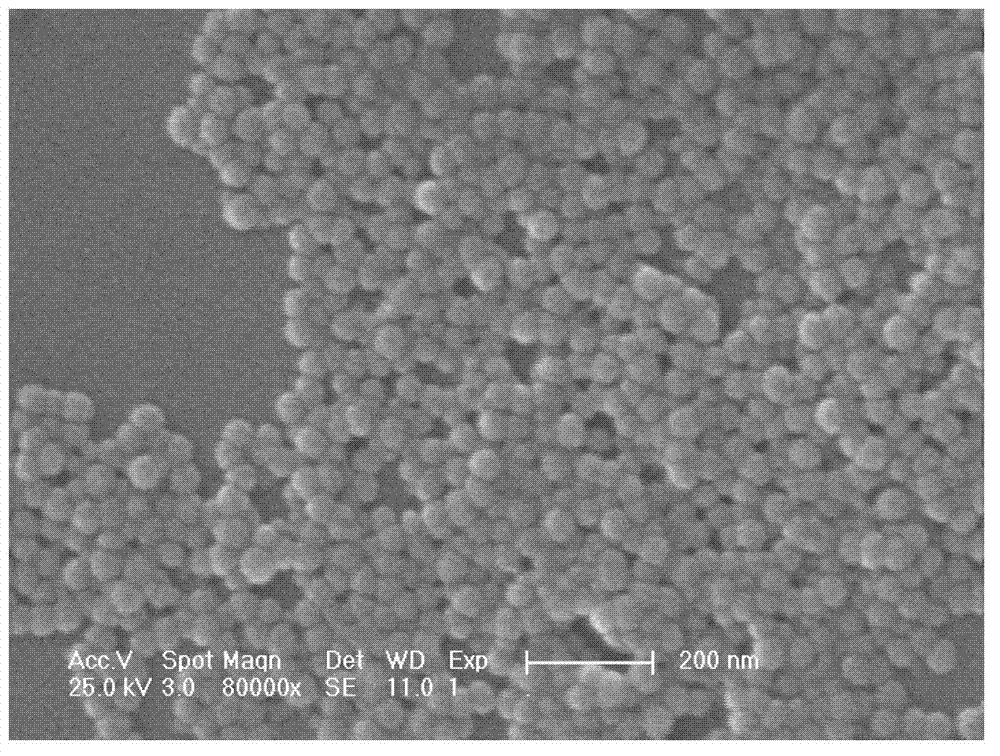

[0044] After feeding nitrogen into the dry reactor for 20 minutes, add styrene monomer and RAFT reagent S-1-carboxypropyl-S'-benzyl trithiocarbonate, the monomer and RAFT reagent molar ratio is 300: 1. Please clarify which catalyst is stirred and dissolved, then heat the reactor to 120°C, and after 12 hours of reaction, use a syringe pump to add 2.5 times the equivalent of styrene monomer into the reactor The copolymerization reaction was carried out, and the copolymerization reaction was carried out for 14 hours. Inject 8% of the total amount of methyl methacrylate at a constant speed for the first 6 hours, then inject 65% of methyl methacrylate instantaneously, and inject 27% of methyl methacrylate at a constant speed for the last 8 hours. Purify the polymer. By NMR spectroscopy ( 1 H NMR) and gel permeation chromatography (GPC) to characterize the gradient copolymers. The polymer had a final molecular weight of 47,000, a molecular weight distribution of 1.38, and a methy...

Embodiment 2

[0050] After feeding nitrogen into the dry reactor for 20 minutes, add styrene monomer and RAFT reagent S-1-carboxypropyl-S'-benzyl trithiocarbonate, the monomer and RAFT reagent molar ratio is 300: 1. After stirring and dissolving, heat the reactor to 120°C. After 12 hours of reaction, use a syringe pump to add methyl methacrylate 2.5 times the equivalent of styrene monomer into the reactor for copolymerization. The copolymerization is carried out for 14 hours. Hour. Inject 8% of the total amount of methyl methacrylate at a constant speed for the first 6 hours, then inject 65% of methyl methacrylate instantaneously, and inject 27% of methyl methacrylate at a constant speed for the last 8 hours. After purification, a gradient copolymer was obtained.

[0051] The gradient copolymer was dissolved in tetrahydrofuran at a concentration of 0.5% (w / v), then deionized water was added dropwise under stirring at 300 rpm, and the final water content was 10% (w / w).

[0052] The above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com